Abstract

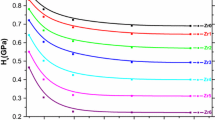

Indentation size effect (ISE) for (Sm123)1−x(Nd123)x superconducting samples which were fabricated by the solid state reaction technique for values of x = 0.00, 0.05, 0.10, 0.20, and 0.30 was investigated by analyzing the theoretical models. When the experimental data of a number of single crystals which have the different crystal structure and different chemical bonding inside the polycrystallined samples were analyzed with the ISE models, the sample encountering with resistance and elastic deformation was observed as well as plastic deformation. The microhardness values on different surfaces of materials were calculated by using Meyer Law, proportional specimen resistance model, modified proportional specimen resistance model, elastic/plastic deformation model and the Hays–Kendall (HK) approach. The results showed that the HK approach was determined as the most successful model. Furthermore, X-ray powder diffraction and scanning electron microscope measurements were analyzed for superconducting properties of (Sm123)1−x(Nd123)x superconductor system. The results showed that microhardness values at the minimum load and averaged plateau region of load increased with increase of Nd123 concentration. Nd123 content can be used as to be estimated the microhardness value of (Sm123)1−x(Nd123)x superconducting sample in the range of 0.878–2.717 GPa. The control of the microhardness value by using Nd123 content in (Sm123)1−x(Nd123)x superconducting structure can be useful in technological applications in superconductivity industry.

Similar content being viewed by others

References

J.H. Gong, J.J. Wu, Z.D. Guan, J. Eur. Ceram. Soc. 19, 2625–2631 (1999)

A.A. Elmustafa, D.S. Stone, J. Mech. Phys. Solids 51, 357–381 (2003)

A. Leenders, M. Ullrich, H.C. Freyhardt, Physica C 279, 173–180 (1997)

R.S. Vennila, N.V. Jaya, S. Natarajan, Mater. Lett. 59, 1764–1766 (2005)

O. Ozturk, C. Terzioglu, I. Belenli, J. Supercond. Nov. Magn. 24, 381–390 (2011)

M. Yilmazlar, H.A. Cetinkara, M. Nursoy, O. Ozturk, C. Terzioglu, Physica C-Supercond. Appl. 442, 101–107 (2006)

U. Kolemen, O. Uzun, M. Yilmazlar, N. Guclu, E. Yanmaz, J. Alloy. Compd. 415, 300–306 (2006)

H. Aydin, O. Cakiroglu, M. Nursoy, C. Terzioglu, Chin. J. Phys. 47, 192–206 (2009)

R. Awad, A.I. Abou Aly, M. Kamal, M. Anas, J. Supercond. Nov. Magn. 24, 1947–1956 (2011)

N.H. Mohammed, A.I. Abou-Aly, I.H. Ibrahim, R. Awad, M. Rekaby, J. Alloy. Compd. 486, 733–737 (2009)

U. Kolemen, J. Alloy. Compd. 425, 429–435 (2006)

E. Asikuzun, O. Ozturk, H.A. Cetinkara, G. Yildirim, A. Varilci, M. Yilmazlar, C. Terzioglu, J. Mater. Sci.-Mater. Electron. 23, 1001–1010 (2012)

J.B. Quinn, G.D. Quinn, J. Mater. Sci. 32, 4331–4346 (1997)

O. Ozturk, H.A. Cetinkara, E. Asikuzun, M. Akdogan, M. Yilmazlar, C. Terzioglu, J. Mater. Sci.-Mater. Electron. 22, 1501–1508 (2011)

H.A. Cetinkara, M. Yilmazlar, O. Ozturk, M. Nursoy, C. Terzioglu, International conference on superconductivity and magnetism (Icsm), p. 153 (2009).

H. Li, R.C. Bradt, J. Mater. Sci. 28, 917–926 (1993)

Q. Ma, D.R. Clarke, J. Mater. Res. 10, 853–863 (1995)

F. Fröhlich, P. Grau, W. Grellmann, Phys. Stat. Sol. (a) 42, 79–89 (1977)

B.D. Michels, G.H. Frischat, J. Mater. Sci. 17, 329–334 (1982)

W.C. Oliver, R. Hutchings, J.B. Pethica, in Microindentation Techniques in Materials Science and Engineering, ed. by P.J. Blau, B.R. Lawn (ASTM, Philadelphia, PA, 1986), p. 90

M. Yilmazlar, O. Ozturk, O. Gorur, I. Belenli, C. Terzioglu, Supercond. Sci. Technol. 20, 365–371 (2007)

K. Sangwal, Mater. Chem. Phys. 63, 145–152 (2000)

G.P. Upit, S.A. Varchenya, Phys. Status Solidi B 17, 831–835 (1966)

S.J. Bull, T.F. Page, E.H. Yoffe, Mag. Lett. 59, 281–288 (1989)

O. Ozturk, J. Mater. Sci.: Mater. Electron. 23, 1235–1242 (2012)

C. Hays, E.G. Kendall, Metallurgica 6, 275–282 (1973)

J.H. Gong, Z. Zhao, Z.D. Guan, H.Z. Miao, J. Eur. Ceram. Soc. 20, 1895–1900 (2000)

Z. Peng, J. Gong, H. Miao, J. Eur. Ceram. Soc. 24, 2193–2201 (2004)

Acknowledgments

This work was supported by The Scientific and Technological Council of Turkey (TÜBİTAK) with project no: TBAG-110T622. The authors thank to Prof. Dr. Nazmi Turan Okumuşoğlu for his advices.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Celik, S., Ozturk, O., Coşkun, E. et al. Analysis of indentation size effect (ISE) behavior in low-load Vickers microhardness testing of (Sm123)1−x(Nd123)x superconductor system. J Mater Sci: Mater Electron 24, 2218–2227 (2013). https://doi.org/10.1007/s10854-013-1082-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-013-1082-9