Abstract

Second-generation bioethanol can be produced from various lignocellulosic biomasses such as wood, agricultural or forest residues. Lignocellulosic biomass is inexpensive, renewable and abundant source for bioethanol production. The conversion of lignocellulosic biomass to bioethanol could be a promising technology though the process has several challenges and limitations such as biomass transport and handling, and efficient pretreatment methods for total delignification of lignocellulosics. Proper pretreatment methods can increase concentrations of fermentable sugars after enzymatic saccharification, thereby improving the efficiency of the whole process. Conversion of glucose as well as xylose to bioethanol needs some new fermentation technologies to make the whole process inexpensive. The main goal of pretreatment is to increase the digestibility of maximum available sugars. Each pretreatment process has a specific effect on the cellulose, hemicellulose and lignin fraction; thus, different pretreatment methods and conditions should be chosen according to the process configuration selected for the subsequent hydrolysis and fermentation steps. The cost of ethanol production from lignocellulosic biomass in current technologies is relatively high. Additionally, low yield still remains as one of the main challenges. This paper reviews the various technologies for maximum conversion of cellulose and hemicelluloses fraction to ethanol, and it point outs several key properties that should be targeted for low cost and maximum yield.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

Introduction

The energy crisis in the early 1970s enforced research and development aimed at sustainable production of biofuels and chemicals from renewable lignocellulosic feedstocks of agriculture and forestry. Lignocellulosic materials comprise a large fraction of municipal solid waste, crop residues, animal manures, forest residues and dedicated energy crops, also providing the required attributes for reducing greenhouse gases emission (Wyman and Hinman 1990; Wang et al. 1999; Sánchez and Cardona 2008). Moreover, biofuel byproducts could also be utilized as soil amendments which can reduce demands of chemical fertilizers (Singla and Inubushi 2014; Singla et al. 2013, 2014a, b).

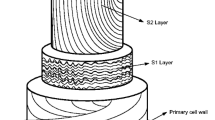

Lignocellulosic biomass is composed of cellulose, hemicellulose, lignin, extractives and several inorganic materials, and compositions of each vary depending on the origin of the lignocellulosic material (Singla et al. 2012; Saini et al. 2014). Cellulose is a linear, crystalline polymer of β-d-glucose unit, and the structure is rigid and difficult to break (Chesson and Forsberg 1988). This cellulosic fraction can be converted into glucose by enzymatic hydrolysis or by chemical methods (Mosier et al. 2005). Hemicellulose is composed of linear and branched heteropolymers of d-xylose, l-arabinose, d-galactose, d-glucose and d-mannose. The structure is not crystalline and is, therefore, easier to hydrolyse (Chang and Holtzapple 2000). Lignin is a three-dimensional polymer molecule consisting of three different phenyl-propane precursor monomer units which are particularly difficult to biodegrade. Hence, lignin is the most non-biodegradable component of the plant cell wall (Palonen 2004).

The conversion of lignocellulosic biomass to ethanol comprises the following main steps: hydrolysis of cellulose and hemicellulose to fermentable reducing sugars, fermentation of sugars to ethanol, separation of lignin residue, and finally, recovery and purification of ethanol to meet fuel specifications (Fig. 1). The hydrolysis is usually done by lignocellulosic enzymes and the fermentation is carried out by yeasts or bacteria (Singla et al. 2011; Maurya et al. 2012). The factors that have been identified to affect the hydrolysis of cellulose and hemicelluloses include porosity (accessible surface area) of the waste materials, crystallinity of cellulose, degree of cellulose and hemicellulose polymerization, and degree of acetylation of hemicellulose (Kumar and Wyman 2009a, b). Several pretreatment approaches have been investigated on different varieties of lignocellulosic biomass and theses have shown varying results based on raw material used for fermentation (Carvalheiro et al. 2008; Taherzadeh and Karimi 2008; Yang and Wyman 2008; Alvira et al. 2010; Geddes et al. 2011). It is because of different physico-chemical properties of various lignocellulosic materials. The aim of the effective pretreatment of lignocellulosic biomass should be focused on: (a) increase the accessible surface area and decrystallize cellulose, (b) partial depolymerization of cellulose and hemicellulose, (c) solubilize hemicelluloses and/or lignin, (d) modify the lignin structure, (e) maximize the enzymatic digestibility of the pretreated material, (f) minimize the loss of sugars, and (g) minimize capital and operating costs. An effective pretreatment must also preserve the pentose (hemicellulose) fractions, avoid the need for reducing the size of biomass particles, and limit the formation of toxic components which inhibit growth of fermentative microorganism (Alvira et al. 2010).

In this review, we have emphasized on some of the major and widely used physical, physico-chemical, chemical and biological pretreatment processes of various lignocellulosic biomasses aiming at removal of lignin and conversion of cellulose and hemicellulose into reducing sugars for the production of bioethanol or other value added products. We have discussed the main principles behind these pretreatment processes, their mechanisms, merits/demerits and maximum yield of obtained sugars. The objective of the present review is on the pretreatment processes and recent advances for bioethanol production from different lignocellulosic biomass, and to analyze the interrelated factors between pretreatment, hydrolysis and fermentation.

