Abstract

Water–rock interaction (WRI) is a topic of interest in geology and geotechnical engineering. Many geological hazards and engineering safety problems are severe under the WRI. This study focuses on the water weakening of rock strength and its influencing factors (water content, immersion time, and wetting–drying cycles). The strength of the rock mass decreases to varying degrees with water content, immersion time, and wetting–drying cycles depending on the rock mass type and mineral composition. The corresponding acoustic emission count and intensity and infrared radiation intensity also weaken accordingly. WRI enhances the plasticity of rock mass and reduces its brittleness. Various microscopic methods for studying the pore characterization and weakening mechanism of the WRI were compared and analyzed. Various methods should be adopted to study the pore evolution of WRI comprehensively. Microscopic methods are used to study the weakening mechanism of WRI. In future work, the mechanical parameters of rocks weakened under long-term water immersion (over years) should be considered, and more attention should be paid to how the laboratory scale is applied to the engineering scale.

Highlights

-

(1)

This paper reviews the water weakening on rock strength and its influencing factors.

-

(2)

Various microscopic methods for studying the pore characterization and weakening mechanism of WRI are compared and analyzed.

-

(3)

We study the weakening mechanism of WRIs using microscopic methods.

-

(4)

Future works on WRI laboratory tests were suggested.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Water–rock interactions (WRIs) are a topic of interest in geology and geotechnical engineering. Many physical and chemical reactions are involved in the WRI, including lubrication, precipitation, oxidation–reduction, and ion exchange. Many geological hazards and engineering failures, such as slope stability (Zhao et al. 2018c), reservoir dam stability (Ukpai 2021), rock bursting (Chen et al. 2019a; Ma et al 2022), karst collapse (Bai et al. 2013), and water inrush from mines and tunnels (Huang et al. 2016; Li et al. 2019b; Liu et al. 2022), are caused by the WRI. Analysis and interpretation of the influence of water on the mechanical behavior of rocks are based on the above problems. In recent years, many studies have illustrated the effects of water on the mechanical characteristics of rocks. In general, the presence of water reduces the elastic modulus, compressive strength, cohesion, tensile strength, and rock brittleness (Baud et al. 2000; Erguler and Ulusay 2009; Zhou et al. 2017; Talesnick and Shehadeh 2007) and changes the fracture distribution and fragment shape after rock failure (Haberfield and Johnston 1990; Shen et al. 2020; Guha Roy et al. 2017; Kataoka et al. 2015). The water presence increases the pore water pressure in rock and soil mass, reducing the effective stress of rock and soil mass skeleton particles and changing the physical and mechanical parameters of the rock and soil mass. In addition, it is easy to cause the dissolution or change of mineral composition in rock, soil mass, and cement between grains to produce new mineral composition. The WRI effect will be greater if the water contains corrosive mineral components (Luo et al. 2021). For example, rocks with higher clay mineral content are more susceptible to water penetration (Verstrynge et al. 2014).

This short review focuses on the water weakening of rock strength and its influencing factors, such as the water content, immersion time, and wetting–drying cycles. On this basis, the micromechanism of WRI and its corresponding research methods are addressed.

2 Water weakening characteristics and its influencing factors

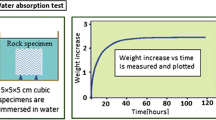

Mechanical experiments combined with corresponding characterization methods are the primary methods used to study the weakening characteristics of the WRI. In conventional mechanical experiments (uniaxial and triaxial compression tests, Brazilian splitting tests, shear tests, point load tests, needle penetration tests, and Hopkins impact tests, as shown in Fig. 1), the shear, tensile, compressive, hardness, and dynamic load strengths can be obtained. In the test process, in addition to obtaining the stress–strain curves, acoustic emission (AE), infrared radiation temperature, digital image correlation (DIC), 3D laser scanning, and other methods are typically used to characterize the influence of the WRI (Fig. 1).

The weakening analysis of the WRI focuses on the influence of water content, immersion time, and wetting–drying cycles on rock strength, as well as the corresponding AE and infrared radiation (IR) characteristics.

2.1 Water content

Water content can be divided into two aspects: (1) the water content state, including the dry state, natural water content state, and saturated water content state, and (2) the actual moisture content of the rock mass. There are two methods for preparing rock samples with different water contents: direct immersion in water and a non-destructive immersion method that places rock samples in a wet and closed environment to avoid the exchange or hydrochemical reaction between rock and water.

The compressive, shear, tensile strength, and elastic modulus decrease to varying degrees with the increasing water content, as summarized in Table 1. Among these, mudstone rocks have the highest water sensitivity. Granite and other hard rocks have the lowest sensitivity to water, and some rocks are unaffected by water. An increase in water content enhances the plasticity of the rock mass and reduces brittleness (Noël et al. 2021). Some quantitative relationships (fitting formula) between the mechanical parameters (σt, σc, σtc, τ, E, v, c φ, etc.) and water content are summarized in Table 1. In addition, the water content reduces the fracture toughness after rock failure (Zhou et al. 2018a, b; Hua et al. 2015).

AE describes the energy release characteristics of rocks during fracturing or cracking. Hard rocks typically accumulate more energy during loading and would release stronger AE signals during failure. As the water content increases, the cumulative and peak AE signals, high-frequency AE signals, AE signal differences, and AE signal distribution uniformity decrease (Li et al. 2019a, 2021b; Ranjith et al. 2008; Guo et al. 2018; Lin et al. 2019; Zhu et al. 2020; Liu et al. 2019). In addition, with an increase in water content, AE is concentrated in the fracture stage, and the fractal dimension decreases (Song et al. 2020; Kong et al. 2017, 2019). Wet rocks generally produce small fragments during failure, which decreases the fractal dimension, and irregular fractures occur during loading.

