Abstract

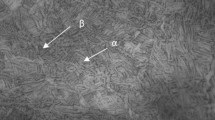

In this work, the surface quality and tool behavior have been investigated. The experiment was conducted by turning Ti-6Al-4V alloy using coated carbide tool wherein the cutting conditions were dry and high-pressure coolant (HPC). Using specially designed nozzle system, the pressurized coolant was directed towards the rake and flank surfaces of the tool. The quality of the machined surfaces was examined in respect of different cutting speed and feed rate, whereas the tool life (and wear) was determined in terms of machining time. Moreover, the tool wear was scrutinized by scanning electronic microscopic (SEM) images of the worn out inserts. The improvement of surface finish, achieved as result, by HPC is attributed to the effective cooling and lubrication, low-material adhesion, reduced chip rubbing, and elimination of built-up edge. Furthermore, the applied coolant prolonged tool life by approximately 40 %. SEM images revealed that the crater and notch wear in dry cutting whilst exorbitant rubbing over rake and abrasion on flank surface in HPC-assisted turning were the dominant wear mechanisms. Overall, the HPC with double jets is found suitable for turning titanium alloy in respect of surface finish and tool performance.

Similar content being viewed by others

References

Nandy A, Gowrishankar M, Paul S (2009) Some studies on high-pressure cooling in turning of Ti–6Al–4V. Int J Mach Tools Manuf 49(2):182–198

Moura RR, da Silva MB, Machado ÁR, Sales WF (2015) The effect of application of cutting fluid with solid lubricant in suspension during cutting of Ti-6Al-4V alloy. Wear 332:762–771

Ezugwu E, Bonney J, Da Silva R, Machado A, Ugwoha E (2009) High productivity rough turning of Ti-6Al-4V alloy, with flood and high-pressure cooling. Tribol Trans 52(3):395–400

Ezugwu E, Bonney J (2005) Finish machining of nickel-base Inconel 718 alloy with coated carbide tool under conventional and high-pressure coolant supplies. Tribol Trans 48(1):76–81

Ezugwu EO, Bonney J, Da Silva RB, Cakir O (2007) Surface integrity of finished turned Ti–6Al–4V alloy with PCD tools using conventional and high pressure coolant supplies. Int J Mach Tools Manuf 47(6):884–891

da Silva RB, Machado ÁR, Ezugwu EO, Bonney J, Sales WF (2013) Tool life and wear mechanisms in high speed machining of Ti–6Al–4V alloy with PCD tools under various coolant pressures. J Mater Process Technol 213(8):1459–1464

Ayed Y, Germain G, Ammar A, Furet B (2015) Tool wear analysis and improvement of cutting conditions using the high-pressure water-jet assistance when machining the Ti17 titanium alloy. Precis Eng 42:294–301

Mia M, Khan MA, Dhar NR (2016) Performance prediction of high pressure coolant assisted turning of Ti-6Al-4V. Int J Adv Manuf Technol. doi:10.1007/s00170-016-9468-5

Mia M, Khan MA, Rahman SS, Dhar NR (2016) Mono-objective and multi-objective optimization of performance parameters in high pressure coolant assisted turning of Ti-6Al-4V. Int J Adv Manuf Technol:1–10. doi:10.1007/s00170–016-9372-z

Ezugwu E, Bonney J (2004) Effect of high-pressure coolant supply when machining nickel-base, Inconel 718, alloy with coated carbide tools. J Mater Process Technol 153:1045–1050

Sharman A, Hughes J, Ridgway K (2008) Surface integrity and tool life when turning Inconel 718 using ultra-high pressure and flood coolant systems. Proc Inst Mech Eng B J Eng Manuf 222(6):653–664

Vagnorius Z, Sørby K (2011) Effect of high-pressure cooling on life of SiAlON tools in machining of Inconel 718. Int J Adv Manuf Technol 54(1–4):83–92

Ezugwu E, Bonney J, Fadare D, Sales W (2005) Machining of nickel-base, Inconel 718, alloy with ceramic tools under finishing conditions with various coolant supply pressures. J Mater Process Technol 162:609–614

Courbon C, Kramar D, Krajnik P, Pusavec F, Rech J, Kopac J (2009) Investigation of machining performance in high-pressure jet assisted turning of Inconel 718: an experimental study. Int J Mach Tools Manuf 49(14):1114–1125

Kumar AS, Rahman M, Ng S (2002) Effect of high-pressure coolant on machining performance. Int J Adv Manuf Technol 20(2):83–91

Mia M, Dhar NR (2015) Effect of high pressure coolant jet on cutting temperature, tool wear and surface finish in turning hardened (HRC 48) steel. Journal of Mechanical Engineering 45(1):1–6

Naves V, Da Silva M, Da Silva F (2013) Evaluation of the effect of application of cutting fluid at high pressure on tool wear during turning operation of AISI 316 austenitic stainless steel. Wear 302(1):1201–1208

