Abstract

The valorization of C5 sugars (xylose) from hemicellulose of agro-industrial residues to xylitol, as one of the multi-products biorefinery approach, mandates the pretreatment of biomass which releases fermentable sugars along with the generation of biological inhibitors affecting xylitol fermentation. This study was therefore evaluated to understand the inhibitory kinetics of furfural, 5-hydroxymethylfurfural and acetic acid on xylitol fermentation. Xylitol fermentation was established using Pichia stipitis NCIM 3497 with xylose as a pure substrate optimized for xylitol yield and productivity of 0.48 g/g of xylose and 0.13 g/L/h, respectively. The functional relationship of yeast specific growth rate and limiting substrate (xylose) was expressed by Monod-type kinetics. The inhibition kinetics results indicated that the effect of inhibitors on xylitol fermentation was furfural > acetic acid > HMF. Furfural (500 mg/L) and acetic acid (1000 mg/L) reduced xylitol yield by 59% and 44%, respectively, with least reduction of 9.89% exhibited by HMF. The synergistic effect of 500 mg/L furfural, 500 mg/L HMF and 1000 mg/L acetic acid showed the highest reduction in xylitol yield of 67.6% as compared to the control. Kinetic studies predicted that the maximum concentration of furfural, HMF and acetic acid which inhibited P. stipitis growth was 884 mg/L, 3258 mg/L and 2922 mg/L, respectively, whereas xylitol production was completely inhibited at 1069 mg/L furfural, 3498 mg/L HMF and 3714 mg/L acetic acid. Furfural and acetic acid were found to be a competitive inhibitor, while uncompetitive inhibition was observed with HMF indicating negligible effect on xylitol fermentation.

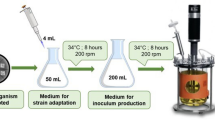

Graphical abstract

Similar content being viewed by others

References

Jeyavishnu K, Thulasidharan D, Shereen MF, Arumugam A (2021) Increased revenue with high value-added products from cashew apple (Anacardium occidentale L.)—addressing global challenges. Food Bioproc Tech 1-28. https://doi.org/10.1007/s11947-021-02623-0

Chen X, Jiang ZH, Chen S, Qin W (2010) Microbial and bioconversion production of D-xylitol and its detection and application. Int J Biol Sci 6:834 https://www.ijbs.com/v06p0834.htm

Franceschin G, Sudiro M, Ingram T, Smirnova I, Brunner G, Bertucco A (2011) Conversion of rye straw into fuel and xylitol: a technical and economical assessment based on experimental data. Chem Eng Res Des 89:631–640. https://doi.org/10.1016/j.cherd.2010.11.001

Mussatto SI, Roberto IC (2002) Xylitol: a sweetner with benefits for human health. Revista Brasileira de Ciências Farmacêuticas 38:401–413. https://doi.org/10.1590/S1516-93322002000400003

Ritter AV, Bader JD, Leo MC, Preisser JS, Shugars DA, Vollmer WM, Holland JC (2013) Tooth-surface-specific effects of xylitol: randomized trial results. J Dent Res 92:512–517. https://doi.org/10.1177/0022034513487211

Jain V, Ghosh S (2021) Biotransformation of lignocellulosic biomass to xylitol: an overview. Biomass Convers Biorefinery 1-19. https://doi.org/10.1007/s13399-021-01904-0

de Albuquerque TL, da Silva Jr IJ, de Macedo GR, Rocha MV (2014) Biotechnological production of xylitol from lignocellulosic wastes: a review. Process biochem 49:1779–1789. https://doi.org/10.1016/j.procbio.2014.07.010

Kim Y, Kreke T, Hendrickson R, Parenti J, Ladisch MR (2013) Fractionation of cellulase and fermentation inhibitors from steam pretreated mixed hardwood. Bioresour Technol 135:30–38. https://doi.org/10.1016/j.biortech.2012.10.130

Jönsson LJ, Alriksson B, Nilvebrant NO (2013) Bioconversion of lignocellulose: inhibitors and detoxification. Biotechnol Biofuels 6:1–10. https://doi.org/10.1186/1754-6834-6-16

El-Tayeb TS, Abdelhafez AA, Ali SH, Ramadan EM (2012) Effect of acid hydrolysis and fungal biotreatment on agro-industrial wastes for obtainment of free sugars for bioethanol production. Braz J Microbio. 43:1523–1535. https://doi.org/10.1590/S1517-83822012000400037

Cortez DV, Roberto IC, Barbosa MH, Milagres AM (2014) Evaluation of cellulosic and hemicellulosic hydrolysate fermentability from sugarcane bagasse hybrids with different compositions. Biomass Convers Biorefin 4:351–356. https://doi.org/10.1007/s13399-014-0119-5