For the correlation between moisture content and IR, the average IR temperature (AIRT) generally increases with increasing load and depends on the state of the rock samples (wet or dry, damaged or not). Before the damage, wet rocks generally show a faster increase in the AIRT, whereas dry rocks would produce more increments in the AIRT during damage (Deng et al. 1997; Liu et al. 2010). However, in the entire loading process, the higher the water content, the greater the AIRT, and the smaller the AIRT fluctuation (Zhou et al. 2018c). Sun et al. (2021a) further showed that the applied stress controls IR; for example, the IR count (IRC) will simultaneously increase when the stress suddenly drops. The water content reduces the stress due to water weakening. The above conclusions mainly rely on the uniaxial compression tests. Shear tests by Yao et al. (2020a) concluded that the IR characteristics were comparable to those of the uniaxial compression tests.

With increasing water content, the dynamic load strength and dissipated energy decreased, but the elastic modulus increased. The dynamic strength of saturated rocks is more sensitive to the strain rate than that of dry rocks. With an increase in the strain rate (43.9–156.7 per second), the water weakening effect decreases gradually (Cai et al. 2020b). Further, compared with the uniaxial compressive strength of dry rock samples, that of saturated rock increases with the loading rate in two stages: rapidly increases at low loading rates, and then decreases at high loading rates (Zhu et al. 2021).

2.2 Wetting–drying cycles

Many practical engineering problems involve wetting–drying (WD) cycles, such as rocks in exposed slopes, coastlines, and pumping reservoirs. Similar to preparing rock masses with different water contents, there are also two methods (free and pressure immersion method, air and oven (or heater) drying) for preparing rock samples experiencing WD cycles. A vacuum pressure condition is adopted to accelerate rock saturation when preparing rock immersion, whereas the free immersion method is performed under atmospheric pressure conditions. In the drying process, oven drying can accelerate the drying of rocks compared with air drying. Previous laboratory tests have shown that the WD cycle treatment has a significant impact on the mechanical and physical properties (Aw, P, PLI, SDI, KIC, KIIC, Keff, Vp, σc, σt, E, c, φ, τ, σcd, Ed, Tc, R, and H) of the rock, as summarized in Table 2 (Liu and Zhang 2020; Momeni et al. 2017; Zhou et al. 2018b; Chen et al. 2019c; He et al. 2020; Huang et al. 2022).

Although the WD cycle treatment methods were different in these studies, consistent weakening characteristics were observed. With progressive WD cycles, the porosity and water absorption increased monotonically, whereas the other parameters in Table 2 generally decreased. The decrease in mechanical and physical parameters gradually diminished with the progression of WD cycles (Sun and Zhang 2019; Khanlari and Abdilor 2015; Huang et al. 2010; Fu et al. 2017; Zhao et al. 2018a; Gratchev et al. 2019; Yao et al. 2019b; Wu et al. 2020b; Cai et al. 2020a; Li et al. 2021c). For example, it was found that the first 10 WD cycles significantly impacted the rock's strength; there was no change (Zhao et al. 2021; Guo et al. 2021) in the following cycles. The fracture toughness and crack propagation were also affected by the WD cycle. The fracture energy and fraction coefficient decrease with WD cyclic treatment (Zhao et al. 2017b, c; Song et al. 2019; Ma et al. 2018). The rock's mineral composition has been found to be the main factor affecting the weakening of the WD cycle (Zhou et al. 2017; Tang et al. 2021).

2.3 Immersion time

The immersion time is more closely related to the actual field situation than the water content. Underground rock masses are occasionally immersed in water for months or years, and immersion time significantly affects rock strength (Bai et al. 2016). However, in most laboratory tests, the maximum immersion time is generally no longer than 1 year. The immersion time is currently limited because some rocks (especially those with strong hydrophilicity, such as mudstone) disintegrate after immersion for a short period (Azhar et al. 2020; Fujii et al. 2020). In addition, many studies have shown that some rocks do not weaken even after long-term immersion (Ai et al. 2021; Lyu et al. 2022).

As the immersion time increases, the mechanical parameters (σc, σt, E, c, φ, τ) of some rocks are weakened, their brittleness decreases, the failure mode becomes stable, and the roughness of the fracture planes increases (Zhu et al. 2020; Ma et al. 2021). The time-dependent immersion weakening varies for different rocks. For example, as the immersion time increases, the uniaxial compressive strength of coarse sandstones first decreases rapidly, then increases slightly, and finally decreases (Wu et al. 2020a). The uniaxial compressive strength and elastic modulus of argillaceous slates decrease with increasing immersion time, whereas Poisson's ratio remains roughly unchanged (Huang et al. 2020b).

2.4 Other WRI related factors

The chemical composition and water pressure play significant roles in WRI weakening. The mechanical parameters (σc, σt, E, c, φ, τ) of chemically treated samples generally demonstrate more significant weakening compared with natural immersion conditions, especially for pre-fractured samples (Zhang et al. 2019; Gong et al. 2021). For example, the salts contained in water can gradually accumulate in the pore networks of rocks under wetting–drying cycles, which can cause rock deterioration (Jiang et al. 2022). The water immersion height also influences rock strength; the strength of partially presoaked specimens is lower than that of wholly presoaked specimens (Chen et al. 2021). Seepage water pressure enhances the deformation resistance of rock and affects rock strength. As seepage pressure increases, the stress thresholds for crack initiation and damage during rock compression decrease (Xiao et al. 2020; Zhong et al. 2019; Li et al. 2020b). Generally, studies on the WRI of rock mass cover various factors, and strength tests investigate the weakening characteristics under various immersion conditions to reflect engineering environments. Then, it is used to predict the degree of influence of the WRI on engineering scales.

