Abstract

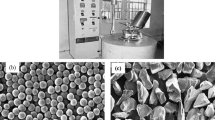

Aluminium alloys are the most popular and widely used materials in the industrial field because of their significant economic range and lower-density nature. In order to extend its utilization, it is necessary to enhance its mechanical properties. As a result, an attempt was made in this work to synthesize an AA6061 aluminium alloy reinforced with stir cast hybrid combinations of 2.5 wt% boron carbide (B4C) and 2.5, 5, and 7.5 wt% titanium oxide (TiO2) microparticles. Scanning electron microscopy (SEM), energy dispersive spectroscopy (EDS), and X-ray diffraction (XRD) analysis are used to characterize the fabricated AA6061 hybrid composites. SEM visuals of prepared hybrid composites certified the consistent distribution of B4C and TiO2 microparticles in the AA6061 matrix. The EDS spectra and XRD pattern are used to analyse the presence of hybrid reinforcements in the matrix. The physical and mechanical properties such as tensile, hardness, and impact are tested for the hybrid composites as per ASTM standards. The tensile fractured samples are also analysed by using SEM. The highest tensile, hardness, and impact test results were obtained for the AA6061/2.5wt%B4C/7.5wt%TiO2 sample. The present study indicates that the presence and concentration of reinforcement addition correspondingly increased the mechanical strength of the hybrid composites and is observed up to 7.5 wt% of TiO2 reinforcements. The fabricated AA6061/2.5wt%B4C/7.5wt%TiO2 hybrid composite attained better performances and is promising for use in automotive and its structural parts applications.

Similar content being viewed by others

Data Availability

The authors confirm that the data supporting the findings of this study are available within the article.

References

A.H. Idrisi, A.H. Ismail Mourad, Conventional stir casting versus ultrasonic assisted stir casting process: mechanical and physical characteristics of AMCs. J. Alloys Compd. 805, 502–508 (2019)

D.B. Miracle, Metal matrix composites—from science to technological significance. Compos. Sci. Technol. 65(15–16), 2526–2540 (2005)

P. Ajay Kumar, P. Rohatgi, D. Weiss, 50 years of foundry-produced metal matrix composites and future opportunities. Int. J. Metals 14, 291–317 (2020). https://doi.org/10.1007/s40962-019-00375-4

I.G. Watson, M.F. Forster, P.D. Lee, R.J. Dashwood, R.W. Hamilton, A. Chirazi, Investigation of the clustering behaviour of titanium diboride particles in aluminium. Compos. Part. A: Appl. Sci. Manuf. 36(9), 1177–1187 (2005)

R.P. Barot, M.P. Sutaria, R.P. Desai, Recycling of aluminium matrix composites (AMCS): a review and the way forward. Int. Metalcast (2022). https://doi.org/10.1007/s40962-022-00905-7

G.K. Sigworth, The modification of Al–Si casting alloys: important practical and theoretical aspects. Int. Metalcast. 2, 19–40 (2008). https://doi.org/10.1007/BF03355425

R.M. Sakthi Sadhasivam, K. Ramanathan, M. Ravichandran, C. Jayaseelan, Experimental investigations on microstructure, properties and workability behavior of zinc oxide reinforced Al–Si–Mg matrix composites. SILICON 14, 2175–2187 (2022)

R.M. Sakthi Sadhasivam, K. Ramanathan, B.V. Bhuvaneswari, R. Raja, A study on tribological behaviour and analysis of ZnO reinforced AA6061 matrix composites fabricated by stir casting route. Ind. Lub. Trib. 73(4), 642–651 (2021)

Y. Pazhouhanfar, B. Eghbali, Microstructural characterization and mechanical properties of TiB2 reinforced Al6061 matrix composites produced using stir casting process. Mater. Sci. Eng. A 710, 172–180 (2018)

H. Aydın, A. Bayram, A. Uğuz, K.S. Akay, Tensile properties of friction stir welded joints of 2024 aluminum alloys in different heat-treated-state. Mater. Des. 30(6), 2211–2221 (2009)

G. Pitchayyapillai, P. Seenikannan, K. Raja, K. Chandrasekaran, Al6061 hybrid metal matrix composite reinforced with alumina and molybdenum disulphide. Adv. Mater. Sci. Eng. (2016). https://doi.org/10.1155/2016/6127624

T. Alemneh Wubieneh, S. Tenager Tegegne, Fabrication and characterization of aluminum (Al-6061) matrix composite reinforced with waste glass for engineering applications. J. Nanomaterial (2022). https://doi.org/10.1155/2022/8409750

C. Ramesh Kumar, R. Ravi Raja Malarvannan, V. JaiGanesh, Role of SiC on mechanical, tribological and thermal expansion characteristics of B4C/Talc-reinforced Al-6061 hybrid composite. SILICON 12, 1491–1500 (2020)

