Abstract

In enhanced geothermal systems (EGS), the natural permeability of deep rocks is normally not high enough and needs to be increased. Permeability increase can be achieved through various stimulation methods, such as hydraulic, chemical, and thermal stimulation. Among these, hydraulic stimulation is the most commonly used technique to increase both reservoir permeability and the specific area for heat exchange. A comprehensive understanding of the underlying processes towards an optimization of hydraulic stimulation performance while minimizing the potential of unwanted induced seismicity is a critical prerequisite for a successful development of any EGS site. In this paper, we review the hydraulic stimulation strategies that have been developed and implemented for EGS. We begin with a description of the underlying mechanisms through which the permeability and heat exchange area increases are achieved. We then discuss the mechanisms of fluid injection-induced seismicity during and after a hydraulic stimulation operation. After that, alternative hydraulic stimulation strategies, namely conventional hydraulic stimulation, multi-stage fracturing, and cyclic soft stimulation, are reviewed based on current research in theoretical studies as well as, laboratory, and in-situ field experiments. Finally, some representative EGS projects are reviewed, focusing on fluid injection strategies, seismic responses, and reservoir permeability enhancement performance. The review shows the importance and need of (a) a comprehensive geological characterization of the natural fracture system including the nearby fault zones as well as the in-situ stress conditions, prior to the development of the site, (b) a proper design of the well arrangement, such as the positioning of the injection and production wells, and (c) the selection of an appropriate fluid injection strategy for the system at hand.

Article highlights

-

A comprehensive geological characterization of the natural fracture system and nearby fault zones is critical before the development of an EGS project.

-

Proper design of the arrangement of the injection and production wells as well as the fluid injection strategy are essential elements for successfully developing an EGS project.

-

Further research in coupled thermo-hydro-mechanical-chemical processes during and after a fluid injection operation in EGS is needed, in particular for better understanding of the processes related to induced seismicity.

Similar content being viewed by others

1 Introduction

Geothermal energy is the thermal energy stored in the deep sub-surface of the earth. It is a potentially very important energy source because of its vast reserves and wide availability (Gong et al. 2020; Pan et al. 2019). One of the main obstacles that has been limiting the development of EGS is the low permeability of the deep rocks at the depths where most of the geothermal energy is stored. Thus, stimulation operations are commonly needed to enhance the reservoir permeability and to increase the specific area for heat exchange (Lu 2018; Olasolo et al. 2016). A system of developing geothermal energy through such stimulation operations is called an enhanced geothermal system (EGS).

Basic reservoir stimulation methods include hydraulic stimulation, chemical stimulation, and thermal stimulation. Of these, hydraulic stimulation is the most commonly used one in both conventional oil and gas industry and in unconventional gas or shale gas development. In this approach, a large amount of fluid is injected into the target reservoir from a packered-off section of a borehole, and the resulting high pressure cracks the rock creating new tensile fractures and, if a number of natural fractures are present, it may also cause opening and/or shear of these natural fractures (Ghassemi 2012; McClure and Horne 2014a, b; Elsworth et al. 2016; Lei et al. 2021). Increased permeability is a result from this tensile fracture aperture opening and the shear dilation of the existing fractures. Furthermore, fracture opening and shearing can also create fractures that connect to natural fractures further away, thereby significantly increasing the overall connectivity and permeability of the reservoir. At the same time, fracture surface areas are also increased, which is important for the heat exchange area and heat extraction from the surrounding rock. Chemical stimulation involves the injection of an acidic fluid into the formation while using a fluid pressure lower than the reservoir breakdown pressure. Permeability increase is then be realized through mineral dissolution, transport, and precipitation processes. This method has been commonly used in the oil and gas industry to enhance oil recovery (Economides and Nolte 1989; Portier et al. 2009; Smith and Hendrickson 1965), it can also be used in EGS, such as in Groß Schönebeck (Henninges et al. 2012), Desert Peak (Davatzes et al. 2012), and Soultz (Portier et al. 2009). For thermal stimulation, cold water is normally injected into the reservoir for a specific time, typically several weeks. Due to the large temperature difference between the injected low-temperature water and the high-temperature reservoir rock, the induced thermal stress causes deformation of in situ natural fractures and initiates new fractures (Liu et al. 2020). Among these three basic stimulation methods, hydraulic stimulation is the most commonly used in EGS to increase reservoir permeability and heat exchange extraction volume. Therefore, hydraulic stimulation is the focus of the present work.

In hydraulic stimulation, an optimal generation of a well-connected, high permeability fracture network with large heat exchange area towards the surrounding rock is critical for an optimal performance. For the design of such a system, a comprehensive understanding of the underlying mechanisms and the role of various factors, such as the existing natural fracture network, is essential. Extensive work has been carried out in this respect, on the related processes and effects (Bowker 2007; Brown 1989; Evans et al. 2005; Fisher et al. 2004; Gale et al. 2007; Ito 2003; Ito and Hayashi 2003; King 2010; Ledésert et al. 2010; Murphy and Fehler 1986; McClure and Horne 2014a, b; Pine and Batchelor 1984; Yin et al. 2019). However, work still remains to be done, especially concerning the role of the natural fracture network and fault zones with varying characteristics.

A specific challenge in hydraulic stimulation is the risk of injection-induced seismicity, both during and after the water injection (Ellsworth 2013; Elsworth et al. 2016). Even though the vast majority of the seismic events observed during the EGS developments have been of magnitudes less than 3.0, some cases of damaging earthquakes have also been reported (Kim et al. 2018a; Knoblauch and Trutnevyte 2018). For instance, a series of earthquakes occurred at the Basel geothermal site in Switzerland from December 2006 and March 2007, with the maximum magnitude of Mw 3.4 (Evans et al. 2012), which led to the suspension of the Basel EGS project. More recently, an earthquake in the Pohang geothermal field in South Korea in November 2017, with a magnitude of Mw 5.5, also directly resulted in the suspension of the Pohang geothermal project (Grigoli et al. 2018). To mitigate seismic risks associated with EGS development, significant research effort has lately been invested into understanding the mechanisms related to fluid injection-induced seismicity (Atkinson et al. 2020; Schultz et al. 2020; Lei et al. 2021; Lei and Tsang 2022).

None of these reviews aims, however, to give a complete overview of all aspects of a hydraulic stimulation operation. In the present paper, we will present a review of hydraulic stimulation strategies for permeability and heat exchange area enhancement while limiting induced seismicity, with an emphasis on insight gained and lessons learned from previous projects. We will first briefly present the mechanisms behind permeability enhancement, heat exchange area increase, and fluid injection-induced seismicity during and after hydraulic stimulation. Next, some typical hydraulic stimulation methods are described, namely conventional hydraulic stimulation, multi-stage fracturing, and cyclic soft stimulations (CSS), based on findings from both theoretical studies and from laboratory and in-situ experiments. This is followed by summaries of some representative in-situ hydraulic stimulation in EGS projects with a focus on their fluid injection procedures, observed seismic response, and reservoir permeability enhancement performance. Lessons learned in each case are discussed, and some overall conclusions are then presented.

2 The mechanism of hydraulic stimulation and fluid injection-induced seismicity

In this section, we first present an overview of the basic mechanism of permeability enhancement during a hydraulic fracturing operation. Next, we discuss the mechanism of the heat exchange area enhancement. Finally, we review some recent studies on the mechanisms of fluid injection-induced seismicity.

2.1 The mechanism of permeability enhancement in EGS

The target reservoirs for EGS are most likely located at depths of several kilometers, where the subsurface is hot enough for heat extraction. Due to the great depths and the associated high in-situ stresses, the formations usually have very low permeability, which would need to be increased. Hydraulic stimulation is one of the most important methods used to increase the reservoir permeability as well as the heat exchange area of the reservoir (Tester et al. 2006; Kennedy et al. 2010; Meyer and Bazan 2011; Pan et al. 2019; Yin et al. 2020, 2021a).

