Abstract

Contamination of aquatic and soil systems by organic and inorganic pollutants has become a serious issue of concern worldwide. Viable and cost-effective solutions are urgently needed to mitigate the negative impacts of diverse pollutants on the environment and human health. Biochar has emerged as an effective and green material for the remediation of a wide spectrum of (in)organic pollutants. However, applications of pristine biochar in decontamination have encountered bottlenecks due to its limited properties which cannot meet the desired remediation requirements. Therefore, multiple modification methods have been developed for tailoring the physicochemical properties of biochar to enhance its effectiveness in environmental decontamination. This work provides a holistic review on the recent advances on the synthesis of engineered biochar using physical, chemical, and biological methods. Further applications and related mechanisms of engineered biochar in the field of environmental decontamination in aquatic and soil systems have also been summarized and discussed. In addition, existing challenges and research gaps are outlined, and future research needs are proposed. This review summarizes the scientific opportunities for a comprehensive understanding of using engineered biochars as effective materials for the remediation of contaminated water and soil.

Graphical abstract

Highlights

• Recent advances on biochar functionalization using physical, chemical, and biological methods are reviewed.

• Decontamination behaviors and mechanisms of (in)organic pollutants by engineered biochar are summarized.

• Existing knowledge gaps are identified, and outlooks of engineered biochar applications are proposed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Rapid urbanization and industrialization together with anthropogenic activities have resulted in ecological disturbances (Monga et al. 2022). Environmental pollution caused by (in)organic pollutants is considered as one of the most urgent issues of recent times due to its alarming health risks to biota (Shaheen et al. 2022b), which requires sustainable remediation approaches. Decontamination techniques using carbonaceous materials such as activated carbon, carbon nanotubes, graphene, and biochar have been developed to minimize the contaminants’ detrimental impacts on the environment (Hu et al. 2020; Kumar et al. 2020). Among them, biochar has several advantages. The estimated cost for biochar is around USD 246 t− 1, which is about 1/6 of commercial activated carbon (Premarathna et al. 2019), and also far less than that of carbon nanotubes and graphene. Furthermore, the source of feedstock for biochar production is more flexible than the others. Considering the perspective of economic and environmental sustainability, biochar is deemed as the most promising carbonaceous material for environmental applications. Biochar is a carbon-rich byproduct produced from a range of renewable biomass wastes under oxygen-limited conditions (Lehmann 2007). As a low-cost and sustainable material with high adsorption capacity and chemical stability, biochar is an effective and eco-friendly adsorbent for pollutant adsorption/immobilization (Shaheen et al. 2022a). For instance, investigations demonstrated that pig-carcass biochar effectively decreased the bioavailability of di-(2-ethylhexyl) phthalate (DEHP) and cadmium (Cd) in contaminated soils (Chen et al. 2019, 2020). Biochar is an appealing choice in the fields of waste management and environmental remediation, owing to its feasibility of large-scale production and multifunctional values (Bolan et al. 2022).

Although biochar has many advantages, the application of pristine biochar in environmental remediation has encountered some bottlenecks: 1) low functionality, such as insufficient porosity and surface area (Kumar et al. 2020); 2) the challenge to separate fine biochar from soil/water phase (Lyu et al. 2020a); 3) limited adsorption efficiency for contaminants at high concentrations (Ahmed et al. 2016); 4) weak affinity to toxic anionic species (e.g., Cr, As, and Sb) due to the negatively-charged surface nature (Chen et al. 2022b) and potential mobilization of oxyanionic contaminants at elevated pH conditions induced by biochar application (Shaheen et al. 2022a, 2022b); 5) potential release of biochar-carried dissolvable pollutants (e.g., metal(loid)s, polycyclic aromatic hydrocarbons (PAHs), persistent free radicals (PFRs) and volatile organic compounds (VOCs)) (Duan et al. 2019).

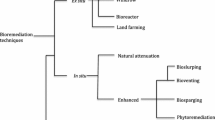

Consequently, various modification methods for tailoring the physicochemical properties of biochar have been applied to enhance its effectiveness in environmental applications. In general, functionalization methods for biochar can be categorized into three types, i.e., physical, chemical, and biological modifications (Zhang et al. 2022d), which are summarized in Fig. 1. Physical modification including steam/CO2 activation, microwave activation, and ball milling alters the pore structure, particle size, surface area, and functional groups of biochar. It offers advantages over chemical methods such as clean and economically feasible biochar production (Duan et al. 2019). Chemical modification methods include acid-base modification, oxidizing treatment, magnetization, loading of clay minerals, carbon nanomaterials, layered double hydroxides, organic surfactants, and nonmetallic element doping, which not only affect the physical properties of biochar, but also significantly influence its chemical properties (e.g., elemental distribution, surface functional groups, point of zero charge, cation exchange capacity, and electron transfer capacity) (Chen et al. 2022b; Medeiros et al. 2022). Changes in the physicochemical properties of biochar affect its potential for environmental applications. Furthermore, biochar can be modified by the biological methods, which takes advantage of microorganisms and biological-related processes (Monga et al. 2022), and further aid in the removal of toxic pollutants.

There have been some reviews focusing on different applications of biochar including aqueous contaminant removal (Hu et al. 2020; Krasucka et al. 2021; Zhang et al. 2020a; Bolan et al. 2022; Medeiros et al. 2022), soil property improvement (Zhang et al. 2022d), soil fertility enhancement (Marcińczyk and Oleszczuk 2022) and catalysis (Monga et al. 2022). To date, most reviews focus more on using pristine and engineered biochar to remove contaminants from aqueous solutions (e.g., Shaheen et al. 2022b, 2022c), particularly the former. However, a holistic review including the applications of engineered biochar in the remediation of both aquatic and soil systems has rarely been reported. Moreover, the summarized information of emerging modification methods for biochar such as nonmetallic heteroatom doping is limited. Recently, Kasera et al. (2022) reviewed the nitrogen-doped biochars as adsorbents in the removal of heavy metals and organics from water, yet biochar doped by other nonmetallic heteroatoms such as sulfur (S) and boron (B) was not well summarized till now. With the aim to provide a detailed overview of engineered biochar for environmental decontamination, based on the publications in recent years, especially in recent five years, this updated review thoroughly summarized the most recent advancements in emerging modification methods for biochar such as nonmetallic heteroatom doping, advanced characterization techniques for biochar analysis, and frontier applications of engineered biochar in both water and soil remediation while addressing pertinent mechanisms involved from multiple aspects. We also maximized the capacity of this review to cover more types of engineered biochar and contaminants to provide an exhaustive reference to the readers. In addition, existing challenges and research gaps are discussed, and future research needs are proposed.

2 Synthesis of engineered biochar

2.1 Physical modification

In general, physical modification of biochar includes steam and microwave activation, CO2 purging, and ball milling, which are usually simpler and less expensive than chemical activation methods (Ahmed et al. 2016). Physical activation has been considered as an effective approach to enhance the biochar functionality by influencing biochar’s properties (e.g., surface functional groups, polarity and hydrophobicity) (Medeiros et al. 2022). However, the drawbacks of physical modification methods include high energy consumption and long activation time (Shaheen et al. 2022b). For these reasons, chemical modification is considered to be the primary option for biochar modification. Future research should focus on filling the knowledge gap to address the disadvantages of physical modifications.

2.1.1 Steam/CO2 activation

Steam activation can upgrade pristine biochar to activated biochar by increasing its porosity and surface area (Medeiros et al. 2022) and introducing oxygen-containing surface functional groups such as carbonyl and hydroxyl groups (Ahmed et al. 2016). There are two reasons for the increased porosity and surface area of resultant biochar after steam treatment: first, interaction of water vapor and labile organic matter of biomass to generate gas; second, consumption of carbon in the precursor (Anderson et al. 2021). Both reactions can reduce the formation of pore blocking tar and enlarge the pores of biochar. Steam activated biochar has shown superior performance in the removal of hazardous compounds, including metal(loid)s (Kwak et al. 2019; Yan and Li 2022); dyes (Yek et al. 2020), phosphate (Han et al. 2020; Wen et al. 2021b), antibiotics (Wang et al. 2020a) and landfill leachate (Yek et al. 2021). In addition, steam-activated biochar also facilitated the stabilization of polyfluoroalkyl substances (PFAS) (Sørmo et al. 2021) and carbamate pesticides (Tang et al. 2021) in the soil. However, Shim et al.’s research reported that Miscanthus derived biochar after steam activation showed a negligible influence on Cu removal, which might be ascribed to the steam activation-induced degradation of functional groups (e.g., −OH, C=O) of biochar and thus weakened the complexation effect (Shim et al. 2015). In practice, other modification methods such as microwave modification (Yek et al. 2020, 2021) and magnetization (Han et al. 2020; Wen et al. 2021b) were applied in parallel with steam activation to obtain a higher adsorption capacity of biochar, which are briefly discussed below.

Biochar tailoring can also be carried out by employing CO2 as an activation gas, which facilitates the formation of microporous structure of biochar (Medeiros et al. 2022). Purging CO2 during pyrolysis has shown favorable effects on the production of biochar with high porosity from barley straw (Pallarés et al. 2018), orange peel (Yek et al. 2020), rice straw and sludge (Islam et al. 2021), and waste timber (Sørmo et al. 2021). Pallarés et al. (2018) reported that barley straw-derived biochar produced in CO2 condition displayed a large surface area, up to nearly 800 m2 g− 1. Moreover, CO2-activated biochar exhibited its effective performance in environmental decontamination. For instance, Islam et al. (2021) demonstrated good adsorption efficiency of CO2-activated biochar derived from paper mill sludge for various heavy metals, including Cu2+ (39.4 mg g− 1), Cd2+ (30.0 mg g− 1), and Pb2+ (250 mg g− 1).

