Abstract

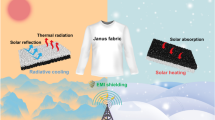

The movement mode of snakes is crawling, and the living environment of snakes with numerous branches and stones will cause plenty of wear for the snake scales. There are plenty of surface structures and morphology on snake scales to avoid severe wear. Among them, the research towards the keeled structure on snake scales is missing. Therefore, in this research, the wear resistance improvement of the keeled structure on the snake scales and the overlapped distribution of snake scales are investigated. The keeled and smooth snake scales were 3D printed and they were distributed on the substrate in the overlapped or paralleled ways. Besides these four samples with keeled/smooth scales and overlapped/paralleled distributed, there is also a reference sample with the same thickness. Based on the tribology test, the number of grooves of samples with the keeled structures is higher than that of samples with smooth surfaces, which indicates that the keeled structure dramatically enhances the wear resistance of snake scales, especially during the wear in the vertical direction. The experiment on surface morphology greatly compromised the result of the tribology test. In addition, the bottom portion of the keeled snake scales can be protected by the keeled structure. Besides, the overlapped distribution can protect the central region of snake scales and provide double-layer protection of the snake body. Overall, the keeled structure and the overlapped distribution play a significant part in the improvement of wear resistance of the snake skin. These findings can enhance the knowledge of the reptiles-mimic surface structure and facilitate the application of military uniforms under high-wear conditions.

Similar content being viewed by others

Data Availability

On behalf of my co-authors, the datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Klein, M. G., & Gorb, S. N. (2016). Scratch resistance of the ventral skin surface in four snake species (Squamata, Serpentes). Zoology (Jena, Germany), 119, 81–96.

Greene, H. W. (1997). Snakes: The Evolution of Mystery in Nature. University of California Press.

Sánchez-López, J. C., Schaber, C. F., & Gorb, S. N. (2021). Long-term low friction maintenance and wear reduction on the ventral scales in snakes. Materials Letters, 285, 129011.

Bapat, S., Tiner, C., Rajurkar, K., Nath, S., Atre, S., & Malshe, A. (2020). Understanding biologicalisation of the snake-skin inspired textures through additive manufacturing for mechanical traction. CIRP Annals, 69, 201–204.

Byrne, G., Dimitrov, D., Monostori, L., Teti, R., van Houten, F., & Wertheim, R. (2018). Biologicalisation: Biological transformation in manufacturing. CIRP J. Manufact. Sci. Technol., 21, 1–32.

Malshe, A., Rajurkar, K., Samant, A., Hansen, H. N., Bapat, S., & Jiang, W. (2013). Bio-inspired functional surfaces for advanced applications. CIRP Annals, 62, 607–628.

Malshe, A. P., Bapat, S., Rajurkar, K. P., & Haitjema, H. (2018). Bio-inspired textures for functional applications. CIRP Annals, 67, 627–650.

Zhang, S., Sunami, Y., & Hashimoto, H. (2018). Deformation behavior of dragonfly-inspired nodus structured wing in gliding flight through experimental visualization approach. Science and Reports, 8, 5751.

Zhang, S., Ochiai, M., Sunami, Y., & Hashimoto, H. (2019). Influence of Microstructures on Aerodynamic Characteristics for Dragonfly Wing in Gliding Flight. Journal of Bionic Engineering, 16, 423–431.

Liu, H., Ravi, S., Kolomenskiy, D., & Tanaka, H. (2016). Biomechanics and biomimetics in insect-inspired flight systems. Philosophical Transactions of the Royal Society of London. Series B, Biological sciences, 371, 20150390.

Ma, Y., Liu, Y., Tong, J.: Tribology of thermosetting composites, In Tribology of Polymer Composites, pp. 189–211 (2021).

Zhong, W., Liu, H., Wang, Q., Zhang, W., Li, Y., Ding, X., & Chen, L. (2021). Investigation of the penetration characteristics of snake skin-inspired pile using DEM. Acta Geotechnica, 16, 1849–1865.

Ballesteros, L. M., Zuluaga, E., Cuervo, P., Rudas, J. S., Toro, A.: Tribological behavior of polymeric 3D-printed surfaces with deterministic patterns inspired in snake skin morphology. Surface Topography: Metrology and Properties, 9, (2021).

Grant, C. (1936). The “Midventral Keel” in Testudinata. Proceedings of the Indiana Academy of Sciences, 46, 246–252.

Kumar, R., Antonov, M., Holovenko, Y., Surzenkov, A.: Erosive Wear Resistance of Nature-inspired Flexible Materials. Tribology Letters, 68 (2020).

