Abstract

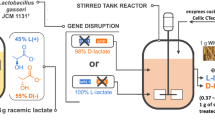

Microbial fermentation of sugars from plant biomass to alcohols represents an alternative to petroleum-based fuels. The optimal biocatalyst for such fermentations needs to overcome hurdles such as high concentrations of alcohols and toxic compounds. Lactic acid bacteria, especially lactobacilli, have high innate alcohol tolerance and are remarkably adaptive to harsh environments. This study assessed the potential of five Lactobacillus casei strains as biocatalysts for alcohol production. L. casei 12A was selected based upon its innate alcohol tolerance, high transformation efficiency and ability to utilize plant-derived carbohydrates. A 12A derivative engineered to produce ethanol (L. casei E1) was compared to two other bacterial biocatalysts. Maximal growth rate, maximal optical density and ethanol production were determined under conditions similar to those present during alcohol production from lignocellulosic feedstocks. L. casei E1 exhibited higher innate alcohol tolerance, better growth in the presence of corn stover hydrolysate stressors, and resulted in higher ethanol yields.

Similar content being viewed by others

References

Atsumi S, Hanai T, Liao JC (2008) Non-fermentative pathways for synthesis of branched-chain higher alcohols as biofuels. Nature 451:86–89. doi:10.1038/nature06450

Atsumi S, Liao JC (2008) Metabolic engineering for advanced biofuels production from Escherichia coli. Curr Opin Biotechnol 19:414–419. doi:10.1016/j.copbio.2008.08.008

Begot C, Desnier I, Daudin JD, Labadie JC, Lebert A (1996) Recommendations for calculating growth parameters by optical density measurements. J Microbiol Methods 25:225–232

Berezina OV, Zakharova NV, Brandt A, Yarotsky SV, Schwarz WH, Zverlov VV (2010) Reconstructing the clostridial n-butanol metabolic pathway in Lactobacillus brevis. Appl Microbiol Biotechnol 87:635–646. doi:10.1007/s00253-010-2480-z

Boguta AM, Bringel F, Martinussen J, Jensen PR (2014) Screening of lactic acid bacteria for their potential as microbial cell factories for bioconversion of lignocellulosic feedstocks. Microb Cell Fact 13:97. doi:10.1186/s12934-014-0097-0

Broadbent JR, Neeno-Eckwall EC, Stahl B, Tandee K, Cai H, Morovic W, Horvath P, Heidenreich J, Perna NT, Barrangou R, Steele JL (2012) Analysis of the Lactobacillus casei supragenome and its influence in species evolution and lifestyle adaptation. BMC Genom 13:533. doi:10.1186/1471-2164-13-533

Broadbent JR, Oberg TS, Hughes JE, Ward RE, Brighton C, Welker DL, Steele JL (2014) Influence of polysorbate 80 and cyclopropane fatty acid synthase activity on lactic acid production by Lactobacillus casei ATCC 334 at low pH. J Ind Microbiol Biotechnol 41:545–553. doi:10.1007/s10295-013-1391-2

Cai H, Rodríguez BT, Zhang W, Broadbent JR, Steele JL (2007) Genotypic and phenotypic characterization of Lactobacillus casei strains isolated from different ecological niches suggests frequent recombination and niche specificity. Microbiology 153:2655–2665. doi:10.1099/mic.0.2007/006452-0

Chilton S, Burton J, Reid G (2015) Inclusion of fermented foods in food guides around the world. Nutrients 7:390–404. doi:10.3390/nu7010390

Dien BS, Cotta MA, Jeffries TW (2003) Bacteria engineered for fuel ethanol production: current status. Appl Microbiol Biotechnol 63:258–266. doi:10.1007/s00253-003-1444-y

Ding S, Tan T (2006) l-lactic acid production by Lactobacillus casei fermentation using different fed-batch feeding strategies. Process Biochem 41:1451–1454. doi:10.1016/j.procbio.2006.01.014

Fortman JL, Chhabra S, Mukhopadhyay A, Chou H, Lee TS, Steen E, Keasling JD (2008) Biofuel alternatives to ethanol: pumping the microbial well. Trends Biotechnol 26:375–381. doi:10.1016/j.tibtech.2008.03.008

Galdeano CM, Perdigon G (2006) The probiotic bacterium Lactobacillus casei induces activation of the gut mucosal immune system through innate immunity. Clin Vaccine Immunol 13:219–226. doi:10.1128/CVI.13.2.219-226.2006

Gold RS, Meagher MM, Hutkins R, Conway T (1992) Ethanol tolerance and carbohydrate metabolism in lactobacilli. J Ind Microbiol 10:45–54. doi:10.1007/BF01583633

