Abstract

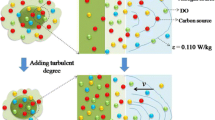

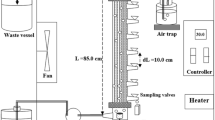

A three-dimensional transient modeling of a two-phase partitioning bioreactor, combining system hydrodynamics, two simultaneous mass transfer and microorganism growth is modeled using computational fluid dynamics code FLUENT 6.2. The simulation is based on standard “k–ε” Reynolds-averaged Navier–Stokes model. Population balance model is implemented in order to describe gas bubble coalescence, breakage and species transport in the reaction medium and to predict oxygen volumetric mass transfer coefficient (kLa). Model results are verified against experimental data and show good agreement as 13 classes of bubble size is taking into account. Flow behavior in different operational conditions is studied. Almost at all impeller speeds and aeration intensities there were acceptable distributions of species caused by proper mixing. The magnitude of dissolved oxygen percentage in aqueous phase has a direct correlation with impeller speed and any increasing of the aeration magnitude leads to faster saturation in shorter periods of time.

Similar content being viewed by others

Abbreviations

- \(\upalpha\) :

-

Interfacial area per unit volume (m−1)

- \(b\left( {\upsilon_{k} :\nu_{l} } \right)\) :

-

Break-up frequency

- \(c\left( {\upsilon_{k} ,\nu_{l} } \right)\) :

-

Bubble production rate

- C D :

-

Drag coefficient

- C k :

-

Concentration of component k (mole/m3)

- \(C_{{O_{2} }}\) :

-

Oxygen level in cell medium (g/m3)

- d :

-

Diameter (m)

- d b :

-

Maximum horizontal bubble dimension

- d 32 :

-

Sauter mean diameter

- D :

-

Diffusivity (m2/s)

- E O :

-

Eotvos number

- F C :

-

Centrifugal force (N/m3)

- F i :

-

Phase interaction force (N/m3)

- G k :

-

Production rate of turbulent energy (m2/s3)

- H :

-

Discontinuous collisional events

- \(\overline{I}\) :

-

Unit tensor

- J :

-

Transport flux of phenol (g/m2s)

- k i :

-

Turbulent kinetic energy (m2/s2)

- K I :

-

Substrate inhibition constant (g/m3)

- k L :

-

Covariance of phases velocities

- K L :

-

Volumetric mass transfer coefficient (1/h)

- K O :

-

Oxygen saturation constant (g/m3)

- K S :

-

Substrate affinity constant (g/m3)

- L :

-

Bubble size (m)

- M :

-

Molecular weight (g/mole)

- M k,l :

-

Mixed order moment of the NDF

- n :

-

Bubble size distribution

- P c (d k ,d l ):

-

Coalescence probability

- \({\mathcal{P}}\) :

-

Partitioning coefficient

- P :

-

Pressure (Pa)

- r :

-

Rate (g/m3s)

- \(\vec{r}\) :

-

Position vector (m)

- Re :

-

Reynolds number

- S cm :

-

Phenol level in cell medium (g/m3)

- S i :

-

Source term of phase i

- S org :

-

Phenol level in organic phase (g/m3)

- Sc t :

-

Turbulent Schmidt number

- T :

-

Temperature (°C)

- U :

-

Reynolds-averaged velocity (m/s)

- U dr :

-

Drift velocity

- X :

-

Cell level in cell medium (g/m3)

- Y :

-

Cell yield on phenol

- \(Y^{{\prime }}\) :

-

Cell yield on dissolved oxygen

- w kl :

-

Collision frequency

- \(\alpha\) :

-

Volume fraction

- ε :

-

Turbulent dissipation energy (m2/s3)

- \(\zeta_{j,k}\) :

-

Break-up redistribution factor

- \(\lambda\) :

-

Eddy length scale

- \(\mu\) :

-

Viscosity (Pa·s)

- \(\nu\) :

-

Bubble volume (m3)

- \(\xi_{kl}\) :

-

Coalescence redistribution factor

- \(\rho\) :

-

Density (g/m3)

- σ :

-

Surface tension (N/m)