2.1.2 Microwave activation

Microwave activation is an advanced technique based on high-frequency electromagnetic irradiation with frequencies ranging from 0.03 to 300 GHz (Duan et al. 2019). Microwave radiation induces dipole rotation at an atomic scale, thus generating heat energy within the materials (Yek et al. 2020). This modification method allows both inner and outer surfaces of biochar to be heated simultaneously without direct contact at a low temperature of 200–300 °C (Zhou et al. 2021b), and renders microwave-activated biochar with more functional groups and higher surface area as compared to the pristine biochar (Zhang et al. 2022c). In a study, Kołtowski et al. (2017) reported that microwave-activated biochar was more effective on decreasing the phytotoxicity of heavy metals (e.g., Pb, Cr, Cu, Cd) and PAHs in Lepidium sativum compared to raw biochar. Additionally, microwave activation for biochar also promoted the removal of methylene blue (Yek et al. 2019) and Congo red (Yek et al. 2020) from wastewater. As an example, Yek et al. (2019) reported that the combined application of microwave and steam activation produced high-grade activated biochar with a high surface area of 571 m2 g− 1, and resulted in an effective performance in the removal of methylene blue with maximum adsorption capacity of 38.5 mg g− 1. However, the environmental application of microwave-activated biochar is still limited, which is mainly attributed to the high cost of equipment operation and maintenance (Foong et al. 2020).

2.1.3 Ball milling

Ball milling, an eco-friendly and low-cost approach, has been employed for the modification of biochar via improvement of specific surface area (SSA) and pore structure (Cheng et al. 2021b), and enrichment of surface functional groups, as compared to the non-activated biochar (Lyu et al. 2018; Xiao et al. 2020). Ball-milling technique mechanically adjusts the particle size to the nanoscale (< 1000 nm) under non-equilibrium conditions (Lyu et al. 2020b). Previous studies have reported that various operational parameters could affect the physicochemical and adsorptive/catalytic properties of resultant biochar, including mass ratio of media: biochar, wet or dry milling (with or without solvent), solvent properties, reaction time, milling speed, milling temperature, ball size distribution, and reaction atmosphere (Lyu et al. 2018; Huang et al. 2020a; Xu et al. 2021; Zhao et al. 2022). In addition, the shape of grinding media (spherical balls, ellipsoids, and cubes) may influence the milling process, and spherical balls are the best grinding media, as indicated by Simba and Moys (2014). Ball-milled biochar in the remediation of inorganic pollutants has been studied in recent years. For instance, Cui et al. (2021b) confirmed that the ball milling method facilitated the incorporation of Mg/Al layered double hydroxide (LDH) into biochar matrix, and the ball-milled Mg/Al LDH-biochar composite showed a very high adsorption capacity for Cd(II) (119 mg g− 1). In addition to metal(loid)s, ball-milled biochar has also shown great potential for the removal of other inorganic pollutants such as ammonia (Qin et al. 2020), phosphate (Feng et al. 2022; Li et al. 2022a), and various organic contaminants such as antibiotics (Huang et al. 2020a), dyes (Luo et al. 2022), phenols (Zhao et al. 2022), etc. Additionally, emerging applications using ball-milled biochars have focused on photo/thermal catalysis (Xiao et al. 2020) and soil remediation (Zhang et al. 2022a, 2022b). Although ball-milling technique is a new field of research to synthesize engineered biochar, it is still in its infancy. Therefore, further research is needed to determine crucial research directions and overcome the existing challenges.

2.2 Chemical modification

2.2.1 Acid, alkaline, and oxidant modifications

For acid treatment, removal of impurities such as metals on biochar is the main purpose, in which the acidic functional groups such as phenolic, carboxylic, and lactonic groups are also introduced (Wang and Wang 2019; Zhou et al. 2021b). The commonly used acids for biochar modification included nitric acid (HNO3), hydrochloric acid (HCl), sulfuric acid (H2SO4), phosphoric acid (H3PO4), citric acid (C5H8O7), and oxalic acid (C2H2O4) (Medeiros et al. 2022). Acid modification can decrease the alkalinity of biochar, thus the biochar with lower pH might show a potential prospect for remediation of alkaline calcareous soil (Zhou et al. 2021b). On the other hand, base activation also significantly affects the biochar properties, causing higher aromaticity and N/C ratio, but a lower O/C ratio of biochar compared to acid modification (Ahmed et al. 2016). Potassium hydroxide (KOH) and sodium hydroxide (NaOH) are the commonly used bases (Duan et al. 2019). The alkaline treatment can cause a decrease in the acidic oxygen-containing functional groups such as C=O, while enriching the hydroxyl groups (Yao et al. 2020). In addition to acid/alkaline modification, biochar can also be modified using oxidizing agents such as hydrogen peroxide (H2O2), potassium permanganate (KMnO4), and ozone (O3) (Yuan et al. 2019). The oxidant-modified biochar has high thermal stability in remediation applications and large affinity to bind pollutants (Zhou et al. 2021b). For instance, KMnO4-modified biochar removed > 97% of sulfamethoxazole within 30 min (Tian et al. 2019). Most studies have reported that modified biochars using acid/alkaline/oxidant improved surface properties of biochar and consequently enhanced the removal of metal(loid)s and organic contaminants in aqueous system (Cheng et al. 2021b; Medeiros et al. 2022). However, some researchers have reported that the above-mentioned modifications showed negative effects on pollutant removal. For example, pinewood biochar modified by 10% H2O2 caused a decrease of adsorption capacity for methylene blue compared to pristine biochar, which is likely attributed to the weakening of π–π dispersive forces caused by the introduction of oxygen functionality (Huff and Lee 2016).

2.2.2 Iron modification

Iron (Fe) modification method for biochar is proposed for two main objectives: i) reinforcing the separation efficiency to recycle and reuse the biochar (Huang et al. 2019b); ii) enhancing the decontamination capacity of biochar via the interaction between the loaded Fe and target contaminants (Wen et al. 2021a). Iron-modified biochar has been developed using iron oxides (e.g., hematite and goethite), iron sulfide (FeS), and nano zero-valent iron (nZVI) (Lyu et al. 2020a). Iron-modified biochar can be synthesized via co-pyrolysis (Yang et al. 2022a), precipitation (Yang et al. 2022b), thermal reduction (Wang et al. 2019a), and ball milling methods (Kumar et al. 2020), which can be classified into “pre-treatment of biomass” and “post-treatment of iron materials” (Huang et al. 2019b). Considering previous publications, the application of Fe-modified biochar can be divided into three types, i.e., an adsorption material, a reductive agent, and a catalyst.

Goethite (α-FeOOH) and hematite (γ-Fe2O3) are the most commonly used Fe minerals to enhance the biochar’s adsorption efficiency for metal(loid)s, including Cd, Pb, Cu, Cr, As, and Hg (Lyu et al. 2020a). Zhu et al. (2020) synthesized an α-FeOOH modified wheat straw biochar (α-FeOOH@BC) and its maximum adsorption capacities for Cd(II) and As(III) were 63 mg g− 1 and 78 mg g− 1, respectively. Shan et al. (2016) prepared three types of Fe-modified biochars, i.e., Fe-biochar, Fe2O3-biochar, and Fe3O4-biochar through one-step ball milling of iron powder (Fe), ferric oxide (α-Fe2O3) and magnetite (Fe3O4), respectively. In the removal trial for pharmaceutical compounds, Fe3O4-biochar displayed the highest adsorption capacities for carbamazepine (63 mg g− 1) and tetracycline (94 mg g− 1).

Iron-modified biochar has also shown great performance in the redox reactions of metal(loid)s (e.g., As(III), Cr(VI) and U(VI)) and organic contaminants to minimize their toxicity (Yuan et al. 2017; Feng et al. 2021; Amen et al. 2020; Zhu et al. 2022). Biochars modified by nZVI, FeS, and FeOOH have been investigated for reductive degradation since they can provide reductive agents (e.g., Fe0, S(II), and Fe(II) species). Zhu et al. (2022) found that the nZVI modified biochar showed effective adsorption for Cr(VI) (54.4 mg g− 1). The reduction of toxic Cr(VI) to less toxic Cr(III) was also noted, which highlighted the vital role of Fe0. The superiority of nZVI modified biochar over pristine biochar or nZVI alone was confirmed for the removal of sulfamethazine, because nZVI modified biochar facilitated the generation of free radicals (•OH) which favored the degradation of sulfamethazine (Deng et al. 2018). Liu et al. (2021a) reported that peanut shell biochar modified by FeS and starch reduced labile U(VI) to non-labile U(IV) species, and the key role of Fe0 and S(II) in the reduction process was highlighted by XPS analysis.