Hydraulic stimulation is a relatively complicated coupled process involving fluid flow, new fracture creation, tensile and shear deformation of newly created and pre-existing natural fractures, and fluid leak-off from fractures to rock matrix at multiple space and time scales.The initial concept of hydraulic stimulation assumed that a single, planar tensile fracture was formed in the direction of the maximum stress, which appears to be what happens in oil and gas reservoirs (Brown et al. 2012), and this was named hydraulic fracturing. However, Willis-Richards et al. (1996) found that shearing slip of pre-existing natural fractures with shear dilation effect was actually the dominant stimulation mechanism, which was then named shear stimulation, hydraulic shearing, or hydroshearing (Cladouhos et al. 2011). Various numerical models have been developed to simulate the shear slip of pre-existing natural fractures (Bruel 2007; Dempsey et al. 2015; Kohl and Mégel 2007; McClure and Horne 2011, 2013a; Rachez and Gentier 2010; Riahi and Damjanac 2013; Tao 2010; Zhou and Ghassemi 2011). As for the dominant mechanism of hydraulic stimulation in EGS, early in-situ experiments at Fenton Hill, USA, found that some natural fractures were both opened and sheared during the hydraulic stimulation through an analysis of micro-seismicity data (Barton et al. 1988; Brown 1989; Brown et al. 2012; Brown and Duchane 1999; Fehler 1989; Moore and Pearson 1989; Norbeck et al. 2018; Pearson 1981; Pine and Batchelor 1984). The experience from the Soultz EGS project also indicated that both the newly created hydraulic fractures and the shear slip of pre-existing natural fractures played a vital role in the permeability enhancement (Grecksch et al. 2003; Jung and Weidler 2000; McClure 2012; McClure and Horne 2013b, 2013c; Norbeck et al. 2018; Rinaldi and Rutqvist 2019). Thus, hydraulic stimulation in EGS combines hydraulic fracturing and hydroshearing, and this viewpoint is now commonly accepted in the EGS community.

Based on previous in-situ experiments and observations, McClure and Horne (2014a, b) summarized four potential mechanisms that may dominate during a hydraulic stimulation operation in EGS, as shown in Fig. 1. The first mechanism is the pure opening mode which is based on the conventional hydraulic fracturing concept, assuming no natural fractures within the reservoir. During stimulation, the injected fluid cracks the reservoir and creates newly opened propagating fractures, thus creating fluid channels and increasing permeability (Adachi et al. 2007; Economides and Nolte 1989; Geertsma and De Klerk 1969; Nordgren 1972; Perkins and Kern 1961). The second stimulation mechanism is the pure shear mode (hydroshearing), which means that permeability enhancement comes from the shear slip of pre-existing natural fractures. In this process, the injected fluid increases the pore pressure within the natural fractures, decreases the normal effective stress on fracture surfaces, and triggers shear slip under appropriate local stress conditions (effective normal and shear stresses). The third mode, defined as the primary fracturing with shear stimulation leak-off, represents a combination of new fracture opening (hydraulic fracturing) and induced shear slip of in-situ natural fractures (hydroshearing). This concept applies to low permeability rocks with a low density of natural fractures, and several numerical models have been developed to study this idea (Nagel et al. 2011; Palmer et al. 2007; Rogers et al. 2010; Warpinski et al. 2001). The fourth stimulation mechanism is called mixed-mechanism stimulation and is also a combination of hydraulic fracturing and hydroshearing. Under this mechanism, high-pressure fluid first cracks the reservoir around the injection point, creates tensile fractures, and drives fracture propagation. When encountering natural fractures, the hydraulic fractures may terminate and then propagate along the direction of natural fractures or cross the natural fractures, depending on the angle between the natural fractures and the hydraulically propagating fractures, the fluid pressure, in-situ stress state, and other geological parameters.

Based on the above four potential mechanisms, research has been carried out to identify the critical parameters that determine which mechanisms may dominates during hydraulic stimulation in an EGS site. These parameters include:

-

(i)

Reservoir’s initial transmissivity and transmissivity heterogeneity. Numerical simulations indicate that if the initial transmissivity is very low near the borehole because of the sparse presence of natural fractures or their very small fracture hydraulic apertures, tensile fracture may be opened near the injection borehole when the injection pressure exceeds rock breakdown pressure. On the other hand, if the transmissivity is high, representing the presence of connected hydraulically conducting fractures, a lower injection pressure would be required to cause shear displacement and dilation on these natural fractures.

-

(ii)

The storativity of the pre-existing natural fracture systems. Numerical simulation results indicate that if the natural fractures are closed and have low storativity, fluid injection will induce very rapid natural fractures propagations. In this case, the closed natural fractures cannot contain much fluid, and pressure buildup is relatively fast. Moreover, the experience from Soultz geothermal site indicated that if there is a large fault zone near the injection borehole, the high storativity of the fault zone can accommodate a large injection fluid volume (Cuenot et al. 2008, 2010; Dezayes and Genter 2008). In that case only shearing fractures were observed, but no tensile fracture opening. Hence, we may conclude that fracture tensile opening tends to take place in regions of low fracture storativity and shear displacement in regions of high fracture storativity.

-

(iii)

The development degree of the fault zone. The development degree indicates the fracture density in the target reservoir. A well-developed or mature natural fracture system with high fracture density and/or a fault zone with reasonable thickness increases the tendency for the shear slip of natural fractures. Moreover, optimally oriented critical fractures intersecting the borehole have large possibility for shearing. Similarly fault zones with large transmissivity and storativity have a higher potential for shear slip initiation, assuming a sufficiently large injection pressure is imposed. However, after the initiation of the shear slip of natural fractures, the resulting increase in the permeability quickly lowers the pressure and hence the probability of large tensile fracture formation within the reservoir (Lei et al. 2021; McClure and Horne 2011, 2014a, b).

-

(iv)

Fluid injection rate and borehole bottom-hole pressure. Evidence from the GPK2 well at Soultz, France, indicated that if the bottom-hole fluid pressure remained substantially below the minimum principal stress due to the low fluid injection rate, the shear slip of pre-existing fractures would be the dominant mechanism and many seismic events with the magnitude less than 2.0 were observed (Valley and Evans 2006). A similar phenomenon was observed at Cooper Basin EGS sites in Australia, where the shear slip was the dominant stimulation mechanism (Baisch et al. 2006, 2009). Conversely, if the fluid was injected into the reservoir with a high injection rate and high bottom-hole pressure, a main hydraulic fracture would be created, which was found to be the case behind the permeability increase of GPK1 and GPK4 wells in Soultz, France (Tischner et al. 2007).

2.2 The mechanism of heat extraction volume increase in EGS

Another objective of hydraulic stimulation is to increase the heat extraction volume and heat exchange surface area, as the effectiveness of heat exchange between the working fluid and the rock is critical in determining whether the EGS site is successful or not.

Research indicates that water circulation in EGS is primarily dominated by flow in the fractures (a single fracture or fracture network), rather than the rock matrix (Baisch et al. 2006; Brown 1997, 2009; Brown and Duchane 1999; Genter et al. 2012; Koh et al. 2011). Therefore, the flow characteristics through the fractures and the heat exchange efficiency between circulating fluid and the surrounding rocks will determine the heat production efficiency (Guo et al. 2016). Thus, it is highly desirable that fluid flow is in contact with a large area of fracture surfaces and that fractures with such flow cover a large rock volume. Spatial heterogeneity in flow will be created during a hydraulic stimulation operation due to the target reservoir’s complicated geological setting (Kosakowski et al. 2001; Méheust and Schmittbuhl 2000; Neretnieks 1987). When fluid flow takes place through a fracture network with fractures of variable permeability values and if, further, individual fractures have a heterogeneous aperture distribution, channelized preferential flow paths would likely be formed (Moreno and Tsang 1994; Tsang and Neretnieks 1998; Tsang and Tsang 1989). Channelized flow is not optimal for heat extraction as the interface between the rock and the circulating flow is reduced. In addition, the phenomenon may be self-enhancing. Rock matrix near the preferential flow paths cools faster than those farther from the flow paths and the cooled rock body could then induce thermal stress and decrease the effective compressive stress near the preferential flow paths, with the possibility of increased local hydraulic permeability, which will make the fluid flow even more channelized along those preferential paths. This phenomenon is not desirable as these preferential paths would carry an increasing portion of the fluid flow, thus leading to early production temperature decline.

