Abstract

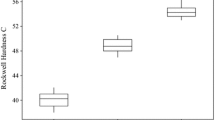

This paper presents the development of mathematical, predictive and optimization models of average surface roughness parameter (\(R_{a}\)) in turning hardened AISI 1060 steel using coated carbide tool in dry condition. Herein, the mathematical model is formulated by response surface methodology (RSM), predictive model by fuzzy inference system (FIS), and optimization model by simulated annealing (SA) technique. For all these models, the cutting speed, feed rate and material hardness were considered as input factors for full factorial experimental design plan. After the experimental runs, the collected data are used for model development and its subsequent validation. It was found, by statistical analysis, that the quadratic model is suggested for \(R_{a}\) in RSM. The adequacy of the models was checked by error analysis and validation test. Furthermore, the constructed model was compared with an analytical model. The analysis of variance revealed that the material hardness exerts the most dominant effect, followed by the feed rate and then cutting speed. Eventually, the RSM model was found with a coefficient of determination value of 99.64%; FIS model revealed 79.82% prediction accuracy; and SA model resulted in more than 70% improved surface roughness. Therefore, these models can be used in industries to effectively control the hard turning process to achieve a good surface quality.

Similar content being viewed by others

References

Mia, M.; Dhar, N.R.: Optimization of surface roughness and cutting temperature in high-pressure coolant-assisted hard turning using Taguchi method. Int. J. Adv. Manuf. Technol. 88(1), 739–753 (2017). doi:10.1007/s00170-016-8810-2

Chinchanikar, S.; Choudhury, S.: Machining of hardened steel—experimental investigations, performance modeling and cooling techniques: a review. Int. J. Mach. Tools Manuf. 89, 95–109 (2015)

Sahoo, A.; Rout, A.; Das, D.: Response surface and artificial neural network prediction model and optimization for surface roughness in machining. Int. J. Ind. Eng. Comput. 6(2), 229–240 (2015)

Mia, M.; Khan, M.A.; Dhar, N.R.: Performance prediction of high-pressure coolant assisted turning of Ti–6Al–4V. Int. J. Adv. Manuf. Technol. 90(5), 1433–1445 (2017). doi:10.1007/s00170-016-9468-5

Mia, M.; Razi, M.H.; Ahmad, I.; Mostafa, R.; Rahman, S.M.S.; Ahmed, D.H.; Dey, P.R.; Dhar, N.R.: Effect of time-controlled MQL pulsing on surface roughness in hard turning by statistical analysis and artificial neural network. Int. J. Adv. Manuf. Technol. (2017). doi:10.1007/s00170-016-9978-1

Singh, D.; Rao, P.V.: A surface roughness prediction model for hard turning process. Int. J. Adv. Manuf. Technol. 32(11–12), 1115–1124 (2007)

Pawade, R.S.; Joshi, S.S.: Multi-objective optimization of surface roughness and cutting forces in high-speed turning of Inconel 718 using Taguchi grey relational analysis (TGRA). Int. J. Adv. Manuf. Technol. 56(1–4), 47–62 (2011)

Bouacha, K.; Yallese, M.A.; Khamel, S.; Belhadi, S.: Analysis and optimization of hard turning operation using cubic boron nitride tool. Int. J. Refract. Met. Hard Mater. 45, 160–178 (2014)

Hamdan, A.; Sarhan, A.A.; Hamdi, M.: An optimization method of the machining parameters in high-speed machining of stainless steel using coated carbide tool for best surface finish. Int. J. Adv. Manuf. Technol. 58(1–4), 81–91 (2012)

Aouici, H.; Yallese, M.A.; Chaoui, K.; Mabrouki, T.; Rigal, J.-F.: Analysis of surface roughness and cutting force components in hard turning with CBN tool: prediction model and cutting conditions optimization. Measurement 45(3), 344–353 (2012)

Sahin, Y.; Motorcu, A.: Surface roughness model in machining hardened steel with cubic boron nitride cutting tool. Int. J. Refract. Met. Hard Mater. 26(2), 84–90 (2008)

Barzani, M.M.; Zalnezhad, E.; Sarhan, A.A.; Farahany, S.; Ramesh, S.: Fuzzy logic based model for predicting surface roughness of machined Al–Si–Cu–Fe die casting alloy using different additives-turning. Measurement 61, 150–161 (2015)

Sarhan, A.A.; El-Tayeb, N.: Investigating the surface quality of the burnished brass C3605—fuzzy rule-based approach. Int. J. Adv. Manuf. Technol. 71(5–8), 1143–1150 (2014)

Rajasekaran, T.; Palanikumar, K.; Vinayagam, B.: Application of fuzzy logic for modeling surface roughness in turning CFRP composites using CBN tool. Prod. Eng. 5(2), 191–199 (2011)

Hessainia, Z.; Belbah, A.; Yallese, M.A.; Mabrouki, T.; Rigal, J.-F.: On the prediction of surface roughness in the hard turning based on cutting parameters and tool vibrations. Measurement 46(5), 1671–1681 (2013)

Bouacha, K.; Yallese, M.A.; Mabrouki, T.; Rigal, J.-F.: Statistical analysis of surface roughness and cutting forces using response surface methodology in hard turning of AISI 52100 bearing steel with CBN tool. Int. J. Refract. Met. Hard Mater. 28(3), 349–361 (2010)

