Abstract

Background

A further increase in renewable energy supply is needed to substitute fossil fuels and combat climate change. Each energy source and respective technologies have specific techno-economic and environmental characteristics as well as social implications. This paper presents a comprehensive approach for prospective sustainability assessment of energy technologies developed within the Helmholtz Initiative “Energy System 2050” (ES2050).

Methods

The “ES2050 approach” comprises environmental, economic, and social assessment. It includes established life cycle based economic and environmental indicators, and social indicators derived from a normative concept of sustainable development. The elaborated social indicators, i.e. patent growth rate, acceptance, and domestic value added, address three different socio-technical areas, i.e. innovation (patents), public perception (acceptance), and public welfare (value added).

Results

The implementation of the “ES2050 approach” is presented exemplarily and different sustainability indicators and respective results are discussed based on three emerging technologies and corresponding case studies: (1) synthetic biofuels for mobility; (2) hydrogen from wind power for mobility; and (3) batteries for stationary energy storage. For synthetic biofuel, the environmental advantages over fossil gasoline are most apparent for the impact categories Climate Change and Ionizing Radiation—human health. Domestic value added accounts for 66% for synthetic biofuel compared to 13% for fossil gasoline. All hydrogen supply options can be considered to become near to economic competitiveness with fossil fuels in the long term. Survey participants regard Explosion Hazard as the most pressing concern about hydrogen fuel stations. For Li-ion batteries, the results for patent growth rate indicate that they enter their maturity phase.

Conclusions

The “ES2050 approach” enables a consistent prospective sustainability assessment of (emerging) energy technologies, supporting technology developers, decision-makers in politics, industry, and society with knowledge for further evaluation, steering, and governance. The approach presented is considered rather a starting point than a blueprint for the comprehensive assessment of renewable energy technologies though, especially for the suggested social indicators, their significance and their embedding in context scenarios for prospective assessments.

Similar content being viewed by others

Background

The goal of the Paris Agreement of 2015 of limiting global warming to below 2 °C can only be achieved if the energy system transformation is implemented quickly and the goals are consistently pursued [1]. Besides reducing the energy demand of all technical activities and social services, a further increase in renewable energy sources for energy supply is required to substitute fossil fuels and combat climate change. The European Green Deal [2] and the German Energiewende [3] are ambitious socio-technical tasks that reach far into the future and comprise many renewable energy sources, such as wind, solar, biomass, and various corresponding technologies, respectively. Each technology has specific techno-economic and environmental characteristics, leading to different social implications. From a sustainability perspective, it is crucial to carry out a comprehensive assessment of renewable energy technologies, including all dimensions of sustainability, i.e. economic, environmental and social aspects, to support political navigation towards a sustainable energy system [4]. Besides greenhouse gas emissions, other environmental aspects are also affected and need to be considered, such as consuming finite resources and the release of environmental pollutants [5]. Against this background, there is a demand for sustainability assessment approaches for technologies, which should meet this request and at the same time offer easily understandable orientation knowledge not only on the environmental but also on the economic and social implications [6]. For the latter's assessment and the implementation of new technologies, the investigation of public perception and technology acceptance is of increasing importance [7]. Although there is growing recognition of the significance to harmonize and align the methodologies for prospective sustainability assessment of energy technologies, no general approach or standard method exists so far [8,9,10]. This is mainly due to the multitude and diversity of technologies and their contexts of application and implementation as well as the multitude of possible criteria and indicators for their evaluation [6, 11]. Another reason is the complex nature of sustainability, which is characterized by its generic normative principles, multidimensionality and long-term perspective (across generations) [12]. To make the broad concept of sustainability applicable as a guideline for an assessment process, it needs to be downscaled and adapted to the object of consideration, the context and the type of questions and assessment needs [6]. This operationalization step needs to be accomplished by selecting meaningful sustainability indicators to carry out prospective assessments [13].

To make a step forward to close this research gap, in this paper, a comprehensive approach for prospective and consistent sustainability assessment of energy technologies is presented, which was developed and applied within the Helmholtz Initiative “Energy System 2050” (ES2050) [14]. The developed approach, subsequently referred to as “ES2050 approach”, is generically applicable, i.e., allows for the assessment of different technologies in a consistent, and future-oriented manner. It comprises economic and environmental life cycle assessment (LCA) and corresponding indicators as well as social indicators, derived from a normative concept of sustainable development. A harmonized environmental Life Cycle Assessment (E-LCA)-database as well as harmonized future framework conditions are used, e.g., projections of future mobility and energy mixes, projections of future energy prices, technology-specific progress rates and technology-specific assumptions on future efficiencies. In this paper, the application of the developed approach is presented for three different emerging technologies and corresponding case studies, which were object of research in the ES2050 project. The chosen case studies cover a wide variety of different aspects concerning, e.g., level of detail in modeling, sources of renewable energies, as well technical concepts:

-

(1)

Synthetic biofuels for mobility

-

(2)

Hydrogen from wind power for mobility

-

(3)

Batteries for stationary energy storage.

All three case studies and related technologies are important to support the transformation of the energy system as well as the mobility sector [15, 16] and are named explicitly in the German Integrated National Energy and Climate Plan [17] and in the European Green Deal [2]. They can especially help improving matching energy demand and energy production from renewable energy sources, resource efficiency and security of supply: Solar and wind technologies are characterized by intermittent generation behavior that has to be mitigated by stationary energy storage technologies like batteries or other conversion technologies such as Power-to-Liquid- or Power-to-Gas-technologies. Stationary batteries can especially help to cushion load peaks in energy demand, carry out voltage power control, frequency stabilization of the power grid, and to avoid additional grid expansion. The production of hydrogen via alkaline water electrolysis is another option to store fluctuating energy from renewable sources and the application of hydrogen in fuel cells is a possibility to use this energy for mobility. Solid biomass stores energy and carbon dioxide in a natural way and is in line with other technologies an important resource to compensate fluctuating availabilities of wind and solar power. Biomass can be converted via pyrolysis, gasification, and synthesis into so-called advanced biofuels as renewable alternative for the transportation sector [16]. Thus, in this paper, the “ES2050 approach” as well as methods and indicators used for prospective sustainability assessment are presented and results are shown and discussed exemplarily for the above mentioned case studies. The comprehensive sustainability assessment of the respective energy technologies using all indicators of the developed approach will be subject of future research papers.

State-of-the-art

In the following sub-sections, concepts for sustainable development (“Concepts for sustainable development” Section) and methods for sustainability assessment of energy technologies (“Life cycle based assessment methods for energy technologies” Section) are presented. Sustainability concepts, such as the Integrative Concept of Sustainable Development (ICoS) and the Sustainable Development Goals (SDGs), and their underlying rules and targets need to be operationalized for the prospective assessment of energy technologies. Although these concepts and frameworks are not structured along different pillars or dimensions of sustainability, this could be achieved, in a first step, by using the so-called triple-bottom line model of sustainability with its environmental, economic and social dimension and corresponding life cycle based assessment methods [18, 19].