The above discussion is illustrated in Fig. 2. Chen and Jiang (2016) presented the following equations to describe the heat conduction in the rock matrix and heat convection and advection for the fluid within the fractures, respectively:

a A schematic simplification of a fracture network for heat extraction between fluid and rock in EGS. b Two extreme cases illustrate the difference in permeability enhancement and heat exchange surface area increase: with the same total permeability, Case I has a smaller heat exchange surface area and heat extraction volume than Case II

In these equations, ρ [kg/m3] is the density; ε [dimensionless] is the porosity; Cp [J/kg/K] is the heat capacity; the subscript f denotes the property of the working fluid and s denotes the property of the solid (rock matrix); u [m/s] is the superficial velocity vector; T [K] is the temperature; a [1/m] is the specific surface area of the fractures; h [W/m2/K] is the convective heat transfer coefficient. The term ha(Ts-Tf) appears in both equations. It describes the heat exchange between the rock matrix and the working fluid in the fractures. The specific surface area represents the rock-fluid heat exchange area per unit reservoir volume. This parameter is a purely geometrical parameter with its value associated with the fracture morphology (Jiang et al. 2014). The heat transfer rate is directly proportional to the specific surface area based on the effective medium theory. It is a direct reflection of the fact that with a larger specific surface area of the fractures, the heat exchange will be more efficient.

Finally, it is useful to highlight the difference between permeability enhancement and specific surface area improvement for heat extraction due to hydraulic stimulation. After a successful hydraulic stimulation, the permeability is enhanced. This permeability enhancement may be due to the creation of one main fracture between the injection well and the production well (Case I in Fig. 2b), or due to the creation of N fractures between the two wells (Case II in Fig. 2b). For the same permeability enhancement, with the flow rate Q between the injection and production wells in the two cases being kept equal, then based on the cubic law, the apertures of the fractures in the two cases can be related through e13/12 = Ne23/12, so that e2 = e1/N1/3. Now, for Case I, the porosity is e1/L, and the specific surface area for heat exchange as defined by Chen and Jiang (2016) is 1/L, where L is the length of the reservoir along the well. As for case II, with N fractures the porosity is Ne2/L = N2/3e1/L, much larger than that of Case I and thus resulting in a slower flow velocity as compared with Case I. Further, in Case II, the specific surface area for heat exchange is N/L, which is N times larger than the specific surface area in case I. Hence, even though the flow in Case I and in Case II are the same (meaning a similar permeability enhancement due to hydraulic fracturing stimulation), Case II provides a significantly better condition for heat transfer in EGS.

As discussed above, it is easy to conclude that the aim of hydraulic stimulation in EGS is not the same as in oil and gas reservoirs. In EGS reservoirs, apart from solely increasing the permeability/transmissivity, it is also important to increase the heat exchange area. That is to say, more fluid channels for heat exchange will benefit the heat production. Thus, in EGS, creating more fractures with smaller hydraulic apertures may be better than fewer fractures with larger hydraulic apertures.

2.3 The mechanism of fluid injection-induced seismicity

A number of recent review papers have summarized the activation mechanisms of fluid injection-induced seismic events (Atkinson et al. 2020; Kang et al. 2019; Rathnaweera et al. 2020; Schultz et al. 2020). McGarr et al. (2015) listed five main industrial operations that may cause fluid injection-induced seismicity, namely (a) wastewater disposal; (b) massive fluid injection to enhance oil recovery; (c) hydraulic fracturing operations; (d) deep injection of CO2; and (e) EGS development. Bommer et al. (2006), Bruhn et al. (2011), Suckale (2009), and Davies et al. (2013) reviewed the fluid injection-induced seismicity in the different applications. Warpinski et al. (2012) examined the induced seismicity specifically related to hydraulic fracturing in shale gas development. Evans et al. (2012) summarized 41 European cases of fluid injection-induced seismicity in the EGS and CO2 storage projects. The review by Ellsworth (2013) focused on earthquakes caused by wastewater injection, especially in the USA. Rubinstein and Mahani (2015) summarized fluid injection-induced seismicity cases associated with wastewater injection, hydraulic stimulation, and enhanced oil recovery. Schultz et al. (2020) reviewed the reported cases of hydraulic fracturing induced seismicity in Canada, USA, UK, and China, during oil and gas exploration, with analysis of earthquake swarms and their proximity to the injection locations. Atkinson et al. (2020) summarized six key issues associated with hydraulic fracturing induced seismicity, including the triggering mechanisms, the effect of the tectonic environment, commonalities and differences between induced and natural earthquakes, damage potential, prediction, and relative hazards evaluation.

Table 1 gives a summary of reported fluid injection-induced earthquakes in geothermal systems. Majer et al. (2007) proposed four possible mechanisms to understand the injection-induced seismicity during EGS development, namely (a) pore pressure increase; (b) fluid temperature decrease; (c) fluid injection/withdrawal-induced fluid volume alternation, and (d) chemical changes in fractures. Ghassemi (2012) in turn summarized the rock mechanics-related issues in fluid injection-induced seismicity, including how coupled thermo-hydro-mechanical-chemical (T-H-M-C) processes affect seismic events during EGS development as well as the role of strain localization, fluid flow and diffusion, and heat exchange during earthquake nucleation. Zang et al. (2014) discussed the relationship between fluid injectivity, fluid volume, in-situ stress conditions, and the occurrence of large seismic events in time and space during hydraulic stimulation in a specific EGS site. Their results indicated that long-term injection had a higher potential to induce earthquakes with large magnitudes than short-time injection.

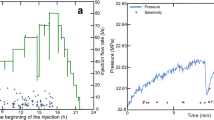

As shown in Fig. 3, Eyre et al. (2019) summarized three commonly accepted, potential mechanisms that induce seismic events during hydraulic stimulation, including (1) direct effect from increased pore pressure on fault; (2) change of fault-loading conditions, and (3) fault loading by aseismic slip. However, underlying these mechanisms are some critical factors that will determine if and how a seismic event will be initiated, such as the total fluid injection volume, fluid injection rate, fluid temperature, reservoir original pore pressure, reservoir permeability, reservoir temperature, and the orientations of pre-existing faults (Dinske and Shapiro 2013; Shapiro and Dinske 2009; Zoback 2010, 2012). Moreover, whether a seismic event with a large magnitude can occur after the activation of the natural fractures/faults depends also on the frictional strength evolution of the faults. Seismologists use rate- and state-friction law to describe the frictional strength evolution as a function of slip velocity and slip history (Dieterich 1978; Marone et al. 1990; Ruina 1983). It has been shown that the so-called frictional stability parameter will determine whether a fracture/fault has velocity strengthening or velocity weakening behavior. The factors that affect the frictional stability of faults include the mineralogical compositions of fault gouges, fluid pressure, and temperature (Kang et al. 2019). Experimental and in-situ results indicate that faults with high content of brittle and hard mineral particles, such as quartz and feldspar, can be expected to have higher frictional strength but lower frictional stability, with a higher tendency for potential seismic slip events (Boulton et al. 2012; Byerlee and Brace 1968; Carpenter et al. 2009; Fang et al. 2017; Ikari et al. 2007, 2011; Moore and Lockner 2004; Morrow et al. 2000; Niemeijer and Collettini 2013; Shimamoto and Logan 1981; Summers and Byerlee 1977; Tembe et al. 2010). Moreover, these results indicate that fluid pressure may enhance or hinder the potential for seismic events for different rocks (De Barros et al. 2016; Jia et al. 2020; Guglielmi et al. 2015; Scuderi and Collettini 2016). Finally, temperature also affects the frictional stability evolution, especially during EGS development where the target reservoir is commonly under a high temperature gradient due to the significant difference in temperature between injected fluid and in-situ fluid (Den Hartog et al. 2012a, 2012b; McClure and Horne 2014a, b; Niemeijer and Collettini 2013; Rutqvist et al. 2008; Verberne et al. 2010, 2015). With a decrease of temperature, the faults’ frictional strength increases dramatically, and the rock may evolve from plastic to semi-brittle deformation behavior, which increases the tendency for seismic events (Blanpied et al. 1995; He et al. 2006). Thus generally, during the EGS development, cold water injection could decrease the temperature of fault gouges, induce more brittle failure, and increase the seismic risks.