Kumar R, Wyman CE (2008) The impact of dilute sulfuric acid on the selectivity of xylooligomer depolymerization to monomers. Carbohydr Res 343:290–300. https://doi.org/10.1016/j.carres.2007.10.022

Panagiotopoulos IA, Bakker RR, De Vrije T, Koukios EG (2011) Effect of pretreatment severity on the conversion of barley straw to fermentable substrates and the release of inhibitory compounds. Bioresour Technol 102:11204–11211. https://doi.org/10.1016/j.biortech.2011.09.090

Sonkar RM, Gade PS, Bokade V, Mudliar SN, Bhatt P (2021) Ozone assisted autohydrolysis of wheat bran enhances xylooligosaccharide production with low generation of inhibitor compounds: a comparative study. Bioresour Technol 338:125559. https://doi.org/10.1016/j.biortech.2021.125559

Fu N, Peiris P (2008) Co-fermentation of a mixture of glucose and xylose to ethanol by Zymomonas mobilis and Pachysolen tannophilus. World J Microbiol Biotechnol 24:1091–1097. https://doi.org/10.1007/s11274-007-9613-2

Agbogbo FK, Wenger KS (2007) Production of ethanol from corn stover hemicellulose hydrolyzate using Pichia stipitis. J Ind Microbiol Biotechnol 34:723–727. https://doi.org/10.1007/s10295-007-0247-z

Modig T, Lidén G, Taherzadeh MJ (2002) Inhibition effects of furfural on alcohol dehydrogenase, aldehyde dehydrogenase and pyruvate dehydrogenase. Biochem J 363:769–776. https://doi.org/10.1042/bj3630769

Liu ZL, Slininger PJ, Dien BS, Berhow MA, Kurtzman CP, Gorsich SW (2004) Adaptive response of yeasts to furfural and 5-hydroxymethylfurfural and new chemical evidence for HMF conversion to 2, 5-bis-hydroxymethylfuran. J Ind Microbiol Biotechnol 31:345–352. https://doi.org/10.1007/s10295-004-0148-3

Palmqvist E, Hahn-Hägerdal B (2000) Fermentation of lignocellulosic hydrolysates. II: inhibitors and mechanisms of inhibition. Bioresour Technol 74:25–33. https://doi.org/10.1016/S0960-8524(99)00161-3

Allen SA, Clark W, McCaffery JM, Cai Z, Lanctot A, Slininger PJ, Liu ZL, Gorsich SW (2010) Furfural induces reactive oxygen species accumulation and cellular damage in Saccharomyces cerevisiae. Biotechnol Biofuels 3:1–10. https://doi.org/10.1186/1754-6834-3-2

Bellido C, Bolado S, Coca M, Lucas S, González-Benito G, García-Cubero MT (2011) Effect of inhibitors formed during wheat straw pretreatment on ethanol fermentation by Pichia stipitis. Bioresour Technol 102:10868–10874. https://doi.org/10.1016/j.biortech.2011.08.128

Almarsdottir AR, Sigurbjornsdottir MA, Orlygsson J (2012) Effect of various factors on ethanol yields from lignocellulosic biomass by Thermoanaerobacterium AK17. Biotechnol Bioeng 109:686–694. https://doi.org/10.1002/bit.24346

Perna MD, Bastos RG, Ceccato-Antonini SR (2018) Single and combined effects of acetic acid, furfural, and sugars on the growth of the pentose-fermenting yeast Meyerozyma guilliermondii. 3 Biotech 8:119. https://doi.org/10.1007/s13205-018-1143-0

Chandel AK, Da Silva SS, Singh OV (2013) Detoxification of lignocellulose hydrolysates: biochemical and metabolic engineering toward white biotechnology. Bioenergy Res 6:388–401. https://doi.org/10.1007/s12155-012-9241-z

Kordala N, Lewandowska M, Bednarski W (2021) Effect of the method for the elimination of inhibitors present in Miscanthus giganteus hydrolysates on ethanol production effectiveness. Biomass Convers Biorefinery 1-9. https://doi.org/10.1007/s13399-020-01255-2

Liu ZL (2006) Genomic adaptation of ethanologenic yeast to biomass conversion inhibitors. Appl Microbiol Biotechnol 73:27–36. https://doi.org/10.1007/s00253-006-0567-3

Wannawilai S, Lee WC, Chisti Y, Sirisansaneeyakul S (2017) Furfural and glucose can enhance conversion of xylose to xylitol by Candida magnoliae TISTR 5663. J Biotechnol 241:147–157. https://doi.org/10.1016/j.jbiotec.2016.11.022