Parameters for effective pretreatment of lignocellulosic biomass

There are several key factors which affect the rate of biological degradation of lignocelluloses (Kumar and Wyman 2009b). The accessible surface area for enzymatic attack may be related to cellulose crystallinity, lignin, and hemicellulose content.

Cellulose crystallinity

The cellulose microfibrils have both crystalline and amorphous regions, and cellulose crystallinity has been considered as one of the important factors in determining the hydrolysis rates of relatively refined cellulosic substrates. The maximum part of cellulose (around 2/3 of the total cellulose) is in the crystalline form (Chang and Holtzapple 2000). In fact, cellulase readily hydrolyzes the more accessible amorphous portion of crystalline cellulose; while the enzyme is not so effective in degrading the less accessible crystalline portion. It is, therefore, expected that high-crystallinity cellulose will be more resistant to enzymatic hydrolysis, and it is widely accepted that decreasing the crystallinity will increase the digestibility of lignocelluloses (Kumar and Wyman 2009b). However, it is not the only factor in effective enzymatic hydrolysis of lignocellulosic biomass due to the heterogeneous nature of celluloses and the contribution of other components such as lignin and hemicelluloses (Kumar and Wyman 2009a).

Effect of accessible surface area

Studies have indicated a good correlation between the pore volumes (accessible surface area for cellulase and hemicellulase) and the enzymatic digestibility of lignocellulosic materials (Chandra et al. 2007). The main advantage of this correlation is in the improvement of enzymatic hydrolysis by removing lignin. Lignocellulosic biomass has two types of surface area: external and internal. The external surface area is related to the particle size and shape; while the internal surface area depends on the capillary structure of cellulosic fibers.

Effect of lignin

The presence of lignin is responsible for integrity, structural rigidity and the prevention of swelling of lignocellulosic material. The cellulose and hemicellulose are covered by lignin. The presence of lignin hinders the access of enzymes to cellulose and hemicelluloses (Kumar and Wyman 2009b), thus reducing the efficiency of the hydrolysis. Lignin is the most important recognized factor for recalcitrance of lignocellulosic materials. Therefore, efficient delignification processes can improve the rate and extent of enzymatic hydrolysis (Laureano-Pérez et al. 2005)

Effect of hemicellulose

Hemicellulose is a physical barrier which covers the cellulose fibers and protects it from the enzymatic hydrolysis. It has been shown that the removal of hemicellulose increases the mean pore size of the substrate and, therefore increases the accessibility and the probability of the cellulose hydrolysis (Jeoh et al. 2005; Chandra et al. 2007; Ishizawa et al. 2007). Degree of acetylation in the hemicellulose is another important factor as lignin and acetyl groups are attached to the hemicellulose matrix and may hinder polysaccharide breakdown (Chang and Holtzapple 2000).

Pretreatment of lignocellulosic biomass

Various pretreatment methods are now available to fractionate, solubilize, hydrolyze and separate cellulose, hemicellulose, and lignin components (Fig. 2). These include concentrated acid, sulfur dioxide (SO2), hydrogen peroxide (H2O2), steam explosion (autohydrolysis), ammonia fiber expansion (AFEX), wet oxidation, lime, liquid hot water, carbon dioxide (CO2) explosion and organic solvent treatments (da Costa et al. 2009; Karimi et al. 2013). The Physical (mechanical), physico-chemical, chemical, and biological processes have been used for pretreatment of lignocellulosic materials. Mechanical pretreatment increases the surface area by reducing the size of the biomass. A high control of operating conditions is required in the physico-chemical methods because these reactions occur at high temperature and pressure (Taherzsadeh and Karimi 2007). Chemical methods remove and/or dislocate hemicelluloses and lignin and thus, loosening the structural of lignin holocellulose network. Biological pretreatment methods are used for the delignification of lignocellulosic biomass (Chandel et al. 2007).

Physical pretreatments

Mechanical comminution

The objective of the mechanical pretreatment is to reduce the particle size and crystallinity of lignocellulosic materials to increase the specific surface area, and to reduce the degree of polymerization of cellulose. The size of feedstock materials is usually 10–30 mm after chipping and 0.2–2 mm after milling or grinding (Sun and Cheng 2002). Different milling processes (two-roll milling, hammer milling, colloid milling and vibratory milling) can be used to improve the digestibility of the lignocellulosic materials compared to ordinary ball milling (Taherzadeh and Karimi 2008). This process is generally not economically feasible because of high energy consumption for obtaining desired particle size (Zhu and Pan 2010).

Extrusion

Extrusion process has been used to produce gaseous products and residual char (Shafizadeh and Bradbury 1979). In this process, materials are treated at a temperature higher than 300 °C followed by mixing and shearing which results in physical and chemical modifications of cellulose. The screw speed and barrel temperature are believed to disrupt the lignocellulosic structure causing defibrillation, fibrillation and shortening of the fibers, followed by increased arability of carbohydrates to enzymatic attack (Karunanithy et al. 2008). The various parameters in bioreactor must be highly efficient in this process. In recent study, the application of enzymes during extrusion process is considered as a novel technology for ethanol production (Zheng et al. 2014).