3 Weakening mechanism and microscopic characterization

Many studies have shown that WRI is mainly the interaction between water and clay-related minerals in rocks, which changes the pore structure and further degrades their strength. Therefore, in addition to characterizing the macroscopic strength, investigating the internal microstructure is a valuable way to uncover WRI mechanisms. Microscopic observations include laser scanning confocal microscopy (LSCM) (An et al. 2020), polarizing microscopy (PM), scanning electron microscopy (SEM) (Dehestani et al. 2020; Zhang et al. 2014; Liu et al. 2018; Yang et al. 2018; Zhou et al. 2018b; Du et al. 2019), neutron radiography (NR), nuclear magnetic resonance (NMR) (Xie et al. 2018; Zhao et al. 2017a, 2018a, b, 2019b), computed tomography (CT), and small angle X-ray scattering (SAXS) and other methods (Liu et al. 2016; Zhao et al. 2014, 2019a; Wang et al. 2021). The main application of the micro-observation techniques is shown in Fig. 2. The XRD pattern shown in Fig. 2 is typically used to investigate the hydrophilic mineral composition of the rocks.

The microinvestigation methods shown in Fig. 2 can be divided into three categories: SEM, PM, and LSCM. They are primarily used to observe the surface structure of a rock mass. SEM can be used to observe the mineral occurrence morphology, crystal morphology, surface morphology, and composition. However, the tested samples must be sprayed before SEM scanning; therefore, it is a destructive test. LSCM is mainly used for scanning the fracture surface. NMR and NR are mainly employed to judge pore structures and immersed liquids. The NMR is a non-destructive test that is widely used to characterize pore structures. However, NMR cannot be used to reconstruct a three-dimensional pore structure. CT, SAXS, and XRD are used for X-ray fluoroscopy, and the pore structure and mineral composition can be reconstructed with post-processing. CT is a non-destructive technique that can reconstruct pore and fracture structures in real time and is widely used to track pore and fracture evolutions during rock deformation. However, in the process of three-dimensional reconstruction of CT images, the division of pore fracture and mineral composition threshold is generally manually defined, which sometimes affects the accuracy of the reconstruction model.

Thus, various microcharacterization techniques are generally used for complementary analysis (Zhang et al. 2021; Ai et al. 2021). For example, NMR, XRD, and CT can be used to accurately reconstruct pore structures and mineral compositions (Fig. 3). Specifically, the mineral composition in the sample is first identified by XRD, such as clay mineral composition with strong hydrophilicity, and then the threshold is used during the reconstruction of CT images. Similarly, NMR can accurately provide the pore structure division threshold for CT reconstruction.

Based on the CT reconstruction method (Fig. 3), we reconstructed the pore structure and mineral composition model of the coal samples before and after water immersion. Table 3 shows the distribution of the pores with increased connectivity (blue) and reduced clay minerals (red) before and after immersion. The locations where the clay minerals are reduced coincide with the positions where the connectivity pores are increased. Further, the change in the pore structure in the sample during WRI is mainly caused by the dissolution and expansion of hydrophilic mineral components (Azhar et al. 2020; Huanget al. 2020b; Liu et al. 2021).

Currently, five mechanisms for rock strength weakening caused by water immersion have been proposed: (1) expansion and dissolution of clay minerals, (2) reduction of capillary tension, (3) increase in pore pressure, (4) reduction of fracture energy, and (5) weakening of intergranular cohesion and friction (Zhu et al. 2020; Li et al. 2020a). By comparing the CT images before and after immersion (Fig. 4), the internal damage process caused by the WRI can be observed. Figure 4a and b show the CT images at the same position before and after immersion. The darkening of the greyscales in the CT images indicates an increase in damage and a decrease in density. Therefore, pre-existing weaknesses are displayed in darker colors. As shown in Fig. 4a, there are apparent darker parts (weaknesses) in the dry sample because coal is a typical porous medium with a large number of pore structures (connected pores and isolated pores) and fracture structures (Yao et al. 2019a). After immersion, the size and aperture of the internal fractures in the coal sample increased, and cleats between beddings gradually developed with water degradation. Fracture structures have better connectivity and higher permeability, forming the main flow channels of the fluid medium; meanwhile, clay minerals near the fractures are dissolved in water. In addition, water weakens the intergranular bonding of pre-existing weaknesses, and the development of fractures and pores (connected pores) increases the contact area between water and coal, resulting in the appearance of cleats between beds. For the rock samples, water mainly weakened the cementation between the crystals (Fig. 4d). The stress and energy required for failure along the fractures and cleats are significantly lower than those required for the direct penetration of the coal matrix and rock crystals; therefore, the higher the water content, the smaller the rock strength and the weaker the AE signal (Fig. 4) (Deng et al. 2021; Li et al. 2021a, b; Miao et al. 2021).

4 Conclusions and prospect

Research on the water weakening of rock masses mainly focuses on the effects of water content, water immersion time, and cyclic water immersion. The strength–weakening degree is characterized by uniaxial and triaxial strength, shear strength, tensile strength, point load, penetration, etc. AE and IR methods are typically used to study the fracture and energy characteristics during loading under WRI. The strength of the rock mass decreases to varying degrees with water content, immersion time, and WD cycles and is related to the type of rock mass and mineral composition. Generally, the strength decreases exponentially with an increase in water content. The previous several WD cycles have a significant impact on the strength of the rock mass and have little effect on the progression of WD cycles. The degree of rock weakening gradually decreases with an increase in the immersion time. The corresponding AE count, intensity, and IR intensity also weaken accordingly. The WRI enhances the plasticity of rocks and reduces their brittleness.