Concepts for sustainable development

The latest and most relevant political framework of sustainable development are the 17 SDGs with corresponding targets and 230 sustainability indicators defined by the United Nations [20]. The SDGs of the 2030 Agenda for Sustainable Development partly build upon the eight Millennium Development Goals (MDGs) adopted by the UN in 2000 [21]. They are aiming at an array of issues, such as slashing poverty, hunger, diseases, gender inequality as well as improving access to fresh water and sanitation. Each SDG has specific targets to be achieved until 2030 and corresponding indicators to measure their achievement. One of these 17 SGDs is to ensure access to affordable, reliable, sustainable and modern energy for all (SDG Goal 7). To achieve this goal, targets are e.g. substantial increase of the share of renewable energy in the global energy mix and the doubling of the global rate of improvement in energy efficiency by 2030. Corresponding indicators are e.g. renewable energy share in the total final energy demand and energy intensity measured in terms of primary energy and gross domestic product (GDP). There are a couple of recent works available where the inclusion of the SDGs for (energy) technology assessment is discussed: e.g., in [22] indicators for sustainability assessment of electrolytic hydrogen production are selected based on the SDGs, comparing the implications due to the selection based on overall goals and on SDGs indicators level. In [23] renewable energy sources selection is carried out according to SDG-linked criteria (SDG 7) and in [24] the potential of Waste-to-Energy technologies to support SDG 7 is assessed.

Another well-founded science-based conceptual approach is the ICoS, developed within the German Helmholtz Association [25, 26]. ICoS is based on the Brundtland report [27], the Rio Declaration [28] and the Agenda 21 [29] and comprises three central goals and preconditions of sustainable development [30]: Securing Human Existence, Maintaining Society´s Productive Potential, and Preserving Society´s Options for Development and Action. These goals are specified by 15 substantial sustainability rules, e.g., protection of human health, sustainable development of man-made, human, and knowledge capital, participation in societal decision-making processes, conservation of social resources, and ten instrumental rules, necessary to achieve the substantial goals, e.g., society´s ability of self-organization [30]. ICoS has been contextualized and applied to date in different projects and consultancy activities, including, e.g., sustainable development of megacities, municipal solid waste management, and water management in emerging countries [31,32,33]. ICoS was also applied for the sustainability assessment of the German energy system, where the evaluation was carried out based on an integrative and comprehensive sustainability indicator system (SIS) aligned with ICoS [30, 34].

The triple bottom line model of sustainability basically says that for achieving more sustainable futures, environmental, economic as well as social impacts of activities have to be taken into account [35]. According to Klöpffer [36], any environmental, economic, or social assessment method has to take into account the respective full life cycle (raw material extraction, production, use, recycling or waste disposal) of an activity or product respectively. The original concept of Life Cycle Assessment (LCA) only dealt with the environmental component [35]. It was harmonized through SETAC’s coordination and ISO’s standardisation activities in the period of 1990–2000. The first decade of the twenty-first century has shown an increasing attention to LCA and it was increasingly used as a tool for supporting policies and performance-based regulations. In this period, e.g., life cycle-based carbon footprint standards were established and LCA methods were elaborated in further detail [35]. LCA subsequently broadened itself from a merely environmental LCA (E-LCA) to a more comprehensive Life Cycle Sustainability Assessment (LCSA) including Life Cycle Costing (LCC) and social LCA (S-LCA) [37].

Life cycle-based assessment methods for energy technologies

One method for sustainability assessment at the technology level and starting point for the developed “ES2050 approach” is LCSA. LCSA is drawing on the three pillar or “triple bottom line” model of sustainability (see “Concepts for sustainable development” Section) and combines the already existing life cycle-based approaches for environmental, economic, and social LCA (E-LCA + LCC + S-LCA) [36,37,38]. A good overview of the current status of LCSA give Costa et al. [39] and Wulf et al. [6]. Both author groups observed an increasing interest in LCSA over the last years with higher publication numbers and a wider field of authors. Energy technologies and mobility aspects are an often discussed topic in LCSA and account for almost half of the available LCSA case studies [6]. Costa et al. [39] mainly criticize the lack of harmonization in LCSA. In particular, the variety of impact categories or just indicators with different quality standards leads to different results that can hardly be compared [39]. While S-LCA is still under development, both LCC and E-LCA are widely recognized and applied procedures for the assessment of environmental impacts and costs of (emerging) technologies [40,41,42]. In [43] prospective LCA is defined as the future-oriented assessment of (emerging) technologies in an early phase of development (e.g., experimental setting or small-scale production) while the technology is modeled at a future, more developed phase (e.g., large-scale production). The challenges of assessing emerging technologies at an early stage using prospective LCA and how to deal with these challenges is increasingly discussed in the LCA community [44, 45] [46]. Thonemann et al. [47] identify comparability (e.g., with respect to chosen system boundaries and methodologies for impact assessment), data (availability, quality, and scaling), and uncertainty as main challenges for conducting prospective LCAs. Prospective aspects with respect to LCA-studies refer first of all to assumptions on the future development of the processes under consideration, i.e., associated mass and energy flows and process efficiencies, but also to assumptions on future raw materials supply chains, background processes, e.g., future electricity and heat mix, transport systems, and industrial process chains and, therefore, also deals with the large epistemological uncertainty about the future to support more robust future assessments of technologies [48]. Prospective developments of the technology under consideration can be included using literature surveys and/or learning curve models, not only for economic developments but also for developments with respect to material efficiencies and emissions [49]. In addition, future background scenarios, e.g., on energy and mobility mixes, need to be defined and used consistently for prospective studies, as there is evidence of the impacts of these background processes, in particular the ones which are based on energy, and the reference processes [49].

Environmental life cycle assessment

Environmental Life Cycle Assessment, which has fast developed over the past three decades, is now a standard tool among scientists and widely applied to assess the environmental impacts of energy technologies (e.g., [50] [51,52,53]). Besides, E-LCA is included in the 14000 series of environmental management standards of the International Organisation for Standardisation (ISO), in particular in ISO 14040 [54] and ISO 14044 [55]. The life cycle of a product is modelled as a so-called product system. All inputs and outputs of the product system are quantified and summarized within the so-called life cycle inventory (LCI). The LCI comprises information on resource consumption and emissions for each process step and corresponding upstream and downstream processes along the value chain and is the basis for the subsequent life cycle impact assessment (LCIA). For LCIA, a number of established methods for environmental impact assessment exist, amongst others the methods according to CML [56], ReCiPe [57] and ILCD [58]. These methods include different sets of environmental impact categories, e.g., Acidification, Climate Change, Ecotoxicity, Eutrophication, Human Toxicity and Resource Depletion, and are partly using different indicators and different calculation methods for the same impact category. To build-up an LCI and to carry out LCIA, different software packages, e.g., openLCA [59], umberto [60], GaBi [61] are available which have internal databases, e.g. GaBi database, or can be used with external LCA-databases, e.g., software openLCA with database ecoinvent [62]. These databases include various LCIs for industrial processes and various products and can be used to model the background processes, i.e., upstream and downstream processes, of the process under consideration. Both, the choice of the method package/indicator set and E-LCA-database can have a significant influence on the results. With respect to prospective assessments, questions of, e.g., future raw materials supply, emission reductions, resource efficiencies and/or recycling are of major concern, not only for the processes under consideration but also for background processes.

Life cycle costing

The term “Life Cycle Costs” is defined as “total” costs generated by a system during its service life time not only from the operator point of view but for all actors in the product system [63, 64]. If the analysis are carried out from the users perspective, the term “total costs of ownership” (TCO) is commonly used [65]. The method aims at minimizing total costs and maximizing the yields of a system and the related activities and processes arising over its life cycle [63]. According to [63], life cycle costs can be divided into the three stages “before utilization”, “during utilization,” and “after utilization” or three different costs types “Capital Expenditures” (CAPEX), “Operational Expenditures” (OPEX), “End Of Life Expenditures” (EOLEX) [66, 67]. Starting from material and energy flows modelled, CAPEX estimations (investment estimations) are typically carried out using empirical values on purchased costs for main equipment of a specific size together with scaling factors and percentages for direct costs, e.g., purchased equipment installation, and indirect costs, e.g., engineering and supervision [68]. Operational expenditures include, e.g., costs for raw materials, operating labor, utilities, maintenance and repairs, operating supplies, taxes and insurance [68]. Economic feasibility of technologies and processes can be assessed using economic indicators such as manufacturing costs of products, net present value or payback period of projects [68, 69]. Prospective LCC provides guidance to technology developers and policymakers and shows if and how a technology could be delivered into the market. To discount all costs to a common reference point, levelized costs are commonly used as an indicator [4, 70, 71]. Concerning prospective economic assessments, amongst others, assumptions on future prices for, e.g., raw and operating materials, process efficiencies, personal demand and/or process automation, as well as on investor expectations need to be made.

