Abstract

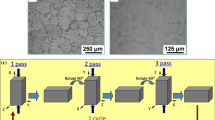

The Tip/ZX60 composites with different Tip contents were prepared by semi-solid stirring casting. After extrusion, the microstructure, work hardening and softening behavior of the Tip/ZX60 composites were analyzed compared with the ZX60 (Mg–6Zn–0.2Ca) alloy. The results showed that the addition of Tip could not only promote the nucleation of dynamic recrystallized (DRXed) grains, but also be propitious to the refinement of DRXed grains. With increasing Tip content, the size of DRXed grains decreased accompanied with increasing volume fraction of DRXed grains. As the Tip content increased to 15 vol.%, the average size and volume fraction of DRXed grains reached to ~ 0.32 μm and 93.2%, respectively. Besides, both the strength and elongation were improved by the addition of Tip. With increasing content of Tip, a substantial increase in the strength was achieved with little change in the elongation. However, the elongation decreased sharply when the Tip content further increased to 15 vol.%. The addition of Tip led to an increase in the work hardening rate, which gradually increased with increasing Tip content. However, the softening rate did not demonstrate the same tendency with increasing Tip content. Unlike the conventional ceramic particles, the Tip can be deformed in coordination with the matrix alloy, which imparted a higher softening rate to the matrix alloy. Even though the softening rate improved as the Tip content increased from 5 to 10 vol.%, it dropped deeply as the Tip content increased to 15 vol.% owing to the fracture of Tip during extrusion.

Similar content being viewed by others

References

Y. Fan, K. Deng, C. Wang, K. Nie, Q. Shi, Mater. Sci. Eng. A 833, 142336 (2022)

Y. Liu, K. Deng, X. Zhang, C. Wang, K. Nie, W. Gan, Q. Shi, Mater. Sci. Eng. A 856, 143997 (2022)

L. Zhang, K. Su, K. Deng, K. Nie, C. Wang, W. Liang, Mech. Mater. 150, 103599 (2020)

J.F. Nie, Scr. Mater. 48, 981 (2003)

X. Qian, Z. Dong, B. Jiang, B. Lei, H. Yang, C. He, L. Liu, C. Wang, M. Yuan, H. Yang, B. Yang, C. Zheng, F. Pan, Mater. Des. 224, 111322 (2022)

H. Somekawa, A. Singh, T. Mukai, Scr. Mater. 60, 411 (2009)

L. Geng, B.P. Zhang, A.B. Li, C.C. Dong, Mater. Lett. 63, 557 (2009)

J. Luo, H. Yan, N. Zheng, R.S. Chen, Acta Metall. Sin. -Engl. Lett. 29, 205 (2016)

C.J. Bettles, M.A. Gibson, K. Venkatesan, Scr. Mater. 51, 193 (2004)

T. Ying, M. Yu, Y. Chen, H. Zhang, J. Wang, X. Zeng, Acta Metall. Sin. -Engl. Lett. 35, 1973 (2022)

K.B. Nie, Z.H. Zhu, P. Munroe, K.K. Deng, J.G. Han, Acta Metall. Sin. -Engl. Lett. 33, 922 (2020)

L.G. Hou, R.Z. Wu, X.D. Wang, J.H. Zhang, M.L. Zhang, A.P. Dong, B.D. Sun, J. Alloys Compd. 695, 2820 (2017)

Y. Zhu, P. Jin, P. Zhao, J. Wang, L. Han, W. Fei, Mater. Sci. Eng. A 573, 148 (2013)

Y.H. Chen, X.Y. Gao, K.B. Nie, Y.N. Li, K.K. Deng, Mater. Sci. Eng. A 847, 143273 (2022)

Q. Shi, C. Wang, K. Deng, K. Nie, Y. Wu, W. Gan, W. Liang, J. Mater. Sci. Technol. 60, 8 (2021)

K. Nie, Y. Guo, K. Deng, X. Kang, J. Alloys Compd. 792, 267 (2019)

H. Li, K. Nie, Z. Liu, A. Yang, K. Deng, JOM 74, 4226 (2022)

A. Meher, M.M. Mahapatra, P. Samal, P.R. Vundavilli, J. Magnes, Alloys 8, 780 (2020)

W.Q. Liu, X.S. Hu, X.J. Wang, K. Wu, M.Y. Zheng, Mater. Des. 93, 194 (2016)

M. Shen, J. Jia, T. Ying, N. He, J. Alloys Compd. 791, 452 (2019)

S. Sankaranarayanan, S. Jayalakshmi, M. Gupta, Mater. Des. 37, 274 (2012)

S. Hasszn, O.O. Nasirudeen, N. Al-Aqeeli, N. Saheb, F. Patel, M.M.A. Baig, J. Alloys Compd. 646, 333 (2015)

Q. Nguyen, M. Gupta, Mater. Sci. Eng. A 527, 1411 (2010)

G. Garces, J. Medina, P. Perez, A. Stark, N. Schell, P. Adeva, J. Magnes. Alloys (2022).

J. Chen, C. Bao, W. Chen, L. Zhang, J. Liu, J. Mater. Sci. Technol. 33, 668 (2017)

R. Chen, G.D. Zhang, S. J. T. U. S. 200030 R. J Wu, H. Sekine, Acta Metall. Sin. -Engl. Lett. 10, 22 (1997).

J.H. Zhang, K.B. Nie, K.K. Deng, J.G. Han, J.Y. Yi, Compos. Commun. 27, 100847 (2021)

