Abstract

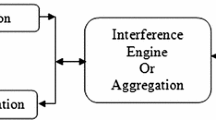

In this work, prediction of burnished surface roughness (R a) is achieved by using a fuzzy rule-based system. The process state variables used were burnishing speed, feed, and depth. The fuzzy rule-based system has achieved an accuracy of 95.4 % to predict the burnished surface roughness and proved to be convenient in terms of least computational complexity and dealing with nonlinear data such as that obtained in this work.

Similar content being viewed by others

References

El-Tayeb NSM, K. O. Low, Brevern PV (2007) Influence of roller burnishing contact width and burnishing orientation on surface quality and tribological behavior of Aluminum 6061. J Mater Process Technol 186:272–278

luca L, Neagu-Ventzel S, Marinescu I (2005) Effects of working parameters on surface finish in ball-burnishing of hardened steels. Pre Eng 29:253–256

Lin YC, Yan BH, Huang FY (2001) Surface improvement using a combination of electrical discharge machining with ball burnish machining based on the Taguchi Method. Int J Adv Manuf Technol 18(9):673–682

K. O. LOW (2011) Surface characteristics modification of polyoxymethylene and polyurethane using burnishing. Tribol Trans 54(1):96–103

Hua W, Man YJ, Liu B (2008) Contact force studies of a burnishing slider. Tri Int 41:60–66

Masmiati N, Sarhan AAD, Hamdi M (2012) “Optimizing the cutting parameters for better surface quality in 2.5D cutting utilizing titanium coated carbide ball end mill.” Int J Precis Eng Manuf 13(12):2097–2102

Korzynski M (2007) Modeling and experimental validation of the force-surface roughness relation for smoothing burnishing with a spherical tool. Int J Mach Tools Manuf 471:1956–1964

El-Tayeb NSM, K.O. Low, Brevern PV (2006) Enhancement of surface quality and tribological properties using ball burnishing process. Mach Sci Technol (JMST) 12(2):234–248

Luo H, Liu J, Wang L, Zhong Q (2006) The effect of burnishing parameters on burnishing force and surface microhardness. Int J Adv Manuf Technol 28(7–8):707–713

El-Tayeb NSM, K.O. Low, Brevern PV (2009) On the surface and tribological characteristics of burnished cylindrical Al-6061. Tribo Int 42(2):320–326

El-Tayeb NSM, K.O. Low, Brevern PV (2008) “The influence of roller burnishing process on hardness and roughness of cylindrical polymer surfaces,” IMechE 2008, Proc. IMechE Vol. 222 Part J: J. Eng Tribol. pp 947–955

K. O. Low, El-Tayeb NSM, Brevern PV, Chong FM (2009) Study on the scratch hardness and indentation hardness of burnished poly(oxymethylene) surfaces. Tribol Trans 52(2):197–203

Gharbi F, Sghaier S, Hamdi H, Benameur T (2012) Ductility improvement of aluminum 1050A rolled sheet by a newly designed ball burnishing tool device. Int J Adv Manuf Technol 60(1–4):87–99

Moshkovich A, Perfilyev V, Yutujyan K, Rapoport L (2007) Friction and wear of solid lubricant films deposited by different types of burnishing. Wear 263:1324–1327

Man YJ, Sk Y, Liu B (2006) Characterization and formation mechanism understanding of asperities to be burnished. J M M Mater 303:101–105

Kohlia AK, Prakashb B (2001) Contact pressure dependency in frictional behavior of burnished molybdenum disulphide coatings. Tribol Trans 44(1):147–151

Némat M, Lyons AC (2000) An investigation of the surface topography of ball burnished mild steel and aluminium. Int J Adv Manuf Technol 16(7):469–473

El-Axir MH, Othman OM, Abodiena AM (2008) Study on the inner surface finishing of aluminum alloy 2014 by ball burnishing process. J Mater Process Technol 202:435–442

El-Axir MH, Othman OM, Abodiena AM (2008) Improvements in out-of-roundness and microhardness of inner surfaces by internal ball burnishing process. J Mater Process Technol 196:120–128

Fusaro RL (1977) Graphite fluoride lubrication: the effect of fluorine content, atmosphere, and burnishing technique. A S L E Trans 20(1):15–24

Sayuti M, Sarhan AAD, Tanaka T, Hamdi M, Saito Y (2013) "Cutting force reduction and surface quality improvement in machining of aerospace duralumin AL-2017-T4 using carbon onion nanolubrication system." Int J Adv Manuf Technol 65(9–12):1493–1500

Sonar DK, Dixit US, Ojha DK (2006) The application of radial basis function neural network for predicting the surface roughness in a turning process. Int J Adv Manuf Technol 27:661–666

Shamshirband S, Kalantari S, Bakhshandeh Z (2010) Designing a smart multi-agent system based on fuzzy logic to improve the gas consumption pattern. Sci Res Essays 5(6):592–605

Jaya ASM, Hashim SZM, Abd Rahman MN (2010) “Fuzzy logic-based for predicting roughness performance of TiN COATING,” 2010 10th International Conference on Intelligent Systems Design and Applications, 978, 1, pp. 4244–8136, IEEE

Leung RWK, Lau HCW, Kwong CK (2003) An expert system to support the optimization of ion plating process: an OLAP-based fuzzy-cum-GA approach. Expert Syst Appl 25:313–330

Oktem H, Erzurumlu T, Erzinchanli F (2006) Prediction of minimum surface roughness in end milling mold part using neural network and genetic algorithms. Int J Mater Des 27:735–744

Luo H, Liu J, Wang L, Zhong Q (2005) Investigation of the burnishing process with PCD tool on non-ferrous metals. Int J Adv Manuf Technol 25(5–6):454–459

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sarhan, A.A.D., El-Tayeb, N.S.M. Investigating the surface quality of the burnished brass C3605—fuzzy rule-based approach. Int J Adv Manuf Technol 71, 1143–1150 (2014). https://doi.org/10.1007/s00170-013-5543-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5543-3