Another important direction for the application of Fe-modified biochar is in the degradation of organic pollutants (Feng et al. 2021), particularly in Fenton-like and persulfate activation systems. Activation of oxidants (e.g., H2O2, persulfate, permanganate, and ozone) by Fe-modified biochar has received extensive attention (Lyu et al. 2020a). Owing to high electron shuttling capacity, abundant PFRs and oxygen-containing functional groups, Fe-modified biochar has been verified for its potential as a Fenton-like catalyst in catalyzing H2O2 to form hydroxyl radicals (•OH) to eliminate organic contaminants in aquatic solution (Feng et al. 2021). When Fe-modified biochar is applied in the Fenton-like system, Fe0 can be oxidized to Fe2+ (Eqs. (1), (2)) and Fe3+ can be reduced to Fe2+ (Eqs. (3), (4)), and •OH is finally generated through Eqs. (5) to degrade organic contaminants (Feng et al. 2021).

In addition, Fe2+, PFRs on Fe-modified biochar can function as effective activators to generate reactive oxygen species (ROS) (e.g., •OH, 1O2 and SO4•−), which can effectively degrade a variety of organic pollutants such as tetracycline (Luo et al. 2021), bisphenol A (Jiang et al. 2019), metronidazole (Yi et al. 2019), and phthalate esters (Dong et al. 2020). For instance, with the aid of ESR analysis, Yi et al. (2019) confirmed that the addition of magnetic sugarcane bagasse-derived biochar favored the generation of ROS in a Fenton-like system, and •OH radical quenching experiments showed that the removal efficiency decreased by approximately 85%, highlighting the dominating role of •OH in the degradation of metronidazole. Moreover, iron modification can result in a narrower band gap of biochar, which aids the adsorption/photocatalysis for aqueous Cr(VI), Pb2+, F− and methylene blue (Herath et al. 2022).

Compared to other metal oxides and metal salts, iron is the most abundant element on the earth, more cost-effective, and less environmentally risky. Therefore, Fe-modified biochar is recommended as an amendment in the remediation of contaminated soil system due to such advantages. Iron modification has been the most widely developed and practical tailoring technique in the remediation of environmental contaminants by biochar at large-scale applications.

2.2.3 Metal oxides and metal salts

Loading of metal oxide and metal salt onto biochar can enhance the adsorption efficiency of biochar by introducing different functional sites. The most commonly used metal, Fe, has been thoroughly discussed in Section 2.2.2. Second to Fe, manganese (Mn) has also been widely applied due to the advantages including abundant earth resources, ease of operation and environmental friendliness (Shaheen et al. 2022b). A series of Mn-coated biochars with different Mn:biochar mass ratios were prepared using MnSO4·H2O as the modifying agent by Jia et al. (2020). The maximum adsorption capacities for Sb(III) and Sb(V) by Mn-coated biochar were 0.9 and 0.7 mg g− 1, respectively (Jia et al. 2020). Moreover, Mn-modified biochar also showed nearly 100% removal of 4-chloro-3-methyl phenol (CMP) in persulfate activation system, and enhanced catalytic performance was ascribed to the generated SO4•−, •OH, and 1O2, which facilitated the CMP degradation (Liu et al. 2021b). Other metals for biochar modification include magnesium (Mg) (Zheng et al. 2020), aluminum (Al) (Wang and Wang 2019), copper (Cu) (Zhong et al. 2020), cerium (Ce) (Dong et al. 2020), lanthanum (La) (Wang et al. 2018), zirconium (Zr) (Rahman et al. 2021), bismuth (Bi) (Zhu et al. 2019), etc. Advanced progress has been achieved in the functionalization of biochar using metal oxides, metal salts, and even metal monoatoms (e.g., cobalt (Co)). In a recent study, a novel biochar based-N, S-anchored single-atom catalyst was developed by Cui et al. (2021a). The authors confirmed an atomic dispersion of Co throughout the coffee grounds-derived biochar, and it demonstrated high degradation efficiency of 90–100% for diethyl phthalate (DEP) and bisphenol A in the peroxymonosulfate activation system.

2.2.4 Nonmetallic heteroatom doping

Nonmetallic heteroatom doping is an emerging technique to functionalize biochar by regulating its electronic properties, thus enhancing its adsorptive/catalytic capacity for pollutant removal (Baser et al. 2021). Previous researches, involving nonmetallic element doped biochar and associated environmental applications and mechanisms, are summarized in the Supplementary Materials (Table S1). As demonstrated, the most commonly used nonmetallic elements for biochar modification include nitrogen (N), sulfur (S), and boron (B). Additionally, biochar doped with phosphorus (P) (Pan et al. 2022) and iodine (I) (Wang et al. 2021) was also reported to remove aqueous contaminants.

Nitrogen is the most intensively explored heteroatom in biochar doping (Baser et al. 2021). The N-doping method can improve the electrochemical performance of biochar via forming graphitic N, pyrrolic N, pyridinic N, and amine-N species during the doping process (Leng et al. 2020; Kumar et al. 2022). The graphitic-N can promote electron transfer within the carbon skeleton, thus improving the catalytic performance of N-doped biochar for persulfate activation (Baser et al. 2021). The pyrrolic N and pyridinic N bonds can act as electron donors, and simultaneously generate N defects which provide additional active sites in N-doped biochar (Zhang et al. 2021a). The amine-N group can act as the binding site for metal(loid)s ions via the chelation effect (Chen et al. 2022b). Therefore, N-doped biochar has been applied as an effective adsorbent/catalyst in the removal of antibiotics, phenols, dyes, and heavy metals, etc. (Table S1). For instance, Cheng et al. (2021a) synthesized N-doped biochar derived from alfalfa and it showed significant adsorption capacity for methylene blue (326.90 mg g− 1) and methyl orange (906.52 mg g− 1). Spectroscopic analyses and theoretical calculations confirmed that the introduced pyrrole N and pyridine N played decisive roles in the removal of both dyes, and the proposed mechanisms included π-π stacking, electrostatic interactions, and hydrogen-bonding (Cheng et al. 2021a). More importantly, N-doped biochar showed great potential in the catalytic performance for pollutant removal. For example, Wang and Chen (2022) reported that the optimized N-doped biochar displayed high surface area (738 m2 g− 1) and N content (13.5%), and this biochar showed great catalytic performance for peroxymonosulfate activation to remove sulfamethoxazole, with a removal rate of 95% within 30 min. As revealed by the quenching tests and EPR spectra, the singlet oxygen (1O2) was found to be the dominating reactive species contributing to the degradation of sulfamethoxazole, and the nonradical oxidation involving 1O2 and electron transfer were the main removal mechanisms.

Other than nitrogen, heteroatom like S can also be used for doping the biochar. Sulfur doping endows biochar with more functional groups such as C–S, C–S–C, C=S, C–S–O, and sulfur rings (Zhang et al. 2021a; Wan et al. 2022). Specifically, C–S–C groups can strengthen the spin density of surrounding carbon atoms, thus improving the catalytic activity of biochar (Liu et al. 2020). Furthermore, C–S–O structure in the biochar can induce nucleophilic addition of peroxymonosulfate to generate abundant singlet oxygen (1O2) (Wan et al. 2022). Biochar after S-doping has shown a high affinity towards (in)organic compounds. For instance, Yang et al. (2019) first fabricated a hierarchical corn-straw biochar/Fe composite, then S2− and Mn2+ were simultaneously introduced, forming a ternary iron-manganese-sulfur/biochar composite. This composite was tested to remove aqueous Pb(II), and the authors concluded that the S doping enhanced Pb removal via precipitation of PbS. Another study showed that S-doping could introduce phenoxyl radicals such as C–O• and vacancy defects on the wood-waste biochar, which facilitated the activation of peroxymonosulfate to degrade 91% of bisphenol A in 30 min (Wan et al. 2022). Scavenging experiments and Raman analyses verified that the S-doped biochar triggered the generation of surface-bound 1O2 (major) and •OH (minor), which contributed to the effective removal of bisphenol A.

Boron is another ideal candidate heteroatom which can modulate electron distribution and tailor the physicochemical properties of biochar, and further provide more defect sites (Sui et al. 2021). Boron-doping increased the specific surface area (up to 898 m2 g− 1) and increased oxygen-containing functional groups of corn-straw biochar, which ultimately enhanced its ability to adsorb Fe(II) (Sui et al. 2021). The interaction mechanisms between Fe(II) and B-doped biochar involved chemical complexation, ion exchange, and co-precipitation. Regarding the catalytic effect of B-doped biochar, Liu et al. (2020) used the B-doped wheat straw biochar to activate peroxydisulfate (PDS) for the removal of sulfamethoxazole, and a superior degradation of sulfamethoxazole (94%) was observed in 120 min. Experimental and theoretical results elucidated that the introduced B species could act as Lewis acid sites to enhance the surface affinity towards PDS and that the biochar mediated electron transfer mechanism was majorly responsible for the nonradical route.

Furthermore, many studies have explored the co-doping of two substances on biochar. Nitrogen and copper co-doped biochar prepared by Zhong et al. (2020) was used to degrade tetracycline, and the co-doped biochar displayed improved performance compared to N-doped biochar or Cu-doped biochar. Zhang et al. (2022e) fabricated three types of doped biochars, i.e., N-doped (N-BC), S-doped (S-BC), and N and S co-doped (NS-BC) biochar derived from moso bamboo. However, they found that the degradation rate of antibiotics by NS-BC (71%) was lower than that of N-BC (92%) and S-BC (89%). The main reason for this phenomenon was that NBC had the highest concentration of persistent free radicals (i.e., SO4•− and •OH), larger specific surface area and higher defects.

