Abstract

Plastics are widely used for various applications. Once discarded, it is commonly known that they represent a high environmental threat due to their slow degradation; for this reason, there is an imminent need to replace these products with eco-friendlier ones. In the present work, four bacterial polyhydroxybutyrate (PHB) producers, two consortia, and two isolated strains were successfully recovered from the facilities of a paper-manufacturing industry. Spectroscopic studies of the biopolymers obtained from these bacteria corroborated their PHB production capabilities, ranging from 4.04 ± 0.16 to 23.82 ± 3.39 g/L. The characterization of the isolate that presented the highest production yield initially coded as E22 led to the identification of a Klebsiella pneumoniae strain, which, compared with other PHA bacterial producers reported to date, could be considered with high production potential. The strain E22 was grown in 5 different media prepared from fruit peel residues of banana, orange, papaya, watermelon, and melon, to determine its growth and PHA production capabilities in these low-cost media. The results obtained show different bacterial growth yields among the media tested, although PHB production yields and productivities were similar in all these low-cost media. Cellular accumulation of the biopolymer was higher in watermelon peel medium (8.4 × 10−10 g/CFU). These results reveal the potential of K. pneumoniae E22 for PHB production applications and establish encouraging alternatives to be broader explored regarding low-cost media that could enhance the scale-up of bacterial PHA production processes.

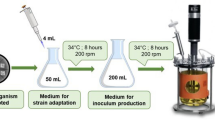

Graphical abstract

Similar content being viewed by others

References

Al-Salem SM, Lettieri P, Baeyens J (2010) The valorization of plastic solid waste (psw) by primary to quaternary routes: from re-use to energy and chemicals. Prog Energ Combust 36:103–129. https://doi.org/10.1016/j.pecs.2009.09.001.2010

Andrady AL, Neal MA (2009) Applications and societal benefits of plastics. Philos Trans R Soc Lond Ser B Biol Sci 364:1977–1984. https://doi.org/10.1098/rstb.2008.0304

Devasahayam S, Raman RKS, Chennakesavulu K, Bhattacharya S (2019) Plastics-villain or hero? Polymers and recycled polymers in mineral and metallurgical processing-a review. Materials 12:1–36. https://doi.org/10.3390/ma12040655

Sukan A, Roy I, Keshavarz T (2015) Dual production of biopolymers from bacteria. Carbohydr Polym 1:47–51. https://doi.org/10.1016/j.carbpol.2015.03.001

Šprajcar M, Horvat P, Krzan A (2012) Biopolymers and bioplastics–plastics aligned with nature. European Regional Development Fund. https://www.umsicht.fraunhofer.de/content/dam/umsicht/de/ dokumente/ueber-uns/nationale-infostelle-nachhaltige-kunststoffe/biopolymers-bioplastics-brochure-for-teachers.pdf. Accessed 14 February 2020

Serwanska-Leja K, Lewandowicz G (2010) Polymer biodegradation and biodegradable polymers-a review. Pol J Environ Stud 19:255–266. https://pdfs.semanticscholar.org/72a6/fb58bf5809b42af5861af6dd2541941e7858.pdf?_ga=2.69194769.1238613553.1588290677-1430679523.1583797552. Accessed 14 February 2020

Krueger CL, Radetski CM, Bendia AG, Oliveira IM, Castro-Silva MA, Rambo CR, Antonio RV, Lima AOS (2012) Bioconversion of cassava starch by-product into Bacillus and related bacteria polyhydroxyalkanoates. Electron J Biotechnol 15:1–13. https://doi.org/10.2225/vol15-issue3-fulltext-6

Sinha K, Rathore P (2015) Study of polyhydroxybutyrate producing Bacillus sp. isolated from soil. Res J Recent Sci 4:61–69. http://www.isca.in/rjrs/archive/v4/iIYSC-2015/12.ISCA-IYSC-2015-3BS-09.pdf. Accessed 18 February 2020

Mohapatra S, Maity S, Dash HR, Das S, Pattnaik S, Rath CC, Samantaray D (2017) Bacillus and biopolymer: prospects and challenges. Biochem Biophys Rep 12:206–213. https://doi.org/10.1016/j.bbrep.2017.10.001

Shah KR (2014) Optimization and production of polyhydroxybutarate (PHB) by Bacillus subtilis G1S1 from soil. Int J Curr Microbiol App Sci 3:377–387. https://www.ijcmas.com/vol-3-5/K.R.Shah.pdf. Accessed 9 March 2020

