Abstract

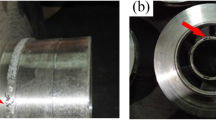

The impellers of centrifugal pumps are highly susceptible to the latent damage of corrosion and cavitation after long periods of transporting chemical fluids. To enhance the structural integrity and effective lifespan of impellers, this study applied mold flow analysis to the design of gating systems for 17-4PH stainless steel enclosed impellers. Our objective was to eliminate shrinkage and porous defects common in investment casting. We adopted various bottom, side, and top pouring systems with different pouring parameters to examine the behavior of the molten metal flow and solidification in the mold cavity. We designed a pressurized gating system with specific gating ratio to achieve a stable flow velocity at in-gates. Physical sensors preset in the interior of the cavity were also used to detect thermodynamic behavior and analyze phase changes during casting simulations. The probability of shrinkage defect formation was assessed using the retained melt modulus (RMM) and the Niyama criterion. Experiments and nondestructive inspections show that optimizing the design of the gating system prevented surface shrinkage and interior defects. The improvements also reduced post-processing time and costs, increased yields, and enhanced casting quality.

Similar content being viewed by others

References

Kalpakjian S, Schmid S (2013) Manufacturing engineering & technology, 7th edition. Pearson Education Centre

Thammachot N, Dulyapraphant P, Bohez ELJ (2013) Optimal gating system design for investment casting of sterling silver by computer-assisted simulation. Int J Adv Manuf Technol 67:797–810

Zhang XP, Chen G (2005) Computer simulation of the solidification of cast titanium dental prostheses. J Mater Sci 40:4911–4916

Kuo JK, Huang PH, Guo MJ (2017) Removal of CrMo alloy steel components from investment casting gating system using vibration-excited fatigue failure. Int J Adv Manuf Technol 89: 101–111

Wu M, Augthun M (2001) Application of laser measuring, numerical simulation and rapid prototyping to titanium dental castings. Dent Mater 17:102–108

Chattopadhyay H (2011) Estimation of solidification time in investment casting process. Int J Adv Manuf Technol 55:35–38

Liang YF, Dong SQ, Ding H, Li GH, Zhang WX (2011) Effects of pouring ways on microstructure and properties of thin walled castings by investment casting process. Foundry 60(7):552–655

Huang PH, Luo JY, Hung SC, Lin CJ, Cheng HH (2014) Optimal pouring system design for investment casting of cladding thin-plate heater using metallic mold flow analyses. Appl Mech Mater 627:46–49

Yi CL, Zhang Q (2012) Simulation on filling and solidification process of stainless steel impeller’s in investment casting. Foundry Technol 33(5):593–595

Huang PH, Chen YT, Wang BT (2014) An effective method for separating casting components from the runner system using vibration-induced fatigue damage. Int J Adv Manuf Technol 74:1275–1282

Zhi X, Han Y, Yuan X (2015) Casting process optimization for the impellor of 200ZJA slurry pump. Int J Adv Manuf Technol 77:1703–1710

Huang PH, Guo MJ (2015) A study on the investment casting of 17-4PH stainless steel helical impeller of centrifugal pump. Mater Res Innov 19(S9):77–81

Swaminathan CR, Voller VR (1994) A time implicit filling algorithm. Appl Math Modeling 18(2):101–108

Jin HP, Li JR, Liu SZ (2010) Simulation of the solidification parameters of single crystal casting. Mater Sci Forum 638-642:2251–2256

Norouzi S, Farhangi H (2011) Effects of cooling condition on hot tearing during investment casting. Adv Mater Res 264-265:355–360

Pan L, Zheng L, Zhang H, Gao W (2011) Applicability of shrinkage porosity prediction for casting with Niyama criterion. Journal of Beijing University of Aeronautics and Astronautics 37(12):1534–1540

Wang MF, Guo X, Wang F (2012) Improvement of the investment casting process used to the production of stainless steel impeller. Foundy Equip Technol 3:21–22

Gao CW, Yu XF, Huang AH, Cong J, Qu DP, Feng WG (2012) Effect of shell preheating and pouring temperature on cast formability of a combined guide vane. Foundry 61(8):882–885

Feng X (2013) Optimum design for casting process of impeller for slurry pump. Foundry Eng 3:46–47

Budavari I, Molnar D (2014) Control volume simulation of casting directional solidification. Mater Sci Forum 790-791:146–151

Chen L, Huang F (2013) Design of exothermic and insulating riser for steel casting of gear ring seat based on AnyCasting. Foundry 62(3):226–229

Wang YC, Li DY, Peng YH, Zeng XQ (2007) Numerical simulation of low pressure die casting of magnesium wheel. Int J Adv Manuf Technol 32:257–264

Guo J, Beckermann C, Carlson K, Hirvo D, Bell K, Moreland T, Gu J, Clews J, Scott S, Couturier G, Backman D (2015) Microporosity prediction and validation for Ni-based superalloy castings. Mater Sci Eng 84:1–5

Xu M, Lekakh SN, Richards VL (2016) Thermal property database for investment casting shells. Int J Met 10:1–9

Yahaya B, Izman S, Idris MH, Dambatta MS (2016) Effects of activated charcoal on physical and mechanical properties of microwave dewaxed investment casting moulds. CIRP J Manuf Sci Technol 13:97–103

Product data sheet of AK steel, No. UNS S17400

User manual of Anycasting. version 6.0

Liao DM, Chen LL, Zhou JX, Liu RX (2011) Numerical simulation of thermal stress fields of steel casting. Adv Mater Res 179-180:1118–1123

Huang PH, Lin CJ (2015) Computer-aided modeling and experimental verification of optimal gating system design for investment casting of precision rotor. Int J Adv Manuf Technol 79:997–1006

Niyama E, Uchida T, Morikawa M, Saito S (1982) A method of shrinkage prediction and its application to steel casting practice. AFS Int Cast Met J 7:52–63

Campbell J (2015) Complete casting handbook: metal casting processes, metallurgy, techniques and design, 2nd edition. Butterworth-Heinemann

Bahmani A, Hatami N, Varahram N, Davami P, Shabani MO (2013) A mathematical model for prediction of microporosity in aluminum alloy A356. Int J Adv Manuf Technol 64:1313–1321

Wang YC, Li DY, Peng YH, Zhu LG (2007) Computational modeling and control system of continuous casting process. Int J Adv Manuf Technol 33:1–6

Homayonifar P, Babaei R, Attar E, Shahinfar S, Davami P (2008) Numerical modeling of splashing and air entrapment in high-pressure die casting. Int J Adv Manuf Technol 39:219–228

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kuo, JK., Huang, PH., Lai, HY. et al. Optimal gating system design for investment casting of 17-4PH stainless steel enclosed impeller by numerical simulation and experimental verification. Int J Adv Manuf Technol 92, 1093–1103 (2017). https://doi.org/10.1007/s00170-017-0198-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0198-0