Abstract

Biochar and biochar-based materials have been studied extensively in multidisciplinary areas because of their outstanding physicochemical properties. In this review article, biochar and biochar-based materials in the removal of environmental pollutants, hydrogen generation and carbon dioxide capture were summarized and compared. The interaction mechanisms were discussed from the experimental results and characterization analysis. The high porous structures, active surface sites, (co)doping of single metals/nonmetals, and incorporation of metal oxides or other materials improved the high activity of biochar-based materials in their applications. However, there are still some challenges such as: (1) the fact that H2 generation with high selectivity or the produced syngas to meet the real application requirement in industrial is the main challenge in H2 production; (2) the fact that the selective capture of CO2 with high stability, high adsorption capacity and recyclability at low-cost should be considered and focused on; (3) the sorption-(photo)degradation of the organic chemicals; and (4) the fact that the sorption-reduction-extraction/solidification of metals/radionuclides are efficient methods for the elimination of environmental pollutants. In the end, the perspectives, challenges and possible techniques for biochar-based materials’ real application in future were described.

Graphical Abstract

Highlights

-

1.

Biochar-based composites exhibited high degradation abilities for organic pollutants.

-

2.

Biochar-based materials showed high removal/immobilization efficiency of metals through sorption-reduction.

-

3.

Biochar and biochar-based materials could generate H2 with high efficiency.

-

4.

Biochar-based materials can capture and separate CO2 from complex systems with high selectivity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The rapid development of industrial, agriculture and high requirement of human life quality produce huge amounts of environmental pollutants such as organic contaminants, metals and radionuclides, which are ubiquitously presented in the environment such as in soils, lakes, rivers, sediments and tailings (Ahmed et al. 2016a; Cai et al. 2022; Hu et al. 2023; Li et al. 2023a; Yang et al. 2022; Zahed et al. 2021). Although some organic contaminants or metal ions have little toxicity even at relative high concentrations, most (in)organic contaminants result in high toxicity to human health even at ultra-low concentrations. The organic pollutants such as dyes, POPs, pesticides, antibiotics could be photocatalytically degraded into less toxic organic molecules, H2O and CO2 (Cai et al. 2023; Li et al. 2023b). However, it needs very long time to totally degrade the organic contaminants under natural sunlight irradiation conditions. The metal ions such as Pb(II), Cr(VI), As(III), Cd(II), Hg(II), Cu(II) and radionuclides such as 235U(VI), 99Tc(VII), 137Cs(I), 60Co(II), 90Sr(II) and other long-lived actinides have very high toxicity, radioactivity, radiotoxicity and mobility in the natural ecosystems and exist in the natural environment system for long time because they are not degraded or immobilized in ecosystems under natural conditions (Lyu et al. 2020; Shahrak et al. 2017; Wu et al. 2023). For example, the presence of Cd(II) in solution could cause the damage of skeletal and renal functions (Zhao et al. 2011), and the presence of Pb(II) could cause the poisoning damage of cardiovascular and cranial nerve systems (Rouhani and Morsali 2018). The existence of organic compounds in the ecosystems could cause the nervous system toxicity (Liu et al. 2021a). Thereby, the efficient elimination of (in)organic contaminants is critical to environmental protection and human health. Till now, different kinds of techniques such as (ad)sorption, membrane separation, (in-situ) solidification, (co)precipitation, (photo/electro)reduction of metals, (photo)degradation of organic chemicals, filtration, ion exchange, and biological degradation/reduction have been applied to eliminating the pollutants from complex systems (Chen et al. 2022a, 2023; Liu et al. 2021b; 2022a; Zhang et al. 2022a; Wang et al. 2023). Each method has its own advantages/disadvantages for the treatment of different pollutants in real applications. From the viewpoint of easy operation and low cost in large scale, sorption and catalysis are more attractive in the elimination of pollutants. Different kinds of natural and manmade materials such as COFs (Gu et al. 2022; Hao et al. 2022a, b, 2023a, b; Guillem-Navajas et al. 2022), MOFs (Li et al. 2018; Yang et al. 2023), MXene (Yu et al. 2022), biochar (Liu et al. 2022b), carbon nanomaterials (Liu et al. 2022c) have been studied extensively to remove the pollutants through sorption or catalysis strategies.

CO2 is critical to global warming because it is the main anthropogenic greenhouse gas. The CO2 capture is crucial for greenhouse emission and reduction. Since the industrialization, the concentration of CO2 in atmosphere has increased from ~ 280 to ~ 421 ppm till 2023, causing global climate change. From the model prediction, the global temperature will increase about 2 °C with the CO2 concentration increasing to about 570 ppm till 2100 (Jeyasubramanian et al. 2021; Su et al. 2023). Thereby, the decrease of CO2 emission and the capture of CO2 are urgent to maintain the global balance. Dissanayake et al. (2020) reviewed the use of biochar-based composites and bare biochar materials for CO2 capture. The CO2 adsorption capacity on biochar was related to the surface area, hydrophobicity, porous structure, porosity, functional groups and aromaticity. The surface properties of biochar contributed to CO2 capture significantly. Kumar et al. (2022) reviewed the application of biochar derived from biomass thermal conversion for the adsorption of CO2. The authors concluded that the surface area, functional groups, porosity and basicity were important parameters affecting the biochar adsorption ability for CO2 capture. Shafawi et al. (2021) reviewed the modification of engineered biochar for the improvement of CO2 capture. After physicochemical modification, the surface area, microstructure, basicity, metal contents, hydrophobicity and functional groups were changed, which enhanced the adsorption capacity and selectivity of CO2 towards other gases and recycle ability of biochar. Zhang et al. (2022b) summarized the CO2 capture techniques by biochar from solid phase and liquid phase. The liquid phase had the adsorption efficiency limitation because of the high volatility and thermal degradation, whereas the solid phase had low CO2 selectivity, especially in the presence of N2. The functionalized cross-linking biochar can not only improve the liquid-phase CO2 adsorption efficiency, but also increase the biomass waste utilization for CO2 capture to reduce CO2 emission.

Hydrogen is the clean and environmentally friendly energy source with no emission of carbon. The energy yield of hydrogen was about 3.7 times of hydrocarbon fuels (Elsamadony et al. 2015). Thereby, the production of H2 is crucial for environmental protection and greenhouse gas mitigation (Sharma and Melkania 2017). Murugesan et al. (2022) reviewed the generation of H2 by food waste valorization. The catalytic and noncatalytic gasification processes for food waste decomposition to generate H2-rich syngas were compared. The catalytic gasification exhibited noteworthy benefits for the selective H2 generation. The steam or hydrothermal gasification is noncatalytic gasification, which generates H2 efficiently, but with other gases products mainly as CO, CO2, CH4 and others as C2H4 or C2H6. The increase of temperature generally increases H2 yield. The transition metals in the catalysts are helpful for the C–C bond breakdown to produce syngas. In the subcritical water gasification of food waste, the addition of NaOH in Ni-based catalyst increased H2 generation and decreased CO2 production (Muangrat et al. 2010). Singh and Yadav (2021) studied syngas production by gasification of kitchen-based food waste under low temperature steam on the production of syngas, and they achieved the highest H2 generation at the steam flow rate of 0.5 mL min–1. The steam flow rate and temperature affected the production of H2 obviously. As the supporting material, biochar could prevent the coke formation on catalyst and thereby improved the generation of H2 (Farooq et al. 2021). The high surface area also improved metal loading, and enhanced H2 production efficiency (Cao et al. 2017). The special physicochemical properties of biochar indicate that biochar has outstanding benefits in H2 production.

From the abovementioned references, one can see that biochar has attracted multidisciplinary research interests because of its special physicochemical properties such as high stability, low cost, porous structures, abundant active sites and functional groups. Biochar has been extensively studied in CO2 capture (Chatterjee et al. 2018; Mohd et al. 2013; Wang et al. 2020; Xu et al. 2016) as CO2 is the anthropogenic greenhouse gas which causes the extreme climate change and global warming; in H2 generation (Cho et al. 2018; Sun et al. 2021, 2022), which is a clean and green energy source; and in environmental pollution management (Chen et al. 2022b; Lu et al. 2022; Luo et al. 2021; Qiu et al. 2022). Li et al. (2015) reviewed the synthesis of biochar from biomass pyrolysis and its applications in catalysis, environmental pollution treatment and energy storage. They also pointed out that the research on the sustainably tuning the biochar functionality, structure and porosity was critical for their applications. One can see that the biochar-based composites and bare biochar have been studied extensively and intensively in gas capture, in energy production and environment pollutants’ remediation. From the reviews, one can see that biochar modified with other chemicals such as KOH or incorporated with other metal oxides or metal atoms could significantly improve the biochar ability in H2 generation or CO2 capture. However, most of the reviews about H2 generation or CO2 capture mainly focused on the description of main results. The interaction mechanism discussion at molecular level from spectroscopic analysis is still not available, especially the effect of porous structures and surface properties on H2 generation or CO2 capture. From the environmental protection and energy storage/conversion, biochar exhibited promising application towards environmental sustainability and carbon neutrality. In this review, we mainly focused on the applications of biochar in environmental pollution treatment, CO2 capture and H2 generation. From the keywords’ summarization, the relationships among the three applications are shown in Fig. 1. One can see that the application of biochar-based materials in the three aspects is research hotspot. Modifications to the biochar structure, active surface sites, (co)doping of single metals/nonmetals, and incorporation of metal oxides or other materials to improve the biochar’s ability in pollutants’ elimination, H2 generation and CO2 capture are summarized. Considering that the techniques for biochar synthesis have been reported in detail, herein we summarized and compared the properties of biochar-based composites and bare biochar in the abovementioned areas, and the mechanism was discussed in detail. In the end of the review article, the perspectives and challenges in future for the real applications of biochar and biochar-based materials were described.