Physico-chemical pretreatments

Steam explosion (autohydrolysis)

Steam explosion is the most commonly used method for pretreatment of lignocellulosic biomass (Chandra et al. 2007; Singh et al. 2015). In this method, the chipped biomass is treated to high pressure saturated steam for few seconds (30 s) to several minutes (20 min), and then pressure is suddenly reduced. Steam explosion is typically a combination of mechanical forces and chemical effects due to the hydrolysis (autohydrolysis) of acetyl groups of hemicellulose. Autohydrolysis is initiated at high temperatures (160–260 °C) which promote the formation of acetic acid from acetyl groups (Pan et al. 2005; Quievy et al. 2009). Furthermore, water can also act as an acid at high temperatures. The mechanical effects are caused because of sudden reduction in pressure and fibers are separated owing to the explosive decompression. This process causes hemicellulose degradation and lignin transformation due to high temperature, thus increasing the potential of cellulose hydrolysis (Pan et al. 2005). The most important parameters that affect the steam explosion pretreatment are: particle size, temperature, residence time, moisture content and the combined effect of temperature (T) and time (t), which is defined by the severity parameter (Ro) [Ro = t exp [T−100/14.75]: t is the reaction time (min), and T is the hydrolysis temperature (°C)]. The optimal conditions for maximum sugar yield following severity parameter were found 3.0–4.5 (Alfani et al. 2000).

Steam explosion processes have many attractive features compared to other pretreatment technologies (Table 1). These include the potential for significant improvement in enzymatic hydrolysis, lower environmental impact, lower capital investment, more potential for energy efficiency, less hazardous process chemicals and conditions, and high sugar recovery (Avellar and Glasser 1998). The advantage of steam explosion pretreatment also includes the possibility of using larger chip size, avoiding unnecessary addition of acid catalyst (except for softwoods), and its feasibility at industrial scale. Steam explosion is recognized as one of the most effective processes for cost reduction in hardwoods and agricultural residues, but it is less effective for softwoods because of low content of acetyl groups in the hemicellulosic portion of softwoods (Sun and Cheng 2002). The addition of SO2 or sulfuric acid (H2SO4) has been proposed as one of the most effective pretreatment methods for softwood material but it has some disadvantages (Berlin et al. 2006; Kumar et al. 2012). The main drawback of this process is equipment requirement for acid addition and the formation of inhibitory/degrading compounds (Mosier et al. 2005).

The main drawbacks of steam explosion pretreatment are the partial degradation of hemicelluloses and the formation of toxic components that could affect the enzymatic hydrolysis and fermentation process (Oliva et al. 2003). Another drawback is the energy consumption for obtaining final chip size before pretreatment which can make up one-third of the power requirement of entire process (Hamelinck et al. 2005). Steam explosion and acid hydrolysis pretreatment may sometime produce furfural and hydroxymethylfurfural as byproducts which have inhibitory effect on the fermentation process. Hence, a separate detoxification step (e.g., addition of activated charcoal, over liming, ion exchange) becomes necessary, thereby increasing the overall process cost (Schmidt and Thomsen 1998; Yang and Wyman 2008).

Liquid hot water

Liquid hot water is one of the hydrothermal pretreatment which does not require rapid decompression and the addition of any catalyst or chemicals. Water pretreatment under high pressure is used to maintain the water in the liquid state at elevated temperatures. Temperature range between 170 and 230 °C and pressure (>5 MPa) are commonly used (Sánchez and Cardona 2008). Liquid hot water removes hemicellulose from lignocellulosic materials which makes the cellulose more accessible (Table 1). The obtained slurry after pretreatment can be filtered to obtain two fractions: one solid cellulose-enriched fraction and a liquid fraction rich in hemicellulose derived sugars. This pretreatment allows better pH control (4–7) which minimizes the non-specific degradation of polysaccharides and also avoids formation of inhibitors (Mosier et al. 2005). Liquid hot water has shown the potential to release high fraction of hemicellulosic sugars mostly in the form of oligomers contributing to reduce the undesired degrading products (Mosier et al. 2005). It was reported that temperature and time showed the most significant effect on the recovery of hemicellulosic sugars and the yield of subsequent enzymatic hydrolysis of pretreated corn stover (Mosier et al. 2005), sugarcane bagasse (Laser et al. 2002) and wheat straw (Perez et al. 2008). Three methods have also been developed to promote an effective contact between the biomass and the liquid water: co-current, countercurrent, and flow-through. In co-current pretreatments, slurry of biomass and water is heated to the desired temperature and held at the pretreatment conditions for controlled residence time before being cooled. Countercurrent pretreatment is designed to move water opposite to lignocellulose through the pretreatment system. Flow-through system allows hot water passage over a stationary bed of lignocelluloses; which hydrolyzes and dissolves lignocellulose components and carries them out of the system (Liu and Wyman 2003; Yang and Wyman 2004).