Social life cycle assessment

When compared with E-LCA, the level of development, application, and harmonization of S-LCA is still in a preliminary stage, because S-LCA is fragmented and a general theoretical concept for which empirical data are widely missing [38, 72, 73]. The S-LCA guidelines from UNEP [74] are based on six social and socio-economic impact categories (e.g., human rights, working conditions, health and safety, etc.) with 40 subcategories and five stakeholder groups (society, worker, consumer, value chain actors and local community) and on context-dependent inventory indicators. The UNEP guidelines [74] do not provide an agreed and standardized framework for social indicators that reflect and measure social impacts of technologies and processes along product life cycles and supply chains. Indicators need to be explicitly defined for different case studies, which makes results difficult to be compared. Nevertheless, the UNEP guidelines are the current landmark in the field. Indicators for S-LCA are often assessed based on qualitative information rather than quantitative, given the nature of the social aspects under assessment. Even more than for E-LCA and LCC, for S-LCA site-specific data need to be collected as social impacts are mainly due to the company’s conduct in a specific geographic location [72]. Lehmann et al. [75] emphasize the lack of data for S-LCA especially of processes still under development and conclude that S-LCA studies are only feasible if companies and institutions involved in the supply chain of the technologies are known. This is especially difficult for prospective assessments. As no standardized and manageable set of social indicators so far exists, the choice of social indicators in LCSA is challenging. Existing LCSA studies mainly justify the more or less arbitrary choice of social indicators with the specific characteristics of the case studies [76, 77]. In some cases, environmental indicators are used as indicators for social issues (e.g., human toxicity potential as an indicator for “Health and Safety”, global warming potential for “Intergenerational issues”) [4]. This approach serves the social pillar, but the set of indicators is ultimately not extended compared to an E-LCA. According to [6, 78, 79], S-LCA must become a more standardized method before LCSA can be harmonized.

Methods: development of the “ES2050 approach”

The appropriate selection and assessment of sustainability indicators for the evaluation of technologies as part of the complex energy system and its transition is a grand challenge since there are many alternatives and criteria that need to be analyzed and evaluated. The discussion on LCSA in general and the challenges of the S-LCA approach, in particular, show that there are good reasons to develop and test other approaches for prospective sustainability assessment at the technology level. This applies predominantly to the inclusion of the social dimension of sustainability for technology assessment. Additionally, there is a need for a generic approach, which is applicable for different technologies and which allows for the prospective and comprehensive technology assessment using consistent system boundaries, future framework conditions, indicators and data where possible and necessary. In this work, we propose and apply a generic and comprehensive sustainability assessment approach for prospective technology assessment. Our approach is addressing three criteria, which we believe are essential for the selection of sustainability indicators:

-

(1)

contextualization of sustainability and corresponding goals such as the SDGs or the rules of ICoS and the integration of all three dimensions of sustainable development (environment, economy, and society),

-

(2)

transparent selection of meaningful indicators based on the availability of methods to analyse the indicator and of data to measure the indicator,

-

(3)

limitation of selected indicators to a practicable and manageable number, easy to communicate and to apply.

Overview

The “ES2050 approach” consists of the three elements environmental, economic and social assessment (cf. Fig. 1). It includes life cycle based economic and environmental indicators together with social indicators. In this paper, social indicators are derived from the Integrative Concept of Sustainable Development (ICoS) and the corresponding Sustainability Indicator System (SIS) developed within the Helmholtz Alliance ENERGY-TRANS (see “Concepts for sustainable development” Section). The chosen methods and indicators are characterized in “Methods and indicators” Section. It should be noted that other indicator sets that take into account the above mentioned three criteria would also be possible. The “ES2050 approach” allows for the identification of sustainable energy technologies for the energy transition systematically and prospectively and can be applied to all kinds of energy technologies within a specific spatial and temporal context. This requires, first of all, accurate and reliable characterization of the respective technologies, including future assumptions on material and energy flows as well as efficiencies, supply chains and emission controls. Also, for the characterization of upstream and downstream processes, consistent databases are needed. Additionally, especially for the prospective assessment of different technologies, a consistent assessment framework, i.e. harmonized system boundaries as well as assumptions concerning economic, environmental and social input data, and a consistent background scenario concerning e.g. energy and mobility mix, is needed. The case studies as well as the assessment framework are described in Section "Characterization and modelling of three case studies".

Methods and indicators

In this section, methods and indicators, used for economic (“Economic assessment” Section), environmental (“Environmental assessment” Section), and social (“Social assessment” Section) assessment within the “ES2050 approach”, are characterized. While existing and established methods are proposed for economic and environmental assessment, indicators and methods for social assessment are conceptually elaborated.

Economic assessment

For economic assessment, the method LCC is chosen. As economic indicator, total costs (TC) are calculated and discounted to a common reference point i.e. levelized total costs (LTC) are estimated according to Eq. (1) (cf. [70]).

Starting point of cost estimations is a detailed investment estimation (CAPEX, i.e. expenses before commissioning). Based on mass and energy flows, main plant components are designed in their size and type and related investments are estimated using price tables and manufacturer´s data. Investment for direct and indirect secondary components are estimated as percentages from main components (cf. [68]) or secondary literature. Operating costs—here divided into consumables (raw materials, utilities, operating supplies) and other operating costs (labor, maintenance and repairs, taxes and insurance, overhead)—and revenues for by-products are estimated based on mass and energy flows together with price data for current and future years:

with LTC Levelized Total Costs (€/unit), I0 capital Expenditures in t = 0 less residual value in t = n (€), o annual operating costs (€/a); c: annual costs for consumables (€/a), r annual revenues (€/a), M annual produced amount (unit/a), n economic lifetime (a), t year of use period, i interest rate.

The same LCC approach can be used to analyze two different economic perspectives: (1) a business economic perspective where the interest rate is determined in such a way that a company makes profit. For this perspective, a range between 7 and 9% is proposed. If desired, the depreciation period, i.e., economic lifetime, may be shorter than the technical lifetime of the individual components. (2) A macroeconomic perspective where the interest rate is set between 1.5 and 3.5%. This range of interest rate only reflects the cost of raising capital on the financial market. A reference point for that are the interest rates on listed Federal securities for Germany [80]. For this perspective, the depreciation period corresponds to the technical lifetime of the components. The chosen ranges for the two perspectives result in bandwidths for LTC. In both cases, taxes are not considered. Prospective LCC-specific aspects include learning curves and progress rates for investment estimations, and price projections for raw materials and utilities (including, e.g., prices for crude oil, natural gas and electricity).

