Abstract

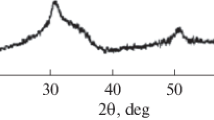

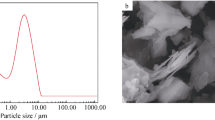

Fabrication and characterization of polymer infiltrated ceramic networks (PICNs) were undertaken for use in dentistry. Calcia-stabilized tetragonal zirconia (7-tCSZ) nanoparticles were synthesized via a modified co-precipitation. The composition and particle size of the prepared nanoparticles were studied using X-ray diffraction (XRD) and transmission electron microscopy (TEM). Densification parameters of porous ceramic samples, with varying amounts of 7-tCSZ, 0, 5, 10, and 15 wt.%, and PICN materials were examined using the Archimedes principle. The flexural strength and elastic modulus of PICNs were measured using a three-point bending strength test. The microhardness and fracture toughness were determined using Vickers microhardness and V-notched bars tests, respectively. The microstructure was investigated for selected materials before and after polymer infiltration using scanning electron microscopy (SEM). The results revealed that the samples with 10 and 15 wt.% of nano-tetragonal zirconia showed the highest elastic modulus (8.24 GPa) and fracture toughness (1.82 MPa m1/2), respectively, which is attributed to transformation toughening of zirconia. The flexural strength and microhardness of PICNs were in the range 66.14–71.72 MPa, 0.18–0.19 GPa, respectively, whilst the brittleness index was maximally 0.21 μm−½, which is significantly below the ultimate brittleness index (4.3 μm−1/2) allowing machinability. Conclusively, the inclusion of nanometric zirconia posed a dramatic enhancement of the mechanical properties without affecting the machinability of these biomimetic materials, making them similar to natural dentin in terms of the elastic modulus and fracture toughness along with ease of machinability, which renders them promising as indirect dental restorative materials.

Similar content being viewed by others

References

M. Montazerian, E.D. Zanotto, History and trends of bioactive glass-ceramics. J. Biomed. Mater. Res. Part A 104(5), 1231–1249 (2016)

N.B. Cramer, J.W. Stansbury, C.N. Bowman, Recent advances and developments in composite dental restorative materials. J. Dent. Res. 90(4), 402–416 (2011)

A.S. Verma, D. Kumar, A.K. Dubey, A review of an innovative concept to increase the toughness of the ceramics by piezoelectric secondary phases. Ceram. Int. 44(14), 16119–16127 (2018)

J.U. Jansen, N. Lümkemann, B. Sener, B. Stawarczyk, Comparison of fracture toughness measurements for zirconia materials using two test methods. Dent. Mater. J. 38(5), 806–812 (2019)

M. Maleki, S.M. Sheikh-Al-Eslamian, E. Hasani, A. Ghasemi, Comparative study on the microstructure and mechanical behavior of monolithic ceramic and laminated composite of high strength 3Y-TZP and high fracture toughness 12Ce-TZP. J. Alloys. Compd. 776(5), 166–171 (2019)

A. Mukhopadhyay, B. Basu, Consolidation–microstructure–property relationships in bulk nanoceramics and ceramic nanocomposites: a review. Int. Mater. Rev. 52(5), 257–288 (2007)

S. Maitra, J. Roy, Nano ceramic matrix composites: types, processing and applications, in Advances in Ceramic Matrix Composites, 2nd edn, ed. by I.M. Low. (Woodhead Publishing is an imprint of Elsevier, United Kingdom, 2018), pp. 27–48. ISBN: 9780081021668

A. Mukhopadhyay, B. Basu, Bulk nanoceramic composites for structural applications: a review. Proc. Indian. Natn. Sci. Acad. 72(2), 97–111 (2006)

S. Zang, N. He, X. Sun, M. Sun, W. Wu, H. Yang, "Influence of additives on the purity of tetragonal phase and grain size of ceria-stabilized tetragonal zirconia polycrystals (Ce-TZP). Ceram. Int. 45(1), 394–400 (2019)

R. Shahmiri, O.C. Standard, J.N. Hart, C.C. Sorrell, Optical properties of zirconia ceramics for esthetic dental restorations: a systematic review. J. Prosth. Dent. 119(1), 36–46 (2018)

Z.J. Ming, J.K. Lee, H.K. Hong, J.J. Ho, Synthesis and thermal stability of nanocrystalline tetragonal zirconia by hydrolysis with ethylene diamine. J. Nanosci. Nanotechnol. 18(2), 1241–1245 (2018)

