Abstract

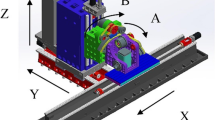

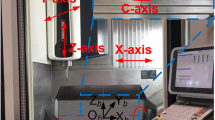

To enhance the accuracy, an efficient methodology was developed and described for systematic geometric error correction and their compensation in five-axis machine tools. The methodology is capable of compensating the overall effect of all position-dependent and position-independent errors which contribute to volumetric workspace. It was implemented on a five-axis grinding machine for error compensation and for the check of its effectiveness. Error compensation algorithm was designed, and a routine was written in Matlab software. The developed technique and software are based on an error table which interprets the function of axis through cubic spline technique and synthesis modeling of a machine tool. Recursive compensation methodology was used to remove the machine errors from the actual tool path and inverse technique was implemented to find the corrected positions of prismatic and rotary joints. Moreover, it can convert the corrected tool paths into practical compensated NC codes. The generated, corrected and modified NC codes directly fed to the controller of a five-axis machine tool. Validation of the technique was preceded by repeated experimentation of measurement and through machining of typical standard workpieces with some additional specific features. Experimental results exhibit effective compensation and remarkable improvement in the parametric and volumetric-workspace accuracy of the five-axis machine tool.

Similar content being viewed by others

References

The Cox report: Chapter 10 Manufacturing process. Available at: www.washingtonpost.com/wp-srv/politics/daily/may99/coxreport/chapter10.htm Washington Post, May 25, 1999. Accessed 20 Feb 2010

Takeuchi Y, Watanabe T (1992) Generation of 5-axis control collision-free tool path and post processing for NC data Ann. CIRP 41(1):539–542

Trankle H (1980) Effects of position errors in five-axis milling processes. Ph.D. Dissertation, Stuttgart University, Federal Republic of Germany

Sprow EE (1993) Step up to five-axis programming? Manuf Eng 111(5):55–60

Chen JS (1995) Computer-aided accuracy enhancement for multi-axis CNC machine tool. Int J Mach Tools Manuf 35(4):593–605

Hemann G (2007) Geometric error correction in coordinate measurement. Acta Polytechnica Hungarica 4(1):474–61

Barakat NA, Elbestawi MA, Spence AD (2000) Kinematic and geometric error compensation of a coordinate measuring machine. Int J Mach Tools Manuf 40(6):833–850

Koliskor AS (1971) Compensating for automatic-cycle machining errors. Machines and Tooling No5 41(1):1–14

Okushima K, Kakino Y (1975) Compensation of thermal displacement by coordinate system correction. Ann CIRP 24(1):327–331

Busch K, Kunzmann H, Wäldele F (1985) Calibration of coordinate measuring machines, vol. 7(3). Butterworth & Co Ltd., London, UK. pp. 139–144

Zhang G, Veale R, Charlton T, Borchardt B, Hocken R (1985) Error compensation of coordinate measuring machines. Ann CIRP 34(1):445–448

Donmez MA, Blomquist DS, Hocken RJ, Liu CR, Barash MM (1986) A general methodology for machine tool accuracy enhancement by error compensation. Prec Eng 8(4):187–196

Donmez MA, Lee. K, Liu CR, Barash, MM (1986) Real-time error compensation system for a computerized control turning center. In: Proc. IEEE Int. Conf on Robotics and Automation, San Francisco, CA

Ferreira PM, Liu CR (1986) A contribution to analysis and compensation of the geometric error of a machining center. Ann CIRP 35(1):259–262

Belforte G, Bona B, Canuto E, Donati F, Ferraris F, Gorini I, Morei S, Peisino M, Sartori S (1987) Coordinate measuring machines and machine tools self-calibration and error correction. Ann CIRP 36(1):359–364

Anjanappa M, Anand DK, Kirk JA, Shyam S (1988) Error correction methodologies and control strategies for numerical control machining. Cont Meth Manuf Process ASME, DSC 7:41–49

Teeuwsen JWMC, Soons JA, Schellekens PHJ, Van der Wolf ACH (1989) A general method for error description of CMMs using polynomial fitting procedures. Ann CIRP 38(1):505–510

Kurtoglu A (1990) The accuracy improvement of machine tools. Ann CIRP 39(1):417–419

Balsamo A, Marques D, Sartori S (1990) A method for thermal-deformation correction of CMMs. Ann CIRP 39(1):557–560

Bryan JB (1990) International status of thermal error research. Ann CIRP 39(2):645–656

Takeuchi Y, Idemura T (1992) Generation of five-axis control collision free tool path and post processing for NC-data. Ann CIRP 41(1):539–542

Chen JS, Yuan JX, Ni J, Wu SM (1993) Real time compensation for time-variant volumetric errors on a machining center. Trans ASME 115:472–479