Although considerable advances in the non-metal elements-doped biochar have been achieved, it still is an emerging direction due to its huge potential for improvement in environmental remediation. The non-radical mechanism behind persulfate activation is still ambiguous, which needs to be further explored. In addition, the complex sample preparation, high cost, and poor reusability of this type of biochar need to be properly addressed in future research.

2.2.5 Clay minerals

Natural clay minerals including montmorillonite, vermiculite, zeolite, kaolinite, and illite are easy to mine, highly abundant, inexpensive, and nontoxic geo-materials (Arif et al. 2021). They have been effectively used as adsorbents in the remediation of various contaminants (Feizi et al. 2019; Han et al. 2019). However, clay minerals have few drawbacks such as small particle size and poor flowability, and hence using them in combination with biochar to produce composite materials is a feasible option to take advantage of both resource materials. The introduction of clay minerals to biochar could increase the porosity and cation exchange capacity of biochar-clay composites, and also improve the adsorption capacity to heavy metals, antibiotics, and polymers, etc. (Premarathna et al. 2019). For instance, Fu et al. (2020) used montmorillonite-corncob biochar composites for Pb(II) removal from wastewater, which showed a significant adsorption capacity for Pb(II), up to 140 mg g− 1. Illite-modified biochar (IBC) with a 1:4 ratio of illite and walnut shell biochar was fabricated by Liu et al. (2022), and it showed effective removal of metolachlor from soil. The Langmuir-derived Qe value for IBC was higher than that of raw biochar (92 mg g− 1 vs 73 mg g− 1).

2.2.6 Layer double hydroxides (LDHs)

Layered double hydroxides (LDHs) are robust adsorbents with layered stacking 3R structure, showing strong anion exchange capacity (Chen et al. 2022c). However, the adsorption performance of LDHs may also be limited by their dense, layered stack structure (Lyu et al. 2021). LDH-engineered biochar has been reported as superior adsorbent to maximize the effectiveness of both materials in the removal of different pollutants (Huang et al. 2019a; Ma et al. 2021a; Lartey-Young and Ma 2022). Lartey-Young and Ma (2022) synthesized a ternary Cu/Zn/Fe LDH engineered biochar derived from bamboo, and this engineered biochar possessed efficient adsorption capacity for atrazine (63.64–87.04 mg g− 1). In another study, compared to the raw biochar, Mg/Fe-LDH engineered biochar also showed enhanced performance in the catalytic degradation of sulfamethoxazole (Chen et al. 2022c). Batch adsorption experiments revealed that the Mg/Fe-LDH engineered biochar could activate urea-hydrogen peroxide to generate •OH, thus enabling enhanced degradation of sulfamethoxazole (91%). In addition to the application in aqueous solutions, LDH-engineered biochar has exhibited its potential in the remediation of contaminated soils. For instance, Lyu et al. (2021) applied Mg/Al LDH-biochar composite to the soil contaminated by uranium (U) (≈1000 mg kg− 1), and results indicated that biochar-LDH treatment significantly decreased the cumulative U loss by 53%, and leaching concentration by 54%, compared to the control.

2.2.7 Carbon nanomaterials

Carbon nanomaterials including graphene, graphene oxide, carbon nanotubes, and graphitic carbon nitride are the commonly used agents to synthesize modified composites (Zheng et al. 2019; Zhang et al. 2020a). These carbon nanomaterials possess a strong affinity to various pollutants, so biochar loaded with carbon nanomaterials has been widely studied to further achieve higher adsorption capacities for different toxic pollutants. Abdul et al. (2017) loaded graphene oxide onto wood biomass biochar and investigated its performance for dimethyl phthalate (DMP) removal. The results indicated that biochar-graphene composite had higher adsorption capacities for DMP (45.65 mg g− 1) via π–π interaction and hydrophobic effect.

2.2.8 Organic surfactants

Recent studies have explored the environmental remediation using biochar modified with organic surfactants, such as chitosan (Chen et al. 2022b), pyromellitic dianhydride (PMDA) (Deng et al. 2017), acrylonitrile (Luo et al. 2018b), polyethyleneimine (PEI) (Li et al. 2020b), rhamnolipid (Zhen et al. 2021), phytic acid (Hua et al. 2022), and cetyltrimethylammonium bromide (CTAB) (Murad et al. 2022). For example, CTAB was employed as a cationic surfactant to enhance the positive charge on the surface of peanut-shell biochar. Adsorption experiments confirmed that the resultant CTAB-engineered biochar showed higher Cr(VI) removal efficiency (79%) than the pristine biochar (37%). Furthermore, its application to soil also significantly decreased the concentration of soil-available Cr(VI) by 92%, compared to the control.

2.3 Biological modification

Compared to physical and chemical modification methods, biological methods for biochar tailoring are less studied, mainly due to their more complex operation characteristics. Initially, researchers used anaerobic bacteria to convert biomass into biogas and used the resulting digested residue for the synthesis of biochar (Yao et al. 2011). Biochar derived from anaerobically digested biomass residues often exhibits high pH, large specific surface area, strong ion exchange capacity and other excellent properties (Kumar et al. 2022), and has shown superior removal efficiency for phosphate (Yao et al. 2011) and heavy metals (Ngambia et al. 2019).

Moreover, a comparatively new approach using the biological post-treatment method to immobilize the microorganisms on biochar has gained recent attention. Biochar has been recommended as an excellent carrier for microbial inoculation, owing to high porosity, cost-effectiveness, richness of nutrients, and simple preparation (Zhou et al. 2021b). Biofilm theory suggests that living cells can secrete a variety of polymers and anchor themselves onto the biochar surface, forming a microbial biofilm surrounded by an extracellular matrix, which facilitates the adsorption/degradation of pollutants (Lin et al. 2021; Zheng et al. 2021; An et al. 2022). A recent study by Zhang and Wang et al. (2021) investigated the removal potential of Bacillus cereus immobilized biochars produced from Chinese medicine residues for chlortetracycline. The maximum removal rate of chlortetracycline was up to 85%. Microbial inactivation test revealed that the removal mechanism of chlortetracycline was majorly governed by microbial degradation and physical/chemical adsorption by biochar (Zhang and Wang 2021). Enhanced bioremediation of diesel oil was reported by Zhou et al. (2021a), who used Vibrio sp. LQ2-immobilized biochar to treat the diesel oil-contaminated seawater. In addition to the aqueous phase, Qi et al. (2021) confirmed that biochar loaded with three strains (i.e., Bacillus subtilis, Bacillus cereus, and Citrobacter sp.) could effectively immobilize U(VI) and Cd(II) in the contaminated soil. Specifically, compared to the control, the concentration of DTPA-extractable U and Cd in the soil decreased by 69% and 56%, respectively, and bacteria-loaded biochar reduced metal uptake thus promoted celery growth.

3 Characterization of engineered biochar

Detailed characterization of engineered biochar is the prerequisite to understand its physicochemical properties and adequately decipher the underlying mechanisms controlling biochar-contaminant interactions. The commonly adopted analytical techniques of biochar can be mainly classified as chemical and spectroscopic analysis (Fig. 2).

Chemical characterization including pH, ash content, surface alkalinity, cation exchange capacity (CEC), elemental composition of biochar, Boehm titration for functional groups, etc. can be measured using traditional techniques used for other environmental samples such as soil with appropriate modifications (Bolan et al. 2022). Conventional and emerging spectroscopic analytical techniques include Brunauer-Emmett-Teller (BET), X-ray diffraction (XRD), thermogravimetric analysis (TGA), scanning electron microscopy (SEM), transmission electron microscopy (TEM), scanning transmission electron microscopy (STEM), energy dispersive X-ray spectrometry (EDS), Fourier transform infrared spectrometry (FTIR), Raman spectroscopy, X-ray photoelectron spectroscopy (XPS), solid state nuclear magnetic resonance (NMR), electron spin/paramagnetic resonance (ESR/EPR), magnetic hysteresis loop analysis, and mediated electrochemical reduction/oxidation (MER/MEO) analyses. In addition to the above-mentioned characterization methods, synchrotron-based X-ray absorption fine structure (XAFS) spectroscopy (extended X-ray absorption fine structure spectrum (EXAFS) and near edge X-ray absorption fine structure (NEXAFS) spectroscopy), and micro-X-ray fluorescence (μ-XRF) spectroscopy have been applied to detect the presence, atomic structure, and detailed speciation of metal(loid)s within biochar (Li et al. 2020a; Yang et al. 2022b). The specific roles of above-mentioned analytical techniques for biochar are illustrated in the Supplementary Material (Text S1). The combination of various analytical techniques allows us to further understand the morphological structure of biochar and underlying decontamination mechanisms.

4 Engineered biochar for environmental decontamination and related mechanisms

4.1 Aquatic systems

4.1.1 Metal(loid)s

Adsorption of metal(loid)s using various engineered biochars has been widely studied, and related adsorption efficiencies and associated mechanisms are summarized in Table 1. In general, the diversity of adsorption efficiency is governed by activation methods, original feedstocks, pyrolysis conditions, and target pollutants. The proposed metal(loid)s adsorption mechanisms by biochar involve pore filling, electrostatic effect, π–π interactions, H–bonding, ion exchange, complexation, precipitation, and redox (Kumar et al. 2022; Shaheen et al. 2022b, 2022c). Figure 3 presents a summary of proposed removal/immobilization mechanisms for metal(loid)s by engineered biochar.