The application of biochar in pollutant elimination, CO2 capture and H2 generation from Web of Science using the keywords “pollutants removal”, “CO2 capture” and “H2 production”. “Web of Science Core Collection” were the selected database, and the collected data were analyzed using VOSviewer software

2 Biochar properties

The physical structures such as pore volume, surface area or pore size are related to the sorption properties of biochar. The properties of biochar are related to the feedstocks, the synthesis conditions and processes. The synthesis temperature is the most important parameter to influence the synthesized biochar properties (Weber and Quicker 2018). Biochar prepared from woody has been studied extensively, but the mechanism is still not completely understood, indicating the complexity of synthesis processes. Thermochemical conversion such as gasification, hydrothermal carbonization, pyrolysis and ionothermal carbonization was used extensively to convert feedstocks to biochar. The increase of synthesis temperature generally increases carbon contents but decreases the hydrogen and oxygen contents. The high synthesis temperature generally leads to the solid structure shrinkage, functional groups’ decrease, porosity increase, and density increase (Brewer et al. 2014; Somerville and Jahanshahi 2015). The surface area also increases with the increase of synthesis temperature, but decreases again at high temperatures of 800–1000 °C, which may be resulted by the shrinking solid matrix (Brown et al. 2006; Lu et al. 1995). High surface area and pore volume are helpful to improve the catalytic ability, gas storage and sorption capacity (Jeyasubramanian et al. 2021). The carbon content of biochar also played critical role of biochar colloid aggregation in aqueous solutions, which affected the sorption ability of biochar. The carbon content is generally high for woody feedstock and low for municipal source (Li et al. 2023c). The low H/C ratio is related with fewer functional groups and more atomic structures. Besides the synthesis temperature, the residence time and gas conditions also affect the biochar properties. However, only a few publications are available, which are not enough to draw a definite conclusion on their influence on biochar properties. The physicochemical properties and surface modification as well as the porosity and functional groups are helpful to improve the biochar properties. The biochar properties are not only related to the properties of feedstocks and the synthesis technological processes, but also related to the post-synthesis treatment such as chemical treatment or incorporation with other kinds of metals or metal oxides (Benis et al. 2020; Vijayaraghavan 2019). The doping of single metals or incorporation of other oxides could improve the catalytic activity of biochar, which are discussed in the following sections.

3 Application of biochar in organic pollutants’ elimination

Organic contaminants in the ecosystems are dangerous to human health. Huang et al. (2019) summarized the synthesis of biochar using different feedstocks such as forest residues, municipal wastes, agricultural residues, industrial by-products, and compared the structures and properties of prepared biochar from different feedstocks. They found that the porous structures and chemical compositions of synthesized biochar were quite different. The biochar synthesized from wood and plants generally had relatively larger surface area, higher carbon content, stronger aromaticity and higher porous structures as compared to the biochar prepared from industrial by-products. The wood/plant-prepared biochar exhibited relatively higher sorption ability to organic contaminants through the interactions of physical adsorption, π–π reaction, electrostatic attraction and surface complexation. The metal-doping or incorporation with other metal oxides could improve the surface properties of biochar, and thereby enhanced the adsorption ability of organic contaminants by biochar-based composites (Zhu et al. 2022). The removal of organic pollutants by different post-modification treated biochar was compared and discussed (Dai et al. 2019). The post-modified biochar with different chemicals or techniques showed quite different adsorption abilities, which was mainly attributed to the differences of surface groups and porous structures. However, the authors also pointed out that the regeneration was the main problem for the real engineering applications although was a low-cost green material in the remediation of organic contaminants. Gasim et al. (2022) reviewed the application of biochar in the removal of organic contaminants from water by different techniques under different conditions. The degradation of organic contaminants by the activation of H2O2, O3, PMS and peroxydisulfate, and the photocatalytic degradation of organic pollutants under visible light irradiation were also compared and discussed. From the published papers, one can concluded that: (1) PMS and peroxydisulfate activations were effective to utilize the biochar active sites to produce ·SO4− active species; (2) H2O2 activation was safety with nonharmful by-products (only oxygen and hydrogen active species); (3) O3 activation had the advantage of strong oxidation for organic pollutant degradation; and (4) the adsorption was generally followed by the catalytic degradation processes.

3.1 Removal of organic contaminants by biochar

The high surface area, abundant functional groups and porous structures of biochar are beneficial for the binding of organic contaminants. Biochar synthesized using rice husk was applied to PMS activation to degrade BPA and TC (Huong et al. 2020). The results showed that higher PMS concentration and biochar amounts resulted in higher BPA and TC degradation. The ESR analysis showed that the generated ·OH and ·SO4− active species were the main active free radicals to degrade BPA and TC (Fig. 2a). The simultaneous degradation of organic chemicals and reduction of Cr(VI) by biochar derived from rice husk were investigated (Zhang et al. 2020). At low Cr(VI) concentration, the degradation of organic molecules was mainly dominated by the ·OH radicals generated by O2 activation. At high Cr(VI) concentration, the degradation of organics was restrained and chemically accelerated by Cr(VI) reduction (Fig. 2b). Meanwhile, the toxic Cr(VI) was reduced to Cr(III) by biochar and the existence of organic chemicals promoted the reduction of Cr(VI) to Cr(III). The defects of biochar accelerated the reactions between organic molecules and Cr(VI) ions, which facilitated Cr(VI) reduction and organics degradation simultaneously. Lu et al. (2022) compared the effective elimination of organic contaminants by different biochar, and concluded that organic chemicals could be eliminated by adsorption and photocatalytic degradation, whereas metal ions could be treated through sorption-reduction-immobilization strategies (Fig. 2c). Although the authors presented the mechanism discussion from advanced different spectroscopic measurements and DFT simulation, the information at the molecule level was not really achieved from real biochar. Till now, theoretical calculation on reaction mechanisms of biochar with the organic pollutants are still not available for real biochar because of the complicated structures of biochar. Patel et al. (2022) studied the adsorption and degradation of PAHs, antibiotics and pesticides by tailored biochar, and concluded that the adsorption of the organic chemicals on biochar was mainly attributed to π–π reactions, H-bond, electrostatic attraction, and pore filling. The anionic attraction occurred at pH < pHpzc and cationic attraction occurred at pH > pHpzc. Electrostatic attraction was obviously affected by ionic strength and pH. From the published papers, one can concluded the following conclusion: (1) the ionic or cationic exchange processes generally had reversible adsorption–desorption properties; (2) the H-bonding interaction had the –OH peak shifting in FTIR after adsorption; (3) the π–π interaction had the change of C=C peak intensity in FTIR after adsorption; (4) the pore filling mechanism generally showed the decrease of SBET and Vtotal after adsorption (Tran et al. 2017, 2020; Zhang et al. 2022f); (5) the addition of PMS or sodium percarbonate improved the degradation of toxic organic chemicals to less toxic chemical or even CO2 and H2O. The cost-effective, green and sustainable biochar is an environmentally friendly material for the remediation of organic pollutants.

Degradation of BPA and TC by biochar with oxidation of PMS (a) (Huong et al. 2020); reduction mechanism of Cr(VI) by biochar from low to high Cr(VI) concentrations (b) (Zhang et al. 2020); adsorption-photocatalytic degradation of organic pollutants and sorption-photoreduction of metals by biochar (c) (Lu et al. 2022)