Mou J, Liu C (1993) A methodology for machine tool error correction—an adaptive approach. ASME-WAM PED 64:69–81

Kruth JP, Vanherck P, De Jonge L (1994) Self-calibration method and software error correction for three-dimensional coordinate measuring machines using artifact measurement. Meas 14:157–67

Kiridena VSB, Ferreira PM (1994) Kinematic modeling of quasi-static errors of three-axis machine centers. Int J Mach Tools Manuf 34(1):85–100

Kiridena VSB, Ferreira PM (1994) Parameter estimation and model verification of 1st order quasistatic error model for machine centers. Int J Mach Tools Manuf 34:101–125

Kiridena VSB, Ferreira PM (1994) Computational approaches to compensating quasistatic errors of three-axis machining. Int J Mach Tools Manuf 34:127–145

Wang SM, Ehmann K F (1994) Compensation of geometric and quasi-static deformation errors of a multi-axis machine, Trans. NARMI/SME XXII

Veldhuis S, Elbestawi MA (1994) Modelling and compensation for five axes machine tool errors. ASME-WAM PED 68(2):827–839

Lo C-H, Yuan JX, Ni J (1995) An application of real-time error compensation on a turning center. Int J Mach Tools Manuf 35(12):1669–1682

Bosch JA (1995) Coordinate measuring machines and systems. Marcel Dekker, New York

Ni J (1997) CNC machine accuracy enhancement through real-time error compensation. J Manuf Sci Eng 119:717–725

Mou J (1997) A systematic approach to enhance machine tool accuracy for precision manufacture. Int J Mach Tools Manuf 37(5):669–685

Mahbuburehman RMD, Hewikkala J, Lappalainen K, Karjalinen JA (1997) Positioning accuracy improvement in five-axis milling by post processing. Int J Mach Tools Manuf 37(2):223–236

Aekambaram R, Raman S (1999) Improved tool-path generation, error measures and analysis for sculptured surface machining. Int J Prod Res 37(2):413–431

Barakat NA, Elbestawi MA, Spence AD (2000) Kinematic and geometric error compensation of a coordinate measuring machine. Int J Mach Tools Manuf 40:833–850

Rahman M, Heikkala J, Lappalainen K (2000) Modeling, measurement and error compensation of multi-axis machine tools. Part I: Theory Int J Mach Tools Manuf 40:1535–1546

Bohez E, Makhnov SS, Sonthipaumpoon K (2000) Adaptive nonlinear tool-path optimization for 5-axis machining. Int J Prod Res 38(17):4329–4343

Sinumerik (2002) Extended Functions (Part 2) Sinumerik 840D/840Di/810D (CCU2). Available at: www.ad.siemens.de. Accessed 15 Dec 2008

Hiroshi S Hideo NTakashi I Seido K (1999) Compensation for the exponential type lost motion to improve the contouring accuracy of NC machine Tools. Technical Paper, Mitsubishi Electric Corporation, IESL, Itami, Japan. pp. 1481–1486

Heidenhain AG (2002) Technical Manual iTNC 530, NC Software 340: 420-07, 1-1052

Bohez ELJ (2002) Compensating for systematic error in 5-axis NC machining. Comput Aided Des 34:391–403

Wang SM, Liu YL, Yuan K (2002) An efficient error compensation system for CNC multi-axis machines. Int J Mach Tools Manuf 42:1235–1245

Lei WT, Hsu YY (2003) Accuracy enhancement of five-axis CNC machines through real-time error compensation. Int J Mach Tools Manuf 43:871–877

Raksiri C, Parnichkun M (2004) Geometric and force errors compensation in a 3-axis CNC milling machine. Int J Mach Tools Manuf 44:1283–1291

Yang SH, Kim KH, Park YK, Lee SG (2004) Error analysis and compensation of the volumetric errors of a vertical machining centre using a hemispherical helix ball bar test. Int J Adv Manuf Trechnol 23:495–500

Lee JH, liu Y, Yang SH (2006) Accuracy improvement of miniaturized machine tool: geometric error modeling and compensation. Int J Mach Tools Manuf 46:1508–1516

Wang SM, Yu HJ, Liao HW (2006) A new high-efficiency error compensation system for CNC multi-axis machine tools. Int J Manf Technol 28:518–526

Hsu YY, Wang SS (2007) A new compensation method for geometry errors of five-axis machine tools. Int J Mach Tool Manuf 47:352–360

Weck M Bibring H (1984) Metrological analysis and performance tests. Handbook of machine tools, vol.4. Wiley-Heyden Ltd., New York

Slocum AH (1992) Precision machine design. Prentice-Hall, Englewood Cliffs

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khan, A.W., Chen, W. A methodology for systematic geometric error compensation in five-axis machine tools. Int J Adv Manuf Technol 53, 615–628 (2011). https://doi.org/10.1007/s00170-010-2848-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-010-2848-3