Antal MJ Jr, Leesomboon T, Mok WS, Richards GN (1991) Mechanism of formation of 2-furaldehyde from D-xylose. Carbohydr. Res 217:71–85. https://doi.org/10.1016/0008-6215(91)84118-X

Klinke HB, Ahring BK, Schmidt AS, Thomsen AB (2002) Characterization of degradation products from alkaline wet oxidation of wheat straw. Bioresour Technol 82:15–26. https://doi.org/10.1016/S0960-8524(01)00152-3

Dasgupta D, Sidana A, Ghosh P, Sharma T, Singh J, Prabhune A, Ghosh D (2021) Energy and life cycle impact assessment for xylitol production from corncob. J Clean Prod 278:123217. https://doi.org/10.1016/j.jclepro.2020.123217

Rodrigues RC, Kenealy WR, Jeffries TW (2011) Xylitol production from DEO hydrolysate of corn stover by Pichia stipitis YS-30. J Ind Microbiol Biotechnol 38:1649–1655. https://doi.org/10.1007/s10295-011-0953-4

Banerjee S, Sen R, Pandey RA, Chakrabarti T, Satpute D, Giri BS, Mudliar S (2009) Evaluation of wet air oxidation as a pretreatment strategy for bioethanol production from rice husk and process optimization. Biomass Bioenerg 33:1680–1686. https://doi.org/10.1016/j.biombioe.2009.09.001

Levenspiel O (1980) The Monod equation: a revisit and a generalization to product inhibition situations. Biotechnol Bioeng 22:1671–1687. https://doi.org/10.1002/bit.260220810

Luong JH (1985) Kinetics of ethanol inhibition in alcohol fermentation. Biotechnol Bioeng 27:280–285. https://doi.org/10.1002/bit.260270311

Cer RZ, Mudunuri U, Stephens R, Lebeda FJ (2009) IC50-to-Ki: a web-based tool for converting IC50 to Ki values for inhibitors of enzyme activity and ligand binding. Nucleic Acids Res. https://doi.org/10.1093/nar/gkp253

Nigam JN (2001) Ethanol production from wheat straw hemicellulose hydrolysate by Pichia stipitis. J Biotechnol 87:17–27. https://doi.org/10.1016/S0168-1656(00)00385-0

Cabral JC, Silva JP, Roberto IC (2005) Influence of pH on ethanol production by Pichia stipitis. Latin American Postgraduate Meeting

Farias D, de Andrade RR, Maugeri-Filho F (2014) Kinetic modeling of ethanol production by Scheffersomyces stipitis from xylose. Appl Biochem Biotechnol 172:361–379. https://doi.org/10.1007/s12010-013-0546-y

Horváth IS, Franzén CJ, Taherzadeh MJ, Niklasson C, Lidén G (2003) Effects of furfural on the respiratory metabolism of Saccharomyces cerevisiae in glucose-limited chemostats. Appl Environ Microbiol 69:4076. https://doi.org/10.1128/AEM.69.7.4076-4086.2003

Almeida JR, Modig T, Petersson A, Hähn-Hägerdal B, Lidén G, Gorwa-Grauslund MF (2007) Increased tolerance and conversion of inhibitors in lignocellulosic hydrolysates by Saccharomyces cerevisiae. J Chem Technol Biotechnol 82:340–349. https://doi.org/10.1002/jctb.1676

Vajzovic A, Bura R, Kohlmeier K, Doty SL (2012) Novel endophytic yeast Rhodotorula mucilaginosa strain PTD3 II: production of xylitol and ethanol in the presence of inhibitors. J Ind Microbiol Biotechnol 39:1453–1463. https://doi.org/10.1007/s10295-012-1154-5

Kashid M, Ghosalkar A (2017) Evaluation of fermentation kinetics of acid-treated corn cob hydrolysate for xylose fermentation in the presence of acetic acid by Pichia stipitis. 3 Biotech 7:240. https://doi.org/10.1007/s13205-017-0873-8

Bura R, Vajzovic A, Doty SL (2012) Novel endophytic yeast Rhodotorula mucilaginosa strain PTD3 I: production of xylitol and ethanol. J Ind Microbiol Biotechnol 39:1003–1011. https://doi.org/10.1007/s10295-012-1109-x

Noronha LD, Fonseca CR, Silva CC, Silva MB, Faria LF (2010) Use of different types of aluminum polychlorides for the purification of sugarcane bagasse hydrolyzate through the coagulation and flocculation technique, Chem. New 33 (8). https://doi.org/10.1590/S0100-40422010000800015