Environmental assessment

The environmental evaluation is carried out following the methodology for LCA according to the international standards ISO 14040 [54] and ISO 14044 [55]. For preparing the LCI, all upstream and downstream processes, i.e., raw materials and energy supply, provision of operating materials and infrastructure (including facility construction), waste and wastewater disposal (including facility deconstruction), as well as product use are included using the open source software openLCA v1.7 [59] together with datasets from the ecoinvent database v3.3 (cutoff-system model) [62]. Likewise, the reference processes are modelled using ecoinvent data sets. As far as possible, specific datasets for Germany (DE) are used. If no data sets are available for Germany, data sets for Switzerland (CH), Europe (RER) or worldwide data sets (GLO) are used. The modelling of electricity production is based on assumptions on gross power generation per energy carrier and technology shares per energy carrier as given in Annex 1. Within our study, we apply 13 environmental impact categories, methods and indicators at midpoint level, as recommended in the ILCD Handbook of the European Commission (cf. Table 1). According to [58], indicators and corresponding impact assessment methods are classified as I: recommended and satisfactory, II: recommended but in need of some improvements, III: recommended, but to be applied with caution, Interim: not recommended to use. Impact categories whose impact assessment methods are classified as “interim” or “III” are neglected in this study (i.e. ionizing radiation, ecosystems; land use; resource depletion, water). The corresponding impact assessment methods are used in our study within the software openLCA [59] and are provided by GreenDelta (LCIA methods v2, ILCD 2011, midpoint). Prospective E-LCA-specific aspects include assumptions on future emission controls of machinery along the value chain of the respective technology and on the fuel and technology mix of the future energy and mobility mix.

Social assessment

In contrast to the chosen standardised and established LCC and E-LCA methods selected to carry out economic and environmental assessment, we do not follow the S-LCA approach to assess the social aspects of energy technologies. The main reason for this methodological change is that critical questions remain to be solved regarding S-LCA concerning methods, framework, paradigms, and indicators and a lack of reliable data. Therefore we are using selected rules of the ICoS (cf. “Concepts for sustainable development” Section) together with the SIS, an indicator set based on these rules [30], to derive reasonable indicators for the social dimension of our approach. The SIS was developed within the Helmholtz Alliance ENERGY-TRANS to monitor the German energy transition. It consists of 45 indicators in total that align with the sustainability rules of ICoS [34]. As a start, we looked at indicators of the SIS aligned to two out of 15 substantial rules of ICoS related to social aspects of sustainability (cf. Annex 1). Our selection of indicators from the SIS aligned with these rules is driven by the preconditions “applicability for technology assessment”, “avoidance of overlapping with established E-LCA and LCC indicators”, and “feasibility and practicability of data availability, collection and analysis”. This results in three indicators for the assessment of the social dimension (see Table 2). Within the “ES2050 approach”, the chosen three indicators are further elaborated for the assessment of (energy) technologies. A short description of the developed indicators and corresponding methods for data gathering is given in the sub-sections below.

The elaborated social indicators, i.e., patent growth rate, domestic value added, and acceptance, address three different socio-technical areas, i.e., innovation (patents), public perception (societal acceptance), and public welfare (value added). It has to be noted, that changes in patent growth, societal acceptance, and domestic value added related to a specific technology have underlying long-term prerequisites, making them only partly suitable for the derivation of statements concerning the future using current data.

Number of domestic patents related to a specific technology

The suitability of patents as a proxy for technological innovation has been discussed considerably since the 1990s and even before [81]. Within the “ES2050 approach”, the number of patents, i.e. the respective growth rates for a defined period of time, are used as an indicator and country comparisons are carried out, i.e. national/international issues for patent applications for specific technologies, i.e. the role of Germany’s research and development (R&D) activities in the global context are analyzed. For patent analysis, the European Patent Office (EPO) database including the Open Patent Service (OPS) is used. The search queries are carried out for the time period 1995–2018 using Cooperative Patent Classification (CPC)-Codes and keywords. For patent search and data analysis, an adopted and freely available python-based patent database crawler [82] together with a MS Excel template is used [83]. The template selects the five most active patenting countries in the considered technology field and compares them to Germany. By analyzing the patent activity, i.e., the sum of patents of a technology in a country over a period of time, not only the R&D activities of one country are evaluated concerning its technological and commercial interest [84], but also the R&D activities of other countries in the same technology field are compared. The so-called technology potential is characterized by the growth rate of patents of a technology in % for a defined time period [85]. A high patent growth rate can indicate a high innovation potential due to increased research effort in the area [86]. More details on methods and indicators for patent analysis can be found in [83]. In contrast to proposed LCC and E-LCA methods, the patent analysis on hand represents an ex-post evaluation. Although the growth rate of patents is analysed based on data from the past, it can be assumed that the identified relations between countries and the comparative competitiveness at the level of technical innovations and trends identified are meaningful at least for some years in a way to make feasible statements on future developments. This assumption is based on the fact that changes in patent growth do not happen suddenly but slowly because patents result from continuous research work and their elaboration as well as registration take sufficient time [83].

Acceptance of a specific energy technology

The acceptance of energy technologies is becoming increasingly important for the development and application of energy technologies [7]. Despite this increasing social relevance, no holistic technology acceptance indicator exists until now, enabling a dynamic (technology-independent) and prospective acceptance measurement of a technology. Nevertheless, there is evidence that technologies that are accepted today will also be accepted in the future and vice versa. This is shown, for example, by the representative acceptance surveys on the expansion of renewable energies conducted by the Agency for Renewable Energies (Agentur für Erneuerbare Energien—AEE) for more than 10 years [87]. This is true unless there are new findings or events over time that lead to a change in the assessment of the benefit/burden ratio and the image in media/the public and thus the individual perception and acceptance of the technology. Thus, conclusions about the acceptance of the technology can already be drawn during technological development processes. This makes it possible in an agile manner to make flexible, user-oriented adjustments in terms of technology design to achieve higher acceptance due to better features and properties of a technology. Within our approach, a quantitative and qualitative survey is conducted focusing on (production) facilities or parts of the infrastructure of the ES2050 case studies about which citizens can express their views, expectations, and fears. Therewith, societal actors are directly involved for the assessment. To investigate public perception, an online survey is conducted based on the methodological background of [88] and [89]. After a short description of the respective technology, the participants are asked to express their concerns regarding this technology. Nine different types of concerns were put to choice, including an open field for further concerns. Furthermore, socio-demographic data is collected regarding gender, residence, income, activity, age, and education. The freely available online platform SoSci-Survey is used for conducting the survey. For the improvement of the questionnaire, a cognitive pre-test with five persons and a standard pre-test with ten persons was carried out. A more detailed description of the approach can be found in [90]. In the first survey, 211 valid responses were obtained in total by social networks to carry out first statistical tests. The second survey was distributed among 10,000 persons by the online platform of SoSci-Survey [91], of which 1,032 responded. Out of this entirety, approximately one third referred to each of the three technologies [90, 92].

Domestic value added related to a specific technology

The pre-condition for a future higher share of domestic value added-creation is the availability of infrastructure and natural, human and capital resources as well as technology acceptance. In the “ES2050 approach”, for the assessment of the fraction of domestic value added as a proxy for job creation, a streamlined approach is implemented, modelling solely direct effects of locally invested money [93]. This is based on the premise that local investment most likely also creates or secures local jobs. In contrast, components purchased globally are not considered to contribute to further job growth in the assessed country or region [93]. This indicator aims to give a qualitative indication regarding whether the energy technology might have a positive effect on job development compared to a conventional technology [94]. For the implementation of the indicator, the data basis of the economic assessment is used: Each cost component, i.e., investment as well as operation and maintenance costs, is further specified: e.g., raw material costs are sub-divided to costs for raw materials provision and costs for raw materials transport. Costs for raw materials transport are in turn specified to costs for machinery (e.g., trucks), operating materials (e.g., fuel), and personnel (e.g., truck driver). At a sufficient level of detail, costs are divided by percentages into three categories: domestic value added, potential domestic value added, non-domestic value added. Based on shares for cost components, shares for domestic value added, potential domestic value added, and non-domestic value added can be calculated for total costs. For prospective assessments, estimated future costs and estimated prospective shares can be used for the estimation of the prospective domestic value added as a percentage of total costs, and assumptions can be made with respect to the expected future domestic job creation potential of the respective technology.