Gold RS, Meagher MM, Tong S, Hutkins RW, Conway T (1996) Cloning and expression of the Zymomonas mobilis “production of ethanol” genes in Lactobacillus casei. Curr Microbiol 33:256–260. doi:10.1007/s002849900109

Han K, Hong J, Lim HC (1993) Relieving effects of glycine and methionine from acetic acid inhibition in Escherichia coli fermentation. Biotechnol Bioeng 41:316–324. doi:10.1002/bit.260410305

Ingram LO (1986) Microbial tolerance to alcohols: role of the cell membrane. Trends Biotechnol 4:40–44. doi:10.1016/0167-7799(86)90152-6

Jarboe LR, Grabar TB, Yomano LP, Shanmugan KT, Ingram LO (2007) Development of Ethanologenic Bacteria. In: Olsson L (ed) Biofuels. Springer, Berlin, pp 237–261

Jia K, Zhang Y, Li Y (2010) Systematic engineering of microorganisms to improve alcohol tolerance. Eng Life Sci 10:422–429. doi:10.1002/elsc.201000076

Jönsson LJ, Alriksson B, Nilvebrant N-O (2013) Bioconversion of lignocellulose: inhibitors and detoxification. Biotechnol Biofuels 6:16. doi:10.1186/1754-6834-6-16

Kandler O, NW (1986) Genus Lactobacillus. In: Sneath PHA et al (ed) Bergey’s manual of systematic bacteriology. Williams & Wilkins, Baltimore, pp 1063–1065

Kim J-H, Block DE, Shoemaker SP, Mills DA (2010) Atypical ethanol production by carbon catabolite derepressed lactobacilli. Bioresour Technol 101:8790–8797. doi:10.1016/j.biortech.2010.06.087

Knoshaug EP, Zhang M (2009) Butanol tolerance in a selection of microorganisms. Appl Biochem Biotech 153:13–20. doi:10.1007/s12010-008-8460-4

Lau MW, Dale BE, Balan V (2008) Ethanolic fermentation of hydrolysates from ammonia fiber expansion (AFEX) treated corn stover and distillers grain without detoxification and external nutrient supplementation. Biotechnol Bioeng 99:529–539. doi:10.1002/bit

Lin Y, Tanaka S (2006) Ethanol fermentation from biomass resources: current state and prospects. Appl Microbiol Biotechnol 69:627–642. doi:10.1007/s00253-005-0229-x

Liu S (2014) Proteomic analyses of ethanol tolerance in Lactobacillus buchneri NRRL B-30929. Proteomics 14:2540–2544. doi:10.1002/pmic.201300538

Liu S, Dien BS, Nichols NN, Bischoff KM, Hughes SR, Cotta MA (2007) Coexpression of pyruvate decarboxylase and alcohol dehydrogenase genes in Lactobacillus brevis. FEMS Microbiol Lett 274:291–297. doi:10.1111/j.1574-6968.2007.00849.x

Liu S, Nichols NN, Dien BS, Cotta MA (2006) Metabolic engineering of a Lactobacillus plantarum double ldh knockout strain for enhanced ethanol production. J Ind Microbiol Biotechnol 33:1–7. doi:10.1007/s10295-005-0001-3

Liu S, Qureshi N (2009) How microbes tolerate ethanol and butanol. New Biotechnol 26:117–121. doi:10.1016/j.nbt.2009.06.984

Mukhopadhyay A, Redding AM, Rutherford BJ, Keasling JD (2008) Importance of systems biology in engineering microbes for biofuel production. Curr Opin Biotechnol 19:228–234. doi:10.1016/j.copbio.2008.05.003

Nadal I, Rico J, Pérez-Martínez G, Yebra MJ, Monedero V (2009) Diacetyl and acetoin production from whey permeate using engineered Lactobacillus casei. J Ind Microbiol Biotechnol 36:1233–1237. doi:10.1007/s10295-009-0617-9

Parreiras LS, Breuer RJ, Avanasi Narasimhan R, Higbee AJ, La Reau A, Tremaine M, Qin L, Willis LB, Bice BD, Bonfert BL, Pinhancos RC, Balloon AJ, Uppugundla N, Liu T, Li C, Tanjore D, Ong IM, Li H, Pohlmann EL, Serate J, Withers ST, Simmons BA, Hodge DB, Westphall MS, Coon JJ, Dale BE, Balan V, Keating DH, Zhang Y, Landick R, Gasch AP, Sato TK (2014) Engineering and two stage evolution of a lignocellulosic hydrolysate-tolerant Saccharomyces cerevisiae strain for anaerobic fermentation of xylose from AFEX pretreated corn stover. PLoS One 9:e107499. doi:10.1371/journal.pone.0107499