Felipe MG, Vieira DC, Vitolo M, Silva SS, Roberto IC, Manchilha IM (1995) Effect of acetic acid on xylose fermentation to xylitol by Candida guilliermondii. J Basic Microbiol 35:171–177. https://doi.org/10.1002/jobm.3620350309

Greetham D, Hart AJ, Tucker GA (2016) Presence of low concentrations of acetic acid improves yeast tolerance to hydroxymethylfurfural (HMF) and furfural. Biomass Bioenergy 85:53–60. https://doi.org/10.1016/j.biombioe.2015.11.026

Zaldivar J, Martinez A, Ingram LO (1999) Effect of selected aldehydes on the growth and fermentation of ethanologenic Escherichia coli. Biotechnol Bioeng 65:24–33. https://doi.org/10.1002/(SICI)1097-0290(19991005)65:1%3C24::AID-BIT4%3E3.0.CO;2-2

Zaldivar J, Martinez A, Ingram LO (2000) Effect of alcohol compounds found in hemicellulose hydrolysate on the growth and fermentation of ethanologenic Escherichia coli. Biotechnol Bioeng 68:524–530. https://doi.org/10.1002/(SICI)1097-0290(20000605)68:5%3C524::AID-BIT6%3E3.0.CO;2-T

Tochampa W, Sirisansaneeyakul S, Vanichsriratana W, Srinophakun P, Bakker HH, Chisti Y (2005) A model of xylitol production by the yeast Candida mogii. Bioproc Biosyst Eng 28:175–183. https://doi.org/10.1007/s00449-005-0025-0

Wannawilai S, Sirisansaneeyakul S, Chisti Y (2015) Benzoate-induced stress enhances xylitol yield in aerobic fed-batch culture of Candida mogii TISTR 5892. J Biotechnol 194:58–66. https://doi.org/10.1016/j.jbiotec.2014.11.037

Slininger PJ, Dien BS, Lomont JM, Bothast RJ, Ladisch MR, Okos MR (2014) Evaluation of a kinetic model for computer simulation of growth and fermentation by Scheffersomyces (Pichia) stipitis fed D-xylose. Biotechnol Bioeng 111:1532–1540. https://doi.org/10.1002/bit.25215

Georgieva TI, Skiadas IV, Ahring BK (2007) Effect of temperature on ethanol tolerance of a thermophilic anaerobic ethanol producer Thermoanaerobacter A10: modeling and simulation. Biotechnol Bioeng 98:1161–1170. https://doi.org/10.1002/bit.21536

Wahlbom CF, Hahn-Hägerdal B (2002) Furfural, 5-hydroxymethyl furfural, and acetoin act as external electron acceptors during anaerobic fermentation of xylose in recombinant Saccharomyces cerevisiae. Biotechnol Bioeng 78:172–178. https://doi.org/10.1002/bit.10188

Ask M, Bettiga M, Duraiswamy VR, Olsson L (2013) Pulsed addition of HMF and furfural to batch-grown xylose-utilizing Saccharomyces cerevisiae results in different physiological responses in glucose and xylose consumption phase. Biotechnol Biofuels 6:1–15. https://doi.org/10.1186/1754-6834-6-181

Thomas KC, Ingledew WM (1992) Production of 21%(v/v) ethanol by fermentation of very high gravity (VHG) wheat mashes. J Ind Microbiol 10:61–68. https://doi.org/10.1007/BF01583635

Acknowledgements

The authors thank the Director, CSIR-CFTRI, Mysore, for providing the infrastructure for carrying out the experiment. The first author gratefully acknowledges the Council and Scientific Industrial Research (CSIR), New Delhi, for providing the financial assistance in the form of Junior Research Fellowship to carry out the present investigation and University of Mysore for successful registration of Ph.D.

Funding

This work was supported by Department of Biotechnology (DBT), India, for financial support through (BT/PR12277/PBD/26/434/2014) project.

Author information

Authors and Affiliations

Contributions

Conceptualization: Bhavana B K, Sandeep N Mudliar, Sukumar Debnath. Methodology: Bhavana B K, Sandeep N Mudliar. Formal analysis and investigation: Bhavana B K. Writing—original draft preparation: Bhavana B K. Writing—review and editing: Bhavana B K, Sandeep N Mudliar, Vijay V Bokade. Funding acquisition: Sandeep N Mudliar, Vijay V Bokade. Supervision: Sandeep N Mudliar, Sukumar Debnath.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

B K, B., Mudliar, S.N., Bokade, V.V. et al. Effect of furfural, acetic acid and 5-hydroxymethylfurfural on yeast growth and xylitol fermentation using Pichia stipitis NCIM 3497. Biomass Conv. Bioref. 14, 4909–4923 (2024). https://doi.org/10.1007/s13399-022-02758-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02758-w