Three potential mechanisms for fluid injection-induced seismicity. (1) Direct effect from increased pore pressure on fault; (2) Change of fault-loading conditions; and (3) Fault loading by aseismic slip (Eyre et al. 2019)

Although it is impossible to predict natural earthquakes accurately at this stage, researchers have attempted to estimate the maximum seismic magnitude of fluid injection-induced seismicity (Foulger et al. 2018). Representative methods include statistical, physical, and hybrid approaches (Cloetingh et al. 2010; Luginbuhl et al. 2019; Gaucher et al. 2015; Schoenball et al. 2012). Some representative models and empirical relationships have been summarised by Shapiro et al. (2011), McGarr (2014), Van der Elst et al. (2016), and Galis et al. (2017). Current results indicate the injected fluid volume to be the main control on the magnitude of the fluid injection-induced seismicity. In Fig. 4, a summary of observed magnitudes of fluid injection-induced seismicity as a function of injected fluid volume in various EGS projects is shown, along with the model predictions by McGarr (2014) and Galis et al. (2017). However, the results also show that some seismic events may significantly deviate from the general model predictions, including a number with much larger magnitudes. This may especially happen if the rupture is a runaway/unarrested rupture (Grigoli et al. 2018). An important example is the Pohang earthquake, where the earthquake sequences cannot be predicted based on the net fluid injection volume (Lee et al. 2019). In general, without the consideration of specific in-situ tectonic stresses and local fault rupture physics, the estimation of the particular extent of seismic events will be difficult.

Another important phenomenon that has been under intense study is post-stimulation seismic events. Parotidis et al. (2004) indicated that the pore pressure diffusion was the dominant triggering mechanism for the post-fracturing induced seismicity. Baisch et al. (2010) found that pore pressure at a nearby fault can dramatically increase after shut-in, bringing the fault to the critically stressed state. Later, Segall and Lu (2015) suggested that the poro-elastic effect is the main reason for the seismic events after shut-in. De Simone et al. (2017) emphasized that during the analysis of the effect of fluid on the post-fracturing induced seismicity, various time scales and distances to the injection borehole should be considered. Mukuhira et al. (2017) further analyzed the distribution of pore pressures after the hydraulic stimulation, concluding that the pore pressure distribution after the shut-in indeed could destabilize a larger portion of a fault, resulting in localized shear slip with the potential of triggering a seismic event with large magnitudes. In addition to these considerations, some other processes may also be important for the post-fracturing induced seismicity; for example, thermal stress associated with the temperature difference between injected fluid and in-situ fluid may also facilitate the triggering of fault slips (Gan and Lei 2020).

As we summarised above, the mechanisms causing post-injection seismicity are under extensive studies and are still very much an open research topic. One possible mechanism could be pore pressure diffusion, in which fluid injection pressure will still diffuse outwards even after the shut-in and subsequently reaches an area under pre-existing critical stress condition. Another possible mechanism is the normal closure of an initially injection-induced opening of fractures in a fault zone near the injection well after shut-in. The opening and closure of the fractures in a fault zone under particular local stress conditions may induce changes in stress, deformation and water pressure in a fault zone that create new critical stress conditions and their disruptions. The post-injection induced seismicity is a coupled hydromechanical process in a fault zone with complex network of fractures which need to be further investigated.

3 Typical hydraulic stimulation techniques

This section reviews the most common hydraulic stimulation techniques used to enhance reservoir permeability. These methods include conventional hydraulic stimulation, multi-stage fracturing, and the so-called cyclic soft stimulations (CCS), which combines cyclic injection protocols and a traffic light system. While the emphasis of this section is on EGS, information and references on hydraulic stimulation methods from related fields are also included, since they form part of the knowledge base for stimulation design for EGS projects and may help to convey a broader view of stimulation approaches and techniques.

3.1 Conventional hydraulic stimulation

Conventional hydraulic stimulation technique is commonly used in the oil and gas industry (Agarwal et al. 1979; Veatch 1983). It generally refers to hydraulic stimulation operation involving a large amount of water and proppant injected into the reservoir. This technique was first used in the oil and gas industry to enhance the permeability of tight sandstone formations, including the Denver Basin and Piceance Basin (Chancellor, 1977; Fast et al. 1977). Due to the high fluid injection rate, fluid pressure will increase quickly at the injection borehole. When the fluid pressure reaches a certain value, rock breakdown occurs, and tensile fractures are created near the injection borehole interval. The fluid pressure at which rock breakdown occurs is defined as the reservoir breakdown pressure, which can be calculated based on the in-situ stress state and tensile strength of reservoir rock (Detournay 2016). After the reservoir rock breakdown, injection fluid pressure also acts as the driving force to further open the generated tensile fracture and to propagate it further. However, after the injection stops, the hydraulic fractures may close again due to in-situ compressive stress. Thus, a combination of slickwater fracturing and proppant injection is commonly used to keep the fracture open (Barati and Liang 2014). After creating long and narrow fractures by slickwater, proppants are then injected into the reservoir as the second step, aiming to keep the hydraulic fractures open. The common materials used as proppants include silica sand as well as resin-coated and ceramic proppants.

3.2 Multi-stage fracturing

Multi-stage fracturing is a more complex hydraulic stimulation technique developed with the advance of horizontal drilling technology. In this approach, horizontal wells (with lengths of hundreds to a few thousand meters) are firstly drilled. Then, packers are used to isolate sections along the borehole, and fluid is injected into those sections simultaneously or in a certain time sequence. Through this process, multiple fractures can be created along the borehole, and a larger rock volume is stimulated with increased permeability (Tang et al. 2016; Yao et al. 2012).

In recent years, the possibility of replacing conventional hydraulic stimulation with multi-stage fracturing has become of interest to the EGS community. In multi-stage fracturing, the stress shadow effect is a critical phenomenon that needs to be addressed. The stress shadow effect refers to the effect of stress redistribution in the region near a generated hydraulic fracture. Then, if a second hydraulic fracture is to be created at the next time stage in its vicinity or in its shadow, a higher fluid pressure may be required. Moreover, the second fracture may have a more limited length, narrower width, and its propagation direction may also deviate from the maximum stress direction, because of the directional change of the local stress field (Taghichian et al. 2014; Zangeneh et al. 2015).

Sneddon and Elliot (1946) presented an analytical solution for stress distribution around a 2D vertical fracture extended from a horizontal borehole. In their derivation, the rock material was assumed to be homogeneous and isotropic, the fracture was open, i.e., unfilled, and the presence of the borehole was neglected. The equations below can be used to describe the stress changes around a created hydraulic fracture (Geertsma and De Klerk 1969; Perkins and Kern 1961):

where Δσx [MPa], Δσy [MPa] and Δσz [MPa] are stress changes caused by the hydraulic fracture in X, Y and Z direction, respectively. Pn [MPa] is the fluid pressure within the fracture, x [m] is the distance to the fracture center, hf [m] is the vertical extent of the fracture, and ν is the Poisson’ ratio. Studies have also been conducted for the case where several fractures are initiated simultaneously from several isolated sections in the horizontal well. The propagating fractures are found to interfere with each other, resulting in complicated fracturing geometries and uneven fracture distribution (Di and Tang 2018; Tang et al. 2016).

Laboratory experiments have been conducted to investigate the role of the stress shadow effect on multi-stage hydraulic fracturing. Geyer and Nemat-Nasser (1982) observed the uneven propagation of fractures and the apparent compression of two long simultaneously propagating fractures. Zhou et al. (2018) found that the stress shadow effect restrained the fracture propagation of adjacent fractures and caused a divergence of adjacent fractures in shale. Gai et al. (2020) found that multiple hydraulic fractures with small spacing would coalesce even under high horizontal stress differences. Moreover, the needed initiation pressure of later hydraulic fracture increases with increased fluid pressure within the earlier fractures. A later fracture would also deviate from the ideal direction perpendicular to the horizontal wellbore and deflect towards the earlier hydraulic fracture.

Due to the limited sample size that can be investigated in the laboratory, numerical simulations were also used to investigate the stress shadow effect. Wong et al. (2013) observed that the stress shadow effect could make fractures diverge outwards from the created group of fractures, and the inside fractures may be closed due to the compression effect of outer factures. Analyses confirmed that an increase in fracture spacing would result in a reduced stress shadow effect and prevent the directional deviation of later fractures (Morrill and Miskimins 2012; Roussel and Sharma 2011; Singh and Miskimins 2010).

Moreover, perhaps the most significant multi-stage hydraulic stimulation tests were performed in the Bedretto Underground Laboratory for Geosciences and Geoenergies (BULGG) to evaluate its capability to improve the quality of the granite rocks reservoir. In this experiment the borehole ST1 was divided into 14 injection intervals by means of a multi-packer system. Results and details can be found in Bröker et al. (2022) and Castilla et al. (2022).