For cationic heavy metals (e.g., Cd, Pb, Cu, Zn, and Ni), their adsorption by engineered biochar is greatly influenced by biochar’s surface area, zeta potential, mineral components, and surface functional groups and solution conditions (Shaheen et al. 2019). For example, engineered biochar by ball milling was found to be an effective adsorbent for Cd(II), showing an excellent adsorption capacity (922 mg g− 1) (Ramanayaka et al. 2020). Ball milling resulted in the enhancement of functional groups on the biochar surface, i.e., −OH, C=O, and amine groups, which favored the adsorption via complexation between Cd ions and functional groups. Furthermore, cadmium exists as a cation in aqueous media and can be bonded by the negatively-charged biochar surface via electrostatic attraction (Ramanayaka et al. 2020). In another study, Yu et al. (2018) reported that N-doped corn straw-derived biochar owned a high graphitic-N percentage (46%) and improved surface area (419 m2 g− 1). Accordingly, the N-doped biochar showed an excellent adsorption capacity for Cd(II) (197.8 mg g− 1). In addition to physical adsorption, the adsorption mechanisms were mainly governed by complexation with graphitic-N and hydroxyl groups and Cd(II)–π bonding (Yin et al. 2020). In parallel, Deng et al. (2017) developed a chitosan/pyromellitic dianhydride (PMDA) modified biochar (CS/PMDA-BC) to remove Cd, Pb, and Cu in ternary solutions. It was noted that CS/PMDA-BC exhibited effective removal of these three cations, and the selective adsorption capacity for Cu(II) was also observed. The authors concluded that introduced N-containing groups after loading of chitosan and PMDA was the plausible reason for the adsorption enhancement. In addition, immobilization of microbes onto biochar has been reported to enhance the removal of Cu(II) and Ni(II) from aqueous solutions (An et al. 2022). The authors introduced Pseudomonas hibiscicola strain L1 onto peanut shell biochar, and the removal rate of bacteria-loaded biochar for Cu(II) and Ni(II) was 45.8% and 81.2%, respectively. The involved mechanisms were ascribed to complexation, ion exchange, precipitation, and enhanced bio-adsorption by strain L1.

Typically, Cr, As, and Sb exist as anions in aqueous media, and their negatively charged surface nature results in the electrostatic repulsion with negatively charged biochar surface. Therefore, the adsorption ability of pristine biochar to such elements is limited and modification is necessary to enhance their removal by biochar. For instance, Zhang et al. (2020b) found that loading of chitosan onto bamboo-derived biochar could facilitate Cr(VI) adsorption, with maximum adsorption capacity up to 127 mg g− 1, which was due to the electrostatic attraction between –OH+/−NH2+ and CrO42−. Liang et al. (2020) used KOH and N-doping to activate the biochar produced from glucose at 800 °C. A significant adsorption capacity of modified biochar for Cr(VI) was achieved as 402.9 mg g− 1, and different mechanisms such as physisorption, electrostatic attraction, surface complexation, and reduction of Cr(VI) into Cr(III) and subsequent adsorption and precipitation of Cr(III) species were involved (Liang et al. 2020). In another study, iron-modified Populus L. derived biochar was prepared using FeCl3 (Xu et al. 2020), and As(III) removal by Fe-modified biochars was up to 99.9%, which was mainly due to the formation of Fe–As complex as highlighted by X-ray fluorescence analysis. Simultaneously, the oxidation of labile As(III) to non-labile As(V) species was noted, which was ascribed to the change in solution pH (Xu et al. 2020). Rahman et al. (2021) fabricated a biosolid-derived biochar modified by zirconium (Zr) and Fe (Zr-Fe/BC) for As(V) removal. The maximum adsorption capacity of As(V) reached up to 62.5 mg g− 1, while that of the pristine biochar was only 15.2 mg g− 1. The presence of Zr and Fe could facilitate As(V) adsorption through the formation of complexes of Zr–O–As, Fe–O–As, and Zr–O–Fe-As. Electrostatic interaction and hydrogen bonding also participated in the removal of As(V). Similar to As, Sb is another typical metalloid in aqueous media. Metal oxides, sulfide and carbon nanomaterials have been employed to functionalize biochar for the removal of aqueous Sb (Jia et al. 2020; Chen et al. 2022b). For example, Wang et al. (2018) prepared lanthanum (La) doped magnetic biochar and its adsorption for Sb(V) was greatly improved, increased from 2.2 to 18.9 mg g− 1 (pH 7.0). FTIR and XPS analyses revealed that the dominant mechanism for enhanced Sb(V) adsorption was the formation of inner-sphere La–O–Sb complex.

In addition to these more popularly studied metal(loid)s above, there are also studies focusing on the removal of mercury (Hg) (O’Connor et al. 2018; Lyu et al. 2020b), uranium (U) (Liu et al. 2021a; Lyu et al. 2021), rare earth elements such as vanadium (V) (Ghanim et al. 2020) and lanthanum (Lakshmi et al. 2021), etc. by engineered biochar reported recently, but it is still a relatively nascent area of research. The choice of modification method is very different for different target pollutants. To maximize both the environmental and economic benefits, appropriate functionalization methods should be applied to tailor the surface properties of biochar and thus to enhance the adsorption efficiency for target contaminants.

4.1.2 Nutrients

Phosphate, nitrate and ammonium are the typical forms of nutrients in water bodies that directly lead to eutrophication and ecosystem toxicity (Long et al. 2019). Engineered biochar has been used to enhance the removal of such inorganic pollutants in aqueous phase, as summarized in the Supplementary Materials (Table S2). Huang et al. (2020b) found that wheat straw biochar after introduction of chitosan enhanced the phosphate removal from aqueous solution with the maximum adsorption capacity of 109 mg g− 1. Electrostatic interaction, ligand exchange, and Lewis acid-base interaction were the main mechanisms during the phosphate removal by chitosan-loaded biochar (Huang et al. 2020b). Sornhiran et al. (2022) prepared a series of biochars modified using different metal salts (i.e., AlCl3, FeCl3, MnCl2, ZnCl2, MgCl2) to remove phosphate in the water bodies, FTIR and XPS results verified that precipitation between metal oxides and phosphate was the predominant mechanism. In parallel, biochars modified by various methods such as ball milling (Qin et al. 2020; Feng et al. 2022), acid-base activation (Hu et al. 2018; Wang et al. 2020c), and metal oxides modification (Long et al. 2019) have been reported to be excellent adsorbents in the removal of aqueous nitrate and/or ammonium. It is worth mentioning that recent studies have shown the potential of combining denitrifying bacteria and biochar to remove nitrate (Zhang et al. 2021b; Zheng et al. 2021; An et al. 2022). For instance, Pseudomonas hibiscicola strain L1 immobilization on the peanut shell biochar achieved 65.29% removal of nitrate (An et al. 2022). A general conclusion can be made that the modifications changed biochar surface chemistry, thereby enhancing nutrients adsorption. The removal mechanisms of nutrients by engineered biochar mainly involved electrostatic interaction, precipitation, surface complexation, ligand exchange, Lewis acid-base interaction and biological adsorption.

4.1.3 Organic pollutants

Organic contaminants including dyes, pesticides, antibiotics, plasticizers, polycyclic aromatic hydrocarbons (PAHs), and phenols are major types of pollutants in the aquatic environment (Ahmed et al. 2016). Table 2 presents the removal of typical organic contaminants by engineered biochar, and the associated mechanisms are also summarized. Various mechanisms govern the adsorption of organic pollutants onto biochar, which mainly contain pore-filling, hydrophobicity, electrostatic interactions, hydrogen bonding, partition, and cation/π–π interactions (Ni et al. 2011; Zhao et al. 2017; Luo et al. 2022). Biodegradation of organic pollutants by bacteria could also be a key mechanism, if the biochar is enriched with target microorganisms through biological modification process (Zhou et al. 2021a). The related removal/immobilization mechanisms of target organic pollutants by engineered biochar are depicted in Fig. 4.

For dyes, Yek et al. (2020) employed microwave and steam modifications to activate orange peel-derived biochar pyrolyzed at 950 °C, and the activated biochar had enhanced adsorption capacity for Congo red (136 mg g− 1). Moreover, a sulfur-doped biochar originated from tapioca peel waste was found to be a good adsorbent for malachite green (30.2 mg g− 1) and rhodamine B (33.1 mg g− 1), and electrostatic attraction, surface complexation and hydrogen bonding were considered as the key removal mechanisms (Vigneshwaran et al. 2021). Regarding pesticides, a magnetic sludge biochar modified by graphene oxide (GO/CoFe2O4-SBC) was synthesized and used to remove imidacloprid (Ma et al. 2021b). The maximum adsorption capacity for imidacloprid by GO/CoFe2O4-SBC was noted as 8.64 mg g− 1, which was ascribed to enlarged surface area, π–π conjugation between graphitic structure/−OH and the pollutant, and more available binding sites (e. g. C–O, Fe–O, Co–O). In a different study, atrazine removal using iron-modified biochar loaded with Acinetobacter lwoffii DNS32 (bFeMBC) was explored by Tao et al. (2019). The maximum removal rate was 8.56 and 9.71 mg L− 1 h− 1, for single bacteria and bFeMBC treatment, respectively. The enhanced removal might be attributed to two aspects: 1) iron oxide nanoparticles can catalyze free radical reactions to generate •OH and thus attack atrazine; 2) iron-modified biochar can promote bacterial growth and biodegradation of atrazine.