Various microscopic methods have been used to study pore characterization and the weakening mechanism of WRI. SEM can qualitatively observe the fracture structure and mineral composition of the rock mass, but it is impossible to directly compare the porosity before and after water immersion owing to gold spraying during observation. NMR can quantitatively determine the porosity and pore size distribution and is a non-destructive test technique, making it possible to compare the pore size changes before and after immersion. CT scanning combined with corresponding reconstruction algorithms can quantitatively compare the changes in pore structure and mineral composition before and after immersion. However, the threshold division in CT image reconstruction is significant and directly affects the accuracy of the analysis. Thus, various micro-methods can be used to study the evolution of pore structure changes under WRI.

In the WRI weakening mechanism, the clay minerals in the rock mass dissolve in water, which expands the pore structures, increases the connected pores, further expands the primary fractures, and consequently increases the porosity and permeability. At the same time, the presence of water weakens the cementation strength near the primary fractures, making it easier to expand the splitting fracture along the joint surfaces. All these weakening processes lead to a decrease in rock strength and AE intensity.

Currently, studies on both the physical and mechanical properties and the weakening mechanism of WRI are relatively mature. Targeted experiments can only be carried out for special rock masses (different mineral compositions) or water environments (different water chemical compositions) in on-site engineering (water influence conditions). On this basis, the corresponding mechanical test modes (tension, compression, shear, or other tests), water influencing factors (moisture content, wetting–drying cycles, immersion time, etc.) and macro (AE, AIRT, etc.) and micro (SEM, NMR, CT, etc.) characterization methods can be considered. Thus, more attention should be paid to how laboratory-scale tests can be applied in engineering scale practice. Therefore, some qualitative conclusions must be transformed into quantitative models, which can then be applied to field engineering problems through numerical simulations. In addition, when investigating the effect of the immersion time, most laboratory tests are applied for less than half a year; however, long-term water immersion (even hundreds of years) problems generally occur. The weakening mechanism of WRI in rocks can also be explained using the changes in water immersion chemical ions and components.

Data availability statement

Some or all the data, models, or codes that support the findings of this study are available from the corresponding author upon reasonable request.

References

Ai T, Wu S, Zhang R, Gao M, Zhou J, Xie J, Zhang Z (2021) Changes in the structure and mechanical properties of a typical coal induced by water immersion. Int J Rock Mech Min Sci 138:104597

An W, Wang L, Chen H (2020) Mechanical properties of weathered feldspar sandstone after experiencing dry–wet cycles. Adv Mater Sci Eng. https://doi.org/10.1155/2020/6268945

Azhar MU, Zhou H, Yang F, Younis A, Lu X, Fang H, Geng Y (2020) Water-induced softening behavior of clay-rich sandstone in Lanzhou Water Supply Project, China. J Rock Mech Geotech Eng 12(3):557–570

Bai H, Ma D, Chen Z (2013) Mechanical behavior of groundwater seepage in karst collapse pillars. Eng Geol 164:101–106

Bai Q, Tu S, Zhang C, Zhu D (2016) Discrete element modeling of progressive failure in a wide coal roadway from water-rich roofs. Int J Coal Geol 167:215–229

Baud P, Zhu W, Wong T (2000) Failure mode and weakening effect of water on sandstone. J Geophys Res Solid Earth 105(B7):16371–16389

Cai X, Zhou Z, Tan L, Zang H, Song Z (2020a) Fracture behavior and damage mechanisms of sandstone subjected to wetting–drying cycles. Eng Fract Mech 234:107109

Cai X, Zhou Z, Zang H, Song Z (2020b) Water saturation effects on dynamic behavior and microstructure damage of sandstone: phenomena and mechanisms. Eng Geol 276:105760

Chen G, Li T, Wang W, Zhu Z, Chen Z, Tang O (2019a) Weakening effects of the presence of water on the brittleness of hard sandstone. Bull Eng Geol Environ 78(3):1471–1483

Chen S, Jiang T, Wang H, Feng F, Yin D, Li X (2019b) Influence of cyclic wetting–drying on the mechanical strength characteristics of coal samples: a laboratory-scale study. Energy Sci Eng 7(6):3020–3037

Chen X, He P, Qin Z (2019c) Strength Weakening and energy mechanism of rocks subjected to wet–dry cycles. Geotech Geol Eng 37(5):3915–3923

Chen P, Tang S, Liang X, Zhang Y, Tang C (2021) The influence of immersed water level on the short-and long-term mechanical behavior of sandstone. Int J Rock Mech Min Sci 138:104631

Dehestani A, Hosseini M, Beydokhti AT (2020) Effect of wetting–drying cycles on mode I and mode II fracture toughness of sandstone in natural (pH= 7) and acidic (pH= 3) environments. Theor Appl Fract Mech 107:102512

Deng MD, Fang Z, Liu X (1997) Research on the action of water in the infrared radiation of the rocks. Earthq Res China 13(3):288–296

Deng H, Qi Y, Li J, Jiang Q, Eleyas A, Li X (2021) Degradation mechanism of intermittent jointed sandstone under water–rock interaction. Chin J Geotech Eng 43(4):634–643

Du B, Bai H, Wu G (2019) Dynamic compression properties and deterioration of red-sandstone subject to cyclic wet–dry treatment. Adv Civ Eng 2019:1–10

