Abstract

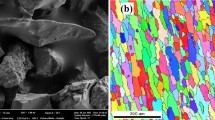

Aluminium-based hybrid composites have the advanced applications for their better qualities like high strength-to-low weight ratio and improved hardness than pure aluminium. This research work has carried out to improve the mechanical and wear properties of AA7475 aluminium alloy due to their need in the structural areas and automotive industry. Hence, the reinforcement of 15 wt.% zirconium silicate (ZrSiO4) with AA7075/SiC composites in different SiC percentages has been carrying out using stir casting. The advanced microscopy technique is used to study the microstructure of virgin matrix and their hybrid composites. Archimedes’ principle is used to evaluate the density of hybrid composites and its effects on void content in hybrid composites are studied. The effect of reinforced zirconium silicate (ZrSiO4) in the AA7475 was analysed by the observed hardness, tensile and compressive behaviour in composites. Finally, the wear rate and worn-out surface is studied. The overall analysis found that the microstructure of composites has been identified that SiC and ZrSiO4 reinforcement particles have spread evenly in matrix alloy. The Al4C3 phase has been observed in the hybrid composite surfaces. The 23.8% hardness, 46% tensile value, 52% yield value, 11% compressive value strength and 46.42% wear rate have been enhanced by adding reinforcements with matrix.

Similar content being viewed by others

References

K. Kaur, O.P. Pandey, Tribol. Lett. 38, 377 (2010)

Y. Ma, G.S. Martynková, M. Valášková, V. Matějka, Y. Lu, Tribol. Int. 41, 166 (2008)

K.S. Sucitharan, P. Senthil Kumar, D. Shivalingappa, J. Jenix Rino, Wear 3, 2 (2013)

E.G. Okafor, V.S. Aigbodion, Tribol. Ind. 32, 31 (2010)

K.S. Arun, T. Panneerselvam, S. Raghuraman, Appl. Mech. Mater. 813, 116 (2015)

H.M. Rajan, S. Ramabalan, I. Dinaharan, S.J. Vijay, Mater. Des. 44, 438 (2013)

J.D. Selvam, D.R. Smart, I. Dinaharan, Mater. Des. 49, 28 (2013)

J.D. Selvam, D.R. Smart, I. Dinaharan, Energy Procedia 34, 637 (2013)

Z. Yu, N. Zhao, E. Liu, C. Shi, X. Du, J. Wang, Compos. Part A Appl. 43, 631 (2012)

S. Sakthivelu, M. Meignanamoorthy, M. Ravichandran, P.P. Sethusundaram, Mech. Mech. Eng. 1, 198 (2019)

A.S. Vasava, D. Singh, Mater. Today Proc. 58, 140 (2022)

P.P. Awate, S.B. Barve, Mater. Res. Express 4, 015023 (2022)

K.K. Alaneme, I.B. Akintunde, P.A. Olubambi, T.M. Adewale, J. Mater. Res. 2, 60 (2013)

K.K. Alaneme, T.M. Adewale, P.A. Olubambi, J. Mater. Res. 3, 9 (2014)

A. Baradeswaran, A.E. Perumal, Compos. B Eng. 56, 464 (2014)

A. Baradeswaran, S.C. Vettivel, A.E. Perumal, N. Selvakumar, R.F. Issac, Mater. Des. 63, 620 (2014)

R. Bauri, M.K. Surappa, J. Mater. Process. Technol. 209, 2077 (2009)

N.E. Bekheet, R.M. Gadelrab, M.F. Salah, A.N. Abd El-Azim, Mater. Des. 23, 153 (2002)

M.T. Guo, C.Y. Tsao, Compos. Sci. Technol. 60, 65 (2000)

A.M. Hassan, A. Alrashdan, M.T. Hayajneh, A.T. Mayyas, Tribol. Int. 42, 1230 (2009)