Apparao U, Krishnaswamy VG (2015) Production of polyhydroxyalkanoate (PHA) by a moderately halotolerant bacterium Klebsiella pneumoniae U1 isolated from rubber plantation area. Int J Environ Biorem Biodegrad 3:54–61. https://doi.org/10.12691/ijebb-3-2-3

Chen BY, Shiau TJ, Wei YH, Chen WM (2012) Feasibility study on polyhydroxybutyrate production of dye-decolorizing bacteria using dye and amine-bearing cultures. J Taiwan Inst Chem Eng 43:241–245. https://doi.org/10.1016/j.jtice.2011.09.001

Eiamsa-ard P (2017) Isolation and identification of polyhydroxyalkanoate (PHA) producing bacteria from food industrial wastewater by using fluorometric screening. Journal of KMUTNB 27:771–781. https://doi.org/10.14416/j.kmutnb.2017.11.004

Menaga M, Felix S, Gopalakannan A (2019) Screening of a biodegradable polymer, polyhydroxy butyrate (PHB) accumulating bacteria from the biofloc based gift tilapia ponds. Aquaculture 2019 - meeting abstract; World Aquaculture Society. https://www.was.org/meetings/ShowAbstract.aspx?Id= 136449. Accessed 9 March 2020

Narayankumar S, Krishnaswamy VG (2017) Characterization and optimization studies on poly[(R)-3-hydroxybutyrate] producing moderately halotolerant bacterial strains isolated from saline environment. J Biodivers Manage Forestry 6:3. https://doi.org/10.4172/2327-4417.1000181

Peña C, Castillo T, García A, Millán M, Segura D (2014) Biotechnological strategies to improve production of microbial poly-(3-hydroxybutyrate): a review of recent research work. Microb Biotechnol 7:278–293. https://doi.org/10.1111/1751-7915.12129.4

Pillai AB, Kumar AJ, Kumarapillai H (2018) Enhanced production of poly (3-hydroxybutyrate) in recombinant Escherichia coli and EDTA-microwave-assisted cell lysis for polymer recovery. AMB Express 8:1–15. https://doi.org/10.1186/s13568-018-0672-6

Sadaf N, Kamthane DC (2019) PHB production from bacteria isolated from oil contaminated soil. Bioscience Discovery 10:103-107. http://biosciencediscovery.com/Vol%2010%20No%202/Nausheen103-107.pdf. Accessed 9 March 2020

Tufail S, Munir S, Jamil N (2017) Variation analysis of bacterial polyhudroxyalkanoates production using saturated and unsaturated hydrocarbons. Braz J Microbiol 48:629–636. https://doi.org/10.1016/j.bjm.2017.02.008

Zhang H, Obias V, Gonyer K, Dennis D (1994) Production of polyhydroxyalkanoates in sucrose-utilizing recombinant Escherichia coli and Klebsiella strains. Appl Environ Microbiol 60:1198–1205. https://aem.asm.org/content/aem/60/4/1198.full.pdf. Accessed 19 February 2020

Kourmentza C, Plácido J, Venetsaneas N, Burniol-Figols A, Varrone C, Gavala HN, Reis MAM (2017) Recent advances and challenges towards sustainable polyhydroxyalkanoate (PHA) production. Bioengineering (Basel) 4:1–43. https://doi.org/10.3390/bioengineering4020055

Guerra-Blanco P, Cortes O, Poznyak T, Chairez I, García-Peña EI (2018) Polyhydroxyalkanoates (PHA) production by photoheterotrophic microbial consortia: effect of culture conditions over microbial population and biopolymer yield and composition. Eur Polym J 98:94–104. https://doi.org/10.1016/j.eurpolymj.2017.11.007

Nielsen C, Rahman A, Rehman AU, Walsh MK, Miller CD (2017) Food waste conversion to microbial polyhydroxyalkanoates. Microb Biotechnol 10:1338–1352. https://doi.org/10.1111/1751-7915.12776

Baird RB, Eaton AD, Rice EW (2001) Standard methods for the examination of water and wastewater. American Public Health Association. https://www.academia.edu/38769108/Standard_Methods_For_the_Examination_of_Water_and_Wastewater_23nd_edition. Accessed 15 May 2017

Bhuwal AK, Singh G, Aggarwal NK, Goyal V, Yadab A (2013) Isolation and screening of polyhydroxyalkanoates producing bacteria from pulp, paper, and cardboard industry wastes. Int J Biomater 2013:1–10. https://doi.org/10.1155/2013/752821

Rivas-Castillo AM, Valdez-Calderón A, Rojas-Avelizapa NG (2019) Culture medium to promote the production of biopolymers (in Spanish). Patent application no. 3895 submitted to the Ministry of Economy in 29 November 2019 for its presentation at the Mexican Institute of Industrial Property (IMPI)