A considerable amount of literature has described the engineered biochar application in antibiotic removal. For instance, Zeng et al. (2022) used H3PO4 to activate the coffee ground derived biochar for the removal of sulfadiazine. Governed by hydrophobic effect and π–π EDA interaction, the modified biochar showed a high sulfadiazine adsorption up to 139.2 mg g− 1. In another study, glucose-derived biochar doped with N and Cu was efficient in catalyzing oxidative degradation of tetracycline in the persulfate activation (Zhong et al. 2020). The targeted biochar showed a large surface area of 352 m2 g− 1, and abundant functional groups (e.g., −OH), which resulted in almost 100% removal for tetracycline. Quenching experiments and EPR analysis revealed that the main degradation reaction was •OH-induced degradation via free radical pathway, and the biochar-mediated electron transfer between tetracycline and persulfate via non-radical pathway. Additionally, biochar loaded with Bacillus cereus LZ01 also showed a removal rate of 82.3% for chlortetracycline via biodegradation by LZ01 and biochar adsorption (Zhang and Wang 2021).

Engineered biochar has also been used to remove the aqueous phthalate esters (PAEs) (Guo et al. 2020). A graphene oxide modified biochar was prepared, and its adsorption capacity for different PAEs was investigated, i.e., 35.2 mg g− 1 for dimethyl phthalate (DMP), 26.4 mg g− 1 for diethyl phthalate (DEP), and 25.1 mg g− 1 for dibutyl phthalate (DBP) (Yu et al. 2020). Interestingly, the authors concluded that the dominant mechanism differed for different PAEs, namely pore filling for DMP, π–π interaction for DEP, and hydrophobic effect for DBP. Guo et al. (2020) reported that the DEP adsorption capacity of N and S co-doped peanut shell biochar was higher than that of raw biochar (14.34 mg g− 1 vs 6.57 mg g− 1). Recently, Cheng et al. (2022) produced a series of hierarchical porous biochars (HPBs) using K2CO3 and CaCO3 as the activators, with a maximum specific surface area of up to 2554 m2 g− 1. The maximum adsorption capacity for DEP by the resultant HPBKCa-1 (biochar produced at the mol ratio of K to Ca was 1: 1) reached 657 mg g− 1. Owing to the remarkably enlarged pore structure, it is deemed that the DEP adsorption was mostly dominated by pore filling; however, other mechanisms such as Lewis acid-base interaction, hydrogen bonding, and partitioning might also involve.

In relation to PAHs, Fe-impregnated biochar coupled with ammonium persulfate (FBC-APS) showed superior performance for degradation of benzo[a]pyrene (BaP) (Li et al. 2022b). The degradation rate of BaP increased from 47.8% to 87.0% as the doses of FBC increased from 0.125 g L− 1 to 0.5 g L− 1. Two pathways were involved in the degradation of BaP: 1) radical pathway mediated by SO4•− and O2•−; 2) non-radical pathway via 1O2 contribution and electron transfer. Moreover, Wang et al. (2020b) developed an N-doped Phragmites australis-derived biochar. Its adsorption capacity for phenanthrene was reported as 1.97 mg g− 1. Characterization analysis and DFT calculations indicated that the phenanthrene removal was majorly dominated by π–π interactions, hydrophobic effect, and electrostatic attraction.

Phenolic compounds including phenol, bisphenol A (BPA), pentachlorophenol (PCP) and p-nitrophenol (PNP) are typical organic contaminants in aquatic environment (Huang et al. 2019b). Removal of phenolic substances is also one of the research directions of engineered biochar’s environmental applications. For example, Heo et al. (2019) synthesized CuZnFe2O4-biochar composite (CZF-BC) by a facile one-pot hydrothermal method. CZF-BC exhibited great adsorption performance in the removal of BPA (263.2 mg g− 1), which could be attributed to H–bonding, hydrophobic effect, and π–π interaction. In addition, the potential of engineered biochar has also been investigated for the removal of perfluorinated compounds (Hassan et al. 2020) and pharmaceuticals (Shan et al. 2016; Fu et al. 2020) from water bodies.

4.2 Soil systems

4.2.1 Metal(loid)s

Due to the vast anthropogenic activities, agricultural soils are polluted with a diverse range of metal(loid)s and organic pollutants (Chen et al. 2021a). Engineered biochar is accepted as a cost-effective soil-remediation material to alleviate the environmental stress of contaminated soils. The remediation mechanisms include the direct process (i.e., immobilization/degradation of contaminants by biochar) and indirect process (i.e., improved soil properties by biochar) in the complex terrestrial system (Chen et al. 2022a). The multiple engineered biochars and their remediation performances for metal(loid)s in soils are summarized in the Supplementary Materials (Table S3).

In a pot experiment, Zubair et al. (2021) amended a Cd-spiked soil (20 mg kg− 1) with 5% textile waste biochar (TWB), chitosan (CH), combined application of TWB and CH (w: w = 1: 1) and CH-coated TWB (CH-BC), respectively. They found that the CH-BC treatment showed the greatest efficiency in decreasing Cd concentrations in soil (58%), and Cd uptake in plant shoot (73%) and root (54%), relative to the control. CH-BC offered negative sites to efficiently bind Cd2+ ions via surface complexation, precipitation and cation exchange. The increased soil pH also strongly influenced the mobility and phytoavailability of Cd. High soil pH may increase the negative charge of the soil, which may favor Cd immobilization via electrostatic attraction. Furthermore, increased soil pH facilitated the formation of hydroxyl bound species of Cd (i.e., CdOH+). In a different study, Irshad et al. (2022) reported that 2% goethite-modified biochar amendment could reduce As uptake in rice grains by 77%, relative to the control. The goethite-modified biochar increased the Fe oxide content in soils, which promoted the formation of root Fe-plaque, and ultimately decreased As content in rice grains. Studies have also been conducted using other types of biochar involving different engineering methods such as sulfur power (O’Connor et al. 2018), Mg-Al LDH (Lyu et al. 2021), ultraviolet activation (Zhang et al. 2021c), cetyltrimethylammonium bromide (CTAB) loading (Murad et al. 2022), polyethyleneimine (PEI) modification (Tang et al. 2022), etc. to remediate metal(loid) contaminated soils.

However, agricultural soils are often simultaneously contaminated with multiple metal(loid)s. Therefore, many researchers have also reported that effect of engineered biochars in the immobilization of various metal(loid)s in co-contaminated soils. Wang et al. (2019b) prepared MnFe2O4-modified biochar derived from tea branches, and explored the effect of its application with different dosages (0.1%, 1% and 2%) on the remediation of Sb and Cd from the contaminated soil. The result of this study demonstrated that MnFe2O4-modified biochar amendment at 2% dose simultaneously decreased the concentration of bioavailable Sb and Cd in soil by 43.5% and 76.0%, respectively. However, the pristine biochar only reduced the bioavailable Cd concentration in soil (12.7%–33.9%). In another study, Liu et al. (2018) evaluated the influence of coconut shell biochar (CSB) and modified biochar after ultrasonication and HCl activation (MCSB) on the availability of Cd, Ni, and Zn in multi-metal contaminated soils. After 63 d of incubation, application of MCSB at 5% dose decreased the concentration of bioavailable Cd, Ni and Zn by 30.1%, 57.2% and 12.7%, respectively, compared to the control. The MCSB contained sufficient active functional groups (e.g., −OH, −COOH, C=O), and its application increased soil pH and CEC, which subsequently decreased the mobility of metal ions in the soil via electrostatic attraction, surface complexation, and cation exchange.

4.2.2 Organic pollutants

In addition to immobilization of metal(loid)s, biochars functionalized by steam/CO2 activation, ball milling, oxidizing, iron materials, LDH, organic surfactants, and bacteria loading for the remediation of various organic pollutants (e.g., pesticides, antibiotics, plasticizer, PAHs, and phenols) in soil have been reported and are summarized in the Supplementary Materials (Table S4). Specifically, a sulfidated nano zerovalent iron (S-nZVI) loaded biochar (S-nZVI@BC) at an S-nZVI: biochar mass ratio of 3:1 was successfully synthesized by Gao et al. (2022). Resultant biochar at 1% dosage showed superior degradation for nitrobenzene with a removal rate of 98% within 24 h. The authors confirmed that the solubilization effect by biochar and reduction by FeSx were the dominant mechanisms for nitrobenzene removal. In addition, S-nZVI@BC also had excellent antioxidant capacity and kept a high removal efficiency for nitrobenzene (73%) after aging for 14 weeks, which suggested that this special biochar had the potential for the field application (Gao et al. 2022). In another study, olive tree pruning residues were first pyrolyzed at 400 °C for 2 h, and 0.025 M KMnO4 was used as an oxidizing agent to obtain the modified biochar with high redox capacity for the remediation of pentachlorophenol (PCP) (Chacón et al. 2022). KMnO4-modified biochar exhibited the highest maximum rate of remediation (kmax) under aerobic (3.73 μgPCP gsoil− 1 d− 1) and anaerobic (2.40 μgPCP gsoil− 1 d− 1) conditions, which was much higher than that of raw biochar. Moreover, Bacillus-siamensis-inoculated biochar was synthesized to minimize dibutyl phthalate (DBP) pollution in agricultural soils (Feng et al. 2020). The bacteria-loaded biochar could enhance the DBP biodegradation by simultaneously raising the degradation rate constant from 0.20 d− 1 to 0.24 d− 1, and half-life from 2.31 d to 2.11 d. A significant reduction of DBP uptake by leafy vegetables was also observed, which could be attributed to the enhanced adsorption/degradation by biochar and Bacillus siamensis strain T7.