A. Kalkanlı, S. Yılmaz, Mater. Des. 29, 775 (2008)

I. Kerti, F. Toptan, Mater. Lett. 62, 1215 (2008)

M. Kok, J. Mater. Process. Technol. 161, 381 (2005)

G.V. Kumar, C.S. Rao, N. Selvaraj, Compos. B Eng. 43, 1185 (2012)

S. Debnath, A.K. Pramanick, I.O.P. Conf, Ser. Mater. Sci. Eng. 1080, 012018 (2021)

A. Bhowmik, D. Dey, A. Biswas, Silicon 13, 2003 (2021)

N. Faisal, K. Kumar, J. Exp. Nanosci. 13, S1–S3 (2018)

K.G. Thirugnanasambantham, T. Sankaramoorthy, R. Karthikeyan, K.S. Kumar, Mater. Today Proc. 45, 2561 (2021)

V.B. Nathan, R. Soundararajan, C.B. Abraham, E. Vinoth, J.K. Narayanan, Mater. Today Proc. 45, 1237 (2021)

R. Harichandran, N. Selvakumar, Arch. Civ. Mech. 16, 147 (2016)

J. Jiang, Y. Wang, Mater. Sci. Eng. A 639, 350 (2015)

A.D. Hamedan, M. Shahmiri, Mater. Sci. Eng. A 556, 921 (2012)

A.K. Sharma, R. Bhandari, C. Pinca-Bretotean, J. Phys. Conf. Ser. 1781, 012031 (2021)

V.S. Kannan, K. Lenin, D. Srinivasan, D. Raj Kumar, Silicon 8, 1 (2021)

S.A. Sajjadi, H.R. Ezatpour, H. Beygi, Mater. Sci. Eng. A 528, 8765 (2011)

P.L. Reznik, B.V. Ovsyannikov, Mater. Sci. Forum 989, 335 (2020)

P. Sharma, S. Sharma, R.K. Garg, K. Paliwal, D. Khanduja, V. Dabra, Powder Metall. Met. Ceram. 56, 264 (2017)

H. Jin, Metall. Mater. Trans. A 49, 6122 (2018)

L. Jinfeng, J. Longtao, W. Gaohui, T. Shoufu, C. Guoqin, Rare Met. Mater. Eng. 38, 1894 (2009)

G. Straffelini, F. Bonollo, A. Molinari, A. Tiziani, Wear 211, 192 (1997)

S. Kumar, V. Balasubramanian, Wear 264, 1026 (2008)

N. Wang, Z. Wang, G.C. Weatherly, Metall. Trans. A 23, 1423 (1992)

H.R. Ezatpour, S.A. Sajjadi, M.H. Sabzevar, Y.Z. Huang, Mater. Sci. Eng. A 607, 589 (2014)

F. Akhlaghi, A. Lajevardi, H.M. Maghanaki, J. Mater. Process. Technol. 155, 1874 (2004)

G.V. Kumar, C.S. Rao, N. Selvaraj, Compos. B Eng. 43, 1185 (2012)

K.N. Chakravartula, N.R. Rajamalla, Mater. Sci. Medžiagotyra 22, 491 (2016)

S.K. Khatkar, R. Verma, S.S. Kharb, A. Thakur, R. Sharma, Silicon 13, 1461 (2021)

T. Sathish, S. Karthick, J. Mater. Res. 9, 3481 (2020)

Funding

The authors have been declared that no funds, grants or other support had not been received in the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

The conceptualization, methodology, writing reviewing discussion, computation, software, analysis and discussion have formed by VSK. The evaluation the analysis section made by KL. The evaluation of entire manuscript made by DS. The software work made by DRK.

Corresponding author

Ethics declarations

Competing Interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kannan, V.S., Lenin, K., Srinivasan, D. et al. Analysis of Microstructural, Mechanical and Surface Properties of Aluminium Hybrid Composites Obtained Through Stir Casting. J. Inst. Eng. India Ser. D (2023). https://doi.org/10.1007/s40033-023-00512-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40033-023-00512-8