Abstract

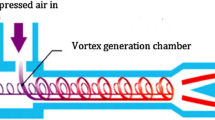

An experimental investigation has been performed in turning of Ti-6Al-4V by using coated carbide tool employed under dry condition and pressurized coolant at the flank and rake surfaces concurrently. To impinge coolant in this manner, customized nozzle was designed and fabricated. As part of the study, the cutting force, feed force, cutting temperature, and chip characteristics were explored as quality indices at varied speed and feed. To do so, the cutting forces and temperature were measured by using a robust 3D dynamometer and tool-work thermocouple, respectively. Apart from experimental investigation, the role of each factor was quantified by the statistical analysis of variance; consequently, it was revealed that the high-pressure coolant exerted a significant impact on all the responses. Results showed that the effective cooling and lubrication were achieved by the coolant jets; this reduced the cutting forces and temperature. In addition, the shortened chip-tool contact length and jet activated wedge effect contributed to the improved machining performance. Nevertheless, the chip breakability was not favorable which can be attributed to the low pressure of the supplied coolant.

Similar content being viewed by others

References

Nandy A, Gowrishankar M, Paul S (2009) Some studies on high-pressure cooling in turning of Ti–6Al–4V. Int J Mach Tools Manuf 49(2):182–198

Su Y, He N, Li L, Li X (2006) An experimental investigation of effects of cooling/lubrication conditions on tool wear in high-speed end milling of Ti-6Al-4V. Wear 261(7):760–766

Mia M, Khan MA, Rahman SS, Dhar NR (2016) Mono-objective and multi-objective optimization of performance parameters in high pressure coolant assisted turning of Ti-6Al-4V. Int J Adv Manuf Technol:1–10. doi:10.1007/s00170-016-9372-z

Ezugwu E, Bonney J, Yamane Y (2003) An overview of the machinability of aeroengine alloys. J Mater Process Technol 134(2):233–253

Hong SY, Ding Y (2001) Cooling approaches and cutting temperatures in cryogenic machining of Ti-6Al-4V. Int J Mach Tools Manuf 41(10):1417–1437

Sharma VS, Dogra M, Suri N (2009) Cooling techniques for improved productivity in turning. Int J Mach Tools Manuf 49(6):435–453

Palanisamy S, McDonald SD, Dargusch MS (2009) Effects of coolant pressure on chip formation while turning Ti6Al4V alloy. Int J Mach Tools Manuf 49(9):739–743

Diniz AE, Micaroni R (2007) Influence of the direction and flow rate of the cutting fluid on tool life in turning process of AISI 1045 steel. Int J Mach Tools Manuf 47(2):247–254

Wertheim R, Rotberg J, Ber A (1992) Influence of high-pressure flushing through the rake face of the cutting tool. CIRP Annals-Manufacturing Technology 41(1):101–106

Ezugwu E, Bonney J (2005) Finish machining of nickel-base Inconel 718 alloy with coated carbide tool under conventional and high-pressure coolant supplies. Tribol Trans 48(1):76–81

Mazurkiewicz M, Kubala Z, Chow J (1989) Metal machining with high-pressure water-jet cooling assistance—a new possibility. Journal of Engineering for Industry 111(1):7–12

Ezugwu E (2005) Key improvements in the machining of difficult-to-cut aerospace superalloys. Int J Mach Tools Manuf 45(12):1353–1367

Naves V, Da Silva M, Da Silva F (2013) Evaluation of the effect of application of cutting fluid at high pressure on tool wear during turning operation of AISI 316 austenitic stainless steel. Wear 302(1):1201–1208

Mia M, Khan MA, Dhar NR (2016) High pressure coolant on flank and rake surfaces of tool in turning of Ti-6Al-4V: investigations on surface roughness and tool wear. International Journal of Advanced Manufacturing Technology doi: 10.1007/s00170-016-9512-5

Ezugwu E, Bonney J, Fadare D, Sales W (2005) Machining of nickel-base, Inconel 718, alloy with ceramic tools under finishing conditions with various coolant supply pressures. J Mater Process Technol 162:609–614

Mia M, Dhar NR (2016) Response surface and neural network based predictive models of cutting temperature in hard turning. J Adv Res. doi:10.1016/j.jare.2016.05.004

Mia M, Dhar NR (2016) Prediction of surface roughness in hard turning under high pressure coolant using Artificial Neural Network. Measurement 92:464–474

Klocke F, Sangermann H, Krämer A, Lung D (2011) Influence of a high-pressure lubricoolant supply on thermo-mechanical tool load and tool wear behaviour in the turning of aerospace materials. Proc Inst Mech Eng B J Eng Manuf 225(1):52–61

Ezugwu E, Bonney J (2004) Effect of high-pressure coolant supply when machining nickel-base, Inconel 718, alloy with coated carbide tools. J Mater Process Technol 153:1045–1050