- \(\overline{\tau }_{eff}\) :

-

Viscous stress tensor (kg/ms2)

- \(\emptyset\) :

-

Bubble composition (mole)

- \(\chi_{kl}\) :

-

Coalescence redistribution factor

- \(\psi_{c}\) :

-

Oxygen concentration in water (mole/m3)

- \(\Gamma\) :

-

Interphase mass transfer source term

- \(\Phi\) :

-

Specific cell growth rate (1/h)

- \(\Phi_{\hbox{max} }\) :

-

Maximum specific cell growth rate (1/h)

References

Xue Q, Fox R (2014) Multi-fluid CFD modeling of biomass gasification in polydisperse fluidized-bed gasifiers. Powder Technol 254:187–198

Jones W, Launder B (1972) The prediction of laminarization with a two-equation model of turbulence. Int J Heat Mass Transf 15:301–314

Launder BE, Spalding D (1974) The numerical computation of turbulent flows. Comput Methods Appl Mech Eng 3:269–289

Yakhot V, Orszag S, Thangam S, Gatski T, Speziale C (1992) Development of turbulence models for shear flows by a double expansion technique. Phys Fluids A: Fluid Dyn (1989–1993) 4:1510–1520

Kazak O, Semko A (2012) Numerical modeling of electro-vortical flows in a confined volume. J Eng Phys Thermophys 85:1167–1178

Soares APK (2013) Simulação numérica do jato plano turbulento com o emprego do método de filtragem lagrangeana

Liu Y, Hinrichsen O (2014) Study on CFD–PBM turbulence closures based on k–ε and Reynolds stress models for heterogeneous bubble column flows. Comput Fluids 105:91–100

Dhotre M, Niceno B, Smith B (2008) Large eddy simulation of a bubble column using dynamic sub-grid scale model. Chem Eng J 136:337–348

Deen NG, Solberg T, Hjertager BH (2001) Large eddy simulation of the gas–liquid flow in a square cross-sectioned bubble column. Chem Eng Sci 56:6341–6349

Ničeno B, Dhotre M, Deen N (2008) One-equation sub-grid scale (SGS) modelling for Euler–Euler large eddy simulation (EELES) of dispersed bubbly flow. Chem Eng Sci 63:3923–3931

Yang F, Zhou S, An X (2015) Gas–liquid hydrodynamics in a vessel stirred by dual dislocated-blade Rushton impellers. Chin J Chem Eng 23:1746–1754

Patwardhan AW, Joshi JB (1999) Design of gas-inducing reactors. Ind Eng Chem Res 38:49–80

Fonte CP, Pinho BS, Santos-Moreau V, Lopes JCB (2014) Prediction of the induced gas flow rate from a self-inducing impeller with CFD. Chem Eng Technol 37:571–579

Pfleger D, Gomes S, Gilbert N, Wagner H-G (1999) Hydrodynamic simulations of laboratory scale bubble columns fundamental studies of the Eulerian–Eulerian modelling approach. Chem Eng Sci 54:5091–5099

Selma B, Bannari R, Proulx P (2010) A full integration of a dispersion and interface closures in the standard k–ε model of turbulence. Chem Eng Sci 65:5417–5428

Moutafchieva D, Popova D, Dimitrova M, Tchaoushev S (2013) Experimental determination of the volumetric mass transfer coefficient. J Chem Technol Metall 48:351–356

Sungkorn R, Derksen J, Khinast J (2012) Modeling of aerated stirred tanks with shear-thinning power law liquids. Int J Heat Fluid Flow 36:153–166

Şeker Ş, Beyenal H, Salih B, Tanyolac A (1997) Multi-substrate growth kinetics of Pseudomonas putida for phenol removal. Appl Microbiol Biotechnol 47:610–614

Ucun H, Yildiz E, Nuhoglu A (2010) Phenol biodegradation in a batch jet loop bioreactor (JLB): kinetics study and pH variation. Bioresour Technol 101:2965–2971

Ahmaruzzaman M, Sharma D (2005) Adsorption of phenols from waste water. J Colloid Interface Sci 287:14–24