Erguler ZA, Ulusay R (2009) Water-induced variations in mechanical properties of clay-bearing rocks. Int J Rock Mech Min Sci 46(2):355–370

Feucht LJ, Logan JM (1990) Effects of chemically active solutions on shearing behavior of a sandstone. Tectonophysics 175(1–3):159–176

Fu Y, Wang Z, Liu X, Yuan W, Miao L, Liu J, Dun Z (2017) Meso damage evolution characteristics and macro degradation of sandstone under wetting–drying cycles. Chin J Geotech Eng 12(4):1653–1661

Fujii Y, Saito S, Oshima T, Kodama JI, Fukuda D, Sakata S, Dassanayake AB (2020) Complete slaking collapse of dike sandstones by fresh water and prevention of the collapse by salt water. Int J Rock Mech Min Sci 131:104378

Gong C, Wang W, Shao J, Wang R, Feng X (2021) Effect of water chemical corrosion on mechanical properties and failure modes of pre-fissured sandstone under uniaxial compression. Acta Geotech 16(4):1083–1099

Gratchev I, Pathiranagei SV, Kim DH (2019) Strength properties of fresh and weathered rocks subjected to wetting–drying cycles. Geomech Geophys Geo-Energy Geo-Resour 5(3):211–221

Guha Roy D, Singh TN, Kodikara J, Das R (2017) Effect of water saturation on the fracture and mechanical properties of sedimentary rocks. Rock Mech Rock Eng 50(10):2585–2600

Guo J, Feng GR, Qi T, Wang P, Yang J, Li Z, Wang Z (2018) Dynamic mechanical behavior of dry and water saturated igneous rock with acoustic emission monitoring. Shock Vib 2018:1–15

Guo P, Gu J, Su Y, Wang J, Ding Z (2021) Effect of cyclic wetting–drying on tensile mechanical behavior and microstructure of clay-bearing sandstone. Int J Coal Sci Technol 8(5):956–968

Haberfield CM, Johnston IW (1990) Determination of the fracture toughness of a saturated soft rock. Can Geotech J 27(3):276–284

Hashiba K, Fukui K (2015) Effect of water on the deformation and failure of rock in uniaxial tension. Rock Mech Rock Eng 48(5):1751–1761

He L, Yu J, Hu Q, Cai Q, Qu M, He T (2020) Study on crack propagation and shear behavior of weak muddy intercalations submitted to wetting–drying cycles. Bull Eng Geol Environ 79(9):4873–4889

Hua W, Dong S, Li Y, Xu J, Wang Q (2015) The influence of cyclic wetting and drying on the fracture toughness of sandstone. Int J Rock Mech Min Sci 100(78):331–335

Hua W, Dong S, Li Y, Wang Q (2016) Effect of cyclic wetting and drying on the pure mode ii fracture toughness of sandstone. Eng Fract Mech 153:143–150

Hua W, Dong S, Peng F, Li K, Wang Q (2017) Experimental investigation on the effect of wetting-drying cycles on mixed mode fracture toughness of sandstone. Int J Rock Mech Min Sci 93:242–249

Huang S, Xia K, Yan F, Feng X (2010) An experimental study of the rate dependence of tensile strength softening of Longyou sandstone. Rock Mech Rock Eng 43(6):677–683

Huang Z, Jiang Z, Zhu S, Wu X, Yang L, Guan Y (2016) Influence of structure and water pressure on the hydraulic conductivity of the rock mass around underground excavations. Eng Geol 202:74–84

Huang S, Wang J, Qiu Z, Kang K (2018) Effects of cyclic wetting–drying conditions on elastic modulus and compressive strength of sandstone and mudstone. Processes 6(12):234

Huang X, Pang J, Liu G, Chen Y (2020a) Experimental study on physicomechanical properties of deep sandstone by coupling of dry–wet cycles and acidic environment. Adv Civ Eng 2020:1–17

Huang Z, Zuo Q, Wu L, Chen F, Hu S, Zhu S (2020b) Nonlinear softening mechanism of argillaceous slate under water–rock interaction. Rock Soil Mech 41(9):2931–2942

Huang X, Pang J, Zou J (2022) Study on the effect of dry–wet cycles on dynamic mechanical properties of sandstone under sulfuric acid solution. Rock Mech Rock Eng 55(3):1253–1269

Jiang X, Li C, Zhou JQ, Zhang Z, Yao W, Chen W, Liu HB (2022) Salt-induced structure damage and permeability enhancement of Three Gorges Reservoir sandstone under wetting–drying cycles. Int J Rock Mech Min Sci 153:105100

Kataoka M, Obara Y, Kuruppu M (2015) Estimation of fracture toughness of anisotropic rocks by semi-circular bend (SCB) tests under water vapor pressure. Rock Mech Rock Eng 48(4):1353–1367

Khanlari G, Abdilor Y (2015) Influence of wet–dry, freeze–thaw, and heat–cool cycles on the physical and mechanical properties of Upper Red sandstones in central Iran. Bull Eng Geol Environ 74(4):1287–1300

Kong X, Wang E, He X, Li Z, Li D, Liu Q (2017) Multifractal characteristics and acoustic emission of coal with joints under uniaxial loading. Fractals Complex Geom Patterns Scaling Nat Soc 25(05):1750045

Kong X, Wang E, Li S, Lin H, Xiao P, Zhang K (2019) Fractals and chaos characteristics of acoustic emission energy about gas-bearing coal during loaded failure. Fractals Complex Geom Patterns Scaling Nat Soc 27(05):1950072