H. Shokry, M. Elkady, H. Hamad, Synthesis and characterization of stabilized tetragonal nano zirconia by precipitation method. J. Nano. Res. 56, 142–151 (2019)

B. Fan, F. Zhang, J. Li, H. Chen, R. Zhang, Synthesis and crystallization behavior of 3 mol% yttria partically stabilized zirconia (3Y-PSZ) nanopowders by microwave pyrolysis process. J. Mater. Sci. Eng. 6(2), 1–4 (2017)

S. Ghorbani, R.S. Razavi, M.R. Loghman-Estarki, A. Alhaji, Development of MgO–Y2O3 composite nanopowder by Pechini sol-gel method: effect of synthesis parameters on morphology, particle size, and phase distribution. J. Cluster. Sci. 28(3), 1523–1539 (2017)

Z. Huang, W. Han, Z. Feng, J. Qi, D. Wu, N. Wei, Z. Tang, Y. Zhang, J. Duan, T. Lu, The effects of precipitants on co-precipitation synthesis of yttria-stabilized zirconia nanocrystalline powders. J. Sol-Gel. Sci. Technol. 90(2), 359–368 (2019)

Y.T. Foo, A.Z. Abdullah, B.A. Horri, B. Salamatinia, Optimised co-precipitation synthesis condition for oxalate-derived zirconia nanoparticles. Ceram. Int. 45(17), 22930–22939 (2019)

A. Coldea, M.V. Swain, N. Thiel, Mechanical properties of polymer-infiltrated-ceramic-network materials. Dent. Mater. 29(4), 419–426 (2013)

J.C. Facenda, M. Borba, P.H. Corazza, A literature review on the new polymer-infiltrated ceramic-network material (PICN). J. Esthet. Restor. Dent. 30(4), 281–286 (2018)

A. Della Bona, P.H. Corazza, Y. Zhang, Characterization of a polymer-infiltrated ceramic-network material. Dent. Mater. 30(5), 564–569 (2014)

H. Wang, B. Cui, J. Li, S. Li, Y. Lin, D. Liu, M. Li, Mechanical properties and biocompatibility of polymer infiltrated sodium aluminum silicate restorative composites. J. Adv. Ceram. 6(1), 73–79 (2017)

M. Petrini, M. Ferrante, B. Su, Fabrication and characterization of biomimetic ceramic/polymer composite materials for dental restoration. Dent. Mater. 29(4), 375–380 (2013)

M.V. Swain, A. Coldea, A. Bilkhair, P.C. Guess, Interpentrating network ceramic-resin composite dental restorative materials. Dent. Mater. 32(1), 34–42 (2016)

A. Zarkov, A. Stanulis, J. Sakaliuniene, S. Butkute, B. Abakeviciene, T. Salkus, S. Tautkus, A.F. Orliukas, S. Tamulevicius, A. Kareiva, On the synthesis of yttria-stabilized zirconia: a comparative study. J. Solgel. Sci. Technol. 76(2), 309–319 (2015)

M. Hajizadeh-Oghaz, R.S. Razavi, M. Barekat, M. Naderi, S. Malekzadeh, M. Rezazadeh, Synthesis and characterization of Y2O3 nanoparticles by sol–gel process for transparent ceramics applications. J. Solgel. Sci. Technol. 78(3), 682–691 (2016)

B. Cui, R. Zhang, F. Sun, Q. Ding, Y. Lin, L. Zhang, C. Nan, Mechanical and biocompatible properties of polymer-infiltrated-ceramic-network materials for dental restoration. J. Adv. Ceram. 9(1), 123–128 (2020)

B. Cui, J. Li, H. Wang, Y. Lin, Y. Shen, M. Li, X. Deng, C. Nan, Mechanical properties of polymer-infiltrated-ceramic (sodium aluminum silicate) composites for dental restoration. J. Dent. 62, 91–97 (2017)

S.E. Elsaka, A.M. Elnaghy, Mechanical properties of zirconia reinforced lithium silicate glass-ceramic. Dent. Mater. 32(7), 908–914 (2016)

G. Zamfirova, A. Dimitrova, Some methodological contributions to the Vickers microhardness technique. Polym. Test. 19(5), 533–542 (2000)

D. Geetha, P.J. Sophia, D. Arivuoli, Evaluation of microindentation properties of epitaxial 3C–SiC/Si thin films. Phys. B 490, 86–89 (2016)

A.R. Boccaccini, Machinability and brittleness of glass-ceramics. J. Mater. Process. Technol. 65(1–3), 302–304 (1997)

