Abstract

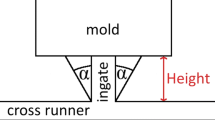

The first requirement of all casting processes is complete filling without any defects after solidification. However, casting defects often occur in casting processes, especially incomplete filling. The causes of incomplete filling are related to poor gating system, incorrect pouring, and molding temperature. A suitable shape and dimension of gating system will increase the melt flow while it is feeding into mold cavity by eliminating excessive pouring and molding temperature. The objective of this study is to develop a new design of gating system for eliminating incomplete filling. The new shape and dimension of pouring cup, main sprue, and sprue base are proposed and investigated. The computational flow model is solved with the aid of computer simulation. The targets of an optimum solution are increasing the efficiency of metal flow and reducing turbulence. The experiments are conducted to validate the simulation data. The results of this study will aid in the elimination of casting defects and increase the productivity.

Similar content being viewed by others

References

Fuoco R, Correa ER (2003) The effect of gating system design on the quality of aluminum gravity casting. Proceedings from the AFS International conference on Structure Aluminum Casting, Orlando, pp. 205–224

Chan D et al (1997) The effect of sprue design on the roughness and porosity of titanium castings. J Prosthet Dent 78(4):400–404

Solidum H (1996) Hollow tree casting technology. Proceedings of the Santa Fe Symposium on Jewelry Manufacturing Technology, Albuquerque, New Mexico, USA, pp. 535–557

Grice S, Cart CJ (2000) I’m dreaming of a white gold Christmas bonus. Proceedings of the Santa Fe Symposium on Jewelry Manufacturing Technology, Albuquerque, New Mexico, USA, pp. 117–145

Desai KD, Raghav R (2005) Innovative lost wax investment casting process. Proceedings of the Santa Fe Symposium on Jewelry Manufacturing Technology, Albuquerque, New Mexico, USA, pp. 193–214

Shamasundar S et al (2003) Computer aided methoding and simulation for the investment casting process using ProCAST. Proceedings of the National Conference on Investment Casting (NCIC 2003), New Delhi, pp. 70–74

Wu M et al (2001) Application of laser measuring, numerical simulation and rapid prototyping to titanium dental castings. Dent Mater 17:102–108

Wright JC (2005) Computer simulation and jewelry production. Proceedings of the Santa Fe Symposium on Jewelry Manufacturing Technology, Albuquerque, New Mexico, USA, pp. 521–535

Grande MA et al (2007) Computer simulation of the investment casting process: Widening of the filling step. Proceedings of the Santa Fe Symposium on Jewelry Manufacturing Technology, Albuquerque, New Mexico, USA, pp. 1–16

Fischer-Bühner J (2007) Advances in the prevention of investment casting defects assisted by computer simulation. Proceedings of the Santa Fe Symposium on Jewelry Manufacturing Technology, Albuquerque, New Mexico, USA, pp. 149–172

Fischer-Bühner J (2006) Computer simulation of jewelry investment casting. Proceedings of the Santa Fe Symposium on Jewelry Manufacturing Technology, Nashville, Tennessee, USA, pp193–216

Bell E (2002) Sprues, feed sprues and gates. Gold Technol (36):1–11

Beeley PR (1972) Foundry technology. London Butterworths, England, pp 24–25

Thomas BG (2003) Modeling of continuous casting. Chapter 5 in Making shaping and treating of steel, 11th edn, vol. 5. In: A. Cramb (ed) Casting volume, AISE Steel Foundation, Pittsburgh, pp. 5.1–5.24

Reilly C et al (2012) The present state of modeling entrainment defects in the shape casting process. Applied Mathematical Modelling. http://www.elsevier.com/locate/apm Accessed 26 June 2012

Bounds G et al (2000) A computational model for defect prediction in shape castings base on the interaction of free surface flow, heat transfer, and solidification phenomena. Metall Mater Trans B 31B:515–527

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Thammachot, N., Dulyapraphant, P. & Bohez, E.L.J. Optimal gating system design for investment casting of sterling silver by computer-assisted simulation. Int J Adv Manuf Technol 67, 797–810 (2013). https://doi.org/10.1007/s00170-012-4523-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4523-3