Characterization and modelling of three case studies

Within the subsequent sections, the uniform system boundaries for E-LCA and LCC (“Consistent assessment framework” Section), the case study “Synthetic biofuels for mobility” (“Case study: synthetic biofuels for mobility” Section), the case study “Hydrogen from wind power for mobility” (“Case study: hydrogen from wind power for mobility” Section), and the case study “Batteries for stationary energy storage” (“Case study: batteries for stationary energy storage” Section) are characterized. The chosen case studies demonstrate the applicability of the developed “ES2050 approach” independent from the respective technology, as they cover, e.g., different types of renewable energies, conversion technologies, and levels of detail. While the analysis for stationary batteries is conducted on the material/elementary level, the analysis of hydrogen and biofuel production concentrate on the plant component level. Furthermore, the case study on biofuels includes decentral and central production networks, while for hydrogen production, different distribution networks are included. It has to be noted that the chosen case studies, i.e., technologies examined, are not regarded in competition with one another, but are assumed to complement one another in a future energy system.

Consistent assessment framework

The year 2020 is used as the base year for the assessment while the year 2050 is used for future projections of impacts. For the prospective sustainability assessment of energy technologies, data from the Helmholtz Alliance ENERGY-TRANS, scenario “Target”, is used as a consistent framework regarding the future energy and mobility mix (including technology shares) as well as for price projections [95], i.e., Germany is used as spatial reference. For the base year, consistent statistical data is taken into account for electricity production mix and economic input data (see Annex 1). If not stated differently, all input data for environmental assessment, i.e., emission data from technical processes, is based on the ecoinvent v3.3. database [62]. In addition, as far as possible and reasonable, for domestic value added estimations, percentage values are assumed consistently across case studies (see Annex 1). For patent analysis, the European Patent Office (EPO) database including the Open Patent Service (OPS) is used. Beyond that, future improvement potentials of the investigated technologies are considered, for example, improvement of energy and resource efficiencies, closed-loop flows (recycling), and management of waste flows using literature data, i.e., learning curves and progress rates where possible and applicable. Technology-specific (prospective) aspects are given in “Case study: synthetic biofuels for mobility”, “Case study: hydrogen from wind power for mobility”, “Case study: batteries for stationary energy storage” Sections.

Besides a consistent assessment framework, consistent system boundaries are defined for the different case studies. In Fig. 2, the system boundary for E-LCA and LCC of the three case studies is displayed including the provision of raw materials, the technology itself and the product use. For the estimation of, e.g.,. fuel production costs or the assessment of emissions related to fuel production excluding the usage in passenger cars, the system boundary is drawn after the production of the energy carriers (process step “Technology” in Fig. 2). For both, the provision of operating materials, infrastructure as well as processes for disposal, recycling and deconstruction are considered. As a result, we balance the resources and emissions along the whole value chain, i.e. the product life cycle.

As mentioned above, it is not possible to strictly follow a life cycle approach for the social indicators. While we follow the system boundaries of the LCC approach for the indicator “domestic value added”, we determine and consider only distinct parts of the (conversion) technologies for the indicator “patent growth rate” (see “Results of the case studies assessment with the “ES2050 approach” Section). For the indicator “acceptance”, we queried citizen concerns regarding the corresponding industrial production facilities of the new technologies or parts of the related infrastructure.

Case study: synthetic biofuels for mobility

Solid biomass stores energy and carbon dioxide naturally and is an important resource to compensate fluctuating availability of wind and solar power [96]. So-called second generation biofuels are regarded as a promising renewable alternative to obtain liquid fuels for the transport sector as they do not compete with food and fodder production and at the same time bear a high potential for greenhouse gas emission reductions [16, 97, 98]. This case study focuses on the industrial scale thermochemical conversion of lignocellulosic biomass, i.e., residual cereal straw and residual forest wood, into fuel, electricity, and heat (bioliq® process chain). The considered process chain includes the provision of raw materials, the decentralized biomass conversion (chipping, drying, pyrolysis), the transport of the intermediate product (biosyncrude) to the centralized conversion steps (gasification, gas treatment, fuel synthesis, CHP), the feeding of electricity into the grid and the use of the gasoline in a passenger car (cf. Figure 3). All process steps of Fig. 3 are assumed to be located in Germany. It is assumed that straw is available on the fields in access, i.e., process steps for straw gathering and transport are considered, while process steps for cereal cultivation and harvest are neglected. Straw is assumed to be collected around 11 pyrolysis plants (100 MW each) within a radius of 30 km and to be transported to the plants via tractor and trailer. The biosyncrude is assumed to be transported over a distance of 250 km by rail to the central production site (1000 MW gasifier). Fuel and electricity are obtained as products, while heat is entirely used internally. For fuel use, a large passenger car is assumed for the base case [99, 100]. As reference processes, the production of conventional gasoline and its use in a passenger car and electricity production via German electricity production mix are considered. More detailed case study characteristics, including process parameters as well as mass and energy flows of the biomass conversion steps are summarized in [99] and [100]. For more information on the bioliq process developed at KIT cf. [98] and on residual straw potentials and transport cf. [101, 102], and [103]. For prospective assessment, higher efficiencies for CHP process for electricity generation are assumed (53% in 2020, 67% in 2050). Based on [104], efficiency enhancements of agricultural machinery using a progress rate of 0.94 based on [104] are assumed for 2050, leading to lower emissions for biomass provision (emissions are reduced by 6% each time the cumulative production is doubled). For rail transport it is assumed that all diesel engines are equipped with particle filters in 2050. For prospective economic assessment of synthetic biofuel production, higher wholesale electricity prices and rising natural gas prices according to [95] and a progress rate for investment estimations of 0.95 based on [105] are assumed. Costs for biomass provision and slurry transport are based on own estimations based on [106] and on [107]. In this paper, no progress rates for biomass provision and slurry transport costs are assumed. Prospective manufacturing costs of fossil gasoline are calculated as average value of product acquisition costs of fossil gasoline of the last ten years according to [108]. When the use phase is included, i.e. for mobility cost estimations, prospective costs for fuel transport, storage and service stations are calculated as average value of contribution margin of fossil gasoline of the last ten years [108]. Car acquisition and operating costs are based on ADAC [109] and are assumed equal for 2020 and 2050 in this paper.

Case study “Synthetic biofuels for mobility”, icons from [110]

Case study: hydrogen from wind power for mobility

Hydrogen from wind power can be used to help electrifying different sectors mainly to defossilize them, e.g. steel production [111]. Furthermore, hydrogen production can be used for balancing out electricity generation from variable renewable energy sources [112]. Hydrogen for mobility applications and other sectors has a chance to be climate friendly only when produced from renewable energy sources [113]. In addition to the potential reduction of greenhouse gases, fuel cell electric vehicles (FCEV) emit only water at the point of use and therefore help fighting high emission levels in cities, e.g. particulate matter or nitrogen oxides. Within ES2050, a case study for Germany is discussed with wind power as an appropriate renewable energy source [93]. The generated electricity is used in an alkaline water electrolyzer [114]. Afterwards, it is stored and transported over 400 km to the hydrogen refueling stations to be dispensed to FCEVs (Fig. 4). The FCEV is comparable to a Toyota Mirai and has a power of 100 kW. For the future size of the FCEV, i.e. mass of the glider, powertrain etc., the current Mirai is downscaled from the current 114 kW to 100 kW. The future hydrogen consumption of the FCEV is taken from literature [115]. The source for LCA modelling the fuel cell [116] includes not only a model for a current model, but also two models for future fuel cells. The optimistic model for the future fuel cell was chosen for 2050 here. Modelling of the FCEV is mainly based on [117]. The increase of energy density for the included battery is based on expert elicitation [118]. For the costs of the FCEV it was assumed, based on literature [119], that FCEVs will reach the same level of costs as conventional internal combustion engine vehicles.