S. Shukla, S. Seal, Mechanisms of room temperature metastable tetragonal phase stabilisation in zirconia. Int. Mater. Rev. 50(1), 45–64 (2005)

F. Cardarelli, Materials Handbook: A Concise Desktop Reference, 2nd edn. (Springer-Verlag, London Limited, New York, London, 2008), pp. 593–689. ISBN: 978-1-84628-668-1

N.D. Lestari, R. Nurlaila, N.F. Muwwaqor, S. Pratapa, Synthesis of high-purity zircon, zirconia, and silica nanopowders from local zircon sand. Ceram. Inter. 45(6), 6639–6647 (2019)

J. Li, X.H. Zhang, B.C. Cui, Y.H. Lin, X.L. Deng, M. Li, C.W. Nan, Mechanical performance of polymer-infiltrated zirconia ceramics. J. Dent. 58, 60–66 (2017)

B. Basu, Toughening of yttria-stabilised tetragonal zirconia ceramics. Int. Mater. Rev. 50(4), 239–256 (2005)

S. Ghasemi-Kahrizsangi, H.G. Dehsheikh, M. Boroujerdnia, Effect of micro and nano-Al2O3 addition on the microstructure and properties of MgO-C refractory ceramic composite. Mater. Chem. Phys. 189(1), 230–236 (2017)

J.F. Nguyen, D. Ruse, A.C. Phan, M.J. Sadoun, High-temperature-pressure polymerized resin-infiltrated ceramic networks. J. Dent. Res. 93(1), 62–67 (2014)

E. Magni, M. Ferrari, R. Hickel, N. Ilie, Evaluation of the mechanical properties of dental adhesives and glass-ionomer cements. Clin. Oral. Invest. 14, 79–87 (2010)

J.H. Kinney, M. Balooch, S.J. Marshall, G.W. Jr Marshall, T.P. Weihs, Hardness and Young’s modulus of human peritubular and intertubular dentine. Arch. Oral. Biol. 41(1), 9–13 (1996)

D. Ziskind, M. Hasday, S.R. Cohen, H.D. Wagner, Young’s modulus of peritubular and intertubular human dentin by nano-indentation tests. J. Struct. Biol. 174(1), 23–30 (2011)

J.L. Cuy, A.B. Mann, K.J. Livi, M.F. Teaford, T.P. Weihs, Nanoindentation mapping of the mechanical properties of human molar tooth enamel. Arch. Oral. Biol. 47(4), 281–291 (2002)

S. Habelitz, S.J. Marshall, G.W. Marshall, M. Balooch, Mechanical properties of human dental enamel on the nanometre scale. Arch. Oral. Biol. 46(2), 173–183 (2001)

H.H. Xu, D.T. Smith, S. Jahanmir, S.E. Romberg, J.R. Kelly, V.P. Thompson, E.D. Rekow, Indentation damage and mechanical properties of human enamel and dentin. J. Dent. Res. 77(3), 472–480 (1998)

A.G. Sheinerman, R.H. Castro, M.Y. Gutkin, A model for direct and inverse Hall-Petch relation for nanocrystalline ceramics. Mater. Lett. 260, 126886 (2020)

M. Turon-Vinas, M. Anglada, Strength and fracture toughness of zirconia dental ceramics. Dent. Mater. 34(3), 365–375 (2018)

M. Montazerian, P. Alizadeh, B.E. Yekta, Processing and properties of a mica–apatite glass–ceramic reinforced with Y-PSZ particles. J. Eur. Ceram. Soc. 28(14), 2693–2699 (2008)

H.N. Yoshimura, C.C. Gonzaga, P.F. Cesar, W.G. Miranda, Relationship between elastic and mechanical properties of dental ceramics and their index of brittleness. Ceram. Int. 38(6), 4715–4722 (2012)

M.N. Rahaman, Sintering of Ceramics, 1st edn, (CRC Press, United States of America, 2007), pp. 1–43. ISBN: 9780849372865

Q. Chen, Y. Zhao, W. Wu, T. Xu, H. Fong, Fabrication and evaluation of Bis-GMA/TEGDMA dental resins/composites containing halloysite nanotubes. Dent. Mater. 28(10), 1071–1079 (2012)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mohammed, N.Y., Wahsh, M.M.S., Motawea, I.T. et al. Fabrication and characterization of polymer-infiltrated ceramic network materials based on nano-tetragonal zirconia. J. Korean Ceram. Soc. 58, 359–372 (2021). https://doi.org/10.1007/s43207-020-00102-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43207-020-00102-4