C. Saravanan, K. Subramanian, V. Ananda Krishnan, R. Sankara Narayanan, Effect of particulate reinforced aluminium metal matrix composite—a review. Mech. Mech. Eng. 19(1), 23–30 (2015)

S. Suresh Kumar, M. Uthayakumar, S. Thirumalai Kumaran, P. Parameswaran, Electrical discharge machining of Al (6351)–SiC–B4C hybrid composite. Mater. Man. Process. 29(11–12), 1395–1400 (2014)

R. Jojith, N. Radhika, Mechanical and tribological properties of LM13/TiO2/MoS2 hybrid metal matrix composite synthesized by stir casting. Part. Sci. Technol. 37(5), 570–582 (2019)

P. Morampudi, V.S.N. Venkata Ramana, K. Sri Ram Vikas, R. Rahul, C. Prasad, Effect of nano ZrB2 particles on physical, mechanical and corrosion properties of Al6061 metal-matrix nano composites through stir casting route. Eng. Res. Express. (2022). https://doi.org/10.1088/2631-8695/ac5f66

M. Shayan, B. Eghbali, B. Niroumand, Synthesis and characterization of AA2024-SiO2 nanocomposites through the vortex method. Int. Metalcast. 15, 1427–1440 (2021). https://doi.org/10.1007/s40962-021-00574-y

John Samson Khalkho, Suresh Vidyasagar Chevuri, Benny Karunakar Dagarapu, Evaluation of microstructure and mechanical properties of TiO2 reinforced aluminium composites developed through multi-step stir casting. Int. Metalcast. (2022). https://doi.org/10.1007/s40962-022-00760-6

G. Kumaresan, B. Arul Kumar, Investigations on mechanical properties of micro- and nano-particulates (Al2O3/B4C) reinforced in Al7075 matrix composite. Int. Metalcast. 16, 1932–1939 (2022). https://doi.org/10.1007/s40962-021-00741-1

R. Soundararajan, A. Sathishkumar, S. Sivasankaran, G. Shanthosh, S. Karthik, Evaluation of microstructures, mechanical and dry-sliding wear performance of A356-(Fly Ash/SiCp) hybrid composites. Inter Metalcast. 16, 2079–2096 (2022). https://doi.org/10.1007/s40962-021-00731-3

J. Hernandez-Sandoval, A.M. Samuel, F.H. Samuel, S. Valtierra, Effect of additions of SiC and Al2O3 particulates on the microstructure and tensile properties of Al–Si–Cu–Mg cast alloys. Inter Metalcast. 10, 253–263 (2016). https://doi.org/10.1007/s40962-016-0035-5

A. Abebe Emiru, D. Kumar Sinha, Fabrication and characterization of hybrid aluminium (Al6061) metal matrix composite reinforced with SiC, B4C and MoS2 via stir casting. Inter. Metalcast. (2022). https://doi.org/10.1007/s40962-022-00800-1

S. Kumar Soni, Benedict Thomas, Influence of TiO2 and MWCNT Nanoparticles dispersion on microstructure and mechanical properties of Al6061 matrix hybrid nanocomposites Mater. Res. Express. (2019). https://doi.org/10.1088/2053-1591/ab5dfe

D.S. Ebenezer Jacob Dhas, C. Velmurugan, K. Leo Dev Wins, K.P. Boopathi Raja, Effect of Tungsten carbide, Silicon carbide and Graphite particulates on the mechanical and microstructural characteristics of AA 5052 hybrid composites. Ceram Intl 45(1), 614–621 (2019)

S. Rajesh, C. Velmurugan, D.S. Ebenezer Jacob Dhas, P.S. Samuel Ratna-Kumar, Studies on the tribological behaviour of exsitu—synthesized AlMg1SiCu/titanium carbide/molybdenum disulfide hybrid composites. Res. Express Mater (2019). https://doi.org/10.1088/2053-1591/ab5f1e

N.M. Siddesh Kumar, N.U. Dheeraj, M. Dhruthi, T.N. Sadashiva, A.K. Shashank, P.K. Rohatgi, Coatings on reinforcements in aluminum metal matrix composites. Inter Metalcast (2022). https://doi.org/10.1007/s40962-022-00831-8

W.Y. Zhang, Y.H. Du, P. Zhang, Vortex-free stir casting of Al-1.5 wt% Si-SiC composite. J. Alloys Compd. 787, 206–215 (2019)

G.B. Ghorbal, A. Tricoteaux, A. Thuault, G. Louis, D. Chicot, Comparison of conventional Knoop and Vickers hardness of ceramic materials. J. Eur. Cer. Soc. 37(6), 2531–2535 (2017)

