Abstract

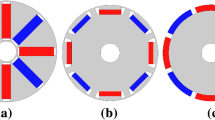

This paper proposed a new compensation method of geometric errors for five-axis machine tools. First, the principle of time-consuming traditional compensation method based on iteration of forward and inverse kinematic solution is analyzed. According to the analysis, the essential cause of this iteration is considered as the synchronous solving of compensated numerical control (NC) code of each axis. This iteration process can be avoided by the algorithm proposed in this paper. This new algorithm compensates NC code in a new order based on the topology relation between each axis in kinematic chain of machine tools. Based on this new order, the universal compensation process for three typical configurations of five-axis machine tools is also established. This new compensation method not only decouples the compensation process between linear and rotary axes as traditional method does, but also decouples the compensation process among each rotary axis and linear axis. Therefore, different with traditional method, there is no need to use time-consuming iteration process to calculate compensated position command of each axis. Also, it contains no complex computation such as derivation or evaluation of high order pseudo-inverse matrix which exist in traditional methods. Therefore, the compensation efficiency is significantly improved. Finally, the accuracy and efficiency of this new method is simulated and verified experimentally on a five-axis machine tool.

Similar content being viewed by others

References

Ibaraki S, Knapp W (2012) Indirect measurement of volumetric accuracy for three-axis and five-axis machine tools: a review. Int J Autom Technol 6(2):110–124. doi:10.3929/ethz-a-007593181

Schwenke H, Knapp W, Haitjema H (2008) Geometric error measurement and compensation of machines—an update. CIRP Ann Manuf Technol 57:660–675. doi:10.1016/j.cirp.2008.09.008

Raksiri C, Parnichkun M (2004) Geometric and force errors compensation in a 3-axis CNC milling machine. Int J Mach Tool Manuf 44:1283–1291. doi:10.1016/j.ijmachtools.2004.04.016

Hongtao Z, Jianguo Y, Yi Z (2011) Measurement and compensation for volumetric positioning errors of CNC machine tools considering thermal effect. Int J Adv Manuf Technol 55:275–283. doi:10.1007/s00170-010-3024-5

Wei W, Yi Z, Jianguo Y (2013) Geometric and thermal error compensation for CNC milling machines based on Newton interpolation method. Proc IMechE C J Mech Eng Sci 227(4):771–778. doi:10.1177/0954406212461595

Gangwei C, Yong L, Jianguang L (2012) Geometric error compensation software system for CNC machine tools based on NC program reconstructing. Int J Adv Manuf Technol 63:169–180. doi:10.1007/s00170-011-3895-0

Yi Z, Jianguo Y, Sitong X (2013) Volumetric error modeling and compensation considering thermal effect on five-axis machine tools. Proc IMechE C J Mech Eng Sci 227(5):1102–1115. doi:10.1243/09544062JMES2200

Tsutsumia M, Tone S, Kato N (2013) Enhancement of geometric accuracy of five-axis machining centers based on identification and compensation of geometric deviations. Int J Mach Tool Manuf 68:11–20. doi:10.1016/j.ijmachtools.2012.12.008

Shaowei Z, Guofu D, Shengfeng Q (2012) Integrated geometric error modeling, identification and compensation of CNC machine tools. Int J Mach Tool Manuf 52:24–29. doi:10.1016/j.ijmachtools.2011.08.011

Chen GS, Mei XS, Li HL (2013) Geometric error modeling and compensation for large-scale grinding machine tools with multi-axes. Int J Adv Manuf Technol 69:2583–2592. doi:10.1007/s00170-013-5203-7

Khan AW, Wuyi C (2011) A methodology for systematic geometric error compensation in five-axis machine tools. Int J Adv Manuf Technol 53:615–628. doi:10.1007/s00170-010-2848-3

Lei WT, Hsu YY (2005) Accuracy enhancement of five-axis CNC machines through real-time error compensation. Int J Mach Tool Manuf 43:871–877. doi:10.1016/S0890-6955(03)00089-0

Jianxiong C, Shuwen L, Bingwei H (2014) Geometric error compensation for multi-axis CNC machines based on differential transformation. Int J Adv Manuf Technol 71:635–642. doi:10.1007/s00170-013-5487-7

Hsu YY, Wang SS (2007) A new compensation method for geometry errors of five-axis machine tools. Int J Mach Tool Manuf 47:352–360. doi:10.1016/j.ijmachtools.2006.03.008

Fangyu P, Ma J, Wang W (2015) Total differential methods based universal post processing algorithm considering geometric error for multi-axis NC machine tool. Int J Mach Tool Manuf 70:53–62. doi:10.1016/j.ijmachtools.2013.02.001

Nuodi H, Yongqiao J, Qingzhen B (2015) Integrated post-processor for 5-axis machine tools with geometric errors compensation. Int J Mach Tool Manuf 94:65–73. doi:10.1016/j.ijmachtools.2015.04.005

Srivasta AK, Veldhuis SC, Elbestawit MA (1994) Modelling geometric and thermal errors in a five-axis CNC machine tool. Int J Mach Tool Manuf 35(9):1321–133. doi:10.1016/0890-6955(94)00048-O

Ramesh R, Mannan MA, Poo AN (2003) Thermal error measurement and modelling in machine tools. Part I Influence of varying operating conditions. Int J Mach Tool Manuf 43:391–404. doi:10.1016/S0890-6955(02)00263-8

Ramesh R, Mannan MA, Poo AN (2000) Error compensation in machine tools - a review Part I: geometric, cutting-force induced and fixture-dependent errors. Int J Mach Tool Manuf 40:1235–1256. doi:10.1016/S0890-6955(00)00009-2

Liang JC, Li HF, Yuan JX (1997) A comprehensive error compensation system for correcting geometric, thermal, and cutting force-induced errors. Int J Adv Manuf Technol 13:708–712. doi:10.1007/BF01179070

Zhouxiang J, Bao S, Xiangdong Z (2015) Single setup identification of component errors for rotary axes on five-axis machine tools based on pre-layout of target points and shift of measuring reference. Int J Mach Tool Manuf 98:1–11. doi:10.1016/j.ijmachtools.2015.08.003

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, X., Jiang, Z., Song, B. et al. A compensation method for the geometric errors of five-axis machine tools based on the topology relation between axes. Int J Adv Manuf Technol 88, 1993–2007 (2017). https://doi.org/10.1007/s00170-016-8919-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8919-3