In general, liquid hot water pretreatments are attractive from a cost savings point of view because no chemicals and corrosion-resistant materials are required for hydrolysis reactors. Another major advantage is that the solubilized hemicellulose and lignin products are present in lower concentration due to high water input (Table 1). Higher pentose recovery and lower formation of inhibitory components are obtained in this pretreatment compared to steam explosion. However, this process is yet not developed at commercial scale because of higher water demand and high energy requirement.

Ammonia-based pretreatments

AFEX is another type of physico-chemical pretreatment in which lignocellulosic biomass is treated with liquid ammonia at relatively moderate temperature (90–100 °C) for a period of 30–60 min. followed by a rapid pressure release (Kim et al. 2011). It results in a rapid expansion of the liquid ammonia that causes swelling and physical disruption of biomass fibers and partial decrystallization of cellulose. AFEX produces only a pretreated solid material. AFEX process can either modify or effectively reduce cellulose crystallinity and lignin fraction of the lignocellulosic materials (Laureano-Pérez et al. 2005). AFEX increases the digestibility of lignocellulosic biomass by removing the least acetyl groups by deacetylation process (Kumar and Wyman 2009a, b). The main advantage of the ammonia pretreatment is that it does not produce inhibitors for the downstream biological processes, so water wash is not necessary (Table 1). The herbaceous and agricultural residues are more effective for AFEX pretreatment, with limited effectiveness on woody biomass and other high lignin feedstocks (Wyman et al. 2005a). Shao et al. (2010) demonstrated that AFEX pretreated corn grain yielded 1.5–3.0 folds higher enzymatic hydrolysis compared to untreated substrates. Sequential addition of cellulases after hydrolysis of starch resulted in 15–20 % higher hydrolysis yield compared to simultaneous addition of hydrolytic enzymes. AFEX pretreated corn stover resulted in 70 % glucan conversion after 72 h of hydrolysis. Ethanol fermentation of AFEX treated (at 6 % w/w glucan loading) corn stover resulted in 93 % ethanol yield (Uppugundla et al. 2014). (Teymouri et al. 2005) optimized the conditions such as ammonia loading, temperature, blowdown pressure, moisture content of biomass and residence time in the AFEX process. It has been observed that at optimal conditions, AFEX can achieve over 90 % conversion of cellulose and hemicellulose to fermentable sugars for a broad variety of lignocellulosic materials. The high volatility of ammonia allows it to be recovered and recycled, leaving the dried biomass ready for enzymatic hydrolysis (Sendich et al. 2008).

The main disadvantage of AFEX process is that it is more effective on the biomass that contains less lignin (Table 1). Furthermore, ammonia must be recycled after the pretreatment to reduce the cost and protect the environment (Sun and Cheng 2002). The cost of ammonia recovery may be significant regarding the commercial potential of the AFEX pretreatment (Mosier et al. 2005). Another type of ammonia-based methodology is ammonia recycled percolation (ARP) in which aqueous ammonia (5–15 wt %) passes through a packed bed reactor along with biomass at elevated temperature (140–210 °C) for 90 min, and percolation rate is kept 5 mL/min (Sun and Cheng 2002; Kim et al. 2008). ARP can solubilize hemicellulose and lignin, and both can be removed from the biomass as the liquid phase (Yang and Wyman 2008). An important challenge for ARP is to reduce the liquid loading or process temperature to reduce energy cost. Soaking in aqueous ammonia (SAA) at lower temperatures (40–90 °C) for longer reaction times has been used to preserve most of the glucan and xylan in the samples which is subsequently fermented using the simultaneous saccharification and co-fermentation (SSCF) process (Kim et al. 2008).

CO2 explosion

This method is based on the utilization of CO2 as a supercritical fluid in which fluid displays gas like mass transfer properties besides a liquid-like solvating power. Supercritical pretreatment conditions can effectively remove lignin by increasing enzymatic digestibility of aspen (hardwood) and southern yellow pine (softwood) (Kim and Hong 2001). The delignification with CO2 (SC-CO2) at high pressure can be improved by the addition of co-solvents such as ethanol. Supercritical CO2 has been mostly used as an extraction solvent for non-extractive purposes due to its several advantages such as availability at relatively low cost, non-toxicity, non-flammability, easy recovery after extraction, and the environmental acceptability (Table 1; Schacht et al. 2008). In aqueous solution, CO2 forms carbonic acid and increases hydrolysis rate. The size of CO2 molecules should be comparable to water and ammonia because CO2 molecules can penetrate small pores accessible to water and ammonia molecules. In this pretreatment, disruption of cellulose and hemicellulose structure occurs and consequently accessible surface area of the substrate to enzymatic attack increases. The comparison of CO2 explosion with steam and ammonia expansion pretreatment methods on several substrates showed that CO2 explosion was more cost-effective than ammonia expansion and the formation of inhibitors was lower compared to steam explosion (Zheng et al. 1998).