Kramar D, Krajnik P, Kopac J (2010) Capability of high pressure cooling in the turning of surface hardened piston rods. J Mater Process Technol 210(2):212–218

Diniz AE, Micaroni R (2007) Influence of the direction and flow rate of the cutting fluid on tool life in turning process of AISI 1045 steel. Int J Mach Tools Manuf 47(2):247–254

Mia M, Al Bashir M, Dhar NR (2016) Effects of cutting parameters and machining environments on surface roughness in hard turning using design of experiment. In: International conference on mechanical engineering: Proceedings of the 11th International Conference on Mechanical Engineering (ICME 2015). AIP Publishing, p 060012. doi:10.1063/1.4958453

Mia M, Dhar NR (2016) Response surface and neural network based predictive models of cutting temperature in hard turning. J Adv Res. doi:10.1016/j.jare.2016.05.004

Mia M, Dhar NR (2016) Prediction of surface roughness in hard turning under high pressure coolant using Artificial Neural Network. Measurement. doi:10.1016/j.measurement.2016.06.048

Gu J, Barber G, Tung S, R-J G (1999) Tool life and wear mechanism of uncoated and coated milling inserts. Wear 225:273–284

Islam AK, Mia M, Dhar NR (2016) Effects of internal cooling by cryogenic on the machinability of hardened steel. Int J Adv Manuf Technol:1–10. doi:10.1007/s00170–016-9373-y

Khan MA, Mia M, Dhar NR (2016) High pressure coolant on flank and rake surfaces of tool in turning of Ti-6Al-4V: Investigations on forces, temperature and chips. Int J Adv Manuf Technol. doi:10.1007/s00170-016-9511-6

Mia M, Dhar NR (2016) Optimization of surface roughness and cutting temperature in high-pressure coolant-assisted hard turning using Taguchi method. Int J Adv Manuf Technol:1–15. doi:10.1007/s00170-016-8810-2

Dahlman P, Escursell M (2004) High-pressure jet-assisted cooling: a new possibility for near net shape turning of decarburized steel. Int J Mach Tools Manuf 44(1):109–115

Courbon C, Sajn V, Kramar D, Rech J, Kosel F, Kopac J (2011) Investigation of machining performance in high pressure jet assisted turning of Inconel 718: a numerical model. J Mater Process Technol 211(11):1834–1851

Crafoord R, Kaminski J, Lagerberg S, Ljungkrona O, Wretland A (1999) Chip control in tube turning using a high-pressure water jet. Proc Inst Mech Eng B J Eng Manuf 213(8):761–767

Kaminski J, Alvelid B (2000) Temperature reduction in the cutting zone in water-jet assisted turning. J Mater Process Technol 106(1):68–73

de Oliveira AJ, Diniz AE, Ursolino DJ (2009) Hard turning in continuous and interrupted cut with PCBN and whisker-reinforced cutting tools. J Mater Process Technol 209(12):5262–5270

Ueda T, Al Huda M, Yamada K, Nakayama K, Kudo H (1999) Temperature measurement of CBN tool in turning of high hardness steel. CIRP Annals-Manufacturing Technology 48(1):63–66

Venugopal K, Paul S, Chattopadhyay A (2007) Growth of tool wear in turning of Ti-6Al-4V alloy under cryogenic cooling. Wear 262(9):1071–1078

Venugopal K, Paul S, Chattopadhyay A (2007) Tool wear in cryogenic turning of Ti-6Al-4V alloy. Cryogenics 47(1):12–18

Venugopal K, Tawade R, Prashanth P, Paul S, Chattopadhyay A (2003) Turning of titanium alloy with TiB2-coated carbides under cryogenic cooling. Proc Inst Mech Eng B J Eng Manuf 217(12):1697–1707

Poulachon G, Bandyopadhyay B, Jawahir I, Pheulpin S, Seguin E (2004) Wear behavior of CBN tools while turning various hardened steels. Wear 256(3):302–310

Mia M, Al Bashir M, Dhar NR (2016) Modeling of principal flank wear: an empirical approach combining the effect of tool, environment and workpiece hardness. J Inst Eng (India): Series C:1–10. doi:10.1007/s40032-016-0262-9

Dearnley P, Grearson A (1986) Evaluation of principal wear mechanisms of cemented carbides and ceramics used for machining titanium alloy IMI 318. Mater Sci Technol 2(1):47–58

More AS, Jiang W, Brown W, Malshe AP (2006) Tool wear and machining performance of cBN–TiN coated carbide inserts and PCBN compact inserts in turning AISI 4340 hardened steel. J Mater Process Technol 180(1):253–262

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mia, M., Khan, M.A. & Dhar, N.R. High-pressure coolant on flank and rake surfaces of tool in turning of Ti-6Al-4V: investigations on surface roughness and tool wear. Int J Adv Manuf Technol 90, 1825–1834 (2017). https://doi.org/10.1007/s00170-016-9512-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9512-5