In summary, the stress shadow effect may cause the following drawbacks: (a) the alteration of local in-situ stress states due to the pressurization of earlier fractures (Cheng 2009; Nagel and Sanchez-Nagel 2011; Olson 2008; Roussel and Sharma 2011); (b) a subsequent fracture may propagate towards the previous fracture regime or terminate due to fracture intersection (Olson 2008; Roussel and Sharma 2011); and (c) the compression effect of outer fractures may decrease the width of inner fractures (Olson 2008). Thus, approaches have been developed to limit the negative effects of stress shadow, and these techniques can be divided into two categories: (a) multi-stage fracturing in space, which means the optimization on fracturing spacing, and (b) multi-stage fracturing in time, which means that fracturing operations are performed sequentially rather than simultaneously.

3.2.1 Multi-stage fracturing in space

One practical idea to eliminate the stress shadow effect is the optimal design of spacings of fracturing intervals based on in-situ stress states and geomechanical properties of the target reservoir. The main point of fracturing stage optimization is to understand how the adjacent parallel fractures interfere with each other as a function of spacing. Yamamoto et al. (2004) developed a three-dimensional simulator, which could effectively describe the paralleled fracture propagation with mechanical interactions between fractures. Olson (2008) used a pseudo-3D model to simulate paralleled fracture propagation, which dramatically decreased the calculation time for obtaining the optimal fracture spacing. Meyer and Bazan (2011) also developed a DFN model to investigate paralleled fracture propagation, which could predict the mechanical interaction impact on the fracture aperture growth for evenly spaced fractures. These techniques can be applied to design optimal spacing based on rock mechanical properties, fluid properties, and geological conditions.

3.2.2 Multi-stage fracturing in time

Another practice to minimize the stress shadow effect is to perform hydraulic fracturing in well-spaced borehole sections according to a certain time sequence. Waters et al. (2009) considered two parallel horizontal wells, where the sections in the two wells opposite each other are stimulated simultaneously in successive time stages when moving towards to the ends of the wells, Fig. 5a. The next modification in the stimulation procedure was to differentiate the timing of the stimulation stages in the two wells, so that the hydraulic fracturing in the two wells follows a particular time sequence, Fig. 5b. This method is referred to as zipper fracturing. Later, a modified zipper fracturing was further introduced by placing the stimulation sections of the two wells not directly opposite to each other, Fig. 5c. In this case, the stress shadow effect was further reduced. Rafiee et al. (2012) found that the modified zipper fracturing technique creates a more complex fracture network in shale in a case where the two parallel wellbores have a distance between 150 and 300 m. A limitation of the method is that the generated fracture network was concentrated in between the two wells, and thus the stimulated volume may be limited. Vermylen and Zoback (2011) investigated the stress shadow effect in multiple lateral wells in Barnett shale, and their results indicated that the zipper fracturing was more effective than the simultaneous fracturing in generating hydraulic fractures with a longer length. Nagel et al. (2013) found that by drilling multiple lateral wells and performing hydraulic fracturing in sequence, the reservoir permeability could be significantly enhanced. Izadi et al. (2015) modeled the hydraulic fracture propagation and found the largest stimulated volume was achieved by the modified zipper fracturing method compared with simultaneous hydraulic fracturing. While most of the work on this stimulation approach is for shale formation, Kumar and Ghassemi (2016, 2019) also conducted three-dimensional numerical simulations to explore the multi-stage fracturing in horizontal wells for EGS design. The results indicated that the modified zipper fracturing could be used for more closely spaced horizontal wells to generate more complicated fracture networks than by the use of simultaneous hydraulic fracturing method. Zangeneh et al. (2015) compared the fracturing performance between conventional hydraulic fracturing, simultaneous fracturing, and zipper fracturing. They found both the maximum hydraulic fracture aperture and length to increase when the stimulation method moves from conventional fracturing to simultaneous fracturing and to zipper fracturing, the latter being the most effective.

a Simultaneous hydraulic fracturing, b Sequential hydraulic fracturing (Zipper fracturing), and c Modified Zipper fracturing. (modified from Cuss et al. 2015). In these figures, two-headed arrows (found only in a) indicate simultaneous fracturing, while single-headed arrows indicate a step delay in time

It should be remarked here that many factors, such as local stress state, pre-existing natural fracture systems (length, density, and hydraulic properties), will strongly influence the performance of a hydraulic fracturing stimulation. Hence, for any given site, site-specific data should be used in numerical modeling to obtain a comprehensive understanding and prediction of the hydraulic fracture propagation prior to a stimulation operation.

3.3 Cyclic soft stimulation (CSS)

The cyclic soft stimulation (CSS) is a hydraulic stimulation strategy that combines (a) cyclic fluid injection and (b) a so-called traffic light system (TLS). CSS’s two major objectives are to enhance the reservoir permeability and to mitigate the fluid injection-induced seismicity caused by hydraulic stimulation (Zang et al. 2013, 2017).

3.3.1 Cyclic fluid injection fracturing

Kiel (1977) first proposed the cyclic injection fracturing concept for increasing the hydraulic conductivity of reservoir rocks. Over the past few years, laboratory-scale as well as in-situ field experiments have been conducted to investigate the breakdown process of the reservoir under cyclic fluid injection (including breakdown pressure, fracture propagation, and distribution), the associated seismic behaviors, and induced fracture permeability, with the goal of understanding the basic mechanism underlying these processes (Hofmann et al. 2018; Zang et al. 2019). More recently, the cyclic injection protocol has been proposed for various applications, including EGS (Zimmermann et al. 2010), shale gas hydraulic fracturing (Jia et al. 2021), and coalbed methane (Xu et al. 2017).

To relate this approach to other methods, Zhuang et al. (2020) and Li et al (2022) presented a summary of several fluid injection schemes, both injection-rate controlled and pressurization controlled, as shown in Fig. 6. Continuous injection with a constant rate is commonly used in massive hydraulic fracturing, as shown in Fig. 6a. Figure 6b shows the stepwise rate injection with increasing injection rates. Figure 6c shows cyclic progressive injection, where high and low injection rates alternate in each cycle, with the high injection rates increasing in successive cycles. Figure 6d shows the stepwise pressurization scheme, in which the fluid injection pressure increases to successively higher pressure in several steps. Figure 6e is a modification of stepwise pressurization with each step maintained through pulsed pressurization. Figure 6f is the cyclic pulsed pressurization, in which the injection pressure is decreased after the pulse pressurization step after each cycle and before the next pressurization cycle.

Six different injection schemes of hydraulic fracturing. a Constant rate continuous injection (CCI), b stepwise rate continuous injection (SCI), c cyclic progressive injection (CPI), d stepwise pressurization (SP), e stepwise pulse pressurization (SPP) and f cyclic pulse pressurization (CPP). (Modified from Zhuang et al. 2020)

The injection schemes in Fig. 6b–f could be regarded as the cyclic injection, which is also known as the fatigue hydraulic fracturing method (Zang et al. 2017). Fatigue failure occurs after a series of successive loadings at a load smaller than the load required to fail a material by static loading. It may result in a violent failure without early warning. The micro-mechanisms of fatigue failure have been well studied in metal materials but are less investigated for rock materials. The Paris-Erdogan law is commonly used to describe the fatigue-based failure in fracture mechanics and expressed as (Zang et al. 2019):

where dc/dN is the fracture growth per cycle; Δk is the stress intensity factor; N is the loading cycles; A and m are two constants. This equation defines the power-law relationship between fracture growth rate and stress intensity factor. Based on this concept, experiments in the laboratory with rock samples have been performed with cyclic loading (Haimson and Kim 1991; Erarslan and Williams 2012; Yin et al. 2021b). More details on mechanical fatigue failure can be found in a review paper by Cerfontaine and Collin (2017). It is worth mentioning that there are two significant differences between cyclic mechanical loading and cyclic hydraulic fracturing in rocks, namely: (a) fluid pressure may affect the rock strength, and (b) potential chemical reactions may occur between fluid and silicate minerals in rocks (Atkinson 1984).