Oxidative pretreatment

Oxidative pretreatment involves the addition of an oxidizing agent such as H2O2 or peracetic acid (C2H4O3) to the water-suspended biomass. H2O2 is the most commonly used oxidizing agent. Studies have shown that dissolution of about 50 % of lignin and most of the hemicellulose has been achieved in a solution of 1–2 % H2O2 at 25–30 °C (Chaturvedi and Verma 2013). This solubilization is generally five folds higher than those of sodium hydroxide (NaOH) treatment without H2O2 addition. This pretreatment method removes hemicellulose and lignin from biomass to increase accessibility to the cellulose (García-Cubero et al. 2009). Several reactions like electrophilic substitution, displacement of side chains, cleavage of alkyl/aryl ether linkages or the oxidative cleavage of aromatic nuclei can occur during this pretreatment (Hon and Shiraishi 2001). It has been observed that diluted alkaline peroxide treatment is an effective method for pretreatment of rice hulls, resulting in almost complete conversion (96 %) of rice hulls to sugars after enzymatic hydrolysis (Saha and Cotta 2007).

Wet oxidation

Wet oxidation is considered as a suitable process for pretreatment of biomass having high lignin content. In this process, materials are treated with water and air/oxygen at temperatures higher than 120 °C for 30 min (Varga et al. 2004). The temperature, reaction time and oxygen pressure are the most effective parameters in wet oxidation (Schmidt and Thomsen 1998). The addition of oxygen at temperatures higher than 170 °C makes the process exothermic, and it becomes self-supporting system with respect to heat (Schmidt and Thomsen 1998). The wet oxidation pretreatment catalyzes the formation of acids from hydrolytic processes and oxidative reactions. All three fractions of lignocellulosic materials are affected in this process. The hemicelluloses are extensively cleaved to low molecular weight sugars that become soluble in water. Lignin undergoes cleavage and oxidation, and cellulose is partly degraded. The cellulose becomes highly susceptible to enzymatic hydrolysis. However, addition of some alkaline agent such as sodium carbonate may help to solubilize hemicellulose fraction and also minimizes the formation of furan-based degradation products that could inhibit enzymes (Ahring et al. 1996).

Szijarto et al. (2009) showed a solubilization of 51.7 % of the hemicellulose and 58.3 % of the lignin; whereas 87.1 % of the cellulose remained in the solids while studying common reed (Phragmites australis). The optimum conditions (185 °C, 12 min) increased the digestibility of reed cellulose more than three times compared to the untreated control. The conversion of 82.4 % cellulose to glucose was also achieved during the same process. Simultaneous saccharification and fermentation of pretreated solids resulted in a final ethanol concentration as high as 8.7 g/L, yielding 73 % of the theoretical yield. Banerjee et al. (2011) investigated pretreatment of rice husk by alkaline peroxide-assisted wet air oxidation (APAWAO) to increase the enzymatic convertibility of cellulose. Rice husk was presoaked overnight in 1 % (w/v) H2O2 solution at room temperature, followed by wet air oxidation (WAO). APAWAO pretreatment resulted in solubilization of 67 % of hemicellulose and 88 % of lignin. It also resulted in 13 folds increase in the amount of glucose compared to untreated rice husk. Almost 86 % of cellulose was converted into glucose within 24 h. The main advantage of wet oxidation is the formation of less inhibitors and efficient removal of lignin (Table 1). The main drawback of this process is that it requires the maintenance of high temperature and pressure, and the presence of strong oxidizing agents such as H2O2. These requirements lead to high costs of maintenance and also require large-scale reaction vessels. Therefore, application of this process in large-scale pretreatment of biomass is limited. The cost of oxygen and catalyst are another disadvantages for this process.

Microwave pretreatment

Microwave irradiation is a process which has been widely used because of its high heating efficiency and easy operation. The residence time in microwave irradiation ranges from 5 to 20 min. It could change the ultra structure of cellulose by degrading lignin and hemicelluloses and by increasing the enzymatic susceptibility of lignocellulosic materials (Maurya et al. 2013). Preliminary experiments identified alkali-treated rice straw as suitable biomass for microwave-based pretreatment (Zhu et al. 2006). NaOH is the most effective alkali reagent for microwave-based pretreatment. One of the studies on microwave-based alkali pretreatment of switchgrass observed the low energy requirement for extended pretreatment time and obtained 70–90 % sugar yields (Hu and Wen 2008). Xu et al. (2011) developed an orthogonal design to optimize the microwave pretreatment of wheat straw and observed ethanol yield of 148.93 (g/kg wheat straw) which was much higher from untreated material (26.78; g/kg wheat straw). Boonmanumsin et al. (2012) reported substantial increase in monomeric sugars yield of Miscanthus sinensis while carrying out microwave-assisted ammonium hydroxide treatment. A loss of 74 % lignin and 24.5 % holocellulose was reported with a yield of 41 % of total reducing sugars in microwave pretreatment of oil palm empty fruit bunch fiber in the presence of alkaline conditions (Nomanbhay et al. 2013).

