Abstract

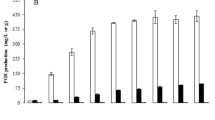

Plant cell culture technology offers a promising alternative for the production of plant bioactive compounds. In this study, a 5-L mechanically agitated culture vessel with introduced aeration was employed to improve the culture conditions for higher biomass production of Artemisia annua, a source of the antimalarial compound artemisinin. The effects of impeller rotational speed and introduced aeration rate on cell biomass production were evaluated by using response surface methodology (RSM). We report the successful scale-up of A. annua cell cultures, with a growth index of 6.9, through the synergistic effects of optimized impeller rotational speed (104 rpm) and introduced aeration rate (0.07 vvm (air volume/culture volume/min)). Use of an impeller blade angle of 30° vertical slant in the 5-L culture vessel significantly increased the biomass obtained over that obtained with a 45° vertical slant angle. This information is a key to future scale-up of bioprocessing in this species.

Similar content being viewed by others

References

Balint GA (2001) Artemisinin and its derivatives: an important new class of antimalarial agents. Pharmacol Ther 90:261–265

Busto VD, Rodríguez-Talou J, Giulietti AM, Merchuk JC (2008) Effect of shear stress on anthraquinones production by Rubia tinctorum suspension cultures. Biotechnol Prog 24:175–181

Chan LK, Singaram N, Boey PL (2010) Production of artemisinin from cell suspension culture of Artemisia annua L. AsPac J Mol Biol Biotechnol 18:139–141

Chattopadhyay S, Farkya S, Srivastava AK, Bisaria VS (2002) Bioprocess considerations for production of secondary metabolites by plant cell suspension cultures. Biotechnol Bioprocess Eng 7:138–149

Fort I, Jirout T, Rieger F, Allner R, Sperling R (2001) Study of the blending efficiency of pitched blade impellers. Acta Polytech 41(6):7–13

Krishna S, Bustamante L, Haynes RK, Staines HM (2008) Artemisinins: their growing importance in medicine. Trends Pharmacol Sci 10:520–527

Lee CWT, Shuler ML (1991) Different shake flask closures alter gas phase composition and ajmalicine production in Catharanthus roseus cell suspension. Biotechnol Tech 5:173–178

Menisher T, Metghalchi M, Gutoff EB (2000) Mixing studies in bioreactors. Bioprocess Eng 22:115–120

Mirjalili N, Linden JC (1995) Gas phase composition effects on suspension cultures of Taxus cuspidata. Biotechnol Bioeng 48:123–132

Pan Z, Wang H, Zhong J (2000) Scale-up study on suspension cultures of Taxus chinensis cells for production of taxane diterpene. Enzyme Microb Technol 27:714–723

Wang GR, Qi NM, Wang ZM (2010) Application of a stir-tank bioreactor for perfusion culture and continuous harvest of Glycyrrhiza inflata suspension cells. Afr J Biotechnol 9:347–351

Zhong J, Pan Z, Wang Z, Wu J, Chen F, Takagi M, Yoshida T (2002) Effect of mixing time on taxoid production using suspension cultures of Taxus chinensis in a centrifugal impeller bioreactor. J Biosci Bioeng 94:244–250

Acknowledgments

The authors wish to thank Universiti Sains Malaysia for research funding (RU-PGRS grant) and laboratory facilities and the MyBrain15 scholarship program.

Author information

Authors and Affiliations

Corresponding author

Additional information

Editor: Randall P. Niedz

Rights and permissions

About this article

Cite this article

Heng, K.W., Chan, D.J.C. & Chan, L.K. Effects of angled-impeller rotational speed and aeration rate on production of artemisinin and cell biomass of Artemisia annua L.. In Vitro Cell.Dev.Biol.-Plant 51, 324–331 (2015). https://doi.org/10.1007/s11627-015-9678-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11627-015-9678-9