Li H, Shen R, Li D, Jia H, Li T, Chen T, Hou Z (2019a) Acoustic emission multi-parameter analysis of dry and saturated sandstone with cracks under uniaxial compression. Energies 12(10):1959

Li S, Gao C, Zhou Z, Li L, Wang M, Yuan Y, Wang J (2019b) Analysis on the precursor information of water inrush in karst tunnels: a true triaxial model test study. Rock Mech Rock Eng 52(2):373–384

Li H, Shen R, Wang E, Li D, Li T, Chen T, Hou Z (2020a) Effect of water on the time-frequency characteristics of electromagnetic radiation during sandstone deformation and fracturing. Eng Geol 265:105451

Li Z, Xiong Z, Chen H, Lu H, Huang M, Ma C, Liu Y (2020b) Analysis of stress–strain relationship of brittle rock containing microcracks under water pressure. Bull Eng Geol Environ 79(4):1909–1918

Li E, Feng J, Zhang L, Zhang H, Zhu T (2021a) Brazilian tests on layered carbonaceous slate under water–rock interaction and weathering. Chin J Geotech Eng 43(2):329–337

Li H, Qiao Y, Shen R, He M, Cheng T, Xiao Y, Tang J (2021b) Effect of water on mechanical behavior and acoustic emission response of sandstone during loading process: phenomenon and mechanism. Eng Geol 294:106386

Li X, Peng K, Peng J, Hou D (2021c) Experimental investigation of cyclic wetting–drying effect on mechanical behavior of a medium-grained sandstone. Eng Geol 293:106335

Liang H, Fu Y (2020) Fracture properties of sandstone degradation under the action of drying–wetting cycles in acid and alkaline environments. Arab J Geosci 13(2):1–8

Lin Q, Cao P, Cao R, Fan X (2019) Acoustic emission characteristics during rock fragmentation processes induced by disc cutter under different water content conditions. Appl Sci 9(1):194

Liu W, Zhang Z (2020) Experimental characterization and quantitative evaluation of slaking for strongly weathered mudstone under cyclic wetting–drying condition. Arab J Geosci 13(2):1–8

Liu S, Wu L, Zhang Y, Chen Q (2010) Change feature of infrared radiation from loaded damp rock. J Northeast Univ 31(2):1034–1038

Liu X, Wang Z, Fu Y, Yuan W, Miao L (2016) Macro/microtesting and damage and degradation of sandstones under dry–wet cycles. Adv Mater Sci Eng 2016:1–16

Liu X, Jin M, Li D, Zhang L (2018) Strength deterioration of a Shaly sandstone under dry–wet cycles: a case study from the Three Gorges Reservoir in China. Bull Eng Geol Environ 77(4):1607–1621

Liu X, Wu L, Zhang Y, Liang Z, Yao X, Liang P (2019) Frequency properties of acoustic emissions from the dry and saturated rock. Environ Earth Sci 78(3):1–17

Liu C, Cheng Y, Jiao Y, Zhang G, Zhang W, Ou G, Tan F (2021) Experimental study on the effect of water on mechanical properties of swelling mudstone. Eng Geol 295:106448

Liu ZY, Wang G, Li JZ, Li HZ, Zhao HF, Shi HW, Lan JL (2022) Water-immersion softening mechanism of coal rock mass based on split Hopkinson pressure bar experiment. Int J Coal Sci Technol 9(1):61

Lu G, Crandall D, Bunger AP (2021) Observations of breakage for transversely isotropic shale using acoustic emission and X-ray computed tomography: effect of bedding orientation, pre-existing weaknesses, and pore water. Int J Rock Mech Min Sci 139:104650

Luo Y (2020) Influence of water on mechanical behavior of surrounding rock in hard-rock tunnels: an experimental simulation. Eng Geol 277:105816

Luo J, Tang H, Sui Z (2021) Hydrochemistry of coal samples in water immersion process. Sci Technol Eng 21(29):12431–12437

Lyu Q, Wang K, Hu C, Dick JM, Shi J, Tan J (2022) Experimental study on the mechanical properties of shale after long-term of immersion in fracturing fluids with different pH. Rock Mech Rock Eng 55:5047–5061

Ma Q, Yu P, Yuan P (2018) Experimental study on the influence of dry wet cycle on creep characteristics of deep siltstone. J Rock Mech Eng 37(3):593–600

Ma D, Duan H, Zhang J, Feng X, Huang Y (2021) Experimental investigation of creep-erosion coupling mechanical properties of water inrush hazards in fault fracture rock masses. Chin J Rock Mech Eng 40(9):1751–1763

Ma D, Duan HY, Zhang JX, Bai HB (2022) A state-of-the-art review on rock seepage mechanism of water inrush disaster in coal mines. Int J Coal Sci Technol 9(1):50. https://doi.org/10.1007/s40789-022-00525-w

Miao C, Yang L, Xu Z, Yang K, Sun X, Jiang M, Zhao W (2021) Experimental study on strength softening behaviors and micro-mechanisms of sandstone based on nuclear magnetic resonance. Chin J Rock Mech Eng 40(11):2189–2198

Momeni A, Hashemi SS, Khanlari GR, Heidari M (2017) The effect of weathering on durability and deformability properties of granitoid rocks. Bull Eng Geol Environ 76(3):1037–1049

Noël C, Baud P, Violay M (2021) Effect of water on sandstone’s fracture toughness and frictional parameters: brittle strength constraints. Int J Rock Mech Min Sci 147:104916

Özbek A (2014) Investigation of the effects of wetting–drying and freezing–thawing cycles on some physical and mechanical properties of selected ignimbrites. Bull Eng Geol Environ 73(2):595–609