Amutha R, Kavusik T, Sudha A (2017) Analysis of bioactive compounds in citrus fruit peels. International Journal of Scientific Research and Review 6:19–27. https://www.researchgate.net/publication/323551324_ANALYSIS_OF_BIOACTIVE_COMPOUNDS_IN_CITRUS_FRUIT_PEELS. Accessed 14 June 2019

Gusakov AV, Kondratyeva EG, Sinitsyn AP (2011) Comparison of two methods for assaying reducing sugars in the determination of carbohydrase activities. Int J Anal Chem 2011:283658–283654. https://doi.org/10.1155/2011/283658

Jones DB (1941) Factors for converting percentages of nitrogen in foods and feeds into percentages of protein. US Department of Agriculture - Circular No 183. https://www.ars.usda.gov/ARSUserFiles/80400525/Data/Classics/cir183.pdf. Accessed 14 June 2019

Mariotti F, Tomé D, Mirand PP (2008) Converting nitrogen into protein-beyond 6.25 and Jones Factors. Crit Rev Food Sci Nutr 48:177–184. https://doi.org/10.1080/10408390701279749

Hungund B, Shyama VS, Patwhardan P, Saleh AM (2013) Production of polyhydroxyalkanoate from Paenibacillus durus BV-1 isolated from oil mill soil. J Microb Biochem Technol 5:13–17. https://doi.org/10.4172/1948-5948.1000092

Sánchez-Moreno SA, Marín-Montoya MA, Mora-Martínez AL, Yepes-Pérez MS (2012) Identification of bacteria that produce polyhydroxyalcanoates (PHAs) in soils contaminated with residues of fique (in Spanish). Revista Colombiana de Biotecnología 16:89-100. https://revistas.unal.edu.co/ index.php/biotecnología/article/view/37286/39379. Accessed 26 May 2019

Thapa C, Shakya P, Shrestha R, Pal S, Manandhar P (2018) Isolation of polyhydroxybutyrate (PHB) producing bacteria, optimization of culture conditions for PHB production, extraction and characterization of PHB. Nepal Journal of Biotechnology 6:62–68. https://www.researchgate.net/publication/330403719_Isolation_of_Polyhydroxybutyrate_PHB_Producing_Bacteria_Optimization_of_Culture_Conditions_for_PHB_production_Extraction_and_Characterization_of_PHB. Accessed 5 August 2020

Kaur G, Roy I (2015) Strategies for large-scale production of polyhydroxyalkanoates. Chem Biochem Eng Q 29:157–172. https://doi.org/10.15255/CABEQ.2014.2255

Pincus DH (2005) Microbial identification using the bioMériueux VITEK® 2 system. In: Miller MJ (ed) Encyclopedia of rapid microbiological methods. PDA, Barcelona, pp. 1–32

Miller JH (1972) Experiments in molecular genetics. Cold Spring Harbor Laboratory Press, Cold Spring Harbor, New York

Cutting SM, Vander Horn PB (1990) Genetic analysis. In: Harwood CR, Cutting SM (eds) Molecular biological methods for Bacillus. John Wiley & Sons, Sussex, pp 27–74

Ratul S, Farrance CE, Verghese B, Hong S, Donofrio RS (2013) Klebsiella michiganensis sp. nov., a new bacterium isolated from a tooth brush holder. Curr Microbiol 66:72–78. https://doi.org/10.1007/s00284-012-0245-x

Shakib P, Kalani MT, Ramazanzadeh R, Ahmadi A, Rouhi S (2018) Molecular detection of virulence genes in Klebsiella pneumoniae clinical isolates from Kurdistan Province, Iran. Biomedical Research and Therapy 5:2581–2589. http://www.bmrat.org/index.php/BMRAT/article/view/467/919. Accessed 5 June 2018

Ben M, Mato T, Lopez A, Vila M, Kennes C, Veiga MC (2011) Bioplastic production using wood mill effluents as feedstock. Water Sci Technol 63:1196–1202. https://doi.org/10.2166/wst.2011.358

Al-Rowaihi IS, Paillier A, Rasul S, Karan R, Grötzinger SW, Takanabe K, Eppinger J (2018) Poly (3-hydroxybutyrate) production in an integrated electromicrobial setup: investigation under stress inducing conditions. PLoS One 13:1–13. https://doi.org/10.1371/journal.pone.0196079

Toczyłowska-Mamińska R (2017) Limits and perspectives of pulp and paper industry wastewater treatment–a review. Renew Sust Energ Rev 78:764–772. https://doi.org/10.1016/j.rser.2017.05.021