5 Conclusions and future perspectives

In this article, we thoroughly discussed the functionalization of biochars using various modification methods and characterizations of engineered biochars. Furthermore, we highlighted the utilization of engineered biochar for the decontamination of aquatic and soil systems polluted by (in)organic contaminants. The specific properties of engineered biochar such as improved surface area, introduction of new functional groups, and enhanced electron transport capacity are the key factors affecting the decontamination efficiency in multifunctional applications, as revealed by the literature reviewed. In general, engineered biochar is an environmentally friendly adsorbent/catalyst/amendment that can be used to address multiple environmental concerns. However, some issues remain unresolved and the following need to be considered to achieve a sustainable future for engineered biochar in environmental applications.

-

Physical and chemical modification methods have often been used to synthesize engineered biochar. The synthesis of engineered biochar using biological modification methods involving microorganisms needs to be explored in detail in relation to its value in the remediation of organic contaminants in aquatic and soil systems.

-

To date, the published results using engineered biochar are majorly based on laboratory tests. The long-term field-scale experiments using engineered biochar are required to be conducted to evaluate its practical applications.

-

Engineered biochar undergoes long-term weathering by abiotic and biotic aging when exposed to environmental conditions. However, little is known about the remediation efficiency of aged engineered biochar. Further research is needed to explore the stability of its remediation potential with aging process and mechanisms affected by different functionalization methods.

-

One of the important benefits of modification is to achieve easy removal of spent biochar after water treatment, e.g., magnetization, and the practical feasibility for recycling magnetic biochar needs to be investigated at pilot scale. In addition, there is insufficient information on the safe disposal of spent engineered biochar after adsorption of toxic pollutants. Therefore, related technology should be developed to recover the spent engineered biochar, such as utilization of specific eluents to efficiently desorb the target contaminant. Moreover, non-renewable spent engineered biochar should also be used for energy production or nutrient source (in the case of N and P laden biochar after adsorption) from economic and environmental perspectives.

-

The presence of heavy metals, PAHs, and persistent free radicals (PFRs) on the biochar has been reported. Moreover, some modification processes may introduce new hazardous chemicals. The ecotoxicity and stability of such potentially hazardous biochars should be evaluated from an ecotoxicological point of view, such as the release of toxic chemicals over long-term.

-

The quality and remediation performance of engineered biochar can be affected by the type of original feedstock, pyrolysis conditions and modification methods. A combined approach following the experimental and modelling results should be implemented to establish standards for biochar production, characterization and life cycle assessment processes.

-

Advanced spectroscopic analysis methods such as synchrotron-based X-ray absorption fine structure (XAFS) spectroscopy and computational approaches based on density functional theory (DFT) and molecular dynamics (MD) calculations should be considered to reveal the decontamination mechanisms for various pollutants. Artificial intelligence and machine learning should be employed as effective techniques to optimize the development of engineered biochar, and further automate and forecast the remediation process.

-

In the context of carbon neutrality worldwide, biochar as a carbon-negative technology has received a wide attention. However, quantitative estimation methods of carbon sequestration by engineered biochar are missing, and the potential carbon sequestration value of engineered biochar has not been effectively verified and developed.

Availability of data and materials

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Abdul G, Zhu X, Chen B (2017) Structural characteristics of biochar-graphene nanosheet composites and their adsorption performance for phthalic acid esters. Chem Eng J 319:9–20

Ahmed MB, Zhou JL, Ngo HH et al (2016) Progress in the preparation and application of modified biochar for improved contaminant removal from water and wastewater. Bioresour Technol 214:836–851

Amen R, Bashir H, Bibi I et al (2020) A critical review on arsenic removal from water using biochar-based sorbents: the significance of modification and redox reactions. Chem Eng J 396:125195

An Q, Jin N, Deng S et al (2022) Ni(II), Cr(VI), Cu(II) and nitrate removal by the co-system of pseudomonas hibiscicola strain L1 immobilized on peanut shell biochar. Sci Total Environ 814:152635

Anderson N, Gu H, Bergman R (2021) Comparison of novel biochars and steam activated carbon from mixed conifer mill residues. Energies 14:8472

Arif M, Liu G, Yousaf B et al (2021) Synthesis, characteristics and mechanistic insight into the clays and clay minerals-biochar surface interactions for contaminants removal-a review. J Clean Prod 310:127548

Baser B, Yousaf B, Yetis U et al (2021) Formation of nitrogen functionalities in biochar materials and their role in the mitigation of hazardous emerging organic pollutants from wastewater. J Hazard Mater 416:126131

Bolan N, Hoang SA, Beiyuan J et al (2022) Multifunctional applications of biochar beyond carbon storage. Int Mater Rev 67:150–200

Chacón FJ, Cayuela ML, Cederlund H et al (2022) Overcoming biochar limitations to remediate pentachlorophenol in soil by modifying its electrochemical properties. J Hazard Mater 426:127805

Chen H, Yang X, Gielen G et al (2019) Effect of biochars on the bioavailability of cadmium and di-(2-ethylhexyl) phthalate to Brassica chinensis L. in contaminated soils. Sci Total Environ 678:43–52

Chen H, Yang X, Wang H et al (2020) Animal carcass- and wood-derived biochars improved nutrient bioavailability, enzyme activity, and plant growth in metal-phthalic acid ester co-contaminated soils: a trial for reclamation and improvement of degraded soils. J Environ Manag 261:110246

Chen H, Qin P, Yang X et al (2021a) Sorption of diethyl phthalate and cadmium by pig carcass and green waste-derived biochars under single and binary systems. Environ Res 193:110594

Chen J, Ouyang J, Lai W et al (2021b) Synthesis of ultralight chitosan/activated biochar composite aerogel globules for ketoprofen removal from aqueous solution. Sep Purif Technol 279:119700

Chen H, Feng Y, Yang X et al (2022a) Assessing simultaneous immobilization of lead and improvement of phosphorus availability through application of phosphorus-rich biochar in a contaminated soil: a pot experiment. Chemosphere 296:133891

Chen H, Gao Y, El-Naggar A et al (2022b) Enhanced sorption of trivalent antimony by chitosan-loaded biochar in aqueous solutions: characterization, performance and mechanisms. J Hazard Mater 425:127971

Chen Q, Cheng Z, Li X et al (2022c) Degradation mechanism and QSAR models of antibiotic contaminants in soil by MgFe-LDH engineered biochar activating urea-hydrogen peroxide. Appl Catal B Environ 302:120866

Cheng L, Ji Y, Liu X et al (2021a) Sorption mechanism of organic dyes on a novel self-nitrogen-doped porous graphite biochar: coupling DFT calculations with experiments. Chem Eng Sci 242:116739

Cheng N, Wang B, Wu P et al (2021b) Adsorption of emerging contaminants from water and wastewater by modified biochar: a review. Environ Pollut 273:116448

Cheng H, Zhang J, Chen Y et al (2022) Hierarchical porous biochars with controlled pore structures derived from co-pyrolysis of potassium/calcium carbonate with cotton straw for efficient sorption of diethyl phthalate from aqueous solution. Bioresour Technol 346:126604

Cui P, Yang Q, Liu C et al (2021a) An N,S-anchored single-atom catalyst derived from domestic waste for environmental remediation. ACS Environ Sci Technol Eng 1:1460–1469

Cui S, Zhang R, Peng Y et al (2021b) New insights into ball milling effects on MgAl-LDHs exfoliation on biochar support: a case study for cadmium adsorption. J Hazard Mater 416:126258

Deng J, Liu Y, Liu S et al (2017) Competitive adsorption of Pb(II), Cd(II) and Cu(II) onto chitosan-pyromellitic dianhydride modified biochar. J Colloid Interface Sci 506:355–364

Deng H, Dong H, Zhang C et al (2018) Nanoscale zero-valent iron/biochar composite as an activator for Fenton-like removal of sulfamethazine. Sep Purif Technol 202:130–137

Diao Z, Yan L, Dong F et al (2020) Degradation of 2,4-dichlorophenol by a novel iron based system and its synergism with Cd(II) immobilization in a contaminated soil. Chem Eng J 379:122313

Dong C, Chen C, Nguyen TB et al (2020) Degradation of phthalate esters in marine sediments by persulfate over Fe-Ce/biochar composites. Chem Eng J 384:123301

Duan W, Oleszczuk P, Pan B et al (2019) Environmental behavior of engineered biochars and their aging processes in soil. Biochar 1:339–351

Feizi M, Jalali M, Antoniadis V et al (2019) Geo- and nano-materials affect the mono-metal and competitive sorption of Cd, Cu, Ni, and Zn in a sewage sludge-treated alkaline soil. J Hazard Mater 379:120567

Feng F, Chen X, Wang Q et al (2020) Use of Bacillus-siamensis-inoculated biochar to decrease uptake of dibutyl phthalate in leafy vegetables. J Environ Mange 253:109636

Feng Z, Yuan R, Wang F et al (2021) Preparation of magnetic biochar and its application in catalytic degradation of organic pollutants: a review. Sci Total Environ 765:142673