B. Tang, J.B. Li, J.L. Ye, H. Luo, Y.T. Wang, B. Guan, Y.F. Lu, X.H. Chen, K.H. Zheng, F.S. Pan, Acta Metall. Sin. -Engl. Lett. 35, 1935 (2022)

H. Yang, X. Chen, G. Huang, J. Song, J. She, J. Tan, K. Zheng, Y. Jin, B. Jiang, F. Pan, J. Magnes, Alloys 10, 2311 (2022)

J. Ye, X. Chen, H. Luo, J. Zhao, J. Li, J. Tan, H. Yang, B. Feng, K. Zheng, F. Pan, J. Magnes, Alloys 10, 2266 (2022)

M. Akbari, S. Rajabi, K. Shirvanimoghaddam, H. Baharvandi, J. Compos. Mater. 49, 3665 (2015)

X. Wang, X. Wang, X. Hu, K. Wu, J. Magnes, Alloys 8, 421 (2020)

J.W. Cha, S.H. Park, J. Magnes. Alloys (2022) In Press https://doi.org/10.1016/j.jma.2022.10.003.

Y. Guo, X. He, Y. Dai, H. Xiang, Q. Zang, F. Shi, X. Dong, Z. Zhang, Mater. Sci. Eng. A 860, 144329 (2022)

X. Wang, H. Liu, X. Tang, Y. Wang, M. Guo, L. Zhuang, Mater. Sci. Eng. A 844, 143154 (2022)

Y. Ren, N. ul H. Tariq, H. Liu, X. Cui, J. Wang, T. Xiong, Mater. Today Commun. 33, 104553 (2022).

K.K. Deng, K. Wu, Y.W. Wu, K.B. Nie, M.Y. Zheng, J. Alloys Compd. 504, 542 (2010)

Q. Shi, K. Deng, K. Nie, W. Zhang, M. Cao, W. Liang, J. Mater. Eng. Perform. 29, 1356 (2020)

X.J. Wang, X.S. Hu, K.B. Nie, K.K. Deng, K. Wu, M.Y. Zheng, Mater. Sci. Eng. A 545, 38 (2012)

J.D. Robson, D.T. Henry, B. Davis, Acta Mater. 57, 2739 (2009)

Q. Shi, C. Wang, K. Deng, K. Nie, M. Cao, W. Gan, W. Liang, Mater. Sci. Eng. A 772, 138827 (2020)

C. Zhao, X. Chen, J. Wang, T. Tu, Y. Dai, K.S. Shin, F. Pan, Adv. Eng. Mater. 21, 1801062 (2019)

D. Zhang, D. Zhang, F. Bu, X. Li, B. Li, T. Yan, K. Guan, Q. Yang, X. Liu, J. Meng, J. Alloys Compd. 728, 404 (2017)

H. Conrad, S. Feuerstein, L. Rice, Mater. Sci. Eng. 2, 157 (1967)

A.D. Rollett, U.F. Kocks, Solid State Phenom. 35–36, 1 (1993)

P. Lukáč, J. Balík, Key Eng. Mater. 97–98, 307 (1994)

C. Zhao, Z. Li, J. Shi, X. Chen, T. Tu, Z. Luo, R. Cheng, A. Atrens, F. Pan, J. Magnes, Alloys 7, 672 (2019)

X. Yang, Y. Wang, G. Wang, H. Zhai, L. Dai, T. Zhang, Acta Mater. 108, 252 (2016)

P. Lukáč, Z. Trojanová, Key Eng. Mater. 465, 101 (2011)

J.A. Valle, F. Carreño, O.A. Ruano, Acta Mater. 54, 4247 (2006)

J. Koike, R. Ohyama, T. Kobayashi, M. Suzuki, K. Maruyama, Mater. Trans. 44, 445 (2003)

M. Hou, K. Deng, C. Wang, K. Nie, Q. Shi, Mater. Sci. Eng. A 856, 143970 (2022)

T. Ungár, M. Zehetbauer, Scr. Mater. 35, 1467 (1996)

Acknowledgements

This work was supported financially by the National Natural Science Foundation of China (Nos. 52271109 and 52001223), the authors also thank the Support from the “the National Key Research and Development Program for Young Scientists” (No. 2021YFB3703300) and the Special Fund Project for Guiding Local Science and Technology Development by the Central Government (No. YDZJSX2021B019).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors state that there are no conflicts of interest to disclose.

Additional information

Available online at http://link.springer.com/journal/40195.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, JK., Wang, CJ., Fan, YD. et al. Effect of Tip Content on the Work Hardening and Softening Behavior of Mg–Zn–Ca Alloy. Acta Metall. Sin. (Engl. Lett.) 37, 551–560 (2024). https://doi.org/10.1007/s40195-023-01557-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-023-01557-0