Asokan, P.; Saravanan, R.; Vijayakumar, K.: Machining parameters optimisation for turning cylindrical stock into a continuous finished profile using genetic algorithm (GA) and simulated annealing (SA). Int. J. Adv. Manuf. Technol. 21(1), 1–9 (2003)

Chen, M.-C.; Tsai, D.-M.: A simulated annealing approach for optimization of multi-pass turning operations. Int. J. Prod. Res. 34(10), 2803–2825 (1996)

Khan, M.A.; Mia, M.; Dhar, N.R.: High-pressure coolant on flank and rake surfaces of tool in turning of Ti–6Al–4V: investigations on forces, temperature, and chips. Int. J. Adv. Manuf. Technol. 90(5), 1977–1991 (2017). doi:10.1007/s00170-016-9511-6

Mia, M.; Khan, M.A.; Dhar, N.R.: High-pressure coolant on flank and rake surfaces of tool in turning of Ti–6Al–4V: investigations on surface roughness and tool wear. Int. J. Adv. Manuf. Technol. 90(5), 1825–1834 (2017). doi:10.1007/s00170-016-9512-5

Mia, M.; Khan, M.A.; Rahman, S.S.; Dhar, N.R.: Mono-objective and multi-objective optimization of performance parameters in high pressure coolant assisted turning of Ti–6Al–4V. Int. J. Adv. Manuf. Technol. 90(1), 109–118 (2017). doi:10.1007/s00170-016-9372-z

Mia, M.; Bashir, M.A.; Khan, M.A.; Dhar, N.R.: Optimization of MQL flow rate for minimum cutting force and surface roughness in end milling of hardened steel (HRC 40). Int. J. Adv. Manuf. Technol. 89(1), 675–690 (2017). doi:10.1007/s00170-016-9080-8

Mia, M.; Khan, M.A.; Dhar, N.R.: Study of surface roughness and cutting forces using ANN, RSM, and ANOVA in turning of Ti-6Al-4V under cryogenic jets applied at flank and rake faces of coated WC tool. Int. J. Adv. Manuf. Technol. (2017). doi:10.1007/s00170-017-0566-9

Montgomery, D.C.: Design and Analysis of Experiments. Wiley, New York (2008)

Sivanandam, S.; Sumathi, S.; Deepa, S.: Introduction to Fuzzy Logic Using MATLAB, vol. 1. Springer, Berlin (2007)

Zadeh, L.A.: Fuzzy Sets, Fuzzy Logic, and Fuzzy Systems: Selected Papers by Lotfi A Zadeh, vol. 6. World Scientific, Singapore (1996)

Mamdani, E.H.; Assilian, S.: An experiment in linguistic synthesis with a fuzzy logic controller. Int. J. Man Mach. Stud. 7(1), 1–13 (1975)

Tamiloli, N.; Venkatesan, J.; Ramnath, B.V.: A grey-fuzzy modeling for evaluating surface roughness and material removal rate of coated end milling insert. Measurement 84, 68–82 (2016)

Hwang, C.-R.: Simulated annealing: theory and applications. Acta Appl. Math. 12(1), 108–111 (1988)

Romeijn, H.E.; Smith, R.L.: Simulated annealing for constrained global optimization. J. Global Optim. 5(2), 101–126 (1994)

Hedar, A.-R.; Fukushima, M.: Hybrid simulated annealing and direct search method for nonlinear unconstrained global optimization. Optim. Methods Softw. 17(5), 891–912 (2002)

Kirkpatrick, S.: Optimization by simulated annealing: quantitative studies. J. Stat. Phys. 34(5–6), 975–986 (1984)

Mia, M.; Dhar, N.R.: Response surface and neural network based predictive models of cutting temperature in hard turning. J. Adv. Res. 7(6), 1035–1044 (2016)

Azam, M.; Jahanzaib, M.; Wasim, A.; Hussain, S.: Surface roughness modeling using RSM for HSLA steel by coated carbide tools. Int. J. Adv. Manuf. Technol. 78(5–8), 1031–1041 (2014)

Mia, M.; Dhar, N.R.: Prediction of surface roughness in hard turning under high pressure coolant using Artificial Neural Network. Measurement 92, 464–474 (2016)

Schultheiss, F.; Johansson, D.; Bushlya, V.; Zhou, J.; Nilsson, K.; Ståhl, J.-E.: Comparative study on the machinability of lead-free brass. J. Clean. Prod. 149, 366–377 (2017)

Ståhl, J.-E.; Schultheiss, F.; Hägglund, S.: Analytical and experimental determination of the Ra surface roughness during turning. Proced. Eng. 19, 349–356 (2011)

Thiele, J.D.; Melkote, S.N.: Effect of cutting edge geometry and workpiece hardness on surface generation in the finish hard turning of AISI 52100 steel. J. Mater. Process. Technol. 94(2), 216–226 (1999)

Acknowledgements

The authors are grateful to Directorate of Advisory Extension and Research Services (DAERS), BUET, Bangladesh, for providing research fund, Sanction No. DAERS/CASR/R-01/2013/DR-2103 (92) dated 23/08/2014, and the Department of Industrial and Production Engineering, BUET, Dhaka, Bangladesh, for providing laboratory facility to carry out the research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mia, M., Dhar, N.R. Modeling of Surface Roughness Using RSM, FL and SA in Dry Hard Turning. Arab J Sci Eng 43, 1125–1136 (2018). https://doi.org/10.1007/s13369-017-2754-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-017-2754-1