3.2 Removal of organic contaminants by biochar-based materials

Compared to pristine biochar, the doping/co-doping of metals/nonmetals and incorporation of metal oxides could improve the sorption and photocatalytic capacities of biochar. Chen et al. (2011) used agricultural biomass waste to prepare biochar and then doped Fe3+/Fe2+ on biochar to prepare magnetic biochar. The magnetic biochar could simultaneously remove organic pollutants and phosphate, and no competitive adsorption of the phosphate and organic pollutants was found. The degradation of organic contaminants (antibiotics, personal care products, pharmaceuticals etc.) by ferrate/biochar catalyst showed that the oxidation rate of the organic chemicals was increased obviously (Tian et al. 2020). The XPS spectra (Fig. 3a, b) showed the phenolic hydroxyl intensity decreased from 20% to 15%, and the carboxylic group intensity increased from ~ 9% to ~ 11% after biochar reaction with ferrate. The graphitic and aliphatic structures did not change obviously (Fig. 3c). The ESR and radical scavenging tests showed that the iron active species {Fe(V) and Fe(IV)} were the main intermediates for the oxidations of organic chemicals. The Fe(IV) and Fe(V) active species not only reacted with organic molecules to accelerate their transformation, but also oxidized the biochar surface structures to expand the surface areas and porous structures, which further improved the adsorption capacity of biochar. The electron-donating moieties may donate the electrons to ferrate to form {Fe(V) and Fe(IV)} intermediates, which further enhances organic molecules degradation (Fig. 3d). Wang et al. (2021a) studied the sorption and photocatalytic degradation of phenol by iodine-doped biochar, and found that the doping of iodine created more extra pores which enhanced phenol adsorption obviously. The iodine-doping facilitated the photo-induced generation of e−–h+ pairs, and generated more active free radicals such as ·OH, ·O2−, and 1O2 (Fig. 3e–g). The possible mechanism of phenol by the ·OH, ·O2− and 1O2 free radicals is illustrated in Fig. 3h. This work highlighted the preparation of low-cost and metal-free biochar to improve the adsorption and degradation of organic contaminants under sunlight. However, the degradation pathways, the analysis of by-products, final products and intermediates were not provided. Chen et al. (2020) studied the adsorption and degradation of p-nitrophenol by biochar, and found that the adsorption of p-nitrophenol decreased with the decrease of pyrolysis temperature, whereas the degradation capacity decreased. The adsorption was related to the surface area whereas the degradation capacity was related to the free radicals, surface functional groups, doped-metals and redox activities of biochar. This work highlighted the relationship of biochar properties with its preparation conditions and their application in organic chemical elimination. Jiang et al. (2023) prepared FeCo/MOF/biochar composites and applied them to TC removal from aqueous solutions. The FeCo/MOF/biochar composites exhibited high sorption capacity of 909 mg g–1, which was higher than the values of most today’s reported materials. Regarding the outstanding physicochemical properties, biochar is a suitable material for in-situ immobilization of environmental contaminants. The porous structures, surface charge, surface groups, active sites, mineral components, incorporated metal oxides and doped/co-coped metals/nonmetals are related to the pyrolysis temperature, types of the feedstock and modification conditions (Yang et al. 2021a).

XPS analysis of C element of biochar (a) and ferrate/biochar (b), quantitative analysis of biochar functional groups of biochar and ferrate/biochar (c), the possible reaction mechanism (d) (Tian et al. 2020). EPR spectra of 1O2 (e), ·O2− (f), and ·OH (g) active radicals generated by iodine-doped biochar under visible light. Possible mechanism of phenol by iodine-doped biochar (Wang et al. 2021a)

Based on the publish papers, it is clear that biochar not only had high sorption ability, but also had high (photo)catalytic capacity in the elimination of organic molecules. The properties such as high surface areas, active sites and porous structures are crucial for the binding of organic molecules, whereas the (non)metal-doping or incorporation of metal oxides could efficiently improve the photo-generation and separation of electrons and holes, which are beneficial to improve the photocatalytic capacity. However, the co-doping or triple-doping of metals or nonmetal in biochar was rarely reported. In the presence of metal ions, the biochar could simultaneously remove organic and inorganic contaminants through adsorption-photocatalysis strategies. Although the relative contribution of different active species could be measured/evaluated by quenching tests, the exact contribution of the free active radicals on organic contaminant degradation is qualitatively, not quantitatively. The measurements of intermediates and final products are not reported in most papers. The on-line characterization of intermediates is still difficult.

4 Elimination of heavy metals and radionuclides by biochar

Heavy metals such as Cr(VI), As(III), Pb(II) and radionuclides especially the 235U(VI) and fission products such as 99TcO4−, 90Sr2+, 137Cs+ and 129I2 vapor during the nuclear energy utilization, are inevitably released into natural ecosystems, which are high toxicity, radioactivity and radiotoxicity. The efficient selective sorption of target metals and radionuclides from solutions is the most useful method for pollution treatment (Zhang et al. 2022g). The reduction of Cr(VI) to Cr(III) is an efficient method to reduce the toxicity of Cr(VI) and to immobilize Cr(VI), whereas the oxidation of As(III) to As(V) could decrease the toxicity efficiently (Dong et al. 2011; Li et al. 2021; Niazi et al. 2018). Nevertheless, the selective extraction of the target toxic metals and radionuclides from large volume of complex solutions is the best method for the pollution treatment. However, the in-situ immobilization and solidification of these toxic metals and radionuclides in soils or sediments are more easily and effectively to reduce the toxicity of these metals or radionuclides to human health through food chain.

4.1 Removal of As(III)

The trivalent As(III) has much higher toxicity than pentavalent As(V) in environment. The removal of As(III) by ferrate/biochar exhibited that As(III) was oxidized to As(V) by ferrate (Wang et al. 2021b). The sorption of As(III) was mainly dominated by electrostatic attraction, H-bond and formation of As–O–Fe bonds. The ferrate enhanced As(III) sorption and then oxidized it to As(V) obviously. The removal of As(III) by biochar/SnS2/PTA composites through sorption and photocatalysis strategies showed that the removal efficiency of As(III) by biochar/SnS2/PTA was 1.5 times higher than that of As(III) by biochar/SnS2, and As(III) was photo-oxidized to form As(V) coprecipitate (Xue et al. 2021). Wongrod et al. (2018) prepared biochar from sewage sludge digestate and further treated the biochar with KOH. The results showed that pHpzc, cation exchange capacity and BET area were increased obviously after KOH treatment. The sorption capacities of Cd(II) (16 μmol/g) and As(V) (1.6 μmol/g) on raw biochar increased to 318 μmol g–1 and 8.5 μmol g–1 on KOH-treated biochar, respectively. More importantly, 70% As(III) was oxidized to As(V) on KOH-treated biochar. The treatment of biochar with KOH or incorporation of biochar with metal oxides increased As(III) sorption and oxidation to As(V), and thereby decreased the toxicity of As(III) in environment.

4.2 Removal of Cr(VI)

The sorption and reduction of Cr(VI) by biochar was investigated and the mechanism was discussed from XAFS and confocal micro-XRF characterization (Liu et al. 2020a). The XAFS analysis showed that Cr(VI) ions were reduced to form Cr(OH)3 precipitate at pH 2 with the Cr–Cr and Cr–O bond distances of 3.03 and 1.97 Å, respectively (Fig. 4a–d). The Cr(VI) and Cr(III) intensities in biochar after 30 min, 6 h and 24 h were measured by confocal micro-XRF spectroscopy. Cr(III) was the main Cr species and only a slight amount of Cr(VI) was found in biochar (Fig. 4e–g). The sorption of Cr(VI) ions from aqueous solution to biochar involved electrostatic attraction on biochar surface, diffusion into the inside of biochar, and reduction at biochar surface and interior. The quinones, aromatic carbon and O-containing groups of biochar contributed mainly to Cr(VI) sorption and the H+ is crucial for Cr(VI) reduction to Cr(III). Liu et al. (2020b) prepared high C content biochar from apple wood and applied it to removing Cr(VI) from wastewater. The biochar exhibited > 99% Cr(VI) removal at pH 2 and the FTIR analysis showed that C=O and C–O groups participated in Cr(VI) sorption. The XAFS analysis indicated the reduction of Cr(VI) to Cr(III) and confocal micro XRF mapping showed the heterogeneous Cr distribution on biochar. The reduction, electrostatic attraction, ion exchange and surface complexation are the main mechanism for Cr(VI) sorption and reduction on biochar.

XAFS spectra of Cr(VI) sorption on biochar samples at pH 2 (a); k space fitting (b); magnitude in R space (c) and real part in R space (d); Confocal micro-XRF spectroscopy mapping of total Cr, Cr(VI) and Cr(III) for different reaction time (e–g) (Liu et al. 2020a)

Shi et al. (2018) modified biochar with Fe3O4@SiO2-NH2 and applied it to Cr(VI) removal from acidic solutions. The results showed that the Fe3O4@SiO2-NH2 modified biochar had the sorption capacity of 27 mg g–1, much higher than that of the bare biochar (18 mg g–1). The sorption of Cr(VI) was mainly dominated by three steps, i.e., (1) Cr(VI) sorption to biochar; (2) Cr(VI) reduction to Cr(III) on biochar; and (3) Cr(III) chelation with amine groups on biochar. Chen et al. (2022c) studied the transformation of Cr(VI) in soil, and found that straw biochar showed higher effect on Cr(VI) transport than the wood biochar, which was attributed to the higher polarity and more negative charge of straw biochar. The biochar could result in Cr(VI) reduction to form Cr(OH)3 to be immobilized on biochar. The extraction of Cr(VI) from complex solutions by photocatalytic reduction showed that Cr(VI) extraction decreased from 97% to 9% with the pH increasing from 4 to 10 (Yao et al. 2022a). The formation of insoluble Cr(V) polyhydroxy contributed to the photo-reduction of Cr(VI) in the presence of competing metal ions. This technique could also extract Cr(VI) ions effectively from Cr-stainless steel and plating wastewater (Yao et al. 2022b). This work highlighted the selective extraction of Cr(VI) from wastewater by adjusting pH under natural sunlight conditions. The separation and extraction of Cr(VI) through sorption-photocatalytic reduction is an efficient and economical method. Considering the low-cost synthesis of biochar and advantages of modification with metals, nonmetals and metal oxides, biochar-based materials will play important role in Cr(VI) pollution treatment.