Case study “Hydrogen from wind power for mobility”, icons from [110]

A passenger car is chosen as a use case to investigate green hydrogen, although the supplied hydrogen could also be used in public buses or light duty vehicles. For transport and distribution of hydrogen, different technologies are available. Currently, the most common transport methods are gaseous hydrogen in high-pressure tanks and liquid hydrogen in cryogenic tanks by truck. Alternatively, hydrogen storage and transport in liquid organic hydrogen carriers (LOHCs) by truck is considered. The fourth alternative analyzed is the construction of a new hydrogen pipeline network in Germany. To be not susceptible to wind power fluctuations, the hydrogen needs to be stored, if necessary, for months. Therefore, for gaseous hydrogen seasonal storage in salt caverns is taken into account. Liquid hydrogen, as well as hydrogen in LOHCs, can be stored in appropriate tanks. The most important technical parameters are summarized in [93]. To consider the prospectivity of the hydrogen supply chains, the efficiency of the hydrogen production by electrolysis is increased based on expert elicitation [120] together with the life time of the electrolyzer stacks. The future cost for alkaline electrolyzers are taken from literature [121], discussing current and future costs and upscaling hydrogen production sites. Future costs for electricity including the electricity from wind power are taken from the already mentioned background scenario ENERGY-TRANS [95]. This scenario was also used to perform the economies of scale for the hydrogen refueling stations. Based on the future FCEV mobility, the number of hydrogen refueling stations was calculated. In addition, it was assumed that the number of hydrogen refueling stations on a global level rises accordingly. As hydrogen refueling stations are traded on the global market, these numbers were used for deriving future investment costs. Regarding hydrogen transport, higher efficiencies for liquefaction and costs were assumed based on literature [122]. For the use of the LOHC technology upscaling was applied based on literature [123] as well as for the compression of hydrogen for transport in pipelines and truck trailers [121].

Case study: batteries for stationary energy storage

For efficient and effective use of installed renewable energy capacities and to cope with the fluctuating solar and wind power production, battery storage technologies are considered. They provide valuable flexibility to facilitate the system integration of renewable energies by, e.g., temporarily avoiding grid expansion investments or congestions in lower voltage level distribution grids. Stationary batteries can also be used for ancillary services, e.g., load levelling, voltage stabilization, and system backup services (see Fig, 5). There are several application fields for grid connected batteries where criteria are the same, but priorities can be different depending on the business case. The application field frequency and voltage regulation is an example where only a short storage duration at high power output is required with high cycle life times. In contrast, load leveling requires battery storage systems with longer storage duration where fewer cycles might be needed. However, batteries have to fulfill simultaneously multiple battery performance requirements, such as high power, high energy, long life, low cost, excellent safety, and minimal environmental impacts. Nowadays, no battery can meet all of these goals. Making the right decision on a proper battery system for a particular application is often a compromise. The analyses in this paper focus on different Lithium Ion batteries [124, 125]. These technologies are then contrasted to other technologies, such as the all-Vandium-redox Flow battery [126], NaNiCl, and the Valve regulated lead acid battery [124, 127]. Detailed information for several business cases and corresponding details on the LCI and techno-economic parameters can be found in the corresponding literature sources [124,125,126,127]. Here, only an overview of the results for Lithium Ion Batteries (LIB), with the highest market share for stationary applications according to [128] (lithium–iron–phosphate (LFP) and nickel–cobalt–manganese-oxide (NMC 811)) is provided. All process steps are assumed to be located in Germany. All prospective considerations for both battery types are provided in the following. Here, no process improvements nor recycling are considered. In addition, a graphite anode is considered for modelling, which might change completely in 2050, when graphite might potentially be exchanged with Li or Si based anodes. Furthermore, NMC 811 will probably not play a role in 2050, as already, e.g., NMC 9 0.6 0.3 is under development [129]. It is hardly possible to estimate how the LIB based systems will look like in 2050 regarding their design (e.g., new cylindrical or pouch cell types with new current collector design etc.), used electrode and electrolyte materials. The electrode material will especially change due to the criticality of used materials such as Nickel, Lithium, and in particular Cobalt [130]. The energy density of LIBs is highly dependent on several factors as, e.g., the used electrode materials has a crucial impact on all E-LCA impact categories. Here, energy densities for 2020 are considered (0.13 Wh/kg for LFP and 0.16 Wh/kg for NMC 811), while for 2050, theoretical values for graphite are used (0.28 and 0.34 Wh/kg for LFP and NMC 811) [131]. However, using Li-metal with a suitable electrolyte could, e.g., lead potentially to energy densities of about 400 Wh/kg for LFP and over 500 Wh/kg for NMC. A detailed overview of the LCI can be found in [132] and [133]. The battery costs are based on a bottom-up model (starting from the specific chemistry and the required raw materials), where scale effects resulting from cell production are considered in combination with higher cell energy densities Fig. 5. The considered battery cost is highly dependent on the manufacturing capacity of the viewed production site, location and chemistry and its properties (in particular energy density). Here, a battery cell manufacturing site located in Germany with a throughput of 4 GWh/a for 2020 and 35 GWh/a in 2050 is considered [134].

Case study “Batteries for stationary energy storage”, icons from [110]

Results of the case studies assessment with the “ES2050 approach”

The following sub-sections give an overview of the application of the “ES2050 approach” for the three different case studies (for the descriptions of the case studies see Section "Characterization and modelling of three case studies". This paper focuses on the presentation of the “ES2050 approach” and its applicability to different energy technologies using consistent framework conditions (see “Methods: development of the “ES2050 approach” Section) rather than on the comprehensive sustainability assessment of the named technologies. Therefore, assessment results are given in the following sub-sections exemplarily for the three case studies: Environmental assessment of the case study “Synthetic biofuels for mobility”, economic assessment of the case study “Hydrogen from wind power for mobility”, patent growth rate for the case study “Batteries for stationary energy storage”, public acceptance for the case study “Hydrogen from wind power for mobility” , domestic value added for the case study “Synthetic biofuels for mobility”. The results for economic and environmental assessment as well as for patent growth rate of the respective other two case studies can be found in Annex 2.

Environmental assessment of the case study “synthetic biofuels for mobility”

As an example for the environmental assessment, the results for the case study “Synthetic biofuels for mobility” are presented (cf. “Case study: synthetic biofuels for mobility” Section). The environmental impacts of the production and use of synthetic gasoline from straw (“Straw”) are compared to the environmental impacts of the production and use of fossil gasoline as a reference (“Ref.”). As during biogenic synthetic fuel production, electricity is generated in excess, environmental impacts from the same amount of electricity generation (German electricity production mix 2020 and 2050) are included in the reference process results (“Ref.”). Modelling of production and use of fossil gasoline refers to the ecoinvent data sets “market for petrol, low-sulfur, CH” and “transport, passenger car, large size, petrol, EURO 4, RER”. Ecoinvent datasets for the modelling of synthetic biofuel production and the German electricity production mix are given in [99] and [100]. Figure 6 shows the results for 13 environmental impact categories according to ILCD (cf. “Economic assessment” Section) for the base year 2020. Synthetic biofuel production from straw shows significantly lower impacts (43–77%) for four categories: Climate Change (CC), Eutrophication-Freshwater (Eutr-fw), Ionizing Radiation–human health (IR-hh) and Ozone Depletion (OD). For two more categories, there are also lower impacts for biogenic gasoline, but the differences are smaller: Acidification (Acid) and Particulate matter/Respiratory inorganics (PM) (7–16% lower impacts, respectively). For four categories the emission equivalents are higher for biogenic gasoline (“Straw”): Eutrophication–marine (Eutr-mar), Eutrophication–terrestrial (Eutr-ter), Human Toxicity–non-cancer effects (HT-nc) and Resource Depletion–mineral, Fossil and Renewable (RD). For the remaining three categories the impacts are rather equal: Ecotoxicity–freshwater (Ecotox-fw), Human Toxicity–cancer effects (HT-c), and Photochemical Ozone Formation (POF).