The main advantage of this process is the short reaction times and homogeneous heating of the reaction mixture. Microwave-assisted pretreatment of biomass could be a useful process to save time, energy and minimum generation of inhibitors. It could be considered as one of the most promising pretreatment methods to change the native structure of cellulose with lignin and hemicelluloses degradation, and thus increasing the enzymatic susceptibility (Lu et al. 2011). Microwave approach could be further combined with the addition of chemicals to improve the sugar yield from the substrate.

Chemical pretreatments

Acid pretreatment

The main objective of the acid pretreatment is chemical hydrolysis which can cause solubilization of hemicelluloses and lignin, and to make the cellulose more accessible to enzymes. Acid pretreatment technologies can be performed with concentrated or diluted acid (Table 1) but use of concentrated acid is less attractive due to the formation of inhibiting compounds (furfural, 5-hydroxymethylfurfural, phenolic acids and aldehydes). Concentrated acids are toxic, corrosive, hazardous, and require equipment that is resistant to corrosion. Diluted acid pretreatment method is the most feasible for industrial scale. Different types of reactors such as percolation, plug flow, shrinking-bed, batch, flow-through reactor and countercurrent reactors have been developed for this approach (Taherzadeh and Karimi 2008). There are two types of dilute acid pretreatment processes: high temperature (e.g., 180 °C) during a short period of time and lower temperature (e.g., 120 °C) for longer retention time (30–90 min). High hydrolysis yields have been reported with dilute H2SO4 which is also the most widely used acid (Mosier et al. 2005; Sindhu et al. 2011).

However, use of hydrochloric acid (HCl), phosphoric acid, nitric acid, C2H4O3, oxalic acid, formic acid, acetic acid and maleic acid has also been tested (Hernández-Salas et al. 2009; Gámez et al. 2006; Rodriguez-Chong et al. 2004; Lee et al. 2011). Oxalic acid treatment in corn cobs produced low level of inhibitors with a total sugar yield of 13.1 % (Lee et al. 2011); while it was 10 % in maleic acid treatment with the generation of higher levels of furfural and hydroxymethylfurfural (Lee and Jeffries 2011). Kim et al. (2011) carried pretreatment of rice straw in two-stage process using aqueous ammonia and dilute H2SO4 in percolation mode. The yield of reducing sugars was observed 96.9 and 90.8 %, respectively, indicating that combination of these two processes resulted in better removal of lignin and hemicelluloses. Pretreatment liquor of Eulaliopsis binata (a perennial grass commonly found in India and China) with diluted H2SO4 at optimum conditions resulted in 21.02 % total sugars, 3.22 % lignin and 3.34 % acetic acid with the generation of low levels of inhibitors (Tang et al. 2013). Bondesson et al. (2013) reported 78 % yield in corn stover by following steam pretreatment with diluted H2SO4. Acid pretreatment of biomass could be inexpensive because H2SO4 and HCl are cheap (Table 1). The process is carried out at high temperatures, and therefore, it requires high energy input, which is costly. The presence of acids at high temperatures can be corrosive, thus, the process requires specific reaction vessels which must be resistant to these conditions. In addition, acid treatment generates inhibitors which need to be removed.

Alkali pretreatments

In the alkaline treatment, biomass is treated with alkali such as sodium, potassium, calcium and ammonium hydroxides at normal temperature and pressure. The main advantage of the process is efficient removal of lignin from the biomass (Table 1). This process removes acetyl and uronic acid groups present on hemicelluloses, thus enhances the accessibility of enzyme that degrades hemicellulose (Chang and Holtzapple 2000). Ester linkages between xylan and hemicelluloses residues are also hydrolyzed (Sun and Cheng 2002). This process can largely improve the cellulose digestibility and it is also more effective for lignin solubilization, exhibiting minor cellulose and hemicellulose solubilization compared to acid pretreatment (Carvalheiro et al. 2008). Alkali pretreatment can also be operational at lower temperature, pressure and time ranging from hours to days. NaOH is more effective than others (Sun et al. 1995; Kumar and Wyman 2009a). It was found to be more effective on increasing the internal surface area of cellulose, decreasing the degree of polymerization and crystallinity, and disrupting the lignin structure (Taherzadeh and Karimi 2008). However, no effect of dilute NaOH was observed on softwoods with lignin content greater than 26 % (Kumar and Wyman 2009a).

Lime [Ca(OH)2] is another widely used alkali. It also removes acetyl groups and lignin-carbohydrate ester and enhances cellulose digestibility (Mosier et al. 2005). It has been proven successful for pretreatment of wheat straw, poplar wood, switchgrass and corn stover (Chang et al. 2001; Kim and Holtzapple 2006). This pretreatment has the additional benefits of low reagent cost and less safety requirements compared to NaOH or KOH pretreatments and can be easily recovered from hydrolysate by reaction with CO2 (Mosier et al. 2005). The addition of air/oxygen to alkaline pretreatment [NaOH/Ca(OH)2] can improve the treatment efficiency by increasing lignin removal (Carvalheiro et al. 2008). Some researchers have also tried combination of two pretreatment processes for significant recovery of reducing sugars: combination of alkaline treatment (lime) with oxidative delignification process. Although, lime and other hydroxides are inexpensive but downstream processing costs are high, thus making it a costly process (Table 1). The process also utilizes a huge amount of water for washing salts of calcium and sodium. Moreover, it is difficult to remove them.