Collins L, Daugulis A (1997) Characterization and optimization of a two-phase partitioning bioreactor for the biodegradation of phenol. Appl Microbiol Biotechnol 48:18–22

Juang R-S, Kao H-C, Zhang Z (2012) A simplified dynamic model for the removal of toxic organics in a two-phase partitioning bioreactor. Sep Purif Technol 90:213–220

Chung T-P, Tseng H-Y, Juang R-S (2003) Mass transfer effect and intermediate detection for phenol degradation in immobilized Pseudomonas putida systems. Process Biochem 38:1497–1507

Daugulis AJ (2001) Two-phase partitioning bioreactors: a new technology platform for destroying xenobiotics. Trends Biotechnol 19:457–462

Zilouei H, Guieysse B, Mattiasson B (2008) Two-phase partitioning bioreactor for the biodegradation of high concentrations of pentachlorophenol using Sphingobium chlorophenolicum DSM 8671. Chemosphere 72:1788–1794

Cruickshank SM, Daugulis AJ, McLellan PJ (2000) Dynamic modeling and optimal fed-batch feeding strategies for a two-phase partitioning bioreactor. Biotechnol Bioeng 67:224–233

Munoz R, Arriaga S, Hernández S, Guieysse B, Revah S (2006) Enhanced hexane biodegradation in a two phase partitioning bioreactor: overcoming pollutant transport limitations. Process Biochem 41:1614–1619

Juang R-S, Kao H-C, Tseng K-J (2010) Kinetics of phenol removal from saline solutions by solvent extraction coupled with degradation in a two-phase partitioning bioreactor. Sep Purif Technol 71:285–292

Juang R-S, Tseng K-J (2010) Experimental investigation of bio-removal of toxic organic pollutants from highly saline solutions in a triphasic system. J Hazard Mater 178:706–712

Collins LD, Daugulis AJ (1997) Biodegradation of phenol at high initial concentrations in two-phase partitioning batch and fed-batch bioreactors. Biotechnol Bioeng 55:155–162

Yan J, Jianping W, Hongmei L, Suliang Y, Zongding H (2005) The biodegradation of phenol at high initial concentration by the yeast Candida tropicalis. Biochem Eng J 24:243–247

Bux F, Atkinson B, Kasan H (1999) Zinc biosorption by waste activated and digested sludges. Water Sci Technol 39:127–130

Aksu Z, Akpınar D (2000) Modelling of simultaneous biosorption of phenol and nickel (II) onto dried aerobic activated sludge. Sep Purif Technol 21:87–99

Wang CC, Lee CM, Lu CJ, Chuang MS, Huang CZ (2000) Biodegradation of 2, 4, 6-trichlorophenol in the presence of primary substrate by immobilized pure culture bacteria. Chemosphere 41:1873–1879

Li Y, Li J, Wang C, Wang P (2010) Growth kinetics and phenol biodegradation of psychrotrophic Pseudomonas putida LY1. Bioresour Technol 101:6740–6744

Hamed TA, Bayraktar E, Mehmetoğlu Ü, Mehmetoğlu T (2004) The biodegradation of benzene, toluene and phenol in a two-phase system. Biochem Eng J 19:137–146

Collins LD, Daugulis AJ (1996) Use of a two phase partitioning bioreactor for the biodegradation of phenol. Biotechnol Tech 10:643–648

Jiang Y, Wen J, Bai J, Jia X, Hu Z (2007) Biodegradation of phenol at high initial concentration by Alcaligenes faecalis. J Hazard Mater 147:672–676

Ein-Mozaffari F, Upreti SR (2010) Investigation of mixing in shear thinning fluids using computational fluid dynamics. INTECH Open Access Publisher, New York

Nielsen DR, Daugulis AJ, McLellan PJ (2003) A novel method of simulating oxygen mass transfer in two-phase partitioning bioreactors. Biotechnol Bioeng 83:735–742

Melgarejo-Torres R, Torres-Martínez D, Gutiérrez-Rojas M, de Jesús AG, Lye G, Huerta-Ochoa S (2011) Regime analysis of a Baeyer–Villiger bioconversion in a three-phase (air–water–ionic liquid) stirred tank bioreactor. Biochem Eng J 58:87–95