Comparison of environmental impacts of the production and use of synthetic gasoline from straw (“Straw”) to fossil gasoline (“Ref.”) for the base year 2020; Acid Acidification, CC Climate Change, Ecotox-fw Ecotoxicity—freshwater, Eutr-fw Eutrophication—freshwater, Eutr-ter Eutrophication—terrestrial, HT-c Human Toxicity—cancer effects, HT-nc Human Toxicity—non-cancer effects, IR-hh Ionizing Radiation—human health, OD Ozone Depletion, PM Particulate Matter/Respiratory Inorganics, POF Photochemical Ozone Formation, RD Resource Depletion, Mineral, Fossil and Renewable

Figure 7 shows the results for six out of 13 impact categories for the base year 2020 and the future year 2050. The chosen categories show the most significant differences for the base year 2020 (see Fig. 6): Climate Change (CC), Eutrophication—freshwater (Eutr-fw), Eutrophication—terrestrial (Eutr-ter), Human Toxicity—non-cancer effects (HT-nc), Ionizing Radiation—human health (IR-hh), Ozone Depletion (OD). In Fig. 7, for each impact category and year, the impacts are specified for different sub-processes along the value chain, e.g. “Production of Gasoline conventional” and “Use of Gasoline conventional” (“Ref.), “Biomass Provision”, “Pyrolysis”, “Gasification” (“Straw”). It has to be noted that transport of residual straw to the decentralized pyrolysis plants is included in “Biomass Provision” and transport of the biosyncrude from decentralized pyrolysis plants to the central production plant is included in “Gasification”. Emission reductions for the year 2050 arise for biogenic gasoline from assumed emission reductions of agricultural machinery through efficiency enhancements, particle filters for diesel engines (transport of biosyncrude), and increased efficiencies for CHP [99, 100]. Concerning the reference process, assumptions on Germany´s future electricity production mix are causing significantly reduced emission equivalents in the categories CC, Eutr-fw, and IR-hh (most notably through renewable energies replacing nuclear power plants and coal-fired power plants) [62].

Comparison of environmental impacts of the production and use of synthetic gasoline from straw (“Straw”) to fossil gasoline (“Ref.”) for 2020 and 2050; CC Climate Change, Eutr-fw Eutrophication—freshwater, Eutr-ter Eutrophication—terrestrial, HT-nc Human Toxicity—non-cancer effects, IR-hh Ionizing Radiation—human health, OD Ozone Depletion

For biogenic synthetic fuel, most impacts arise from fuel use in a passenger car (production and use) and biomass provision (production and use of agricultural machinery). For Eutrophication terrestrial (Eutr-ter) the contribution of emissions from CHP is comparably high (due to nitrogen oxides emissions).

The advantages of biogenic synthetic fuel over fossil gasoline are most apparent for the impact categories Climate Change (CC) and Ionizing radiation—human health (IR- hh) also for the year 2050. However, reference process emissions are declining due to renewable energies replacing nuclear power plants (especially category IR-hh) and coal-fired power plants (especially category CC) in 2050. For IR-hh, impacts are comparably high for the production of fossil gasoline. This goes back to petroleum production (first of all, carbon-14 emissions during treatment of low-level radioactive waste). For the category CC the advantages of biogenic gasoline mainly arise from the absence of fossil carbon dioxide emissions during fuel use (fuel combustion in passenger car). For all other impact categories, impacts from fuel use in passenger car are assumed to be the same for synthetic gasoline and conventional gasoline. For Eutr-ter, environmental impacts are higher for biogenic gasoline compared to fossil gasoline for 2020 and 2050. This goes mainly back to comparably high nitrogen oxides emissions in the course of straw provision from agricultural machinery. Considerable emission reductions for biogenic synthetic fuels could be achieved via emission reductions in the use phase (foremost passenger car production) as well as production and use of agricultural machinery (straw provision).

Economic assessment of the case study “hydrogen from wind power for mobility”

As an example for the economic assessment, the case study about hydrogen mobility is shown. As part, the costs for the supply of hydrogen are analyzed. Therefore, the four hydrogen distribution options described in "Case study: hydrogen from wind power for mobility" Section are compared.

For basic commodities a common data source is chosen (see Annex 1), e.g., electricity generation cost are based on data from the project ENERGY-TRANS [95]. The basis year for the assessments is 2020, for the technology costs and for the money value. Therefore, all costs are displayed in €2020.

Figure8 displays the hydrogen supply costs for 2020 and 2050 with a discount rate of 2.5%. For all hydrogen supply options, a significant drop in costs can be observed, particularly for the hydrogen production with alkaline water electrolysis and for the hydrogen refueling stations (dispension in Fig. 8). The investment costs in 2050 will be lower because the number of systems installed increases and larger capacities are installed (economies of scale). Furthermore, lower costs for electricity generation by wind power can be expected. In the future, the lowest supply costs are realized by the transport by pipeline. However, the costs for hydrogen transport in high-pressure trailers for gaseous hydrogen are only slightly higher and a more detailed assessment is necessary to define the preferable solution. The efforts of liquefying hydrogen or using a LOHC also lead in the future to higher costs than transporting smaller amounts of hydrogen under high-pressure. [93]

Regarding the cost categories for hydrogen mobility compared with an internal combustion engine vehicle (ICEV) fuelled with gasoline (Fig. 9) the costs for fuel, i.e., hydrogen or gasoline, have the lowest share. With 0.11 €/km capital costs make up the largest portion of the costs for the gasoline vehicle in 2020 and 2050. For the FCEV the capital costs are in the same order of magnitude due to assumptions made. Fuel costs for hydrogen will lower significantly from 2020 to 2050 and will be slightly higher than today’s cost for gasoline.

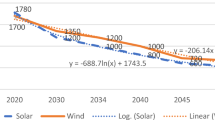

Patent analysis on the example of case study “batteries for stationary energy storage”

From the three different social indicators, here, the results for the indicator “patent growth rate” related to the ICoS sustainability rule “Sustainable development of man-made, human and knowledge capital “ (cf. Table 2) are shown for the use case "Batteries for stationary energy storage". The patent search is carried out for the time period 1995—2018 using CPC-codes and keywords and a customized patent crawler combined with a MS Excel template [83]. Used CPC-codes, keywords and search strings applied can be found in Baumann et al. [83]. In total, 5.822 patents were found via the EPO-database based on the defined search string used for this assessment (see Annex 2). In contrast to the LCC and E-LCA indicators shown before, it is impossible to predict the future development of patents based on this data, which is analysed in detail in [83]. The MS excel template used [83], analyses the most active countries in the respective technology field and contrasts them to Germany. The y-axis in Fig. 10 shows the total patents per year published with the corresponding positive or negative patent growth rate in %. Additionally, the share of the most active countries over time is also provided in the same figure. It can be seen that Japan (JP) has the highest patenting activity so far, followed by China (CN), which is also very active in the area. The United States (US) and Korea (KR) are also rather active in the area with a high amount of patents. Germany, in comparison, has a lower degree of patents in recent years. The analyses of patent growth make it possible to provide a picture of the innovation potential of a technology by depicting the patent growth resulting from positive or negative patent application growth rates. This allows deriving, at least to a certain degree, how strong the technology under assessment contributes to the ICoS rule “Sustainable development of man-made, human and knowledge capital” over the years. The patent growth is based on the assumption that the present rapid growth of patent applications indicates increasing R&D expenditures and a corresponding high future growth potential of the technology. The opposite comes true in the case of low or decreasing patent growth, which might indicate that the technology is entering a maturity phase [83, 84, 86].