Ozonolysis

The biomass is treated with ozone (O3) which is a powerful oxidizing agent. It degrades lignin by attacking aromatic rings structures, and does not affect hemicellulose and cellulose. It can be used to disrupt the structure of many lignocellulosic materials such as wheat straw, bagasse, pine, peanut, cotton straw, rye straw and poplar sawdust (Sun and Cheng 2002; García-Cubero et al. 2009). Ozonolysis is usually performed at room temperature and pressure, and it does not produce toxic residues that can affect the subsequent hydrolysis and fermentation. The O3 gas is passed through a reaction vessel containing the substrate. The vessel could be packed beds, fixed beds or stirred semi-batch reactors (Vidal and Molinier 1988; García-Cubero et al. 2009).

Moisture content and type of biomass significantly affect ozonolysis. Miura et al. (2012) studied the effect of ozonolysis and wet disk milling (WDM) on Japanese cedar (Cryptomeria japonica) to improve sugar production by enzymatic saccharification. They observed decrease in O3 consumption if moisture content reached more than 40 % and it resulted in less delignification. The application of WDM following O3 treatment increased glucose and xylose yields (68.8 and 43.2 %, respectively) without significantly affecting mannose yield. A major drawback of ozonolysis is the requirement of large amounts of O3, making the process expensive (Sun and Cheng 2002).

Organosolv

Organosolv process uses organic or aqueous organic solvent mixtures with inorganic acid catalysts to extract lignin from lignocellulosic biomass. Numerous organic solvent mixtures including methanol, ethanol, acetone, ethylene glycol, triethylene glycol and tetrahydrofurfuryl alcohol have been used (Zhao et al. 2009a). Some organic or aqueous organic solvents like oxalic, acetylsalicylic and salicylic acid can also be used as catalysts at higher temperatures with or without addition of some organic acids (Sarkanen 1980). Pretreatment of wheat straw by glycerol-based autocatalytic organosolv pretreatment resulted in removal of 70 % hemicelluloses and 65 % lignin (Sun and Chen 2008). It also resulted in 98 % cellulose retention. A modified organosolv method using ethanol under mild conditions followed by H2O2 post-treatment in horticultural waste resulted in a hydrolysate containing 26.9 g/L reducing sugar (Geng et al. 2012). Fermentation of this hydrolysate medium produced 11.69 g/L ethanol using Saccharomyces cerevisiae. Hideno et al. (2013) have reported that the application of alcohol-based organosolv treatment in combination with Ball Milling (BM) for pretreatment of Japanese cypress (Chamaecyparis obtusa) significantly improved the enzymatic digestibility and decreased the required severity of organosolv treatment. It was also observed that the combination of alcohol-based organosolv treatment in mild conditions and short time BM had a synergistic effect on the enzymatic digestibility of Japanese cypress. Organosolv process has been extensively used for extraction of high quality lignin which is a value added product. This process has shown high amounts of enzymatic hydrolysis of treated biomass (around 90 %) due to efficient removal of lignin.

The main drawback of the process is the cost of solvent and the catalysts (Table 1). Removal and recovery of the solvent can considerably reduce the operational cost (Sun and Cheng 2002). Another important aspect is safety measures which have to be implemented because organic solvents are inflammable and uncontrolled use can cause fires and explosions. This additional requirement increases the cost of the process. Organic solvents are also the inhibitors of enzymatic hydrolysis, so their removal is necessary for proper enzymatic hydrolysis (Mosier et al. 2005). Removal of organic solvents also burdens an additional cost.

Ionic liquids (ILs)

This pretreatment process uses ILs in a ratio of biomass and ionic liquid (1:10 w/w) and temperatures ranging from 100 to 150 °C. The antisolvent such as water, methanol and ethanol use the regeneration of soluble biomass and then subject to enzymatic hydrolysis to produce fermentable sugars. ILs behave like salt which is typically a combined effect of large organic cations and small inorganic anions and it exist as liquids at relatively low temperatures (room temperature). ILs have the capability to form hydrogen bonds with cellulose at high temperatures because of the presence of anions like chloride, formate, acetate or alkyl phosphonate. ILs have tremendous potential for pretreating lignocellulosic biomass and producing a substrate that can achieve more than 90 % cellulose digestibility (Lee et al. 2009).

Residual ILs remaining in the biomass could interfere with hydrolytic enzyme activities and downstream fermentation steps (Sathitsuksanoh et al. 2012; Shi et al. 2013). It may affect the final sugar and biofuel yields. After regeneration, ILs may be recovered from antisolvents by flash distillation and it could be reused (Joglekar et al. 2007). Development of energy efficient recycling methods for ILs is a prerequisite for large-scale application. Toxicity to enzymes and fermentative microorganisms must also be considered before their application in biomass pretreatment (Yang and Wyman 2008; Zhao et al. 2009b). Significant negative effect on cellulase activity may also occur in ILs treatment. Further research is needed to improve the economics of ILs pretreatment before they can be applied at industrial scale. In addition, techniques need to be developed to recover hemicellulose and lignin from solutions after extraction of cellulose. Despite these current limitations, development of ILs pretreatment offers a great potential for future biorefinering processes of lignocelluloses.