Feng Q, Chen M, Wu P et al (2022) Simultaneous reclaiming phosphate and ammonium from aqueous solutions by calcium alginate-biochar composite: sorption performance and governing mechanisms. Chem Eng J 429:132166

Foong SY, Liew RK, Yang Y et al (2020) Valorization of biomass waste to engineered activated biochar by microwave pyrolysis: Progress, challenges, and future directions. Chem Eng J 389:124401

Fu C, Zhang H, Xia M et al (2020) The single/co-adsorption characteristics and microscopic adsorption mechanism of biochar-montmorillonite composite adsorbent for pharmaceutical emerging organic contaminant atenolol and lead ions. Ecotoxicol Environ Saf 187:109763

Gao F, Ahmad S, Tang J et al (2022) Enhanced nitrobenzene removal in soil by biochar supported sulfidated nano zerovalent iron: Solubilization effect and mechanism. Sci Total Environ 826:153960

Ghanim B, O’Dwyer TF, Leahy JJ et al (2020) Application of KOH modified seaweed hydrochar as a biosorbent of vanadium from aqueous solution: Characterisations, mechanisms and regeneration capacity. J Environ Chem Eng 8:104176

Guo R, Yan L, Rao P et al (2020) Nitrogen and sulfur co-doped biochar derived from peanut shell with enhanced adsorption capacity for diethyl phthalate. Environ Pollut 258:113674

Han H, Rafiq MK, Zhou T et al (2019) A critical review of clay-based composites with enhanced adsorption performance for metal and organic pollutants. J Hazard Mater 369:780–796

Han T, Lu X, Sun Y et al (2020) Magnetic bio-activated carbon production from lignin via a streamlined process and its use in phosphate removal from aqueous solutions. Sci Total Environ 708:135069

Hassan M, Liu Y, Naidu R et al (2020) Adsorption of Perfluorooctane sulfonate (PFOS) onto metal oxides modified biochar. Environ Technol Innov 19:100816

Heo J, Yoon Y, Lee G et al (2019) Enhanced adsorption of bisphenol a and sulfamethoxazole by a novel magnetic CuZnFe2O4–biochar composite. Bioresour Technol 281:179–187

Herath A, Navarathna C, Warren S et al (2022) Iron/titanium oxide-biochar (Fe2TiO5/BC): a versatile adsorbent/photocatalyst for aqueous Cr(VI), Pb2+, F− and methylene blue. J Colloid Interface Sci 506(614):603–616

Hu X, Xue Y, Long L et al (2018) Characteristics and batch experiments of acid- and alkali-modified corncob biomass for nitrate removal from aqueous solution. Environ Sci Pollut Res 25:19932–19940

Hu B, Ai Y, Jin J et al (2020) Efficient elimination of organic and inorganic pollutants by biochar and biochar based materials. Biochar 2:47–64

Hua L, Cheng T, Liang Z et al (2022) Investigation of the mechanism of phytate-modified biochar-catalyzed persulfate degradation of Ponceau 2R. Biochar 4:6

Huang D, Liu C, Zhang C et al (2019a) Cr(VI) removal from aqueous solution using biochar modified with Mg/Al layered double hydroxide intercalated with ethylenediaminetetraacetic acid. Bioresour Technol 276:127–132

Huang Q, Song S, Chen Z et al (2019b) Biochar-based materials and their applications in removal of organic contaminants from wastewater: state-of-the-art review. Biochar 1:45–73

Huang J, Zimmerman AR, Chen H et al (2020a) Ball milled biochar effectively removes sulfamethoxazole and sulfapyridine antibiotics from water and wastewater. Environ Pollut 258:113809

Huang Y, Lee X, Grattieri M et al (2020b) Modified biochar for phosphate adsorption in environmentally relevant conditions. Chem Eng J 380:122375

Huff MD, Lee JW (2016) Biochar-surface oxygenation with hydrogen peroxide. J Environ Manag 165:17–21

Irshad MK, Noman A, Wang Y et al (2022) Goethite modified biochar simultaneously mitigates the arsenic and cadmium accumulation in paddy rice (Oryza sativa) L. Environ Res 206:112238

Islam MS, Kwak JH, Nzediegwu C et al (2021) Biochar heavy metal removal in aqueous solution depends on feedstock type and pyrolysis purging gas. Environ Pollut 281:117094

Jia X, Zhou J, Liu J et al (2020) The antimony sorption and transport mechanisms in removal experiment by Mn-coated biochar. Sci Total Environ 724:138158

Jiang S, Ling L, Chen W et al (2019) High efficient removal of bisphenol a in a peroxymonosulfate/iron functionalized biochar system: mechanistic elucidation and quantification of the contributors. Chem Eng J 359:572–583

Jung KW, Lee SY, Choi JW et al (2019) A facile one-pot hydrothermal synthesis of hydroxyapatite/biochar nanocomposites: adsorption behavior and mechanisms for the removal of copper(II) from aqueous media. Chem Eng J 369:529–541

Kasera N, Kolar P, Hall SG (2022) Nitrogen-doped biochars as adsorbents for mitigation of heavy metals and organics from water: a review. Biochar 4:17

Kołtowski M, Charmas B, Skubiszewska-Zięba J et al (2017) Effect of biochar activation by different methods on toxicity of soil contaminated by industrial activity. Ecotoxicol Environ Saf 136:119–125

Krasucka P, Pan B, Ok YS et al (2021) Engineered biochar - a sustainable solution for the removal of antibiotics from water. Chem Eng J 405:126926

Kumar M, Xiong X, Wan Z et al (2020) Ball milling as a mechanochemical technology for fabrication of novel biochar nanomaterials. Bioresour Technol 312:123613

Kumar A, Singh E, Mishra R et al (2022) Biochar as environmental armour and its diverse role towards protecting soil, water and air. Sci Total Environ 806:150444

Kwak JH, Islam MS, Wang S et al (2019) Biochar properties and lead(II) adsorption capacity depend on feedstock type, pyrolysis temperature, and steam activation. Chemosphere 231:393–404

Lakshmi D, Akhil D, Kartik A et al (2021) Artificial intelligence (AI) applications in adsorption of heavy metals using modified biochar. Sci Total Environ 801:149623

Lartey-Young G, Ma L (2022) Optimization, equilibrium, adsorption behaviour of Cu/Zn/Fe LDH and LDH/BC composites towards atrazine reclamation in an aqueous environment. Chemosphere 293:133526

Lehmann J (2007) A handful of carbon. Nature 447:143–144

Leng L, Xu S, Liu R et al (2020) Nitrogen containing functional groups of biochar: An overview. Bioresour Technol 298:122286

Li L, Lai C, Huang F et al (2019) Degradation of naphthalene with magnetic bio-char activate hydrogen peroxide: synergism of bio-char and Fe/Mn binary oxide. Water Res 160:238–248

Li J, Wang S, Zhang J et al (2020a) Coconut-fiber biochar reduced the bioavailability of lead but increased its translocation rate in rice plants: elucidation of immobilization mechanisms and significance of iron plaque barrier on roots using spectroscopic techniques. J Hazard Mater 389:122117

Li T, Tong Z, Gao B et al (2020b) Polyethyleneimine-modified biochar for enhanced phosphate adsorption. Environ Sci Pollut Res 27:7420–7429

Li H, Cui S, Tan Y et al (2022a) Synergistic effects of ball-milled biochar-supported exfoliated LDHs on phosphate adsorption: insights into role of fine biochar support. Environ Pollut 294:118592

Li X, Yu Z, Chen Q et al (2022b) Kill three birds with one stone: iron-doped graphitic biochar from biogas residues for ammonium persulfate activation to simultaneously degrade benzo[a]pyrene and improve lettuce growth. Chem Eng J 430:132844

Liang H, Sun R, Song B et al (2020) Preparation of nitrogen-doped porous carbon material by a hydrothermal-activation two-step method and its high-efficiency adsorption of Cr(VI). J Hazard Mater 387:121987

Liao J, He X, Zhang Y et al (2022) Bismuth impregnated biochar for efficient uranium removal from solution: adsorption behavior and interfacial mechanism. Sci Total Environ 819:153145

Lin J, Mariuzza D, Volpe M et al (2021) Integrated thermochemical conversion process for valorizing mixed agricultural and dairy waste to nutrient-enriched biochars and biofuels. Bioresour Technol 328:124765

Liu H, Xu F, Xie Y et al (2018) Effect of modified coconut shell biochar on availability of heavy metals and biochemical characteristics of soil in multiple heavy metals contaminated soil. Sci Total Environ 645:702–709

Liu H, Wei Y, Luo J et al (2019) 3D hierarchical porous-structured biochar aerogel for rapid and efficient phenicol antibiotics removal from water. Chem Eng J 368:639–348

Liu S, Lai C, Li B et al (2020) Role of radical and non-radical pathway in activating persulfate for degradation of p-nitrophenol by sulfur-doped ordered mesoporous carbon. Chem Eng J 384:123304

Liu R, Wang H, Hu B et al (2021a) Reductive and adsorptive elimination of U(VI) ions in aqueous solution by SFeS@biochar composites. Environ Sci Pollut Res 28:55176–55185

Liu T, Cui K, Chen Y et al (2021b) Removal of chlorophenols in the aquatic environment by activation of peroxymonosulfate with nMnOx@biochar hybrid composites: performance and mechanism. Chemosphere 283:131188