Ezugwu EO, Bonney J, Da Silva RB, Cakir O (2007) Surface integrity of finished turned Ti–6Al–4V alloy with PCD tools using conventional and high pressure coolant supplies. Int J Mach Tools Manuf 47(6):884–891

Kumar AS, Rahman M, Ng S (2002) Effect of high-pressure coolant on machining performance. Int J Adv Manuf Technol 20(2):83–91

Islam AK, Mia M, Dhar NR (2016) Effects of internal cooling by cryogenic on the machinability of hardened steel. Int J Adv Manuf Technol:1–10. doi:10.1007/s00170-016-9373-y

Kramar D, Krajnik P, Kopac J (2010) Capability of high pressure cooling in the turning of surface hardened piston rods. J Mater Process Technol 210(2):212–218

da Silva RB, Machado ÁR, Ezugwu EO, Bonney J, Sales WF (2013) Tool life and wear mechanisms in high speed machining of Ti–6Al–4V alloy with PCD tools under various coolant pressures. J Mater Process Technol 213(8):1459–1464

de Angelo Sanchez LE, Palma GL, Marinescu I, Modolo DL, Nalon LJ, Santos AE (2013) Effect of different methods of cutting fluid application on turning of a difficult-to-machine steel (SAE EV-8. Proc Inst Mech Eng B J Eng Manuf 227(2):220–234

Mia M, Dhar NR (2016) Optimization of surface roughness and cutting temperature in high-pressure coolant-assisted hard turning using Taguchi method. Int J Adv Manuf Technol. doi:10.1007/s00170-016-8810-2

Crafoord R, Kaminski J, Lagerberg S, Ljungkrona O, Wretland A (1999) Chip control in tube turning using a high-pressure water jet. Proc Inst Mech Eng B J Eng Manuf 213(8):761–767

Kaminski J, Alvelid B (2000) Temperature reduction in the cutting zone in water-jet assisted turning. J Mater Process Technol 106(1):68–73

Moura RR, da Silva MB, Machado ÁR, Sales WF (2015) The effect of application of cutting fluid with solid lubricant in suspension during cutting of Ti-6Al-4V alloy. Wear 332:762–771

Machado A, Wallbank J, Pashby I, Ezugwu E (1998) Tool performance and chip control when machining Ti6A14V and Inconel 901 using high pressure coolant supply. Mach Sci Technol 2(1):1–12

Ezugwu E, Wang Z (1997) Titanium alloys and their machinability—a review. J Mater Process Technol 68(3):262–274

De Lacalle LL, Perez-Bilbatua J, Sánchez J, Llorente J, Gutierrez A, Albóniga J (2000) Using high pressure coolant in the drilling and turning of low machinability alloys. Int J Adv Manuf Technol 16(2):85–91

Komanduri R, Von Turkovich B (1981) New observations on the mechanism of chip formation when machining titanium alloys. Wear 69(2):179–188

Koné F, Czarnota C, Haddag B, Nouari M (2013) Modeling of velocity-dependent chip flow angle and experimental analysis when machining 304L austenitic stainless steel with groove coated-carbide tools. J Mater Process Technol 213(7):1166–1178

Moufki A, Molinari A (2005) A new thermomechanical model of cutting applied to turning operations. Part II. Parametric study. Int J Mach Tools Manuf 45(2):181–193

Smart E, Trent E (1975) Temperature distribution in tools used for cutting iron, titanium and nickel. The International Journal of Production Research 13(3):265–290

An Q, Fu Y, Xu J (2011) Experimental study on turning of TC9 titanium alloy with cold water mist jet cooling. Int J Mach Tools Manuf 51(6):549–555

Courbon C, Kramar D, Krajnik P, Pusavec F, Rech J, Kopac J (2009) Investigation of machining performance in high-pressure jet assisted turning of Inconel 718: an experimental study. Int J Mach Tools Manuf 49(14):1114–1125

Mia M, Dhar NR (2015) Effect of high pressure coolant jet on cutting temperature, tool wear and surface finish in turning hardened (HRC 48) steel. Journal of Mechanical Engineering 45(1):1–6

Chiappini E, Tirelli S, Albertelli P, Strano M, Monno M (2014) On the mechanics of chip formation in Ti–6Al–4V turning with spindle speed variation. Int J Mach Tools Manuf 77:16–26

Sharman A, Hughes J, Ridgway K (2008) Surface integrity and tool life when turning Inconel 718 using ultra-high pressure and flood coolant systems. Proc Inst Mech Eng B J Eng Manuf 222(6):653–664

Ezugwu E, Machado A, Pashby I, Wallbank J (1991) The effect of high-pressure coolant supply when machining a heat-resistant nickel-based superalloy. Lubr Eng 47(9):751–757

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khan, M.A., Mia, M. & Dhar, N.R. High-pressure coolant on flank and rake surfaces of tool in turning of Ti-6Al-4V: investigations on forces, temperature, and chips. Int J Adv Manuf Technol 90, 1977–1991 (2017). https://doi.org/10.1007/s00170-016-9511-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9511-6