Abstract

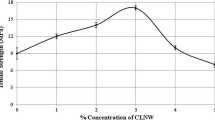

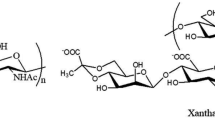

Cotton linter nano-fibers (CLNFs) were prepared from cotton linters by a refining process. The prepared CLNFs were characterized for morphology, crystallinity and degree of polymerization. CLNF was used as a reinforcing agent in guar gum to improve its performance properties. Guar gum/CLNF nanocomposite films were prepared by a solution-casting process. CLNF was added in concentrations of 0.1, 0.25, 0.5 and 1.0 % (w/w) in guar gum. The prepared guar gum/CLNF nano-composite films were characterized for mechanical, thermal, rheological, crystallinity, water vapor transmission rate (WVTR) and light transparency properties. The enthalpy of melting and melting temperature of guar gum increased with increased concentration of CLNF; but up to 0.25 % (w/w) concentration, above which they started decreasing. Tensile strength and Young’s modulus of guar gum increased by 32 and 35 %, respectively, by 0.25 % (w/w) addition of CLNF; however, it decreased on further increase in the concentration of CLNF. The percentage elongation at break and WVTR decreased by 58 and 57 % for 0.25 % (w/w) CLNF-added guar gum. The observed improvements in the properties were due to better interaction between CLNF and guar gum. CLNF was found to have uniformly dispersed in guar gum on addition up to 0.25 % concentration; however, it started forming aggregates at higher concentration, as evident from scanning electron microscopy. Viscosity increased, whereas transparency decreased with increased concentration of CLNF in guar gum.

Similar content being viewed by others

References

Lu DR, Xiao CM, Xu SJ (2009) Starch-based completely biodegradable polymer materials. Express Polym Lett 3:366–375

Tokiwa Y, Calabia BP, Ugwu CU, Aiba S (2009) Biodegradable plastics. Int J Mol Sci 10:3722–3742

Bismarck A (2008) Are hierarchical composite structures the way forward to improve the properties of truly green composites? Express Polym Lett 2:687

Thakur VK, Singha AS (2010) Natural fibres-based polymers: part 1-Mechanical analysis of pine needles reinforced biocomposites. Bull Mater Sci 33:257–264

Petersson L, Kvien I, Oksman K (2007) Structure and thermal properties of poly(lactic acid)/cellulose whiskers nanocomposite materials. Compos Sci Technol 67:2535–2544

Hule RA, Pochan DJ (2007) Polymer nanocomposites for biomedical applications. MRS Bull 32:354–358

Zeng X, Gan YX (2011) Advances in composite materials for medicine and nanotechnology, 1st edn. InTech, Croatia 119

Lee SY, Mohan DJ, Kang IA, Doh GH, Lee S, Han SO (2009) Nanocellulose reinforced PVA composite films: effects of acid treatment and filler loading. Fibre Polym 10:77–82

Wang S, Cheng Q, Rials TG and, Lee SH (2006) Cellulose microfibril/nanofibril and its nanocompsites. Proceedings of the 8th Pacific Rim Bio-based Composites Symp, Kuala Lumpur, Malaysia. 301–308

Habibi Y, Lucia LA, Rojas OJ (2010) Cellulose nanocrystals: chemistry, self-assembly, and applications. Chem Rev 110:3479–3500

Kamel S (2007) Nanotechnology and its applications in lingo-cellulosic composites, a mini review. Express Polym Lett 1:546–575

Hult EL, Iversen T, Sugiyama J (2003) Characterization of the supermolecular structure of cellulose in wood pulp fibers. Cellulose 10:103–110

Li Q, Renneckar S (2009) Molecularly thin nanoparticles from cellulose: isolation of sub-microfibrillar structures. Cellulose 16(6):1025–1032

Lee SY, Chun SJ, Kang IA, Park JY (2009) Preparation of cellulose nanofibrils by high-pressure composite films. J Ind Engg Chem 15:50–55

Shi B, Shannon TG, Pelky E (2010) Novel use of waste keratin and cotton linter fibres for prototype tissue papers and their evaluation. Bioresources 5:1425–1435

Ahola S, Salmi J, Johansson LS, Laine J, Osterberg M (2008) Model films from native cellulose nanofibrils. Preparation, swelling, and surface interactions. Biomacromolecues 9:1273–1282

Nakagaito AN, Yano H (2005) Novel high-strength biocomposites based on microfibrillated cellulose having nano-order-unit web-like network structure. Appl Phys A 80:155–159

Siqueira G, Bras J, Dufresne A (2010) Cellulosic bionanocomposites: a review of preparation, properties and applications. Polymer 2:728–765

D’Mello D, Sabnis A, Shenoy MA, Kathalewar M (2012) Preparation of acetylated guar gum—unsaturated polyester composites and effect of water on their properties. Curr Chem Lett 1:147–156