4.3 Removal of U(VI)

Hexavalent U(VI), especially U-235, is the main element to prepare nuclear fuel. Yang et al. (2021b) doped N and Fe atoms in porous carbon to prepare Fe–Nx–C–R catalyst (R is amidoxime group), which was rich in amidoxime functional groups and FeN4 sites, favorable for U(VI) sorption and reduction. The Fe–Nx–C–R electrode could continuously extract U(VI) from seawater by electro-catalytic extraction processes (Fig. 5a). The yellow precipitates formed on the electrode could be separated from seawater easily. The XAFS spectra analysis showed the formation of Na2O(UO3·H2O)x without UO2 precipitate formation (Fig. 5b). The possible mechanisms of U(VI) elimination by sorption-electrocatalysis strategies are described in Fig. 5c. More importantly, this method showed high selective preconcentration of U(VI) from wastewater in the existence of different foreign cation ions (Fig. 5d). However, the intermediates were not measured in this work. The in-situ Raman spectroscopy was used to measure the intermediates after different reaction time (Liu et al. 2022f). The U(VI)-adsorbed sample had the peak at Raman shift of 489 cm−1, and then a new signal peak at Raman shift of 810 cm−1 appeared, which confirmed U(V) intermediate formation (Pointurier and Marie 2013). The new signal at 374 cm−1 corresponded to Na2O(UO3·H2O)x (Fig. 5e). The in-situ Raman spectroscopy characterization directly indicated the formation of UO2+ intermediate and then it was re-oxidized to form Na2O(UO3·H2O)x on the electrode. The continuous selective separation of U(VI) from complex solutions is not only for U(VI) elimination from solutions, but also beneficial for the sustainable development of nuclear power energy.

Photographs of Fe–Nx–C–R electrode for U(VI) electrocatalytic extraction from U(VI)-spiked seawater (a), XAFS spectra for electrochemical products using Fe–Nx–C–R as catalyst (b), possible mechanism of U(VI) extraction from seawater by Fe–Nx–C–R as catalyst (c) (Yang et al. 2021b); selective U(VI) sorption from real seawater (d) and the in-situ Raman spectroscopy analysis as a function of reaction time (e) (Liu et al. 2022f)

4.4 Removal of other metals

The removal of Cu(II), Zn(II) and Cd(II) by magnetic biochar from solutions achieved the sorption capacities of 23 mg g–1 for Cd(II), 56 mg g–1 for Cu(II) and 22 mg g–1 for Zn(II). The authors attributed the high sorption to the presence of –COOH and –OH functional groups (Son et al. 2018). The removal of Cu(II), Zn(II) and Pb(II) by different biochar was investigated and the results showed that the B. pendula biochar had the highest Cu(II) sorption ability (129 μg g–1) whereas P. sylvestris L. biochar had the highest Zn(II) sorption ability (107 μg g–1) (Komkiene and Baltrenaite 2016). The removal of Hg0 by metal-doped biochar exhibited higher sorption efficiency than bare biochar (Jia et al. 2021). The sorption of Hg0 on biochar was divided into external sorption and internal mass transfer. The adsorbed Hg0 was oxidized to form HgO and HgO-metal forms. The doping of metals or metal oxides played synergistic roles to enhance Hg0 removal performance. Besides the sorption of metals from solutions, the addition of biochar into agricultural soils also immobilized the mobilization of metals such as Cd(II), Pb(II), Cu(II) and Zn(II) in soils (Kim et al. 2015). The bioavailability of Cr(VI), Cd(II), Pb(II) and Cu(II) by tomato plant showed that the addition of biochar to soil decreased the accumulation and bioavailability of metals in tomato fruit. The presence of biochar decreased the intake of metals (Alam et al. 2021).

From the abovementioned references, one can see that the selective extraction of the target radionuclides or metals is the best method, which is not only applicable for pollution treatment, but also for the enrichment of target materials. The in-situ immobilization of metals is also efficient to immobilize the metals, thereby decreasing the immobilization and toxicity to the ecosystems. The abundant functional groups, active sites and porous structures of biochar provide the high sorption, separation and solidification abilities to separate/extract metals or radionuclides from solutions.

5 CO2 capture by biochar and biochar-based materials

The capture of CO2 is critical for greenhouse effect and global warming. Yuan et al. (2022) reviewed CO2 capture by porous carbon, and concluded that the microporosity and functional groups were critical for CO2 capture. The authors also pointed out that excellent selectivity of CO2, high adsorption at low pressure, stability for long cycles and high resistance to moisture were still the main challenges. In this section, we mainly reviewed and compared the capture of CO2 by different biochar, i.e., pristine biochar, KOH-treated biochar and biochar-based composites.

5.1 CO2 capture by pristine biochar

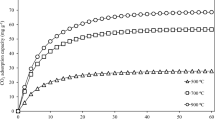

The pristine biochar has porous structures and high surface areas, which are beneficial for CO2 capture. The biochar prepared from sugarcane bagasse and hickory wood under different temperatures (600, 450 and 300 °C) were applied to CO2 adsorption (Creamer et al. 2014). The results showed that the biochar prepared at higher temperature exhibited higher adsorption capacity. The biochar prepared at 600 °C exhibited the adsorption capacity of 73.6 mg g–1 at 25 °C through physisorption. The high surface area, porous structures and surface functional groups were important to improve the adsorption ability and selectivity of CO2 on biochar. The biochar synthesized from wood and straw was used for CO2 adsorption (Cao et al. 2022). The surface area of wood biochar was 2.7–4.4 times higher than that of straw biochar, which was in good agreement with the results reported by Li et al. (2023c). The CO2 adsorption capacity of wood biochar (41–46 mg g–1) was much higher than that of the straw biochar (26–41 mg g–1). The adsorption of CO2 by biochar was related to the surface area and basicity of biochar, which was confirmed by the linear correlation analysis of CO2 adsorption data (Fig. 6a). The interaction of CO2 with biochar was mainly dominated by physical adsorption and Lewis acid–base reactions. More importantly, the biochar was easily regenerated at high temperature, i.e., the adsorption of CO2 decreased about 71–80% when the temperature increased from 0 to 65 °C. The biochar still exhibited high reusability (96–99%) after 10 adsorption–desorption recycles, suggesting the possible real applications in CO2 capture in future. Salem et al. (2021) synthesized leaf biochar under different pyrolysis temperatures and use it for CO2 adsorption. The results showed that the porous structures were beneficial for the high adsorption capacity through chemisorption and physisorption reactions. The CO2 adsorption capacity increased with the increase of synthesis temperature. The highest adsorption capacity was achieved to be 0.25 g CO2 g–1 biochar synthesized at 600 °C. Zhang et al. (2022c) prepared biochar with fine-tuned micropore structure and then impregnated it with sodium lignosulfonate to modify the surface area and porosity. The impregnated biochar had higher surface area and micropore volume, and was used for the adsorption of CO2 and VOCs (using acetone and benzene as representative VOCs). The micropore structure, high surface area and micropore volume were critical and beneficial for CO2 capture, with the adsorption capacity of 77–103 mg g–1 and high reusability. More importantly, the treated biochar also showed high adsorption ability for benzene (31–61 mg g–1) and acetone (45–81 mg g–1) (Fig. 6b). This work highlighted the application of impregnated biochar for the capture of VOCs and CO2 in pollution treatment. The abovementioned results showed that biochar synthesized at higher temperature exhibited higher porosity, higher surface area and density, which thereby enhanced CO2 adsorption ability. The biochar prepared from different feedstocks also showed different porous structures and element contents, which also affected CO2 capture ability. Nevertheless, biochar prepared by woody feedstock under high temperature generally showed high CO2 adsorption capacity.

