Abstract

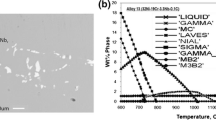

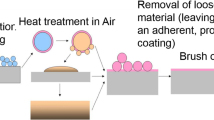

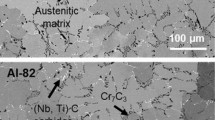

A family of alumina-forming austenitic (AFA) stainless steels is under development for use in aggressive oxidizing conditions from ~600–900 °C. These alloys exhibit promising mechanical properties but oxidation resistance in air with water vapor environments is currently limited to ~800 °C due to a transition from external protective alumina scale formation to internal oxidation of aluminum with increasing temperature. The oxidation behavior of a series of AFA alloys was systematically studied as a function of Cr, Si, Al, C, and B additions in an effort to provide a basis to increase the upper-temperature oxidation limit. Oxidation exposures were conducted in air with 10% water vapor environments from 800–1000 °C, with post oxidation characterization of the 900 °C exposed samples by electron probe microanalysis (EPMA), scanning and transmission electron microscopy, and photo-stimulated luminescence spectroscopy (PSLS). Increased levels of Al, C, and B additions were found to increase the upper-temperature oxidation limit in air with water vapor to between 950 and 1000 °C. These findings are discussed in terms of alloy microstructure and possible gettering of hydrogen from water vapor at second phase carbide and boride precipitates.

Similar content being viewed by others

References

T. Sourmail, Materials Science and Technology 17, 1 (2001).

K. H. Lo, C. H. Shek, and J. K. L. Lai, Materials Science and Engineering R: Reports on ScienceDirect 65, 39 (2009).

P. Kofstad, High Temperature Corrosion, (Elsevier, London, 1988).

Y. Yamamoto, M. P. Brady, Z. P. Lu, P. J. Maziasz, C. T. Liu, B. A. Pint, K. L. More, H. M. Meyer, and E. A. Payzant, Science 316, 433 (2007).

T. Fujioka, M. Kinugasa, S. Iizumi, S. Teshima, and I. Shimizu (US Patent 3,989,514, Nov 2, 1976).

J. A. McGurty (US Patent 4,086,085, April 25, 1978).

J. C. Pivin, C. Roquescarmes, J. Chaumont, and H. Bernas, Corrosion Science 20, 351 (1980).

M. P. Brady, Y. Yamamoto, M. L. Santella, P. J. Maziasz, B. A. Pint, and C. T. Liu, Journal of Metals, Minerals, and Materials Society 60, 12 (2008).

Y. Yamamoto, M.P. Brady, M.L. Santella, H. Bei, P.J. Maziasz, and B.A. Pint, Metallurgical and Materials Transactions A. doi:10.1007/s11661-010-0295-2.

M. P. Brady, Y. Yamamoto, M. L. Santella, and L. R. Walker, Oxidation of Metals 72, 311 (2009).

V. Ramakrishnan, J. A. McGurty, and N. Jayaraman, Oxidation of Metals 30, 185 (1988).

B. A. Pint BA, Oxidation of Metals 45, 1 (1996).

S. R. J. Saunders and J. A. Little, in The Role of Active Elements in the Oxidation Behavior of High Temperature Metals and Alloys, ed. E. Lang (Elsevier Applied Science, London, 1989), p. 175.

Y. Murata, M. Nakai, K. Nagai, M. Morinaga, Y. Sasaki, and R. Hashizume, Material Science Forum 522–523, 147 (2006).

K. Nagai, M. Nakai, T. Kunieda, Y. Murata, M. Morinaga, S. Matsuda, and M. Kanno, Material Science Forum 522–523, 197 (2006).

B. A. Pint, R. Peraldi, and P. J. Maziasz, Material Science Forum 461–464, 815 (2004).

B. A. Pint, J. P. Shingledecker, M. P. Brady, and P. J. Maziasz, Proceedings of GT2007 ASME Turbo Expo 2007: Power for Land, Sea, and Air (Montreal, Canada, May 14–17, 2007).

Q. Ma and D. R. Clarke, Journal of the American Ceramic Society 77, 298 (1994).

B. A. Pint, M. P. Brady, Y. Yamamoto, M. L. Santella, J. Y. Howe, R. Trejo, and P. J. Maziasz, Proceedings of ASME Turbo Expo 5, 271 (2009).