Ghribi M, Meddeb-Mouelhi F, Beauregard M (2016) Microbial diversity in various types of paper mill sludge: identification of enzyme activities with potential industrial applications. Springerplus 5:1–14. https://doi.org/10.1186/s40064-016-3147-8

Karigar CS, Rao SS (2011) Role of microbial enzymes in the bioremediation of pollutants: a review. Enzyme Res 2011:1–11. https://doi.org/10.4061/2011/805187

Singh P, Parmar N (2011) Isolation and characterization of two novel polyhydroxybutyrate (PHB)-producing bacteria. Afr J Biotechnol 10:4907–4919. Accessed 7 November 2017

Flores-Vásquez ADP, Idrogo E-III, Carreño-Farfán CR (2018) Yield of polyhydroxyalcanoates (PHA) in halophilic microorganisms isolated from salt flats (in Spanish). Revista Peruana de Biología 25:153–160. https://doi.org/10.15381/rpb.v25i2.14249

Ashby RD, Solaiman DKY, Strahan GD (2011) Efficient utilization of crude glycerol as fermentation substrate in the synthesis of poly (3-hydroxybutyrate) biopolymers. J Am Oil Chem Soc 88:949–959. https://doi.org/10.1007/s11746-011-1755-6

Silva AF, Taciro MK, Michelin-Ramos ME, Carter JM, Pradella JGC, Gomez JGC (2004) Poly-3-hydroxybutyrate (P3HB) production by bacteria from xylose, glucose and sugarcane bagasse hydrolysate. J Ind Microbiol Biotechnol 31:245–254. https://doi.org/10.1007/s10295-004-0136-7

Zhu C, Nomura CT, Perrotta JA, Stipanovic AJ, Nakas JP (2010) Production and characterization of poly-3-hydroxybutyrate from biodiesel-glycerol by Burkholderia cepacia ATCC 17759. Biotechnol Prog 26:424–430. https://doi.org/10.1002/btpr.355

Li R, Jiang Y, Wang X, Yang J, Gao Y, Zi X, Zhang X, Gao H, Hu N (2013) Psychrotrophic Pseudomonas mandelii CBS-1 produces high levels of poly-β-hydroxybutyrate. Springerplus 2:1–7. https://doi.org/10.1186/2193-1801-2-335

Oliveira FC, Dias ML, Castilho LR, Freire FMG (2007) Characterization of poly (3-hydroxybutyrate) produced by Cupriavidus necator in solid-state fermentation. Bioresour Technol 98:633–638. https://doi.org/10.1016/j.biortech.2006.02.022

Kiran GS, Lipton AN, Anitha SPK, Cruz-Suárez LE, Arasu MV, Choi KC, Selvin J, Al-Dhabi NA (2014) Antiadhesive activity of poly-hydroxy butyrate biopolymer from a marine Brevibacterium casei MSI04 against shrimp pathogenic vibrios. Microb Cell Factories 13:1–12. https://doi.org/10.1186/s12934-014-0114-3

Mohapatra S, Sarkar B, Samantaray DP, Daware A, Maity S, Pattnaik S, Bhattacharjee S (2017) Bioconversion of fish solid waste into PHB using Bacillus subtilis based submerged fermentation process. Environ Technol 38:3201–3208. https://doi.org/10.1080/09593330.2017.1291759

Egli T (2015) Microbial growth and physiology: a call for better craftsmanship. Front Microbiol 6:1–12. https://doi.org/10.3389/fmicb.2015.00287

Penkhrue W, Jendrossek D, Khanongnuch C, Pathom-aree W, Aizawa T, Behrens RL, Lumyong S (2020) Response surface method for polyhydroxybutyrate (PHB) bioplastic accumulation in Bacillus drentensis BP17 using pineapple peel. PLoS One 15:e0230443. https://doi.org/10.1371/journal.pone.0230443

Batool N, Shakir HA, Qazi JI (2015) Comparative growth potential of different Bacillus species on fruit peels. Punjab University Journal of Zoology 30:25-29. http://pu.edu.pk/images/journal/zology/ PDF-FILES/6-Comparative%20growth%20potential%20of%20different%20Bacillus%20species%20 on% 20fruit%20peels.pdf. Accessed 12 June 2019

Lyte M (1997) Induction of gram-negative bacterial growth by neurochemical containing banana (Musa x paradisiaca) extracts. FEMS Microbiol Lett 154:245–250. https://doi.org/10.1111/j.1574-6968.1997.tb12651.x

Torrado AM, Cortés S, Salgado JM, Max B, Rodríguez N, Bibbins BP, Converti A, Domínguez JM (2011) Citric acid production from orange peel wastes by solid- state fermentation. Braz J Microbiol 42:394–409. https://doi.org/10.1590/S1517-83822011000100049