5.2 CO2 capture by KOH treated biochar

Considering the property of CO2, the treatment of biochar with base solution would change the surface basicity of biochar and thereby improve CO2 capture ability. Igalavithana et al. (2020) synthesized biochar using feedstock mixtures with different ratios of wood waste and food waste by gasification technique, and then activated the biochar with KOH. The KOH-activated biochar exhibited higher CO2 adsorption with high recyclability as compared to untreated biochar. The characterization showed that N and S groups contributed significantly to high CO2 adsorption. It is necessary to note that the high percentage of food waste was unfavorable for the adsorption of CO2, which was in good agreement with the conclusion of the aforementioned results, i.e., biochar synthesized from woody feedstock exhibited high CO2 adsorption capacity. The KOH-activated biochar with the surface area of 3167 m 2 g–1 exhibited the CO2 adsorption capacity of 1.15 g g–1 at 25 °C and 30 bar (Li et al. 2016). The KOH-activated biochar exhibited the CO2 capture ability of 50.7 mg g–1, much higher than that of pristine biochar (22 mg g–1) and steam-activated biochar (25.5 mg g–1) (Zhang et al. 2022d). The surface charge, porosity, surface area, pore volume and morphology of biochar were changed after KOH treatment, which increased the CO2 capture ability. The introduction of alkaline groups on biochar also contributed to CO2 adsorption. The increase of KOH amount used for biochar treatment increased the adsorption ability of CO2 because the surface pH increased with the increase of KOH amount used. The effect of humidity on CO2 adsorption showed that CO2 capture decreased with the increase of relative humidity. The H2O molecule has higher binding energy and polarity, which results in the binding on the biochar active sites and thus reduces CO2 adsorption on biochar. The biochar prepared by bamboo was activated with KOH and used for CO2 capture under different conditions (Zhang et al. 2022e). The KOH-treated biochar exhibited the CO2 capture ability of 3.49 mmol g–1 under atmospheric pressure at 25 °C, and still achieved the adsorption capacity of 51.7 μmol g–1 in direct air capture by column experiments. The adsorption of CO2 increased with the increase of KOH amount used for biochar surface charge modification (Fig. 7a). Similar results were also found for N2 adsorption (Fig. 7b). The KOH treatment changed the surface basicity of biochar and thereby increased CO2 adsorption. The effect of relative humidity showed high stability of CO2 capture under 2.7% relative humidity, but decreased with the increase of relative humidity. After KOH treatment, the surface properties of biochar facilitated CO2 capture. The porosity and surface area of biochar were significantly increased after KOH treatment, which was favorable for CO2 capture. KOH could intercalate in the carbon layers and reacted with CO2 to form potassium carbonates and metallic potassium. These properties are beneficial for CO2 capture by KOH-treated biochar (Sajjadi et al. 2018). In most published papers, the biochar was treated with KOH to surface basicity. Other kinds of bases for biochar treatment were not available and should be carried out in future.

5.3 CO2 capture by biochar-based materials

Besides the physisorption of CO2 by biochar, the incorporation of metals or metal oxides could improve the chemisorption of CO2, which is favorable to enhanced CO2 capture. Creamer et al. (2016) incorporated different metal oxyhydroxides (Fe2O3, AlOOH nanoparticles) on biochar and used them for the capture of CO2. The biochar had high surface area for CO2 capture through physical adsorption process. The AlOOH-biochar exhibited the adsorption capacity of 71 mg g–1 at 25 °C under 1 atmospheric pressure. The adsorbed CO2 could be desorbed at 120 °C for regeneration. This work highlighted the incorporation of metal oxides on biochar to improve the CO2 capture ability at low cost with high adsorption efficiency. The Mg was impregnated into biochar using magnesium salts (i.e., Mg(NO3)2, MgSO4, MgCl2, MgC2H3O2) (Zubbri et al. 2020). The adsorption capacities of CO2 were in the sequences of Mg(NO3)2-modified biochar > MgSO4-modified biochar > MgCl2-modified biochar > MgC2H3O2-modified biochar. The CO2 adsorption capacity by the metallized biochar achieved 76.8 mg g–1, much higher than that of pristine biochar (68.4 mg g–1). The metallized biochar also showed high selectivity for CO2 adsorption as compared to other gases such as nitrogen, methane and air. Although the authors mentioned that the introduction of Mg ions with basic properties increased the biochar surface basicity, which enhanced the acidic gas CO2 adsorption ability, however, the mechanism and the reason for CO2 adsorption sequences on the magnesium salt-modified biochar were not described. Lahijani et al. (2018) incorporated different metals into biochar and used it for CO2 capture. The incorporation of metal in the biochar skeleton enhanced the adsorption of CO2 in the following sequence: Mg-biochar > Al-biochar > Fe-biochar > Ni-biochar > Ca-biochar > pristine biochar > Na-biochar (Fig. 7c). The Mg-biochar showed the CO2 adsorption capacity of 82 mg g–1 at 25 °C under 1 atmospheric pressure. The kinetic study showed that the physisorption was the main mechanism for CO2 adsorption to the metalized biochar. The surface area, surface basicity and porosity are significantly beneficial for CO2 capture. However, the high metal deposition reduced the physical adsorption of CO2 by pore blockage (Fig. 7d). Although the metal deposition reduced the physisorption of CO2, the chemisorption contribution of basic metal oxides interacting with CO2 increased the adsorption ability. The high stability, reusability and easy regeneration of the low-cost biochar indicated it a promising material in CO2 capture in real applications.

From the above mentioned results, one can see that biochar is a low-cost material for the capture of CO2 with high reusability. Generally, the sorption ability decreased with the temperature increasing, which can be utilized in the regeneration of biochar. The advantages and disadvantages of pristine biochar, KOH-treated biochar and biochar-based composites in CO2 capture are tabulated in Table 1. For most biochar materials, the surface area, porosity, functional surface groups and basicity are important parameters affecting the adsorption of CO2. The activation of biochar with base such as KOH could improve the basicity of biochar, which is favorable for the adsorption of CO2. The incorporation of biochar with single metals or metal oxides could improve the adsorption ability and selectivity. However, it is clear to see that the mechanism of CO2 capture is still unclear although most works reported the mechanism of physisorption for most kinds of biochar. The mechanism characterization at the molecule level from advanced spectroscopy analysis is still scarce, which may be restricted by the biochar complex structures. The adsorption capacities were measured under different conditions such as different temperatures, different pressures, different CO2 contents etc. No standard method for the adsorption capacity measurement was available, and most values were achieved at the laboratory level. Nevertheless, the outstanding physicochemical properties of biochar such as low cost, high surface area, high porosity, abundant active sites and easy modification of structures and surface properties make biochar a suitable material for CO2 capture in real applications. The conversion of CO2 into other useful chemicals is a research hotspot and should be considered.

6 H2 production by biochar and biochar-based materials

In this section, we mainly described the use of biochar for H2 production by different techniques such as electrolysis, photocatalysis, chemical pyrolysis, and summarized the main challenges for each technique.

6.1 H2 production by electrolysis strategy

Electrolysis is an easy and simple method to produce H2. Amikam et al. (2020) reported the hydrogen production by biochar-assisted electrolysis. H2 was generated in divided electrolysis cells where the H2 evolution reaction occurred on the cathode and ferrous iron oxidation occurred on the anode. About 98% current efficiency of H2 production was achieved at the current density of 50 mA cm−2 (Fig. 8a). The chemical bonds were destroyed to form free H+ ions and then reformed to form H2 under the electrolysis condition. The metal-doped biochar was used for H2 generation, and achieved the hydrogen production ability of 1.5 mol kg−1 with the selectivity of 22.9% (Su et al. 2022). The alkali metal-doped biochar not only showed high hydrogen production but also immobilized heavy metal ions efficiently. The doping of Zn, Cd, Mn, Pb in biochar enhanced the production of hydrogen effectively. Metal doping could enhance the generation of intermediates such as formate, which reacted with water to produce Hcatal and catalyzed H2O to H2 conversion. The doped metal could also damage the biomass cells of biochar, resulting in the release of organic matter in aqueous solution, which was further gasified to produce syngas including H2 and CO2 (Muangrat et al. 2010). This work highlighted the doping of metals in biochar for H2 generation and metal ion stabilization. For electro-generation, the metal doping improved the H2 generation efficiency. Till now, the application of bare biochar as electrode for H2 generation is still scarce. The stability of the biochar electrode and the efficiency for H2 generation with high selectivity are still the main challenges in electrolytic H2 production.

Proposed process for iron-mediated biochar-assisted water electrolysis for hydrogen production (a) (Amikam et al. 2020); enhanced and decreased hydrogen production by biochar in the absence and presence of DOM and the contribution of reactive oxygen species and microbial community to hydrogen production (b) (Wu et al. 2022)

6.2 H2 production by photocatalysis strategy

Besides electrolysis strategy, the utilization of natural solar energy for H2 production is a cost-effective way. Zou et al. (2022a) synthesized biomass biochar by microwave-assisted stover technique and used it as catalyst to produce hydrogen with high selectivity and ability. The selectivity of hydrogen production was achieved to be 72% at the biochar/feedstock ratio of 4:1, and the production of CO2 and CH4 was obviously hindered in the synthesized gases. More importantly, the microwave-prepared biochar showed high stability and reusability in hydrogen generation, still achieving the production selectivity of > 50% after 10 cycles of reuses. The degradation of low-density polyethylene and biomass could form H2O, CH4 and CO. These small molecules can further react to form H2 and aromatics. H2 can also be formed through the H-abstraction reaction in the β-scission reactions of the free radicals (Zou et al. 2022b). Bhavani et al. (2022) used rice huck-derived biochar as cocatalyst to improve the ZnIn2S4 photocatalytic activity for H2 production. ZnIn2S4 was incorporated on biochar as few layered nanosheets after ultra-sonication treatment. The ZnIn2S4/biochar exhibited the H2 production ability of 4.47 mmol (h·g)−1 with high selectivity and high stability under solar light irradiation conditions (30 h photocatalytic experiments). The efficient generation of e−–h+ pairs, effective separation of e−–h+ pairs, charge carrier separation and long-life shuttling enhanced the photocatalytic H2 generation under sunlight irradiation. Under solar light, the electrons in ZnIn2S4 diffuse to ZnIn2S4 surface, which leads to charge accumulation and the upwards of the band bending. The high dense charge allows the subsequent transfer to the skeleton of biochar and results in water splitting to generate H2 (Bie et al. 2019). The electrons also accelerate water molecule reduction and thereby generates H2. The high biochar porous skeleton can promote electron acceleration efficiently to achieve high H2 production efficiency. Fe-dopped biochar was used for the catalytic cracking of toluene to produce hydrogen (Liu et al. 2022e). The produced hydrogen amount by toluene catalysis using 4% Fe-loaded biochar was 3 times higher than that by toluene self-pyrolysis. The metal-doping biochar could enhance the interaction of biochar with the organic molecules through π–π interaction and electrostatic attraction, thereby enhancing the catalytic activity for H2 production.