Yearly patent growth of Li-Ion batteries. The y-axis shows patent applications per country and the percentages refer to the overall patent growth per year (based on [83])

Lithium-Ion batteries can be considered to enter into a maturity phase where patent growth decreases slightly at least until 2018. More information about the patent analysis for the three case studies can be found in [83]. It is worth mentioning that using different search strings and databases can lead to different findings related to patents in the field of batteries, as presented in [135].

Public acceptance on the example of case study “hydrogen from wind power for mobility”

The case study “Hydrogen from wind power for mobility” consists of several different technologies, e.g. wind turbines, electrolyzers, FCEV etc. Thus, every technology might be of interest for the discussion of public acceptance. After discussion with technology experts and citizens, it was identified that in this process chain, hydrogen refueling stations are one of the most controversial technologies in the process chain. Not only the users of the FCEV need to accept them, but also the surrounding local community. Furthermore, the area around hydrogen refueling stations is more densely populated than around centralized electrolyzers for hydrogen production. For this reason, here, exemplary results of local acceptance for hydrogen refueling stations are discussed. They refer to the statistical pretests (see “Social assessment” Section) based on a survey with 211 answers [90]. From these people, 70 were answering the questions regarding hydrogen refueling stations. The others were randomly assigned to the other two case studies.

Participants were first introduced to the technology, which they were to evaluate. The questionnaire continued with a multiple-choice list of seven aspects and a blank text box for further concerns. Furthermore, socio-demographic aspects were asked from the participants. The evaluation of the socio-demographic data of all 211 participants showed that they were predominantly male, aged between 25 and 29 years, had a university degree, were in employment with a higher income and lived in rather rural areas. The 70 participants for the hydrogen refueling stations questionnaire, however, were predominantly students.

From the seven presented concerns, the participants regard Explosion Hazard as the most pressing (Fig. 11) followed by Fire Hazard as the second most important concern.

Citizen concerns about hydrogen refuelling stations, based on [90]

Other concerns of the people did not refer to hydrogen refueling stations itself but to refueling stations in general. This is not only visible in the number of answers for noise pollution and negative effects on land- and cityscape. In fact, a FCEV produces with its fuel cell and electric motor less noise than a conventional vehicle with an internal combustion engine. The submitted comments dealt with the competition to other technologies, e.g. less funding for charging points for battery electric vehicles or the competition for land between food and energy crops. The participants were also asked to state the level of knowledge they had about the technologies. For the hydrogen refueling stations, 64% stated that they had known nothing or only very little about it before the study. This was also reflected in some of the answers. Hydrogen is an odorless gas, which makes odor pollution very unlikely. Additionally, FCEVs’ only emission is water so that from them and from a hydrogen refueling station, very little odor pollution can be expected.

Domestic value added on the example of case study “synthetic biofuels for mobility”

In this section, exemplary results for domestic value added estimation of synthetic biofuel production from straw are shown and compared to fossil gasoline production. As stated in “Social assessment” Section, domestic value added estimation is based on results of the economic assessment (see Annex 2): Estimations of manufacturing costs of synthetic biofuel production result in about 120 €cent/l for 2050 (interest rate of 2.5%, depreciation period 20 a). For fossil gasoline production (Ref.), manufacturing costs of about 46 €cent/l are calculated for 2050 as average value of gasoline product acquisition costs of the years 2011 to 2020 according to [108]. For domestic value added estimation of synthetic biofuel from straw, all cost components along the value chain, i.e. biomass provision, pyrolysis, gasification, and fuel synthesis, are sub-divided into capital (investment), consumable, and operating costs and percentages of domestic value added are estimated for each cost item. Percentages for domestic value added of different cost items across case studies are given in Annex 1. Furthermore, for synthetic biofuel production, for catalyst costs for fuel synthesis, 100% non-domestic value added are assumed, and for utility costs, 100% domestic value added. For costs for maintenance and repairs, 80% domestic and 20% potentially domestic value added are assumed. Domestic value added estimations of bioliq plant construction (42% domestic value added, 39% potentially domestic value added, 18% non-domestic value added) are based on in total about 100 single technical components and experiences from the bioliq pilot plant construction at KIT [98]. Furthermore, for costs for purchased equipment installation, measurement and control systems, piping and electrics, 50% domestic value added are assumed. For costs for buildings, site development, engineering services, permits and project management, 100% domestic value added are assumed. For manufacturing costs of fossil gasoline, a rather rough estimate is made: All costs other than crude oil are assigned to domestic value added. Crude oil costs of 40.2 €cent/l are calculated for 2050 based on [136] as average value of the years 2011–2020 and are assumed to be fully non-domestic. As a result, domestic value added for synthetic biofuel from straw (Straw) accounts for 66% compared to 13% for fossil gasoline (Ref.) in 2050 (see Fig. 12). Determining factors for this difference are assumptions on raw materials supply for the respective production processes: crude oil is assumed to be fully imported (non-domestic value added) while residual straw for synthetic biofuel production is assumed to be provided fully domestically (cf. [100]). For the time being, no differentiation of shares for domestic, potentially domestic and non-domestic value added of cost items related to the reference year has been made. Therefore, the total share of domestic value added of synthetic biofuel production differs only slightly for 2020 (67% domestic value added), assuming the same interest rate and depreciation time for cost estimations (2.5% and 20 a). Variation of interest rate and depreciation time (8% and 10 a respectively) results in a reduced total share of domestic value added of 61% for synthetic biofuel production from straw in 2050 (see Fig. 12).

Discussion of the “ES2050 approach”

In this section, we reflect on our experiences by applying the “ES2050 approach” to the different case studies to conclude on weaknesses and needs for further development of the assessment concept and chosen indicators, respectively. First, the assessment results are mirroring the chosen system boundaries, spatial and temporal context, input data, allocation methods, reference systems, and other assumptions. Regarding the spatial context, our analyses refer to Germany. However, no specific location analysis was carried out with respect to the implementation of technologies and/or infrastructures, and use of products. Consequently, results may be biased towards determining development strategies or hiding potential indirect economic, environmental, and social effects caused at a regional/local scale where the respective technologies and infrastructures are built, and products will be used.

The prospective environmental and economic assessment based on E-LCA and LCC focuses on aspects that can be analyzed using aggregated quantitative data on inputs (e.g., resources) and outputs (e.g., emissions) from process modeling and databases together with progress rates and future price estimations. To evaluate the respective processes, the modelling results are related to a functional unit and compared with selected conventional references. In the given examples for E-LCA and LCC (“Environmental assessment of the case study “Synthetic biofuels for mobility”” and “Economic assessment of the case study “Hydrogen from wind power for mobility”” Sections) the production and use of fossil gasoline (see Figs. 6, 7, 9) are used as a reference.