Toro, A., Abdel-Aal, H. A., Zuluaga, E., Cuervo, P., Ballesteros, L. M., Sanchez, J. C., Rudas, J. S., Isaza, C., & Misiolek, W. Z. (2021). Influence of surface morphology and internal structure on the mechanical properties and tribological response of Boa Red Tail and Python Regius snake skin. J. Mechan. Behavior Biomed. Mater, 119, 104497.

Greiner, C., & Schafer, M. (2015). Bio-inspired scale-like surface textures and their tribological properties. Bioinspir. Biomimet., 10, 044001.

Bedajangam, S. K., & Jadhav, N. P. (2013). Friction losses between piston ring-liner assembly of internal combustion engine: a review. Int. J. Sci. Res. Publication, 3, 282–284.

Cuervo, P., López, D. A., Cano, J. P., Sánchez, J. C., Rudas, S., Estupiñán, H., Toro, A., and Abdel-Aal, H. A. (2016) Development of low friction snake-inspired deterministic textured surfaces. Surface Topography: Metrology and Properties, 4.

Klein, M. C., & Gorb, S. N. (2012). Epidermis architecture and material properties of the skin of four snake species. J. Royal Soc. Interf., 9, 3140–3155.

Zheng, L., Zhong, Y., Gao, Y., Li, J., Zhang, Z., Liu, Z., & Ren, L. J. J. O. B. E. (2018). Coupling effect of morphology and mechanical properties contributes to the tribological behaviors of snake scales. Journal of Bionic Engineering, 15, 481–493.

Nosonovsky, M., & Bhushan, B. (2012). Green Tribology: biomimetics, energy conservation and sustainability. NY: Springer.

Wakuda, M., Yamauchi, Y., Kanzaki, S., & Yasuda, Y. (2003). Effect of surface texturing on friction reduction between ceramic and steel materials under lubricated sliding contact. Wear, 254, 356–363.

Baruah, M., Das, M., & Sengupta, S. (2001). Food and feeding of Amphiesma stolatum (Linnaeus 1758). Journal of Environmental Biology, 22, 315–317.

Branch, W. R. (1999). Bitis arietans peghullaeStewart 1973 (Serpentes: Viperidae): a valid race of puff adder? African J. Herpetol., 48, 15–19.

Abdel-Aal, H.A.: The Structure of Ventral Scale Textures in Snakes in Comparison to Texturing of Deterministic Tribological Surfaces, In Processing Techniques and Tribological Behavior of Composite Materials, pp 268–315 (2015)

Abdel-Aal, H. A., El Mansori, M., & Mezghani, S. (2009). Multi-scale investigation of surface topography of ball python (Python regius) shed skin in comparison to human skin. Tribology Letters, 37, 517–527.

Ratner, S.B.: Comparison of the abrasion of rubbers and plastics. In: James, D.I. (Eds.). Abrasion of Rubber. Maclaren: London, p. 23 (1967)

Ratner, S. B., Farberova, I. I., Radyukevich, O. V., & Lure, E. G. (1964). Connection between wear resistance of plasticsand other mechanical properties. Soviet Plastics, 12, 37.

Lancaster, J. K. (1969). Abrasive wear of polymers. Wear, 14, 223–239.

Ramaraj, B. (2006). Mechanical and thermal properties of ABS and leather waste composites. Journal of Applied Polymer Science, 101, 3062–3066.

Sabah, F., Wahid, A., Nassih, F., El Ghorba, M., & Chakir, H. (2019). Prediction of the lifetime of Acrylonitrile Butadiene Styrene (ABS), by calculation of damage by two methods: damage based on residual stresses and damage by stages evolution. Key Engineering Materials, 820, 203–211.

Suarez, H., Barlow, J. W., & Paul, D. R. (1984). Mechanical properties of ABS/Polycarbonate blends. Journal of Applied Polymer Science, 29, 3253–3259.

Acknowledgements

This research was funded By Key Scientific And Technological Program Of Ningbo City (No. 2021Z108) and Yongjiang Talent Introduction Programme (No. 2021A-154-G).

Author information

Authors and Affiliations

Contributions

C.L. and S.Z. did most writing for the manuscript and literature studying. Y.C. assisted in partial writing and literature searching. J.B., S.X., and Y.Z. provided the guidance and framework of the study. S.Z. supervised the manuscript process.

Corresponding authors

Ethics declarations

Conflict of Interest

The authors declare no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, C., Chen, Y., Zheng, Y. et al. Wear Resistance Improvement of Keeled Structure and Overlapped Distribution of Snake Scales. J Bionic Eng 20, 1121–1131 (2023). https://doi.org/10.1007/s42235-022-00300-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42235-022-00300-2