6.3 H2 production by chemical pyrolysis strategy

Chemical pyrolysis could produce syngas in large scale. In the chemical pyrolysis, H2 could be produced with high ratio. Wu et al. (2022) studied the biochar-derived DOM in the fermentation production of hydrogen. The biochar pyrolysis at low temperature showed the inhibition of H2 production. The DOM derived from biochar pyrolysis at low temperature prolonged the hydrogen fermentation period and reduced hydrogen generation as compared to the relative high pyrolysis temperature. The inhibiting mechanism of DOM on the bio-production of hydrogen was attributed to the increase of reactive oxygen species and microbial community shift to less hydrogen-production strains (Fig. 8b). The DOM induced the biotoxicity to hydrogen production microflora, thereby decreasing the H2 production ability. The DOM derived from the pyrolyzed biochar exhibited more significant effect on the utilization of xylose than glucose. The DOM also inhibited the formation of soluble metabolites, which were favorable for the stoichiometric reactions for xylose and glucose conversion to butyrate and acetate (Dessi et al. 2017). The acetate or butyrate is favorable for biohydrogen production (Hitit and Hallenbeck 2021). Thereby, the biochar-derived DOM showed negative impact on H2 production.

The syngas was produced by chemical looping gasification of biochar using BaFe2O4 as oxygen carrier (Abdalazeez et al. 2022). The maximum syngas production of 18.2 mol kg−1 at the temperature of 900 °C with the H2/CO ratio of 0.39 was achieved. The addition of steam enhanced biochar chemical looping gasification and the H2 content in the syngas, the syngas production reached 77.8 mol kg−1 with the H2/CO ratio of 3.2, which satisfied the requirement of syngas application. The metal ferrites have the spinel-type structure with the formular of M2+Fe23+O4. The spinel structure has high reactivity with carbon through solid–solid reactions and thereby lowers the reactive energy for syngas production. This work indicated that the biochar prepared from rice husk could be used to generate syngas for real applications in industry. Su et al. (2020) used SCWG technique to covert plumbizincicola into hydrogen and simultaneously to immobilize heavy metals in biochar. At the temperature of 440 °C, the hydrogen production achieved 2.74 mol kg−1, and the increase of temperature increased hydrogen generation and heavy metal immobilization efficiency, which was attributed to the quick formation of biochar, thereby immobilizing metal ions with high efficiency. The GC–MS and NMR analysis showed that the oxygenated compounds, phenols and aromatic compounds in the hyperaccumulators were degraded at high temperature to generate H2-rich gas. This work highlighted the change of waste (hyperaccumulators) into treasure (H2-rich gas and biochar), also decreased environmental pollution (immobilization of heavy metal into biochar, which was the strategy for metal-doping biochar to improve the photocatalytic activity of biochar). H2-rich syngas was produced by biomass biochar through chemical looping gasification method using CaFe2O4 as oxygen carrier (Liu et al. 2022d). The CaFe2O4 catalyst showed excellent hydrogen production (2.0 Nm3 kg−1)−1 at 850 °C at the CaFe2O4/biochar ratio of 1:1. The hydrogen content in the syngas was measured for gas–solid and solid–solid reactions, and the results showed that H2 was the dominant gas in gas–solid reaction. The reaction of biochar with steam included two processes, i.e., reduced O carrier + H2O → O carrier + H2, and H2O + biochar → H2 + CO/CO2. The addition of CaFe2O4 enhanced the conversion of CH4 and CO, which was attributed to the lattice oxygen oxidation. The XPS analysis showed that the lattice oxygen content in CaFe2O4 decreased obviously after the reaction, indicating the reaction participation. The spinal structure of CaFe2O4 is beneficial for carbon gasification and H2 production because the CaO component in the catalyst promoted H2 production due to the accelerated water–gas-shift reactions (Yan et al. 2021). The oxygen vacancies also catalyzed the water–gas-shift reaction, playing important roles in H2 production (Xin et al. 2021). The catalyst showed high stability and reusability even after 5 cycles. However, the generated Si by biochar caused the destruction of CaFe2O4, thereby decreasing CO conversion after the H2-production reactions.

From the abovementioned works, one can see that the biochar and biochar-based materials are suitable candidates for H2 production as catalysts or H2 resources. The hydrogen generation efficiency is relatively low by bare biochar. To improve the H2 production ability, the incorporation of biochar with metal oxides is an efficient method to improve the hydrogen generation. However, the selectivity of hydrogen generation is still a problem. Generally, the produced gases generally contain different kinds of gases such as H2, CO, CO2 etc. The generation of H2-rich gases is relatively achieved as compared to pure H2 gas by biochar or biochar-based materials. Considering the low cost and easy synthesis of biochar in large scale, it is economical for the application of biochar in H2 production if the H2 generation efficiency is high and the H2 content in the produced gases is high enough to meet the requirement of syngas for real applications in industry. Considering the large applications of syngas, biochar-based materials show great potential in production of syngas in future.

7 Conclusion and perspective

In this review, the application of biochar-based composites and bare biochar materials for the removal of organic chemicals, metals and radionuclides through sorption and catalysis strategies for the capture of carbon dioxides and for the generation of hydrogen was summarized. In the removal of organic pollutants, the high surface area, porosity and abundant functional groups are beneficial for the uptake of organic molecules. The doping of metals or incorporation of metal oxides could improve the photocatalytic activity, and thereby could improve the photocatalytic degradation of organic pollutants. The elimination of metals/radionuclides from aqueous solutions is mainly dominated by the active sites and special functional groups of biochar through strong surface complexation or reduction-solidification on biochar. The incorporation of biochar with other metal oxides or doping of single atoms on biochar could enhance the reduction ability to solidify metals/radionuclides, thereby immobilizing the migration or transport of the metals/radionuclides in the environment. For the efficient capture of CO2, the high porosity, high surface area, abundant functional groups and surface basicity are important parameters for the binding of CO2. The interaction of CO2 with biochar was mainly dominated by physical adsorption and Lewis acid–base reactions. The adsorption capacity is strongly dependent on temperature, and it can be easily desorbed at high temperature. The H2 production by biochar is strongly dependent on the metal oxides, which act as catalysts to promote the generation of H2. H2 can be generated through the techniques of electrocatalysis, photocatalysis, chemical pyrolysis, etc. The main mechanisms for the application of biochar/biochar-based materials in the removal of the pollutants, CO2 capture and H2 generation are illustrated in Fig. 9. Based on the outstanding physicochemical properties of biochar-based materials such as highly porous structures, abundant active sites, sufficient functional groups, high surface areas, high stability, reusability, low cost environmental friendliness, biochar has promising future applications in multidisciplinary areas.

Biochar in organic pollutant elimination (a); elimination of heavy metals and radionuclides by biochar and biochar-based materials (b); CO2 capture by biochar and biochar-based materials (c); H2 production by electrolysis strategy (d-1); H2 production by photocatalysis strategy (d-2); H2 production by chemical pyrolysis strategy (d-3)

However, there are still some challenges for the real applications of biochar in future.

-

(1)

The cost for synthesis of biochar is still not definitely described as the quite differences in the raw materials, the synthesis conditions and processes etc. The production costs ranged from 51 to 5668 US$ ton−1 (roughly 100–800 US$ ton−1) from the published papers (Ahmed et al. 2016b; Das et al. 2016; Maroušek 2014). The cost of biochar and other materials in pollutant removal, CO2 capture and H2 generation are still not comparable. Considering the cost-effective synthesis, the economic feasibility of biochar in real applications is satisfactory, since many feedstocks used for biochar synthesis are environmental wastes.

-

(2)

The selective adsorption of target pollutants is still low. Although the biochar has high adsorption ability for the removal of organic or inorganic contaminants from solutions, the selective extraction of target pollutants from complex solutions is still limited, which is related to the absence of special functional groups on biochar for selective binding of target pollutants.

-

(3)

The catalysis capacity for the degradation of organic molecules or extraction/reduction of metals or radionuclides is still not high for bare biochar. The weak natural sunlight absorption and photogeneration of e−–h+ pairs, the weak catalytic capacity of bare biochar restricted the biochar as catalyst in photocatalytic reduction of metals or photocatalytic degradation of organic chemical molecules. The doping or co-doping of metals/nonmetals or the incorporation of metal oxides could improve the porous structures and surface properties of biochar and then enhanced the photocatalytic capacity.

-

(4)

The use of biochar for the generation of H2 could easily achieve high content of H2 in syngas, which could meet the requirements for industrial applications. Although the doping of metals or incorporation of other (nano)materials or metal oxides with biochar could improve the hydrogen generation, the high selectivity for H2 generation is still difficult.