Badino A, Facciotti M, Schmidell W (2001) Volumetric oxygen transfer coefficients (k L a) in batch cultivations involving non-Newtonian broths. Biochem Eng J 8:111–119

Venneker BC, Derksen JJ, Van den Akker HE (2002) Population balance modeling of aerated stirred vessels based on CFD. AIChE J 48:673–685

Laurenzi F, Coroneo M, Montante G, Paglianti A, Magelli F (2009) Experimental and computational analysis of immiscible liquid–liquid dispersions in stirred vessels. Chem Eng Res Des 87:507–514

Galaction A-I, Cascaval D, Oniscu C, Turnea M (2004) Prediction of oxygen mass transfer coefficients in stirred bioreactors for bacteria, yeasts and fungus broths. Biochem Eng J 20:85–94

Cachaza EM, Díaz ME, Montes FJ, Galán MA (2009) Simultaneous computational fluid dynamics (CFD) simulation of the hydrodynamics and mass transfer in a partially aerated bubble column. Ind Eng Chem Res 48:8685–8696

Kerdouss F, Bannari A, Proulx P, Bannari R, Skrga M, Labrecque Y (2008) Two-phase mass transfer coefficient prediction in stirred vessel with a CFD model. Comput Chem Eng 32:1943–1955

Alopaeus V, Koskinen J, Keskinen KI (1999) Simulation of the population balances for liquid–liquid systems in a nonideal stirred tank: Part 1 description and qualitative validation of the model. Chem Eng Sci 54:5887–5899

Chen P, Sanyal J, Dudukovic M (2004) CFD modeling of bubble columns flows: implementation of population balance. Chem Eng Sci 59:5201–5207

Ekambara K, Sanders R, Nandakumar K, Masliyah J (2008) CFD simulation of bubbly two-phase flow in horizontal pipes. Chem Eng J 144:277–288

Buffo A, Marchisio DL, Vanni M, Renze P (2013) Simulation of coalescence, break up and mass transfer in bubble columns by using the conditional quadrature method of moments in OpenFOAM

Petitti M, Vanni M, Marchisio DL, Buffo A, Podenzani F (2013) Simulation of coalescence, break-up and mass transfer in a gas–liquid stirred tank with CQMOM. Chem Eng J 228:1182–1194

Wang T, Wang J, Jin Y (2005) Population balance model for gas–liquid flows: influence of bubble coalescence and breakup models. Ind Eng Chem Res 44:7540–7549

Hulburt HM, Katz S (1964) Some problems in particle technology: a statistical mechanical formulation. Chem Eng Sci 19:555–574

Gimbun J, Rielly CD, Nagy ZK (2009) Modelling of mass transfer in gas–liquid stirred tanks agitated by Rushton turbine and CD-6 impeller: a scale-up study. Chem Eng Res Des 87:437–451

Moilanen P, Laakkonen M, Visuri O, Alopaeus V, Aittamaa J (2008) Modelling mass transfer in an aerated 0.2 m3 vessel agitated by Rushton, Phasejet and Combijet impellers. Chem Eng J 142:95–108

Dhanasekharan KM, Sanyal J, Jain A, Haidari A (2005) A generalized approach to model oxygen transfer in bioreactors using population balances and computational fluid dynamics. Chem Eng Sci 60:213–218

Ishii M, Zuber N (1979) Drag coefficient and relative velocity in bubbly, droplet or particulate flows. AIChE J 25:843–855

Qi N, Zhang H, Zhang K, Xu G, Yang Y (2013) CFD simulation of particle suspension in a stirred tank. Particuology 11:317–326

Bartrand TA, Farouk B, Haas CN (2009) Countercurrent gas/liquid flow and mixing: implications for water disinfection. Int J Multiph Flow 35:171–184

Bakker A, Akker HA (1994) A computational model for the gas-liquid flow in stirred reactors. Chem Eng Res Des 72:594–606

McClure DD, Kavanagh JM, Fletcher DF, Barton GW (2014) Development of a CFD model of bubble column bioreactors: part two-comparison of experimental data and CFD predictions. Chem Eng Technol 37:131–140