K. Amouri, Sh. Kazemi, A. Momeni, M. Kazazic, Microstructure and mechanical properties of Al-nano/micro SiC composites produced by stir casting technique. Mater. Sci. Eng. A 674, 569–578 (2016)

Y. Han, X. Liu, X. Bian, In situ TiB2 particulate reinforced near eutectic Al–Si alloy composites. Compos. Part A: Appl. Sci. Manuf. 33(3), 439–444 (2002)

S. Mozammil, J. Karloopia, R. Raviraj Verma, P.K. Jha, Effect of varying TiB2 reinforcement and its ageing behaviour on tensile and hardness properties of in-situ Al-4.5%Cu-xTiB2 composite. J. Alloys Compd. 793, 454–466 (2019)

E. Ghasali, M. Alizadeh, T. Ebadzadeh, Amir hossein Pakseresht, Ali Rahbari, Investigation on microstructural and mechanical properties of B4C–aluminum matrix composites prepared by microwave sintering. J. Mat. Res. Tech. 4(4), 411–415 (2015)

J. Liu, Q. Guo, Yu. Mei, S. Li, Effect of TiO2 nanostructures on specific capacitance of Al2O3–TiO2 composite film on etched aluminum foil formed by the sol–gel and anodizing. Cer. Inter. 40(2), 3687–3692 (2014)

R. Kalaivani, M. Maruthupandya, T. Muneeswaran, A. Hameedha Beevi, M. Anand, C.M. Ramakritinan, A.K. Kumaragurua, Synthesis of chitosan mediated silver nanoparticles (Ag NPs) for potential antimicrobial applications. Fro. Lab. Med. 2(1), 30–35 (2018)

M. Sambathkumar, P. Navaneethakrishnan, K. Ponappa, K.S.K. Sasikumar, Mechanical and Corrosion Behavior of Al7075 (Hybrid) Metal Matrix Composites by Two Step Stir Casting Process. Lat. Ame. J. Sol. Stru. 14(2), 243–255 (2017)

S.M. Aqida, M.I. Ghazali, J. Hashim, The effects of stirring speed and reinforcement particles on porosity formation in cast MMC. Jurnal Mekanikal. 16(2), 22–30 (2003)

A. Sanaty-Zadeh, Comparison between current models for the strength of particulate-reinforced metal matrix nanocomposites with emphasis on consideration of Hall-Petch effect. Mater. Sci. Eng. A 531, 112–118 (2012)

N. Hansen, Hall-Petch relation and boundary strengthening. Scripta Mater. 51(8), 801–806 (2004)

P. Madhukar, N. Selvaraj, C.S.P. Rao, G.B. Veeresh Kumar, Fabrication and characterization two step stir casting with ultrasonic assisted novel AA7150-hBN nanocomposites. J. Alloys Compd. 815, 1–11 (2020)

S.-J. Huang, A. Abbas, Effects of tungsten disulfide on microstructure and mechanical properties of AZ91magnesium alloy manufactured by stir casting. J. Alloys Compd. 817, 153321 (2020). https://doi.org/10.1016/j.jallcom.2019.153321

M.A. Maleque, A.A. Adebisi, N. Izzati, Analysis of fracture mechanism for Al-Mg/SiCp composite materials. IOP Conf. Ser.: Mater. Sci. Eng. 184, 1–8 (2017)

A.M. Razzaq, D.L. Majid, M.R. Ishak, U.M. Basheer, Effect of fly ash addition on the physical and mechanical properties of AA6063 alloy reinforcement. Met. 7(11), 1–15 (2017)

V. Kilicli, N. Akar, M. Erdogan, K. Kocatepe, Tensile fracture behavior of AA7075 alloy produced by thixocasting. Trans. Nonfer. Metals Soc. China 26(5), 1222–1231 (2016)

J.J. Moses, I. Dinaharan, J.S. Sekhar, Production and characterization of titanium carbide particulate reinforced AA6061 aluminum alloy composites using stir casting. Kovo. Mater. 54(4), 257–267 (2016)

S.V. Alagarsamy, M. Ravichandran, Synthesis, microstructure and properties of TiO2 reinforced AA7075 matrix composites via stir casting route. Mater. Res. Exp. 6, 086519 (2019)

Acknowledgement

The authors express their sincere thanks to Alagappa Chettiar Government College of Engineering & Technology, Karaikudi, Tamilnadu, India, for the support provided to this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Consent for Publication

Consent was obtained from all the authors for the publication of this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Raja, R., Ramanathan, K., Sakthi Sadhasivam, R. et al. Synthesis, Microstructure, Physical and Mechanical Characterization of AA6061/B4C/TiO2 Hybrid Composites. Inter Metalcast 17, 2904–2916 (2023). https://doi.org/10.1007/s40962-023-00969-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-023-00969-z