-

(5)

For the capture of CO2 using biochar, the surface area, porosity, functional surface groups and basicity are important parameters for the adsorption of CO2. The incorporation of biochar with single metals or metal oxides could improve the adsorption ability and selectivity. No standard method for the adsorption capacity measurement was available, and most values were achieved at the laboratory level.

-

(6)

The mechanisms of CO2 capture, H2 generation and organic contaminant’ photocatalytic degradation are still unclear. The mechanism characterizations at the molecule level from advanced spectroscopy measurements and DFT calculations are still not available. More detailed work from theoretical calculation, in-situ measurements and spectroscopic analysis are necessary in future.

-

(7)

For the environmental impacts, biochar is a sustainable platform to generate functional materials. After the sorption of metal ions or organic pollutants, the spent biochar is itself polluted and should not be disposed easily. Fast pyrolysis may be a suitable technique to convert the adsorbed metals into metallic nanoparticles, which can be used as catalysts. The self-functionalized biochar can be further used for photodegradation of organic pollutants, CO2 capture or H2 generation.

Availability of data and materials

Authors can confirm that all relevant data are included in the article.

Abbreviations

- 4-CP:

-

4-Chlorophenol

- BET:

-

Brunauer–Emmett–Teller

- BPA:

-

Bisphenol A

- COFs:

-

Covalent organic frameworks

- DFT:

-

Density functional theory

- DOM:

-

Dissolved organic material

- ESR:

-

Electron spin resonance

- GC–MS:

-

Gas Chromatography–Mass Spectrometer

- MOFs:

-

Metal organic frameworks

- NMR:

-

Nuclear Magnetic Resonance

- PAHs:

-

Polycyclic aromatic hydrocarbons

- PMS:

-

Peroxymonosulfate

- POPs:

-

Persistent organic pollutants

- PTA:

-

Phosphotungstic acid

- PZC:

-

Point of zero charge

- SCWG:

-

Supercritical water gasification technique

- SSF:

-

Simultaneous saccharification and fermentation

- TC:

-

Tetracycline

- VOCs:

-

Volatile organic compounds

- XAFS:

-

X-ray absorption fluorescence structure

- XRF:

-

X-ray fluorescence

References

Abdalazeez A, Tianle L, Cao Y, Wang W, Abuelgasim S, Liu C (2022) Syngas production from chemical looping gasification of rice husk-derived biochar using BaFe2O4 as an oxygen carrier. J Energy Inst 105:376–387

Ahmed MB, Zhou JL, Ngo HH, Guo W, Chen MF (2016a) Progress in the preparation and application of modified biochar for improved contaminant removal from water and wastewater. Bioresour Technol 214:836–851

Ahmed MB, Zhou JL, Ngo HH, Guo WS (2016b) Insight into biochar properties and its cost analysis. Biomass Bioenergy 84:76–86

Alam I, Alam M, Khan A, Haq SU, Ayaz A, Jalal A, Bhat JA (2021) Biochar supplementation regulates growth and heavy metal accumulation in tomato growth in contaminated soils. Physiol Plant 173:340–351

Amikam G, Fridman-Bishop N, Gendel Y (2020) Biochar-assisted iron-mediated water electrolysis process for hydrogen production. ACS Omega 5:31908–31917

Benis KZ, Damuchali AM, Soltan J, McPhedran KN (2020) Treatment of aqueous arsenic-a review of biochar modification methods. Sci Total Environ 739:139750

Bhavani P, Kumar DP, Hussain M, Aminabhavi TM, Park YK (2022) Eco-friendly rice husk derived biochar as a highly efficient noble metal-free cocatalyst for high production of H2 using solar light irradiation. Chem Eng J 434:134743

Bie C, Zhu B, Xu F, Zhang L, Yu J (2019) In situ grown monolayer N-doped graphene on CdS hollow spheres with seamless contact for photocatalytic CO2 reduction. Adv Mater 31:1902868

Brewer CE, Chuang VJ, Masiello CA, Gonnermann H, Gao X, Dugan B, Driver LE, Panzacchi P, Zygourakis K, Davies CA (2014) New approaches to measuring biochar density and porosity. Biomass Bioenergy 66:176–185

Brown RA, Kercher AK, Nguyen TH, Nagle DC, Ball WP (2006) Production and characterization of synthetic wood chars for use as surrogates for natural sorbents. Org Geochem 37:321–333

Cai Y, Zhang Y, Lv Z, Zhang S, Gao F, Fang M, Kong M, Liu P, Tan X, Hu B, Wang XK (2022) Highly efficient uranium extraction by a piezo catalytic reduction-oxidation process. Appl Catal B Environ 310:121343

Cai YW, Chen ZS, Wang SH, Chen JR, Hu BW, Shen C, Wang XK (2023) Carbon-based nanocomposites for the elimination of inorganic and organic pollutants through sorption and catalysis strategies. Sep Purif Technol 38:122862

Cao X, Sun S, Sun R (2017) Application of biochar-based catalysts in biomass upgrading: a review. RSC Adv 7:48793–48805

Cao L, Zhang X, Xu Y, Xiang W, Wang R, Ding F, Hong P, Gao B (2022) Straw and wood based biochar for CO2 capture: adsorption performance and governing mechanism. Sep Purif Technol 287:120592

Chatterjee R, Sajjadi B, Mattern D, Chen WY, Zubatiuk T, Leszczynska D, Leszczynski J, Egiebor NO, Hammer N (2018) Ultrasound cavitation intensified amine functionalization: a feasible strategy for enhancing CO2 capture capacity of biochar. Fuel 225:287–298

Chen B, Chen Z, Lv S (2011) A novel magnetic biochar efficiently sorbs organic pollutants and phosphate. Bioresour Technol 102:716–723

Chen Q, Ma C, Duan W, Lang D, Pan B (2020) Coupling adsorption and degradation in p-nitrophenol removal by biochars. J Clean Product 271:122550

Chen ZS, He X, Li Q, Yang H, Liu Y, Wu LN, Liu ZX, Hu BW, Wang XK (2022a) Low-temperature plasma induced phosphate groups onto coffee residue-derived porous carbon for efficient U(VI) extraction. J Environ Sci 122:1–13

Chen H, Gao Y, Li J, Fang Z, Bolan N, Bhatnagar A, Gao B, Hou D, Wang S, Song H, Yang X, Shaheen SM, Meng J, Chen W, Rinklebe J, Wang H (2022b) Engineered biochar for environmental decontamination in aquatic and soil systems: a review. Carbon Res 1:4

Chen M, Chen X, Xu X, Xu Z, Zhang Y, Song B, Tsang DCW, Xu N, Cao X (2022c) Biochar colloids facilitate transport and transformation of Cr(VI) in soil: active site competition coupling with reduction reaction. J Hazard Mater 440:129691

Chen Z, Wang J, Hao M, Xie Y, Liu X, Yang H, Waterhouse GIN, Wang X, Ma S (2023) Tuning excited electronic structure and charge transport in covalent organic frameworks for enhanced photocatalytic performance. Nat Commun 14:1106

Cho DW, Tsang DCW, Kim S, Kwon EE, Kwon G, Song H (2018) Thermochemical conversion of cobalt-loaded spent coffee grounds for production of energy resource and environmental catalyst. Bioresour Technol 270:346–351

Creamer AE, Gao B, Zhang M (2014) Carbon dioxide capture using biochar produced from sugarcane bagasse and hickory wood. Chem Eng J 249:174–179

Creamer AE, Gao B, Wang S (2016) Carbon dioxide capture using various metal oxyhydroxide-biochar composites. Chem Eng J 283:826–832

Dai Y, Zhang N, Xing C, Cui Q, Sun Q (2019) The adsorption, regeneration and engineering applications of biochar for removal organic pollutants: a review. Chemosphere 223:12–27

Das O, Bhattacharyya D, Sarmah AK (2016) Sustainable eco-composites obtained from waste derived biochar: a consideration in performance properties, production costs and environmental impact. J Clean Prod 129:159–168

Dessi P, Lakaniemi AM, Lens PNL (2017) Biohydrogen production from xylose by fresh and digested activated sludge at 37, 55 and 70 degrees C. Water Res 115:120–129

Dissanayake PD, You S, Igalavithana AD, Xia Y, Bhatnagar A, Gupta S, Kua HW, Kim S, Kwon JH, Tsang DCW, Ok YS (2020) Biochar-based adsorbents for carbon dioxide capture: a critical review. Renew Sustain Energy Rev 119:109582

Dong X, Ma LQ, Li Y (2011) Characteristics and mechanisms of hexavalent chromium by biochar from sugar beet tailing. J Hazard Mater 190:909–915

Elsamadony M, Tawfik A, Danial A, Suzuki M (2015) Optimization of hydrogen production from organic fraction of municipal solid waste (OFMSW) dry anaerobic digestion with analysis of microbial community. Int J Energy Res 39:929–940

Farooq A, Jang S, Hoon S, Jung S, Hoon G, Jeon B, Park Y (2021) Catalytic steam gasification of food waste using Ni-loaded rice husk derived biochar for hydrogen production. Chemosphere 280:130671