Viollet P, Simonin O (1994) Modelling dispersed two-phase flows: closure, validation and software development. Appl Mech Rev 47:S80–S84

Fluent F (2006) 6.3 User’s guide. Fluent Inc: New York

Kashid MN, Agar DW, Turek S (2007) CFD modelling of mass transfer with and without chemical reaction in the liquid–liquid slug flow microreactor. Chem Eng Sci 62:5102–5109

Kawase Y, Halard B, Moo-Young M (1992) Liquid-phase mass transfer coefficients in bioreactors. Biotechnol Bioeng 39:1133–1140

Laakkonen M, Moilanen P, Alopaeus V, Aittamaa J (2007) Modelling local gas–liquid mass transfer in agitated vessels. Chem Eng Res Des 85:665–675

Lamont JC, Scott D (1970) An eddy cell model of mass transfer into the surface of a turbulent liquid. AIChE J 16:513–519

Jia X, Wang X, Wen J, Feng W, Jiang Y (2010) CFD modelling of phenol biodegradation by immobilized Candida tropicalis in a gas–liquid–solid three-phase bubble column. Chem Eng J 157:451–465

CFX-Solver, A. (2005) Release 10.0: Theory. ANSYS Inc

Wilke C, Chang P (1955) Correlation of diffusion coefficients in dilute solutions. AIChE J 1:264–270

Marchisio DL, Fox RO (2013) Computational models for polydisperse particulate and multiphase systems. Cambridge University Press, Cambridge

Fox RO (2007) Introduction and fundamentals of modeling approaches for polydisperse multiphase flows. In: Marchisio DL, Fox RO (eds) Multiphase reacting flows: modelling and simulation. Springer, Berlin, pp 1–40

Hagesaether L, Jakobsen HA, Svendsen HF (2002) A model for turbulent binary breakup of dispersed fluid particles. Chem Eng Sci 57:3251–3267

Prince MJ, Blanch HW (1990) Bubble coalescence and break-up in air-sparged bubble columns. AIChE J 36:1485–1499

Luo H, Svendsen HF (1996) Theoretical model for drop and bubble breakup in turbulent dispersions. AIChE J 42:1225–1233

Spalding DB (1963) Physicochemical hydrodynamics: VG Levich, Prentice-Hall, 1962, 700 pp. Pergamon, New York

Hibiki T, Ishii M (2000) Two-group interfacial area transport equations at bubbly-to-slug flow transition. Nucl Eng Des 202:39–76

Gibbs R, Hopkins M (1983) Effects of solids concentration and turbulence upon the coagulation rate of sewage sludge in seawater. Technical Report, Center of Colloidal Science, College of Marine Studies, University of Delaware, Newark, Delaware

Clift R, Grace JR, Weber ME (2005) Bubbles, drops, and particles. Courier Corporation, Mineola

Wang L, Fox RO (2003) Application of in situ adaptive tabulation to CFD simulation of nano-particle formation by reactive precipitation. Chem Eng Sci 58:4387–4401

Wu B (2013) Advances in the use of CFD to characterize, design and optimize bioenergy systems. Comput Electron Agric 93:195–208

Aghbolaghy M, Karimi A (2014) Simulation and optimization of enzymatic hydrogen peroxide production in a continuous stirred tank reactor using CFD–RSM combined method. J Taiwan Inst Chem Eng 45:101–107

Wu C, Ayeni O, Berrouk A, Nandakumar K (2014) Parallel algorithms for CFD–DEM modeling of dense particulate flows. Chem Eng Sci 118:221–244

Blelloch GE (1990) Vector models for data-parallel computing. MIT Press, Cambridge

Hillis WD, Steele GL Jr (1986) Data parallel algorithms. Commun ACM 29:1170–1183

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Moradkhani, H., Anarjan Kouchehbagh, N. & Izadkhah, MS. Experimental and CFD–PBM approach coupled with a simplified dynamic analysis of mass transfer in phenol biodegradation in a three phase system of an aerated two-phase partitioning bioreactor for environmental applications. Heat Mass Transfer 53, 1073–1091 (2017). https://doi.org/10.1007/s00231-016-1876-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-016-1876-4