Savadekar NR, Mhaske ST (2012) Synthesis of nano cellulose fibers and effect on thermoplastics starch based films. Carbohydr Polym 89:146–151

Choi Y, Simonsen J (2006) Cellulose nanocrystal-filled carboxymethyl cellulose nanocomposites. J Nanosci Nanotechnol 6:633–639

Lu Y, Weng L, Cao X (2006) Morphological, thermal and mechanical properties of ramie crystallites—reinforced plasticized starch biocomposites. Carbohydr Polym 63:198–204

Lu Y, Weng L, Zhang L (2004) Morphology and properties of soy protein isolate thermoplastics reinforced with chitin whiskers. Biomacromolecules 5:1046–1051

Wongpanit P, Sanchavanakit N, Pavasant P, Bunaprasert T, Tabata Y, Rujiravanit R (2007) Preparation and characterization of chitin whisker-reinforced silk fibroin nanocomposite sponges. Eur Polym J 43:4123–4135

Huang M, Yu J, Ma X (2006) High mechanical performance MMT-urea and formamide-plasticized thermoplastic cornstarch biodegradable nanocomposites. Carbohydr Polym 63:393–399

Zhang J, Elder TJ, Pu Y, Ragauskas AJ (2007) Facile synthesis of spherical cellulose nanoparticles. Carbohydr Polym 69:607–611

Ljungberg N, Bonini C, Bortolussi F, Boisson C, Heux L, Cavaillé JY (2005) New nanocomposite materials reinforced with cellulose whiskers in atactic polypropylene: effect of surface and dispersion characteristics. Biomacromolecules 6:2732–2739

Chazeau L, Cavaill JY, Perez J (2000) Plasticized PVC reinforced with cellulose whiskers II. Plastic behavior. J Polym Sci Part B Polym Phys 38:383–392

Bondeson D, Mathew A, Oksman K (2006) Optimization of the isolation of nanocrystals from microcrystalline cellulose by acid hydrolysis. Cellulose 13:171–180

Shimazaki Y, Miyazaki Y, Takezawa Y, Nogi M, Abe K, Ifuku S, Yano H (2007) Excellent thermal conductivity of transparent cellulose nanofiber/epoxy resin nanocomposites. Biomacromolecules 8:2976–2978

Nelson ML, O’Connor RT (1964) Relation of certain infrared bands to cellulose crystallinity and crystal lattice type part II. A new infrared ratio for estimation of crystallinity in celluloses I and II. J Appl Polym Sci 8:1325–1341

Terinte N, Ibbett R, Schuster KC (2011) Overview on native cellulose and microcrystalline cellulose I structure studied by X-ray diffraction (WAXD): comparison between measurement techniques. Lenzing Ber 89:118–131

Grobe A, Brandrup J, Immergut EH (1989) Polymer handbook, Chapter 5. Wiley, NY, pp 101–107

Sun Y, Lin L, Pang C, Deng H, Peng H, Li J, He B, Liu S (2007) Hydrolysis of cotton fibre cellulose in formic acid. Energy Fuels 21:2386–2389

Wang L, Kumar R, Zhang L (2009) Investigation into hemp fiber- and whisker- reinforced soy protein composites. Frontiers Chem China 4:313–320

Alemdar A, Sain M (2008) Isolation and characterization of nanofibers from agricultural residues—wheat straw and soy hulls. Bioresour Technol 99:1664–1671

Chen Y, Liu C, Chang PR, Anderson DP, Huneault MA (2009) Pea starch-based composite films with pea hull fibers and pea hull fiber-derived nanowhiskers. Polym Eng Sci 49:369–378

Svagan AJ, Hedenqvist MS, Berglund L (2009) Reduced water vapour sorption in cellulose nanocomposites with starch matrix. Compos Sci Technol 69:500–506

Vilas K, Bharimalla AK, Vighneswaran VN, Mhaske ST (2012) Effect of cellulose nanowhiskers on performance properties of guar gum. ANTEC Mumbai 2012, paper no: 1456451

Acknowledgments

The authors are thankful to the National Agricultural Innovation Project (NAIP), Indian Council of Agricultural Research (ICAR) for providing financial support for this work, through a project entitled “Synthesis and characterization of nanocellulose and its applications as biodegradable polymer composites to enhance their performance properties” (code number 417101). We are also thankful to the Society of Plastic Engineers (SPE) for giving us the opportunity to participate in Antec-Mumbai 2012 [39].

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Karande, V.S., Bharimalla, A.K., Vigneshwaran, N. et al. Cotton linter nano-fibers as the potential reinforcing agent for guar gum. Iran Polym J 23, 869–879 (2014). https://doi.org/10.1007/s13726-014-0283-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-014-0283-2