Abstract

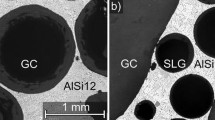

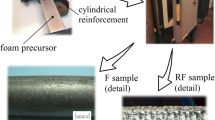

Metal matrix syntactic foam (MMSF) blocks were produced by an inert gas-assisted pressure infiltration technique. MMSFs are advanced hollow sphere reinforced-composite materials having promising application in the fields of aviation, transport, and automotive engineering, as well as in civil engineering. The produced blocks were investigated in free and constrained compression modes, and besides the characteristic mechanical properties, their deformation mechanisms and failure modes were studied. In the tests, the chemical composition of the matrix material, the size of the reinforcing ceramic hollow spheres, the applied heat treatment, and the compression mode were considered as investigation parameters. The monitored mechanical properties were the compressive strength, the fracture strain, the structural stiffness, the fracture energy, and the overall absorbed energy. These characteristics were strongly influenced by the test parameters. By the proper selection of the matrix and the reinforcement and by proper design, the mechanical properties of the MMSFs can be effectively tailored for specific and given applications.

Similar content being viewed by others

References

L. Peroni, M. Scapin, M. Avalle, J. Weise, and D. Lehmhus, Mater. Sci. Eng. A 552, 364 (2012).

L. Peroni, M. Scapin, M. Avalle, J. Weise, D. Lehmhus, J. Baumeister, and M. Busse, Adv. Eng. Mater. 14, 909 (2012).

J. Weise, D. Lehmhus, J. Baumeister, R. Kun, M. Bayoumi, and M. Busse, Steel Res. Int. 85, 486 (2013).

N. Babcsán, D. Leitlmeier, and J. Banhart, Colloid Surf. A 261, 123 (2005).

N. Babcsán, F.G. Moreno, and J. Banhart, Colloid Surf. A 309, 254 (2007).

J.A. Santa Maria, B.F. Schultz, J.B. Ferguson, and P.K. Rohatgi, Mater. Sci. Eng. A 582, 415 (2013).

J.B. Ferguson, J.A. Santa Maria, B.F. Schultz, and P.K. Rohatgi, Mater. Sci. Eng. A 582, 423 (2013).

J.A. Santa Maria, B.F. Schultz, J.B. Ferguson, N. Gupta, and P.K. Rohatgi, J. Mater. Sci. 49, 1267 (2014).

G.H. Wu, Z.Y. Dou, D.L. Sun, L.T. Jiang, B.S. Ding, and B.F. He, Scripta Mater. 56, 221 (2007).

R.A. Palmer, K. Gao, T.M. Doan, L. Green, and G. Cavallaro, Mater. Sci. Eng. A 464, 85 (2007).

P.K. Rohatgi, J.K. Kim, N. Gupta, S. Alaraj, and A. Daoud, Compos. Part A 37, 430 (2006).

P.K. Rohatgi, N. Gupta, B.F. Schultz, and D.D. Luong, JOM 63 (2), 36 (2011).

M. Kiser, M.Y. He, and F.W. Zok, Acta Mater. 47, 2685 (1999).

D.K. Balch, J.G. O’Dwyer, G.R. Davis, C.M. Cady, G.T. Gray, and D.C. Dunand, Mater. Sci. Eng. A 391, 408 (2005).

D.K. Balch and D.C. Dunand, Acta Mater. 54, 1501 (2006).

X.F. Tao, L.P. Zhang, and Y.Y. Zhao, Mater. Des. 30, 2732 (2009).

X.F. Tao and Y.Y. Zhao, Scripta Mater. 61, 461 (2009).

X.F. Tao and Y.Y. Zhao, Mater. Sci. Eng. A 549, 228 (2012).

Z.Y. Dou, L.T. Jiang, G.H. Wu, Q. Zhang, Z.Y. Xiu, and G.Q. Chen, Scripta Mater. 57, 945 (2007).

A. Rabiei and A.T. O’Neill, Mater. Sci. Eng. A 404, 159 (2005).

L.J. Vendra and A. Rabiei, Mater. Sci. Eng. A 465, 59 (2007).

A. Rabiei and M. Garcia-Avila, Mater. Sci. Eng. A 564, 539 (2013).

D.P. Mondal, S. Das, N. Ramakrishnan, and K. Uday Bhasker, Compos. Part A 40, 279 (2009).

D.P. Mondal, S. Das, and N. Jha, Mater. Des. 30, 2563 (2009).

D.P. Mondal, N. Jha, A. Badkul, S. Das, and R. Khedle, Mater. Sci. Eng. A 534, 521 (2012).

D.P. Mondal, N. Jha, B. Gull, S. Das, and A. Badkul, Mater. Sci. Eng. A 560, 601 (2013).

D.P. Mondal, M.D. Goel, and S. Das, Mater. Des. 30, 1268 (2009).

O. Couteau and D.C. Dunand, Mater. Sci. Eng. A 488, 573 (2008).

M. Ramachandra and K. Radhakrishna, Wear 262, 1450 (2007).

M. Ramachandra and K. Radhakrishna, J. Mater. Sci. 40, 5989 (2005).

P.K. Rohatgi and R.Q. Guo, Tribol. Lett. 3, 339 (1997).

I. Orbulov and Á. Németh, Per. Pol. Mech. Eng. 53, 93 (2009).

T. Bárczy and G. Kaptay, Mater. Sci. Forum 473–474, 297 (2005).

K.P. Trumble, Acta Mater. 46, 2363 (1998).

P.K. Rohatgi, R.Q. Guo, H. Iksan, E.J. Borchelt, and R. Asthana, Mater. Sci. Eng. A 244, 22 (1998).

I.N. Orbulov, Mater. Sci. Eng. A 583, 11 (2013).

I.N. Orbulov and J. Dobránszky, Per. Pol. Mech. Eng. 52, 35 (2008).

L. Bardella and F. Genna, Int. J. Sol. Struct. 38, 307 (2001).

L. Bardella and F. Genna, Int. J. Sol. Struct. 38, 7235 (2001).

P.R. Marur, Mater. Lett. 59, 1954 (2005).

P.R. Marur, Comput. Mater. Sci. 46, 327 (2009).

P.R. Marur, Finite Elem. Anal. Des. 46, 1001 (2010).

I.N. Orbulov and K. Májlinger, Mater. Des. 49, 1 (2013).

H.M. Jaeger and S.R. Nagel, Science 5051, 1523 (1992).

I.N. Orbulov and J. Ginsztler, Compos. Part A 43, 553 (2012).

Hollomet GmbH, http://www.hollomet.com/home.html. Accessed 4 Mar 2014.

Envirospheres Ltd., http://www.envirospheres.com/products.asp. Accessed 4 Mar 2014.

I.N. Orbulov, Mater. Sci. Eng. A 555, 52 (2012).

DIN 50134, Testing of Metallic Materials Compression Test of Metallic Cellular Materials, 2008.

Acknowledgements

This research was supported by the European Union and the State of Hungary, co-financed by the European Social Fund in the framework of TÁMOP 4.2.4. A/2-11-1-2012-0001 National Excellence Program.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Orbulov, I.N., Májlinger, K. Compressive Properties of Metal Matrix Syntactic Foams in Free and Constrained Compression. JOM 66, 882–891 (2014). https://doi.org/10.1007/s11837-014-0914-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-014-0914-2