Generally, during cyclic fluid injection into the reservoir, a high-frequency water pulse could dismantle and remove weak minerals from fracture surfaces while decreasing the rock strength locally (Fig. 7a). Through these processes, the fatigue hydraulic fracturing could achieve three goals: (a) lowering the breakdown pressure of the reservoir; (b) generating a more complicated fracture network with higher permeability and heat-transfer surface area of the reservoir and (c) minimizing the potential for large earthquakes by inducing smaller seismic events with the cyclic injection of a smaller amount of fluid.

a In fatigue hydraulic fracturing, rock particles are removed from fracture faces through high-frequency vibrations and reached the fracture tip. A fracture process zone is created during fatigue hydraulic fracturing. (modified from Zang et al. 2019). b The traffic light system for cyclic fluid injection schemes (modified from Hofmann et al. 2018)

A number of laboratory experiments have been performed to validate whether CSS is an effective technique to increase reservoir permeability while mitigating seismic risks. Zang et al. (2000, 2002) conducted laboratory experiments with granites and sandstones, and the results indicated that cyclic mechanical loadings could form a damaged zone with different widths. Later experiments with tuff and monzonite gave similar findings indicating that cyclic mechanical loading produced a smaller but more intense fracture zone than static failure loading (Ghamgosar and Erarslan 2016). Experiments on Pocheon granites with X-ray CT technology indicated that cyclic hydraulic fracturing reduced the breakdown pressure by about 20% compared to conventional hydraulic stimulation with a constant injection rate. Moreover, cyclic hydraulic fracturing was found to produce complex and branched fractures, whereas the conventional hydraulic fracturing tended to create a single main fracture. However, the induced fracture aperture was smaller for cyclic injection, resulting in a limited permeability enhancement, as shown in CT images (Zhuang et al. 2016). Similar experiments with sandstone samples indicated that the breakdown pressure is lowered by about 16% compared with conventional hydraulic fracturing. Moreover, BSE-SEM images showed that cyclic injection could create a damaged zone around the induced fractures that is twice as wide as the fracture zone created by continuous fluid injection (Patel et al. 2017).

3.3.2 Traffic light systems (TLS)

Another component of cyclic soft stimulation (CSS) is the traffic light system (TLS) (Hofmann et al. 2018). The TLS involves careful monitoring of seismic events over the duration of the stimulation procedure and adjusting operation accordingly, such as decreasing injection flow rate, reducing fluid pressure, shutting-in, or flowing-back, when the seismic magnitude or the peak ground velocity reaches a specific threshold, or when other unexpected observations occur. The oil and gas industry has adopted the TLS as part of a hydraulic stimulation operation (Bommer et al. 2015).

A typical TLS proposed by Hofmann et al. (2018) for hydraulic fracturing stimulation in EGS is shown in Fig. 7b. The threshold of each stage is calculated based on the maximum tolerable seismic moment magnitude (Mwmax) and magnitude increase (ΔMw). Details could be found in Hofmann et al. (2018). A challenge is that seismic events with increased magnitudes have been observed in a period of time after injection shut-in (Majer et al. 2007), and the question exists whether the TLS can effectively mitigate such post-injection seismic risks.

In-situ experiments have been carried out to investigate the potential of using fatigue hydraulic fracturing for EGS, by combing CSS and TLS. An example is the experiments conducted at Äspö Hard Rock Laboratory, Sweden (Lopez-Comino et al. 2017; Zang et al. 2017; Zimmermann et al. 2019). In these experiments, three different injection procedures were investigated: (a) conventional hydraulic fracturing with a constant injection rate, (b) an approach where injection flow rate was gradually increased in a cycle of alternating high and low pressures, and (c) an additional pressure pulsation imposed on each step of the cyclic injection. The results indicated that a lower breakdown pressure was observed for the cyclic pulse injection protocols (c). Moreover, both the number and magnitudes of the seismic events were lower in this case. However, the authors pointed out that further investigations are needed to understand the parameters influencing the number and magnitude of seismic events during and after fluid injection (Zang et al. 2017). The fluid injection strategy was instructed to follow a cyclic protocol to dissipate hydraulic energy at Espoo near Helsinki, Finland, in 2018 and 2020 (Hillers et al. 2020; Kwiatek et al. 2019; Leonhardt et al. 2021). Five hydraulic stimulations were conducted in 2018 in well OTN-3 at this site, and the CSS method was deployed with a total of 18,160 m3 freshwater injected into the target reservoir over 49 days (Ader et al. 2020; Kwiatek et al. 2019). The results indicated that the reservoir conductivity increased, and no seismic events were recorded with magnitudes higher than 2.0 (Kwiatek et al. 2019; Kukkonen and Pentti 2021). Hydraulic stimulations were also performed in another well, OTN-2, with ~ 7000 m3 fluid injection through a 1.3 km open hole section. Even though details of those hydraulic stimulations have not yet been published, the experience at this site illustrates the possibility of CSS to increase the reservoir permeability while mitigating seismic risks in EGS. Another hydraulic stimulation project has also been proposed, combining cyclic injection, TLS, and risk analysis system in a well RV-43 near Reykjavik, Iceland, at a depth from 1001 to 1750 m (Broccardo et al. 2020). Furthermore, CSS hydraulic stimulation was also applied to an EGS project in Pohang, South Korea (Park et al. 2020), which will be discussed in more detail in Sect. 4.3.2.

4 Examples of EGS hydraulic stimulation projects and some lessons learned

In this section, we present some representative EGS projects around the world during the last few decades. Many ways of grouping these projects can be used, but in this study, we group them into three categories: (a) experimental EGS projects intended basically for scientific research; (b) commercial EGS projects that have been led by industrial companies, aiming at electricity generation or heat production; and (c) EGS projects which have been suspended or terminated due to certain reasons such as borehole damage or seismic risks. These three categories of projects are summarized in Tables 2, 3 and 4, with information on their locations, years of activity, reservoir rock types, well depths, stimulation methods, and some remarks. We then select two representative sites from each category (indicated by ** in the tables) for a more detailed review in the following subsections with a focus on the implemented hydraulic stimulation strategy, the resulting permeability enhancement performance, and induced seismicity. Some lessons learned and insights gained from each case are summarized.

4.1 Experimental EGS sites

4.1.1 Fenton Hill, USA

The first extensive in-situ experiments aimed to study the extraction of heat from “hot dry rock” (HDR) started in 1975 at Fenton Hill, on the western flank of Valles Caldera, USA (Fig. 8a). The whole project could be divided into three stages: (a) The early stage (1970–1973) aimed to develop the basic concept and to conduct some preliminary tests; (b) Phase I (1974–1980), which involved borehole drilling, hydraulic stimulation and flow experiments; (c) Phase II (1981–1995) which involved a further development in drilling and testing operations (Brown 1997, 2009).

a The location of the Fenton Hill geothermal project. b The well location and basic geological condition. c The injection rate, pressure at the surface during the conventional hydraulic fracturing test in EE-2 wellbore. d The section-view of microseismic activities cloud map of EE-2 and EE-3 borehole. a to d are extracted from Kennedy et al. (2010). e The microseismic map after the hydraulic fracturing in well EE-3 (Dash et al. 1985). f The position of well EE-3A after re-drilling (Tester et al. 2006)

Figure 8b shows the well distribution of the Fenton Hill geothermal project. More information about the drilling history can be found in Tester et al. (1986, 1989). In Phase I, the first injection borehole (GT2) was drilled to the final depth of 2932 m in host rock consisting of jointed granodiorite. After that, a second borehole (EE-1) was directionally drilled below the bottom of the GT-2 borehole (Duchane and Brown 2002). In Phase II, wells EE-2 and EE-3 were drilled to depths of approximately 3500 m. Conventional hydraulic fracturing was performed in the EE-2 well aiming at creating a penny-shaped fracture propagating upwards to intersect the EE-3 borehole above. During a 2.5-day period, about 21,000 m3 water was injected into well EE-2 with an average fluid pressure of about 48.0 MPa at the surface (Kennedy et al. 2010). Figure 8c shows the flow rate and fluid pressure evolution with time. It could be observed that the fluid pressure curve followed a similar shape with injection rate evolution, and no pressure drop was observed. This means that no fluid flow channels had been created to connect EE-2 and EE-3 wells. In Fig. 8d, the microseismic activity map also supports this interpretation since the seismic clouds were located near the EE-2 borehole, and not penetrated by borehole EE-3. The conventional hydraulic fracturing test ended with a high-pressure flange failure, so that the wellhead pressure could not be controlled, and the EE-2 borehole experienced sustained severe damage. Subsequently, an additional larger stimulation test was performed in the EE-3 borehole (May 1984), but the results were still unsatisfactory (Tester et al. 2006). As shown in Fig. 8e, the microseismic events caused by EE-3 stimulation are concentrated near and above the injection well EE-3, and do not overlap with EE-2 seismic clouds. It was concluded that the hydraulic fractures created by these experiments did not grow in the direction predicted, probably due to an unanticipated shift in the stress field in the deeper part of the formation (Brown 1997). To provide an adequate connection between the two wells (EE-2 and EE-3), a branch borehole EE-3A was drilled, in September 1985, off from the EE-3 well at 2830 m to a depth of 4018 m. The relative position of EE-3A and EE-3 is shown in Fig. 8f. EE-3A intersected several of the fractures created by the previous hydraulic stimulations (Dash et al. 1989), and in January 1986, another hydraulic stimulation was conducted in well EE-3A to further enhance the reservoir permeability, and a good connection between EE-2 and EE-3A was finally established. More details could be found in Dash et al. (1989).