Gasim MF, Choong ZY, Koo PL, Low SC, Abdurahman MH, Ho YC, Mohamad M, Suryawan IWK, Lim JW, Oh WD (2022) Application of biochar as functional material for remediation of organic pollutants in water: an overview. Catalyst 12:210

Gu H, Liu X, Wang S, Chen Z, Yang H, Hu B, Shen C, Wang X (2022) COF-based composites: extraordinary removal performance for heavy metals and radionuclides from aqueous solutions. Rev Environ Contam Toxicol 260:23

Guillem-Navajas A, Martin-Illan JA, Salagre E, Michel EG, Rodriguez-San-Miguel D, Zamora F (2022) Iron oxyhydroxide-covalent organic framework nanocomposites for efficient As(III) removal in water. ACS Appl Mater Interface 14:50163–50170

Hao M, Chen Z, Yang H, Waterhouse GIN, Ma S, Wang X (2022a) Pyridinium salt-based covalent organic framework with well-defined nanochannels for efficient and selective capture of aqueous 99TcO4−. Sci Bull 67:924–932

Hao M, Chen Z, Liu X, Liu X, Zhang J, Yang H, Waterhouse GIN, Wang X, Ma S (2022b) Converging cooperative functions into the nanospace of covalent organic frameworks for efficient uranium extraction from seawater. CCS Chem 4:2294–2307

Hao M, Xie Y, Liu X, Chen Z, Yang H, Waterhouse GIN, Ma S, Wang X (2023a) Modulating the uranium extraction performance of multivariate covalent organic frameworks through donor−acceptor linkers and amidoxime nanotraps. JACS Au 3:239–251

Hao M, Liu Y, Wu W, Wang S, Yang X, Chen Z, Tang Z, Huang Q, Wang S, Yang H, Wang X (2023b) Advanced porous adsorbents for radionuclides elimination. EnergyChem 5:100101

Hitit ZY, Hallenbeck PC (2021) Analytical procedures, data reporting and selected reference values for biological hydrogen production. Biomass Bioenergy 147:106014

Hu Y, Tang D, Shen Z, Yao L, Zhao G, Wang X (2023) Photochemically triggered self-extraction of uranium from aqueous solution under ambient conditions. Appl Catal B Environ 322:122092

Huang Q, Song S, Chen Z, Hu B, Chen J, Wang X (2019) Biochar-based materials and their applications in removal of organic contaminants from wastewater: state-of-the-art review. Biochar 1:45–73

Huong PT, Jitae K, Tahtamouni TMA, Tri NLM, Kim HH, Cho KH, Lee C (2020) Novel activation of peroxymonosulfate by biochar derived from husk toward oxidation of organic contaminants in wastewater. J Water Process Eng 33:101037

Igalavithana AD, Choi SW, Dissanayake PD, Shang J, Wang CH, Yang X, Kim S, Tsang DCW, Lee BK, Ok YS (2020) Gasification biochar from biowaste (food waste and wood waste) for effective CO2 adsorption. J Hazard Mater 391:121147

Jeyasubramanian K, Thangagiri B, Sakthivel A, Raja JD, Seenivasan S, Balinayagam P, Madhavan D, Devi SM, Rathika B (2021) A complete review on biochar: production, property, multifaceted applications, interaction mechanism and computational approach. Fuel 292:120243

Jia L, Yu Y, Li ZP, Qin SN, Guo JR, Zhang YQ, Wang JC, Zhang JC, Fan BG, Jin Y (2021) Study on the Hg0 removal characteristics and synergistic mechanism of iron-based modified biochar doped with multiple metals. Bioresour Technol 323:125086

Jiang YC, Luo MF, Niu ZN, Xu SY, Gao Y, Gao Y, Gao WJ, Luo JJ, Liu RL (2023) In-situ growth of bimetallic FeCo-MOF on magnetic biochar for enhanced clearance of tetracycline and fruit preservation. Chem Eng J 451:138804

Kim HS, Kim KR, Kim HJ, Yoon JH, Yang JE, Ok YS, Owens G, Kim KH (2015) Effect of biochar on heavy metal immobilization and uptake by lettuce (Lactuca sativa L.) in agricultural soil. Environ Earth Sci 74:1249–1259

Komkiene J, Baltrenaite E (2016) Biochar as adsorbent for removal of heavy metal ions [cadmium(II), copper(II), lead(II), zinc(II)] from aqueous phase. Int J Environ Sci Technol 13:471–482

Kumar A, Singh E, Mishra R, Lo SL, Kumar S (2022) A green approach towards sorption of CO2 on waste derived biochar. Environ Res 214:113954

Lahijani P, Mohammadi M, Mohamed AR (2018) Metal incorporated biochar as a potential adsorbent for high capacity CO2 capture at ambient condition. J CO2 Utilization 26:281–293

Li WJ, Jiang H, Yu HQ (2015) Development of biochar-based functional materials: toward a sustainable platform carbon material. Chem Rev 115:12251–12285

Li Y, Ruan G, Jalilov AS, Tarkunde YR, Fei H, Tour JM (2016) Biochar as a renewable source for high-performance CO2 sorbent. Carbon 107:344–351

Li J, Wang X, Zhao G, Chen C, Chai Z, Alsaedi A, Hayat T, Wang X (2018) Metal–organic framework-based materials: superior adsorbents for the capture of toxic and radioactive metal ions. Chem Soc Rev 47:2322–2356

Li Y, Xiong W, Wei X, Qin J, Lin C (2021) Transformation and immobilization of hexavalent chromium in the co-presence of biochar and organic acids: effects of biochar dose and reaction time. Biochar 3:535–543

Li Y, Huang T, Liu X, Chen Z, Yang H, Wang X (2023a) Sorption-catalytic reduction/extraction of hexavalent Cr(VI) and U(VI) by porous framework materials. Sep Purif Technol 314:123615

Li J, Liu X, Zhao G, Cai Y, Shen C, Wang X (2023b) Piezoelectric materials and techniques for environmental pollution remediation. Sci Total Environ 869:161767

Li Q, Zhang X, Mao M, Wang X, Shang J (2023c) Carbon content determines the aggregation of biochar colloids from various feedstocks. Sci Total Environ 880:163313

Liu P, Ptacek CJ, Wlowes DW, Finfrock Y, Liu Y (2020a) Characterization of chromium species and distribution during Cr(VI) removal by biochar using confocal micro-X-ray fluorescence redox mapping and X-ray absorption spectroscopy. Environ Int 134:105216

Liu N, Zhang Y, Xu C, Liu P, Lv J, Liu Y, Wang Q (2020b) Removal mechanisms of aqueous Cr(VI) using apple wood biochar: a spectroscopic study. J Hazard Mater 384:121371

Liu XL, Ma R, Zhuang L, Hu BW, Chen JR, Liu XY, Wang XK (2021a) Recent developments of doped g-C3N4 photocatalysts for the degradation of organic pollutants. Crit Rev Environ Sci Technol 51:751–790

Liu XL, Pang HW, Liu XW, Li Q, Zhang N, Mao L, Qiu MQ, Hu BW, Yang H, Wang XK (2021b) Orderly porous covalent organic frameworks-based materials: superior adsorbents for pollutants removal from aqueous solutions. Innovation 2:100076

Liu X, Zhang A, Ma R, Wu B, Wen T, Ai Y, Sun M, Jin J, Wang S, Wang X (2022a) Experimental and theoretical insights into copper phthalocyanine-based covalent organic frameworks for highly efficient radioactive iodine capture. Chin Chem Lett 33:3549–3555

Liu Z, Xu Z, Buyong F, Chay TC, Li Z, Cai Y, Hu B, Zhu Y, Wang X (2022b) Modified biochar: synthesis and mechanism for removal of environmental heavy metals. Carbon Res 1:8

Liu ZX, Ling Q, Cai Y, Xu L, Su J, Yu K, Wu X, Xu J, Hu B, Wang X (2022c) Synthesis of carbon-based nanomaterials and their application in pollution management. Nanoscale Adv 4:1246–1262

Liu C, Luo J, Dong H, Zhao Z, Xu C, Abuelgasim S, Abdalazeez A, Wang W, Chen D, Tang Q (2022d) Hydrogen-rich syngas production from biomass char by chemical looping gasification with Fe/Ca-based oxygen carrier. Sep Purif Technol 300:121912

Liu H, Ye C, Xu Y, Wang Q (2022e) Effect of activation conditions and iron loading content on the catalytic cracking of toluene by biochar. Energy 247:123409

Liu X, Xie Y, Hao M, Chen Z, Yang H, Waterhouse GIN, Ma S, Wang X (2022f) Highly efficient electrocatalytic uranium extraction from seawater over an amidoxime−functionalized In−N−C catalyst. Adv Sci 9:2201735

Lu GQ, Low JCF, Liu CY, Lua AC (1995) Surface area development of sewage sludge during pyrolysis. Fuel 74:344–348

Lu Y, Cai Y, Zhuang L, Hu B, Wang S, Chen J, Wang X (2022) Application of biochar-based photocatalysts for sorption-(photo)degradation/reduction of environmental contaminants: Mechanism, challenges and perspective. Biochar 4:45