Abstract

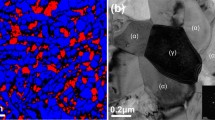

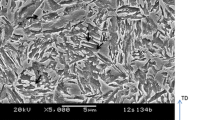

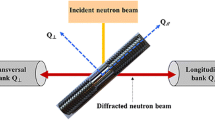

The macroscopic behavior of metallic materials is a complex function of microstructure. The size, morphology, volume fraction, crystallography, and distribution of a 2nd phase within a surrounding matrix all control the mechanical properties. Understanding the contributions of the individual microconstituents to the mechanical behavior of multiphase materials has proven difficult due to the inability to obtain accurate constitutive relationships of each individual constituent. In dual-phase steels, for example, the properties of martensite or ferrite in bulk form are not representative of their behavior at the microscale. In this study, micropillar compression was employed to determine the mechanical properties of individual microconstituents in metallic materials with “composite” microstructures, consisting of two distinct microconstituents: (I) a Mg–Al alloy with pure Mg dendrites and eutectic regions and (II) a powder metallurgy steel with ferrite and martensite constituents. The approach is first demonstrated in a Mg–Al directionally solidified alloy where the representative stress–strain behavior of the matrix and eutectic phases was obtained. The work is then extended to a dual-phase steel where the constitutive behavior of the ferrite and martensite were obtained. Here, the results were also incorporated into a modified rule-of-mixtures approach to predict the composite behavior of the steel. The constitutive behavior of the ferrite and martensite phases developed from micropillar compression was coupled with existing strength–porosity models from the literature to predict the ultimate tensile strength of the steel. Direct comparisons of the predictions with tensile tests of the bulk dual-phase steel were conducted and the correlations were quite good.

Similar content being viewed by others

References

M. Delince, P.J. Jacques, and T. Pardoen, Acta Mater. 54, 3395 (2006).

V.H.B. Hernandez, S.K. Panda, Y. Okita, and N.Y. Zhou, J. Mater. Sci. 45, 1638 (2010).

V.H.B. Hernandez, S.K. Panda, M.L. Kuntz, and Y. Zhou, Mater. Lett. 64, 207 (2010).

J.L. Stewart, J.J. Williams, and N. Chawla, Metall. Mater. Trans. 43, 124 (2012).

W.D. Nix and H. Gao, J. Mech. Phys. Solids 46, 411 (1998).

M.D. Uchic, D.M. Dimiduk, J.N. Florando, and W.D. Nix, Science 305, 986 (2004).

M.D. Uchic and D.M. Dimiduk, Mater. Sci. Eng. A 400–401, 268 (2005).

J.R. Greer, W.C. Oliver, and W.D. Nix, Acta Mater. 53, 1821 (2005).

J.R. Greer and W.D. Nix, Appl. Phys. A 80, 1625 (2005).

C. Motz, T. Schöberl, and R. Pippan, Acta Mater. 53, 4269 (2005).

W.D. Nix, J.R. Greer, G. Feng, and E.T. Lilleodden, Thin Solid Films 515, 3152 (2007).

C.P. Frick, B.G. Clark, S. Orso, A.S. Schneider, and E. Arzt, Mater. Sci. Eng. A 489, 319 (2008).

A.S. Schneider, B.G. Clark, P.A. Gruber, and E. Arzt, Mater. Sci. Eng. A 508, 241 (2009).

G.F. Vander Voort, G.M. Lucas, and E.P. Manilova, ASM Handbook 9, 670 (2004).

H. Bei, S. Shim, M.K. Miller, G.M. Pharr, and E.P. George, Appl. Phys. Lett. 91, 111915 (2007).

W.C. Oliver and G.M. Pharr, J. Mater. Res. 7, 1564 (1992).

Magnesium and Magnesium Alloys, ASM Specialty Handbook, ed. M.M. Avedesian and H. Baker (Materials Park, OH: ASM International, 1999), p. 67.

R.E. Reed-Hill and R. Abbaschian, Physical Metallurgy Principles, 3rd ed. (Boston, MA: PWS Publishing Company, 1994).

D.R.P. Singh, N. Chawla, G. Tang, and Y.-L. Shen, Acta Mater. 58, 6628 (2010).

M.A. Pouchon, J. Chen, R. Ghisleni, J. Michler, and W. Hoffelner, Exp. Mech. 50, 79 (2010).

G.R. Speich and R.L. Miller, Structure and Properties of Dual-Phase Steels (Englewood, CA: American Institute of Mining, Metallurgical, and Petroleum Engineers, 1979), pp. 145–182.

I. Tamura, Y. Tomota, and M. Ozawa, Proceedings 3 rd Int. Conf. Strength of Metals and Alloys, vol. 1, Cambridge, U.K., 1973, p. 611.

P.R. Rios, J.R.C. Guimarães, and K.K. Chawla, Scripta Metall. 15, 899 (1981).

N.A. Fleck and R.A. Smith, Powder Metall. 24, 126 (1981).

Acknowledgements

The authors acknowledge Pacific Northwest National Laboratory and Hoeganaes Corporation for providing the materials and financial support for this research. A portion of the research was performed using Environmental and Molecular Science Laboratory (EMSL), a national scientific user facility sponsored by the Department of Energy’s Office of Biological and Environmental Research and located at PNNL. The assistance of Bruce Arey (EMSL, PNNL) for fabricating the micropillars in the Mg alloy is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Williams, J.J., Walters, J.L., Wang, M.Y. et al. Extracting Constitutive Stress–Strain Behavior of Microscopic Phases by Micropillar Compression. JOM 65, 226–233 (2013). https://doi.org/10.1007/s11837-012-0516-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-012-0516-9