B. A. Pint, L. R. Walker, and I. G. Wright, Materials at High Temperatures 26, 211 (2009).

S. W. da Silva, F. Nakagomi, M. S. Silva, A. Franco Jr., V. K. Garg, A. C. Oliveira, and P. C. Morais, Journal of Applied Physics 107, 09B503 (2010).

F. Gesmundo and B. Gleeson, Oxidation of Metals 44, 211 (1995).

D. J. Young and B. Gleeson, Corrosion Science 44, 345 (2002).

F. H. Stott, G. C. Wood, and J. Stringer, Oxidation of Metals 44, 113 (1995).

E. Essuman, G. H. Meier, J. Zurek, M. Hansel, L. Singheiser, and W. J. Quadakkers, Scripta Materialia 57, 845 (2007).

E. Essuman, G. H. Meier, J. Zurek, M. Hansel, and W. J. Quadakkers, Oxidation of Metals 69, 143 (2008).

M. Nakai, K. Nagai, Y. Murata, M. Morinaga, S. Matsuda, and M. Kanno, Materials Transactions 46, 69 (2005).

Z. G. Yang, M. S. Walker, P. Singh, and J. W. Stevenson, Electrochemical and Solid State Letters 6, B35 (2003).

G. Hultquist, B. Tveten, and E. Hornlund, Oxidation of Metals 54, 1 (2000).

G. Hultquist, B. Tveten, E. Hornlund, M. Limback, and R. Haugsrud, Oxidation of Metals 56, 313 (2001).

C. T. Fujii and R. A. Meussner, Journal of the Electrochemical Society 111, 1215 (1964).

W. J. Quadakkers, J. Zurek, and M. Hansel, JOM-Journal of Metals, Minerals, and Materials Society 61, 44 (2009).

H. Buscail, S. Heinze, Ph. Dufour, and J. P. Larpin, Oxidation of Metals 47, 445 (1997).

H. Gotlind, F. Liu, J.-E. Svensson, M. Halvarsson, and L.-G. Johansson, Oxidation of Metals 67, 251 (2007).

B. A. Pint, J. A. Haynes, Y. Zhang, K. L. More, and I. G. Wright, Surface and Coatings Technology 201, 3852 (2006).

R. Janakiraman, G. H. Meier, and F. S. Pettit, Metallurgical and Materials Transactions A 30, 2905 (1999).

J. L. Smialek, Electrochimica Acta. doi:10.1016/j.electacta.2010.09.072.

M. C. Maris-Sida, G. H. Meier, and F. S. Pettit, Metallurgical and Materials Transactions A 34A, 2609 (2003).

K. Onal, M. C. Maris-Sida, G. H. Meier, and F. S. Pettit, Materials at High Temperatures 20, 327 (2003).

S. R. J. Saunder, M. Monteiro, and F. Rizzo, Progress in Materials Science 53, 775 (2008).

J. Takahashi, K. Kawakami, Y. Kobayashia, and T. Toshimi, Scripta Materialia 63, 261 (2010).

M. P. Brady, M. Fayek, J. R. Keiser, H. M. Meyer III, K. L. More, L. M. Anovitz, D. J. Wesolowski, and D. R. Cole, Corrosion Science (in press).

Acknowledgements

The authors thank B.A. Pint for providing comparative FeCrAlY material, suggestions regarding the addition of high levels of B, and for helpful comments on this manuscript. The authors also thank S. Dryepondt and Govindarajan Muralidharan for helpful comments in reviewing this manuscript and Dorothy Coffey for the FIB sample preparation. Funding from the U.S. Department of Energy’s Energy Efficiency and Renewable Energy Industrial Technologies Program and collaboration with the SHaRE User Facility at ORNL is also acknowledged. ORNL is managed by UT-Battelle, LLC for the US DOE under contractDE-AC05-00OR22725.

Author information

Authors and Affiliations

Corresponding author

Additional information

Notice: This submission was sponsored by a contractor of the United States Government under contract DE-AC05-00OR22725 with the United States Department of Energy. The United States Government retains, and the publisher, by accepting this submission for publication, acknowledges that the United States Government retains, a nonexclusive, paid-up, irrevocable, worldwide license to publish or reproduce the published form of this submission, or allow others to do so, for United States Government purposes.

Rights and permissions

About this article

Cite this article

Brady, M.P., Unocic, K.A., Lance, M.J. et al. Increasing the Upper Temperature Oxidation Limit of Alumina Forming Austenitic Stainless Steels in Air with Water Vapor. Oxid Met 75, 337–357 (2011). https://doi.org/10.1007/s11085-011-9237-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-011-9237-7