Qin Z, Chen X, Fu H (2018) Damage features of altered rock subjected to drying–wetting cycles. Adv Civ Eng 2018:1–10

Rabat Á, Cano M, Tomás R, Tamayo ÁE, Alejano LR (2020) Evaluation of strength and deformability of soft sedimentary rocks in dry and saturated conditions through needle penetration and point load tests: a comparative study. Rock Mech Rock Eng 53(6):2707–2723

Ranjith PG, Jasinge D, Song J, Choi SK (2008) A study of the effect of displacement rate and moisture content on the mechanical properties of concrete: use of acoustic emission. Mech Mater 40(6):453–469

Shen R, Li H, Wang E, Chen T, Li T, Tian H, Hou Z (2020) Infrared radiation characteristics and fracture precursor information extraction of loaded sandstone samples with varying moisture contents. Int J Rock Mech Min Sci 130:104344

Song C, Ji H, Liu Z, Zhang Y, Wang H, Tan J (2019) Experimental study on acoustic emission characteristics of weakly cemented rock under dry wet cycle. J Min Saf Eng 36(04):812–819

Song H, Zhao Y, Jiang Y, Du W (2020) Experimental investigation on the tensile strength of coal: consideration of the specimen size and water content. Energies 13(24):6585

Sun Q, Zhang Y (2019) Combined effects of salt, cyclic wetting and drying cycles on the physical and mechanical properties of sandstone. Eng Geol 248:70–79

Sun X, Xu H, Zheng L, He M, Gong W (2016) An experimental investigation on acoustic emission characteristics of sandstone rockburst with different moisture contents. Sci China Technol Sci 59(10):1549–1558

Sun H, Ma L, Fu Y, Han J, Liu S, Chen M, Tian F (2021a) Infrared radiation test on the influence of water content on sandstone damage evolution. Infrared Phys Technol 118:103876

Sun X, Miao C, Jiang M, Zhang Y, Yang L, Guo B (2021b) Experimental and theoretical study on creep of sandstone with different moisture content based on modified Nishihara model. Chin J Rock Mech Eng 40(12):2411–2420

Talesnick M, Shehadeh S (2007) The effect of water content on the mechanical response of a high-porosity chalk. Int J Rock Mech Min Sci 44(4):584–600

Tang S (2018) The effects of water on the strength of black sandstone in a brittle regime. Eng Geol 239:167–178

Tang SB, Yu CY, Heap MJ, Chen PZ, Ren YG (2018) The influence of water saturation on the short-and long-term mechanical behavior of red sandstone. Rock Mech Rock Eng 51(9):2669–2687

Tang C, Yao Q, Xu Q, Shan C, Xu J, Han H, Guo H (2021) Mechanical failure modes and fractal characteristics of coal samples under repeated drying-saturation conditions. Nat Resour Res 30(6):4439–4456

Topal T, Sözmen B (2003) Deterioration mechanisms of tuffs in Midas monument. Eng Geol 68(3–4):201–223

Ukpai SN (2021) Stability analyses of dams using multidisciplinary geoscience approach for water reservoir safety: case of Mpu Damsite, Southeastern Nigeria. Bull Eng Geol Environ 80(3):2149–2170

Verstrynge E, Adriaens R, Elsen J, Van Balen K (2014) Multi-scale analysis on the influence of moisture on the mechanical behavior of ferruginous sandstone. Constr Build Mater 54:78–90

Wang Y, Huang W, Li Z, Chang L, Li D, Chen R, Lv B (2021) Small furnace for the small angle X-ray scattering (SAXS) and wide angle X-ray scattering (WAXS) characterization of the high temperature carbonization of coal. Instrum Sci Technol 49(4):445–456

Wu B, Liu K, Guo D (2020a) Study on the change law of mechanical properties of gritstone under the influence of mine water. J Min Sci Technol 5(6):632–637

Wu B, Wang W, Guo D (2020b) Strength damage and AE characteristics of fractured sandstone under the influence of water intrusion times. J Min Saf Eng 37(5):1054

Xiao W, Zhang D, Wang X (2020) Experimental study on progressive failure process and permeability characteristics of red sandstone under seepage pressure. Eng Geol 265:105406

Xie K, Jiang D, Sun Z, Chen J, Zhang W, Jiang X (2018) NMR, MRI and AE statistical study of damage due to a low number of wetting–drying cycles in sandstone from the three gorges reservoir area. Rock Mech Rock Eng 51(11):3625–3634

Yang X, Wang J, Hou D, Zhu C, He M (2018) Effect of dry-wet cycling on the mechanical properties of rocks: a laboratory-scale experimental study. Processes 6(10):199

Yao Q, Chen T, Ju M, Liang S, Liu Y, Li X (2016) Effects of water intrusion on mechanical properties of and crack propagation in coal. Rock Mech Rock Eng 49(12):4699–4709

Yao Q, Chen T, Tang C, Sedighi M, Wang S, Huang Q (2019a) Influence of moisture on crack propagation in coal and its failure modes. Eng Geol 258:105156

Yao Q, Hao Q, Chen X, Zhou B, Fang J (2019b) Design on the width of coal pillar dam in coal mine groundwater reservoir. J China Coal Soc 44(3):891–899

Yao Q, Tang C, Xia Z, Liu X, Zhu L, Chong Z, Hui X (2020a) Mechanisms of failure in coal samples from underground water reservoir. Eng Geol 267:105494

Yao Q, Wang W, Zhu L, Xia Z, Tang C, Wang X (2020b) Effects of moisture conditions on mechanical properties and AE and IR characteristics in coal–rock combinations. Arab J Geosci 13(14):1–15