The Fenton Hill geothermal project reached the granite reservoir with a temperature of 300 °C at 4.4 km depth and provided heat energy to a 60-kW binary cycle power generator. Even though the project was terminated in 1995 due to its inability to reach the expected capacity, it provided critical lessons for later deep geothermal development. The most important lesson learned is that due to the in-situ stress complexity, hydraulic fractures may not propagate as predicted. In particular, a vertical penny-shaped fracture was not observed; rather, fractures occurred around the stimulated borehole as indicated by the observed microseismic clouds. The experiments suggested that the most direct way for EGS development may be one in which one well is drilled first to conduct hydraulic stimulation, and then a second well is drilled and specifically directed to the created fracture zone, as indicated by data on the location of the microseismic event clouds. This would then result in a hydraulic conductivity (permeability) between the two wells high enough to enable a significant flow rate between them (Brown 2009). Results from this case also suggest the following points: (a) for the development of an EGS site, comprehensive seismic surveys and downhole logging and testing should be performed to acquire data about the in-situ stress states and existing natural fracture network (density, orientation, permeability, and spatial distribution); (b) during the hydraulic stimulation, microseismic activities should be monitored and comprehensively recorded, and (c) tracer and hydraulic tests could also be used at detecting the reservoir connectivity, and these test data may be important for evaluation of permeability enhancement and heat extraction performance.

4.1.2 Groß Schönebeck, Germany

The research EGS site at Groß Schönebeck, Germany, was established in 2001 to investigate various techniques for extracting geothermal energy (Huenges et al. 2002). The site was located in the North German Basin, and two wells were drilled into the Lower Permian sedimentary and volcanic layers. The first well “E GrSk 3/90” served as an injection well, and it was a previously abandoned gas exploration well (Zimmermann et al. 2011). The second well Gt GrSk 4/05, was drilled in 2006 to a depth of 4404.4 m. The well path was designed with a deviation between 37° to 49° inclination and reached 48° at the well bottom. This well was designed as a production well, and the bottom distance to the injection well (E GrSk 3/90) was 475 m. The geological conditions of Groß Schönebeck EGS site are shown in Fig. 9a. After the well completion, three consecutive hydraulic stimulations were performed in various depth intervals (Zimmermann and Reinicke 2010; Zimmermann et al. 2010), resulting in a productivity index increase from 4.25 to 10.10 m3/h/MPa in the injection well.

a The schematic map of the Groß Schönebeck site (modified from Zimmermann et al. 2008); b The wellhead pressure and flow rate evolution with time for cyclic injection in Gt GrSk 4/05 well. (modified from Zimmermann et al. 2008); c The monitoring seismic events associated with the hydraulic stimulation in Groß Schönebeck geothermal site. (modified from Kwiatek et al. 2010). The MP0 represents the location of the deep borehole seismometer. The color reflects the hypocentral depth of events. The black arrow shows the migration of seismic events with time. d The calculated fracture distribution after the hydraulic stimulation is based on numerical simulation results. Each curve represented one hour of fracture propagation, and the stress profile was the minimum principal stress. (modified from Zimmermann et al. 2010)

In 2007, the Fatigue Hydraulic Fracturing (FHF) method was applied by cyclic injection in the second well Gt GrSk 4/05 to test its feasibility (Zimmermann et al. 2010). The target reservoir was volcanic rock, and its permeability was mainly fracture-dominated. The proposed plan was to form a hydraulic fracture with a half-length of 150–200 m, fracture height of 80–100 m, and average effective hydraulic aperture of 5–10 mm. The detailed wellhead pressure and flow rate curves are shown in Fig. 9b. During the cyclic injection, the fracture propagation and final distribution were influenced by the flow rate, wellhead pressure, and cycle duration. Horizontal fracture propagation was found to be dominant during high flow rate injections, while low injection rate periods led to an increased fracture aperture. During high flow rate injections, low concentrations of quartz sand were also injected to support the fracture aperture, and a friction-reducing agent was used to avoid high wellhead pressure. In total, 13,170 m3 of water was injected into the reservoir, and results indicated a maximum wellhead pressure of 58.6 MPa when the injection rate reached its maximum value. Figure 9c shows the seismic monitoring result, indicating extremely low seismicity during and after the stimulation. Only 80 events were observed during the six-day fluid injection, with magnitudes ranging from -1.8 to -1.0. Moreover, an estimated fracture distribution after the hydraulic stimulation was calculated by numerical modeling, as shown in Fig. 9d. The simulation results indicated that the final mean fracture aperture was 19.5 mm, and the length and width were 190 m and 90 m, respectively. More details about the numerical simulation can also be found in Zimmermann and Reinicke (2010). The cyclic injection test in well Gt GrSk 4/05 at Groß Schönebeck is a successful attempt to use this advanced injection protocol to increase the reservoir permeability while mitigating the seismic risks. Through a series of in-situ test, cyclic injection may decrease the reservoir breakdown pressure compared to conventional hydraulic fracturing. The total number of seismic events is smaller and the magnitudes of those events are also lower. Moreover, based on production tests after several hydraulic stimulations with gel/proppant, the productivity of Gt GrSk4/05 was found to be lower than expected. It was suggested that this could be the result of a filter cake near the open-hole section caused by drilling fluid, and hence acid stimulation was recommended in the near-wellbore region to improve the performance of well productivity. Finally, the hydraulic stimulation methods and fluid injection protocols should be designed based on site-specific conditions, including the reservoir properties and geological conditions. Moreover, if the natural fractures are not well-developed before the hydraulic fracturing stimulation and the created fracture networks are dominated by tensile fractures, then proppant sand should be added to keep the fracture open in order to maintain a good flow rate in the reservoir.

4.2 Commercial sites

4.2.1 Soultz-sous-Forêts, France

Soultz-sous-Forêts EGS could be regarded as the most successful commercial EGS projects to date. By 2019, the annual electricity production is about 11 GWh/year (Ravier et al. 2019). The site is located in the upper Rhine Graben, as shown in Fig. 10a.

a The location of Soultz geothermal site (modified from Dèzes et al. 2004); b The cross-section map of the Soultz geothermal system (modified from Dezayes and Genter 2008; Hébert et al. 2011; Ledésert and Hébert 2012); c The wellhead pressure (dotted line), the fluid injection rate (solid line), and the rate of induced seismic events (vertical bars) evolution with time for four main hydraulic fracturing stimulation operations in the Soultz EGS project (modified from Baisch et al. 2010)

In 1987, the first well GPK1 was drilled to the depth of 2002 m, with a number of challenging issues, including direction control, circulation loss, pipe stuck, and an overrun budget. The temperature at 2000 m was only about 140 °C, which was lower than expected (Baria et al. 2005). In 1990, an existing oil well EPS1 was deepened from 930 to 2227 m, where the temperature was measured to be near 150 °C (Genter and Traineau 1996). This well was used to characterize the natural fracture systems in the area. Figure 10b shows the cross-sectional map of the Soultz geothermal system (Dezayes and Genter 2008; Hébert et al. 2011; Ledésert and Hébert 2012). Details of the drilling work and the development history of the Soultz EGS project can be found in Baria et al. (1999, 2005), Gérard et al. (1997), and Jung et al. (1996). Since the present review has a focus on hydraulic stimulation strategies, we shall summarize the three stimulation operations that were conducted at Soultz:

(a) After the re-drilling of the GPK2 well in 2000, a hydraulic stimulation operation was performed. A total of 23,400 m3 fluid was injected into the reservoir with the flow rate ranged from 30 to 50 kg/s, and the maximum wellhead pressure reached 14.5 MPa. The detailed injection rate, wellhead pressure, and seismic event rates were shown in Fig. 10c (Baria et al. 2005; Gérard et al. 1997). Results of acoustic events mapping indicated that hydraulic fracturing was well developed over a region 500 m in width and 1000 m in length. Additionally, geophysical logging results indicated a major fracture set, oriented towards N160E, and two secondary fracture sets oriented in N140E and N20E, which contributed to a significant permeability enhancement (Moriya et al. 2003).