Piotrowski JS, Zhang Y, Bates DM, Keating DH, Sato TK, Ong IM, Landick R (2014) Death by a thousand cuts: the challenges and diverse landscape of lignocellulosic hydrolysate inhibitors. Front Microbiol. doi:10.3389/fmicb.2014.00090

Pisithkul T, Jacobson TB, O’Brien TJ, Stevenson DM, Amador-Noguez D (2015) Phenolic amides are potent inhibitors of de novo nucleotide biosynthesis. Appl Environ Microbiol 81:5761–5772. doi:10.1128/AEM.01324-15

Ruegg TL, Kim E-M, Simmons BA, Keasling JD, Singer SW, Soon Lee T, Thelen MP (2014) An auto-inducible mechanism for ionic liquid resistance in microbial biofuel production. Nat Commun 5:3490. doi:10.1038/ncomms4490

Schwalbach MS, Keating DH, Tremaine M, Marner WD, Zhang Y, Bothfeld W, Higbee A, Grass JA, Cotten C, Reed JL, da Costa Sousa L, Jin M, Balan V, Ellinger J, Dale B, Kiley PJ, Landick R (2012) Complex physiology and compound stress responses during fermentation of alkali-pretreated corn stover hydrolysate by an Escherichia coli ethanologen. Appl Environ Microbiol 78:3442–3457. doi:10.1128/AEM.07329-11

Skinner KA, Leathers TD (2004) Bacterial contaminants of fuel ethanol production. J Ind Microbiol Biotechnol 31:401–408. doi:10.1007/s10295-004-0159-0

Solem C, Dehli T, Jensen PR (2013) Rewiring Lactococcus lactis for ethanol production. Appl Environ Microbiol 79:2512–2518. doi:10.1128/AEM.03623-12

Vinay-Lara E, Hamilton JJ, Stahl B, Broadbent JR, Reed JL, Steele JL (2014) Genome-scale reconstruction of metabolic networks of Lactobacillus casei ATCC 334 and 12A. PLoS One 9:e110785. doi:10.1371/journal.pone.0110785

Wang H, Wang F, Wang W, Yao X, Wei D, Cheng H, Deng Z (2014) Improving the expression of recombinant proteins in E. coli BL21 (DE3) under acetate stress: an alkaline pH shift approach. PLoS One 9:e112777. doi:10.1371/journal.pone.0112777

Wang L, Zhao X-Q, Xue C, Bai F-W (2013) Impact of osmotic stress and ethanol inhibition in yeast cells on process oscillation associated with continuous very-high-gravity ethanol fermentation. Biotechnol Biofuels 6:133. doi:10.1186/1754-6834-6-133

Wang T-Y, Huang C-J, Chen H-L, Ho P-C, Ke H-M, Cho H-Y, Ruan S-K, Hung K-Y, Wang I-L, Cai Y-W, Sung H-M, Li W-H, Shih M-C (2013) Systematic screening of glycosylation- and trafficking-associated gene knockouts in Saccharomyces cerevisiae identifies mutants with improved heterologous exocellulase activity and host secretion. BMC Biotechnol 13:71. doi:10.1186/1472-6750-13-71

Welker DL, Hughes JE, Steele JL, Broadbent JR (2015) High efficiency electrotransformation of Lactobacillus casei. FEMS Microbiol Lett 362:1–6. doi:10.1093/femsle/fnu033

Xu N, Liu J, Ai L, Liu L (2015) Reconstruction and analysis of the genome-scale metabolic model of Lactobacillus casei LC2W. Gene 554:140–147. doi:10.1016/j.gene.2014.10.034

Zwietering MH, Jongenburger I, Rombouts FM, van’t Riet K (1990) Modeling of the bacterial growth curve. Appl Environ Microbiol 56:1875–1881

Acknowledgments

This work was funded by the DOE Great Lakes Bioenergy Research Center (DOE BER Office of Science DE-FC02-07ER64494) and by the National Research Initiative Competitive Grant No. 2011-67009-30043 from the USDA National Institute of Food and Agriculture. Elena Vinay-Lara gratefully acknowledges the scholarship from CONACyT to pursue her postgraduate studies. We will also thank Great Lakes Bioenergy Research Center for providing E. coli GLBRC E1, strains used for this study.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Vinay-Lara, E., Wang, S., Bai, L. et al. Lactobacillus casei as a biocatalyst for biofuel production. J Ind Microbiol Biotechnol 43, 1205–1213 (2016). https://doi.org/10.1007/s10295-016-1797-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-016-1797-8