Golden DA, Rhodehamel EJ, Kautter DA (1993) Growth of Salmonella spp. in cantaloupe, watermelon, and honeydew melons. J Food Prot 56:194–196. https://doi.org/10.4315/0362-028X-56.3.194

Blin C, Passet V, Touchon M, Rocha EPC, Brisse S (2017) Metabolic diversity of the emerging pathogenic lineages of Klebsiella pneumoniae. Environ Microbiol 19:1881–1898. https://doi.org/10.1111/1462-2920.13689

Lu X, Ji G, Zong H, Zhuge B (2016) The role of budABC on 1,3-propanediol and 2,3-butanediol production from glycerol in Klebsiella pneumoniae CICIM B0057. Bioengineered 7:439–444. https://doi.org/10.1080/21655979.2016.1169355

Sun S, Zhang H, Lu S, Lai C, Liu H, Zhu H (2016) The metabolic flux regulation of Klebsiella pneumoniae based on quorum sensing system. Sci Rep 6:1–9. https://doi.org/10.1038/srep38725

Afzal AM, Rasool MH, Waseem M, Aslam M (2017) Assessment of heavy metal tolerance and biosorptive potential of Klebsiella variicola isolated from industrial effluents. AMB Express 7:1–9. https://doi.org/10.1186/s13568-017-0482-2

Aransiola EF, Ige OA, Ehinmitola EO, Lakoyun SK (2017) Heavy metals bioremediation potential of Klebsiella species isolated from diesel polluted soil. Afr J Bitechnol 16:1098–1105. https://doi.org/10.5897/AJB2016.15823

Muñoz AJ, Espinola F, Ruiz E (2015) Removal of Pb(II) in a packed-bed column by a Klebsiella sp. 3S1 biofilm supported on porous ceramic Raschig rings. J Ind Eng Chem 40:118–127. https://doi.org/10.1016/j.jiec.2016.06.012

Muñoz AJ, Espinola F, Ruiz ER (2017) Removal of heavy metals by Klebsiella sp. 3S1. Kinetics, equilibrium and interaction mechanisms of Zn (II) biosorption. J Chem Technol Biotechnol 93:1213–1511. https://doi.org/10.1002/jctb.5503

Cardona-Echavarría AC, Mora-Martínez AL, Marín-Montoya M (2013) Molecular identification of bacteria that produce polyhydroxyalcanoates in dairy subproducts and sugar cane (in Spanish). Revista Facultad Nacional de Agronomía Medellín 66:7129-7140. https://revistas.unal.edu.co/index.php/refame/ article/view/41230/42790. Accessed 5 November 2018

Fathima N, Krishnaswamy VG (2016) Optimization of poly-β-hydroxybutyrate production by halotolerant bacterial strains isolated from saline environment. Int J Bioassays 5.8:4775-4781. https://www.doi.org/2F10.21746%2Fijbio.2016.08.0011

Favaro L, Basaglia M, Casella S (2018) Improving polyhydroxyalkanoate production from inexpensive carbon sources by genetic approaches: a review. Biofuels Bioprod Biorefin 13:208–227. https://doi.org/10.1002/bbb.1944

Mitrea L, Vodnar DC (2019) Klebsiella pneumoniae—a useful pathogenic strain for biotechnological purposes: diols biosynthesis under controlled and uncontrolled pH levels. Pathogens 8:1–10. https://doi.org/10.3390/pathogens8040293

Acknowledgments

We deeply thank Prof. Gilberto José López de la Mora, Coordinator of the Scientific Illustration Program of the Universidad Tecnológica de la Zona Metropolitana del Valle de México, for his valuable assistance in the elaboration of the graphical abstract. Biochemical characterization of strain E22 was performed in Acosta Group—Laboratories, in Tizayuca, Hgo., Mexico.

Funding

This project was supported by the budget from the Annual Operational Program assigned to the Universidad Tecnológica de la Zona Metropolitana del Valle de México for Scientific, Technological, and Educational Research Projects, item numbers 251001 and 255001 for years 2017 and 2018.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

ESM 1

(DOCX 121 kb)

Rights and permissions

About this article

Cite this article

Valdez-Calderón, A., Barraza-Salas, M., Quezada-Cruz, M. et al. Production of polyhydroxybutyrate (PHB) by a novel Klebsiella pneumoniae strain using low-cost media from fruit peel residues. Biomass Conv. Bioref. 12, 4925–4938 (2022). https://doi.org/10.1007/s13399-020-01147-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-01147-5