Abstract

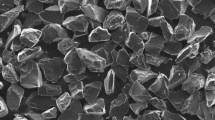

In the present investigation, Aluminium based metal matrix composite containing up to 15% weight percentage of flyash particulates were successfully synthesized using vortex method. The properties like density, hardness, microhardness, ductility and ultimate tensile strength were investigated. The MMC produced was also subjected to corrosion, dry sliding wear and slurry erosive wear test to investigate its behavior under different material wearing conditions. The results of microhardness revealed higher hardness of the matrix material in the immediate vicinity of flyash particle. The addition of flyash particles reduces the density of composite while increasing some of their mechanical properties. The results of wear studies have shown that the resistance to wear increases with increase in percentage of flyash. Corrosion resistance decreases with increase in flyash content. The macrostructural and microstructural characteristics of the MMC were investigated with particular emphasis on the distribution of flyash particles in the matrix. Macrostructural studies have shown near uniform distribution of flyash particles in matrix. Analysis of fractured surface of tensile test specimen is also made which revealed brittle fracture behavior of MMCs.

Similar content being viewed by others

References

P. S. GILMAN, J. Met, 43(8) (1991) 7.

A. L. GEIGER and J. A. WALKER, ibid. 43(8) (1991) 8.

T. S. SRIVATSAN and J. MATTINGLY, J. Met. Sci. 28 (1993) 611.

R. Q. GUO, P. K. ROHATGI and D. NATH, J. Mat Sci, 32 (1997) 3971.

P. K. ROHATGI, B. N. KESHAVARAM, P. HUANG, R. GUO and D. M. GOLDEN, AFS Trans., 103 (1995) 575.

P. K. ROHATGI J. Metals, Nov, 46 (1994) 55.

M. K. SURAPPA and P. K. ROHATGI, Metal Tech., 4, (1981) 41.

M. K. SURAPPA and P. K. ROHATGI, J. Mat. Sci., 16, (1981) 983.

S. MANOHARAN and J. J. LEWANDOWSKI, Acta Metall, 38 (1990) 489.

Glossary of Terms and Definitions in the field of Friction, Wear and Lubrication. Research Group on Wear of Engineering Materials, OECD, Paris, 1969.

R. L. DEUIS, C. SUBRAMANIAN and J. M. YELLUP, Wear 201 (1996) 132.

ASTM B117, Method of salt spray (fog) Testing.

P. K. ROHATGI, R. Q. GUA and B. N. KESHAVARAM, Key Engg Mater. 104–107 (1995) 283.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ramachandra, M., Radhakrishna, K. Synthesis-microstructure-mechanical properties-wear and corrosion behavior of an Al-Si (12%)—Flyash metal matrix composite. J Mater Sci 40, 5989–5997 (2005). https://doi.org/10.1007/s10853-005-1303-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-005-1303-6