(b) From 2001, the GPK3 well was drilled to the depth of 5093 m to reach the fractured zone, which had been previously created by stimulation of well GPK2 in 2000. The distance between the GPK2 and the GPK3 well bottoms was 600 m. An injection test was performed with the GPK3 as the injection well and GPK2 as the production well. The results indicated a productivity index of 3.5 kg/s/MPa, implying an excellent connection between the two wells. Thus, in 2003, hydraulic stimulation was conducted in GPK3 with the injection of ~ 37,000 m3 water into the reservoir. The wellhead pressure, injection rate, and seismic event evolution are shown in Fig. 10c.

(c) An inclined well GPK4 was drilled from 2003 to 2004, reaching 5105 m depth, at a bottom-hole distance of 650 m from the GPK3 well. After the well completion, the GPK4 well was stimulated by injection of heavy brine as the working fluid. However, the results of the stimulation operation were not as good as expected, explainable by the possible presence of a linear aseismic zone separating GPK4 from the two wells, GPK2 and GPK3. Even though acid fracturing was further used, the connection was still limited. The total fluid volume injected into the GPK4 was 22,000 m3. The hydraulic stimulation results of the GPK4 well are shown in Fig. 10c.

Based on the fluid injection history, we can see that conventional hydraulic fracturing was generally used at the Soultz site. For some stimulation operations in GPK2 and GPK3 wells, hydraulic stimulations were successful in creating new fractures connecting the wells as shown by results from acoustic mapping monitoring. However, in some cases, such as the two consecutive hydraulic fracturing stimulation in GPK4, the permeability enhancement was limited. Nevertheless, the Soultz EGS project can perhaps be regarded as one of the most successful EGS system commercially, and furthermore the project provided data from more than 30 years of scientific/technical research, covering petrogeology investigation, well-drilling design, hydraulic fracturing optimization, and seismic monitoring. One important lesson learned is that proper site selection and characterization should be an essential element for the development of an EGS site. The natural fracture system was found to be well-developed in one area (GPK2 and GPK3), where significant permeability enhancement and well connections were accomplished through hydraulic stimulation, while the absence of large critically stressed faults near the site decreased the potential of large earthquakes. However, in some other areas (e.g., near GPK4), the natural fractures are not well-connected, in which case hydraulic stimulation was found to be not so effective and some other stimulation methods would need to be applied to enhance the reservoir permeability.

4.2.2 Cooper Basin, Australia

Inspired by oil and gas drilling results that the temperature at a depth of 4 km reached 250 °C in the Cooper Basin area in Australia (Fig. 11a), the Cooper Basin EGS project was initiated in 2002 (Mills and Humphreys, 2013). The target reservoir was identified as composed of radiogenic granites and uranium-rich rocks (Meixner et al. 2000). The objective of the project was to investigate the EGS feasibility in this area.

a Location of the Cooper Basin EGS site. (modified from Ayling et al. 2016); b The schematic map of the cross-section of the Habanero wells (modified from Holl and Barton 2015); c The wellhead pressure, injection rate, and injectivity evolution with time for the hydraulic fracturing stimulation in Habanero-1 well. (modified from Riffault et al. 2018). The blue line is injection rate and red line is wellhead pressure

The well distribution is shown in Fig. 11b. Well Habanero-1 was finished at a depth of 4421 m, with the bottom-hole temperature of 250 °C. It intersected the granite at a depth of 3668 m and was located near the McLeod-1 well, an oil-exploration well that had previously penetrated the granitic basement. Data indicated that the granite was critically stressed for shear failure, and some of these fractures intersected Habanero-1 with a fluid pressure of 35 MPa. During well drilling, heavy-weight fluids were used to avoid potential mud loss. However, fracture permeability was higher than expected and some fractures slipped, which resulted in massive mud loss during well drilling. Details of the drilling history can be found in Humphreys et al. (2014).

After completing Habanero-1, hydraulic stimulations were performed in the well from November to December 2003 (Garcia-Aristizabal, 2018). The wellhead pressure, flow rate, and injectivity are shown in Fig. 11c. Conventional hydraulic fracturing technique with step injection pulses was used to enhance the reservoir permeability. A total of 20,000 m3 of water was injected into the reservoir at a depth of 4250 m, with the flow rate first increasing from 8.0 L/s to 24.0 L/s, and then, in the third and fourth steps, the wellhead pressure was maintained between 31.0 MPa and 35.0 MPa. The wellhead pressure was found to increase quicker than the injection rate, which indicated that the injectivity decreased, and the permeability enhancement was poor. A total of 10,436 seismic events larger than the magnitude of − 0.8 were recorded during this hydraulic stimulation, and they formed a large planar cloud dipping at 10° to the west direction, with an area of 1000 m times 2000 m and a thickness over 150 m (Kumano et al. 2005; Soma et al. 2004). It was suggested that all these events occurred in a single large fault, which was later confirmed and the fault was named Habanero Fault (Baisch et al. 2006; Bendall et al. 2014).

Besides this hydraulic stimulation in Habanero-1, some other stimulations were performed in other wells in the Cooper Basin (Hogarth et al. 2013a, 2013b; Holl and Barton 2015). Moreover, some injection tests and close-loop flow tests were performed before production operation and more details and results about close-loop and injection tests can be found in the references (Hogarth et al. 2013a, 2013b; Holl and Barton 2015; Hogarth and Bour 2015).

After almost 20 years of planning, drilling, testing, and scientific research concerning the Cooper Basin EGS project, some lessons were summarized by Hogarth and Holl (2017). They pointed out that the natural fracture systems in these granite rocks were likely to be closed, which means that the natural fractures are isolated from the general fluid flow in the domain. However, upon hydraulic stimulation, they were hydraulically connected and thus the reservoir permeability was enhanced. Moreover, the pre-existing natural fractures/faults that experienced high slip during the stimulation stage may serve as the main fluid channels and paths. It is suggested that, for a potential EGS site, the in-situ stress state should be carefully investigated since it plays a dominant role in hydraulic fracture propagation. Also, a comprehensive identification of critically stressed fractures/faults is important for efforts to mitigate induced seismic risks. Finally, it is suggested that induced seismicity cannot be totally avoided during long-term hydraulic stimulation and fluid circulation in a successful EGS project. Thus, a proper design of fluid injection strategy is crucial in reducing seismic potential and lowering the maximum magnitude of seismic events.

4.3 Suspended (or terminated) EGS sites

4.3.1 Basel, Switzerland

The Basel EGS project is located at the south-eastern end of the Rhine Graben, Switzerland, as shown in Fig. 12a. Geological investigation indicated a north-northwest trending compression and a west-northwest extension making this area a seismically active environment (Dèzes et al. 2004; Laubscher 2001). The first exploration well, Otterbach2, was drilled to the depth of 2755 m to be used for recording regional seismic events (Hölker and Graf 2005). Then, Basel 1 well was drilled from May to October 2006 to the depth of 5000 m, and it crossed the sedimentary rocks at a depth of 2400 m and the granitic basement at a depth of 2600 m. The bottom of the wellbore reached a temperature of about 200 °C (Wyss and Rybach, 2010). An acoustic borehole imager was used to identify natural fractures from 2557 to 5000 m depth, and a total of 984 natural fractures were found near the borehole (Vidal and Genter 2018; Ziegler et al. 2015). Before hydraulic stimulation of Basel 1 well, an injection test was performed to characterize the hydraulic properties of pre-existing natural fractures. The results yielded a value of effective permeability of 1 × 10–17 m2 (Bourdet 2002), and the reservoir permeability was found to be dominated by a few major fractures in the open hole section.

a The location of Basel EGS site and topographic map of Switzerland and surrounding regional seismic stations. (modified from Deichmann and Giardini 2009); b Lithological sequence along the Basel-1 borehole modified after c The evolution of injection rates, wellhead pressure, triggered event rates, and earthquake magnitude during hydraulic stimulation. (modified from Ladner and Häring 2009; Häring et al. 2008).