Yao W, Li C, Zhan H, Zhou JQ, Criss RE, Xiong S, Jiang X (2020c) Multiscale study of physical and mechanical properties of sandstone in three Gorges reservoir region subjected to cyclic wetting–drying of yangtze river water. Rock Mech Rock Eng 53(5):2215–2231

Yu C, Tang S, Duan D, Zhang Y, Liang Z, Ma K, Ma T (2019) The effect of water on the creep behavior of red sandstone. Eng Geol 253:64–74

Zhang Z, Jiang Q, Zhou C, Liu X (2014) Strength and failure characteristics of Jurassic Red-Bed sandstone under cyclic wetting–drying conditions. Geophys J Int 198(2):1034–1044

Zhang N, Wang S, Yan C, Gao J, Guo R, Wang H (2019) Pore structure evolution of hydration damage of mudstone based on NMR technology. J China Coal Soc 44(S1):110–117

Zhang W, Zhang D, Zhao J (2021) Experimental investigation of water sensitivity effects on microscale mechanical behavior of shale. Int J Rock Mech Min Sci 145:104837

Zhao Y, Liu S, Elsworth D, Jiang Y, Zhu J (2014) Pore structure characterization of coal by synchrotron small-angle X-ray scattering and transmission electron microscopy. Energy Fuels 28(6):3704–3711

Zhao Y, Xue S, Han S, Chen Z, Liu S, Elsworth D, Chen D (2017a) Effects of microstructure on water imbibition in sandstones using X-ray computed tomography and neutron radiography. J Geophys Res Solid Earth 122(7):4963–4981

Zhao Z, Yang J, Zhang D, Peng H (2017b) Effects of wetting and cyclic wetting–drying on tensile strength of sandstone with a low clay mineral content. Rock Mech Rock Eng 50(2):485–491

Zhao Z, Yang J, Zhou D, Chen Y (2017c) Experimental investigation on the wetting-induced weakening of sandstone joints. Eng Geol 225:61–67

Zhao Y, Ren S, Jiang D, Liu R, Wu J, Jiang X (2018a) Influence of wetting–drying cycles on the pore structure and mechanical properties of mudstone from Simian Mountain. Constr Build Mater 191:923–931

Zhao Y, Xue S, Han S, He L, Chen Z (2018b) Characterization of unsaturated diffusivity of tight sandstones using neutron radiography. Int J Heat Mass Transf 124:693–705

Zhao Z, Guo T, Ning Z, Dou Z, Dai F, Yang Q (2018c) Numerical modeling of stability of fractured reservoir bank slopes subjected to water–rock interactions. Rock Mech Rock Eng 51(8):2517–2531

Zhao Y, Peng L, Liu S, Cao B, Sun Y, Hou B (2019a) Pore structure characterization of shales using synchrotron SAXS and NMR cryoporometry. Mar Pet Geol 102:116–125

Zhao Y, Wu Y, Han S, Xue S, Fan G, Chen Z, El Abd A (2019b) Water sorptivity of unsaturated fractured sandstone: fractal modeling and neutron radiography experiment. Adv Water Resour 130:172–183

Zhao F, Sun Q, Zhang W (2020) Combined effects of salts and wetting–drying cycles on granite weathering. Bull Eng Geol Environ 79(7):3707–3720

Zhao B, Li Y, Huang W, Yang J, Sun J, Li W, Zhang L (2021) Mechanical characteristics of red sandstone under cyclic wetting and drying. Environ Earth Sci 80(22):1–12

Zhong C, Zhang Z, Ranjith PG, Lu Y, Choi X (2019) The role of pore water plays in coal under uniaxial cyclic loading. Eng Geol 257:105125

Zhou Z, Cai X, Chen L, Cao W, Zhao Y, Xiong C (2017) Influence of cyclic wetting and drying on physical and dynamic compressive properties of sandstone. Eng Geol 220:1–12

Zhou Z, Cai X, Ma D, Cao W, Chen L, Zhou J (2018a) Effects of water content on fracture and mechanical behavior of sandstone with a low clay mineral content. Eng Fract Mech 193:47–65

Zhou Z, Cai X, Ma D, Chen L, Wang S, Tan L (2018b) Dynamic tensile properties of sandstone subjected to wetting and drying cycles. Constr Build Mater 182:215–232

Zhou Z, Xiong C, Cai X, Zhao Y, Li X, Du K (2018c) Mechanical and infrared radiation properties of sandstone with different water contents under uniaxial compression. J Cent South Univ (sci Technol) 49(5):1189–1196

Zhu J, Deng J, Chen F, Huang Y, Yu Z (2020) Water saturation effects on mechanical and fracture behavior of marble. Int J Geomech 20(10):04020191

Zhu J, Deng J, Chen F, Ma Y, Yao Y (2021) Water-weakening effects on the strength of hard rocks at different loading rates: an experimental study. Rock Mech Rock Eng 54(8):4347–4353

Acknowledgements

Financial support for this work was provided by the National Natural Science Foundation of China (52104155), Natural Science Foundation of Beijing (8212032), and Fundamental Research Funds for the Central Universities (2023YQNY).

Author information

Authors and Affiliations

Contributions

CZ, QB, and PH drafted the manuscript. LW, XW, and FW participated in the drawing of figures in the paper. All authors approved the final manuscript for publication.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest regarding the publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhang, C., Bai, Q., Han, P. et al. Strength weakening and its micromechanism in water–rock interaction, a short review in laboratory tests. Int J Coal Sci Technol 10, 10 (2023). https://doi.org/10.1007/s40789-023-00569-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40789-023-00569-6