Biological pretreatments

Conventional physico-chemical methods for lignin degradation require large inputs of energy and also cause pollution. Therefore, biological pretreatment of lignocellulosic biomass is considered as an efficient, ecofriendly and cheap alternative (Wan and Li 2012). The biological pretreatment of lignocellulosic biomass is usually performed using cellulolytic and hemicellulolytic microorganisms. The commonly used microorganisms are filamentous fungi which are ubiquitous and can be isolated from the soil, living plants or lignocellulosic waste material (Vats et al. 2013). Studies have shown that white-rot fungi are the most effective microorganisms for the pretreatment of most of the lignocellulosic materials (Kumar and Wyman 2009a). Several white-rot fungi such as Phanerochaete chrysosporium, Ceriporia lacerata, Cyathus stercolerus, Ceriporiopsis subvermispora, Pycnoporus cinnarbarinus, Pleurotus ostreaus and P. chrysosporium produce lignin peroxidases which is lignin-degrading enzymes and manganese-dependent peroxidases. These have shown high delignification efficiency on various lignocellulosic biomasses (Shi et al. 2008; Kumar and Wyman 2009a). An effective delignification of various feedstocks was reported by fungus Ceriporiopsis subvermispora in the combined action of manganese peroxidase and laccase (Wan and Li 2012). A glucose yield of 24.2–56.5 % was reported during enzymatic hydrolysis which was 2–3 folds higher than those of the raw materials. Biological pretreatment of rice husks by fungus Phanerochaete chrysosporium resulted in 44.7 % reducing sugars (Potumarthi et al. 2013). Biological treatments of wheat straw by solid state and submerged fermentations in the presence of white-rot basidiomycetes such as Bjerkandera adusta, Fomes fomentarius, Ganoderma resinaceum, Irpex lacteus, Phanerochaete chrysosporium, Trametes versicolor, Euc-1 and Lepista nuda were evaluated and T. versicolor for enzymatic hydrolysis of holocellulose proved better strain compared to others (Pinto et al. 2012). The treatment of hardwood and softwood was also found to be effective with Streptomyces griseus (Saritha et al. 2012).

It has been observed that performing saccharification and fermentation processes at high-substrate concentration may increase the concentration of inhibitors (furan derivatives and phenolic compounds). Treatment with enzymes such as laccases has been suggested to prevent production of such inhibitors (Alvira et al. 2010). Martins et al. (2013) showed that recovery of phenolic compounds in the leaves of Larrea tridentata was 33 % more in combination of biological treatment followed by methanol extraction compared to methanol extraction alone. Some other advantages of biological pretreatments are: low-capital cost, low energy requirement, no chemicals requirement, and mild environmental conditions (Table 1). However, the main drawback to develop biological methods is that the rate of hydrolysis is very low (Sun and Cheng 2002). There is need to keep on testing more and more isolates such as basidiomycetes fungi for their ability to delignify the plant material quickly and efficiently.

Conclusions and future perspectives

The various pretreatment technologies for lignocellulosic biomass have been described to improve ethanol production. A major bottleneck in this technology is the presence of lignin which is a major inhibitor of hydrolysis of cellulose and hemicellulose. This has led to extensive research in the development of various pretreatment processes. These processes are based on physical, chemical and biological principles. Chemical and thermo-chemical are currently the most effective and include the most promising technologies for industrial applications. One important point that emerges is that no treatment technology offers 100 % conversion of biomass into fermentable sugars. There is always a loss of biomass, which affects the final yield and increases the cost of finished product, i.e., biofuel. Although pretreatment of lignocellulosic biomass with combination of two or more pretreatment processes has shown promising results, we still feel that there is a need for extensive research in this area so that either a new efficient treatment process is developed or an existing process is upgraded to give promising results. Predictive models will enable the selection, design, optimization, and process control pretreatment technologies that match biomass feedstock with the appropriate method and process configuration.

References

Ahring BK, Jensen K, Nielsen P, Bjerre AB, Schmidt AS (1996) Pretreatment of wheat straw and conversion of xylose and xylan to ethanol by thermophilic anaerobic bacteria. Bioresour Technol 58:107–113

Alfani A, Gallifuoco F, Saporosi A, Spera A, Cantarella M (2000) Comparison of SHF and SSF process for the bioconversion of steam-exploded wheat straw. J Ind Microbiol Biotechnol 25:184–192

Alvira P, Toma´s-Pejo E, Ballesteros M, Negro MJ (2010) Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: a review. Bioresour Technol 101:4851–4861

Avellar BK, Glasser WG (1998) Steam-assisted biomass fractionation. I. Process considerations and economic evaluation. Biomass Bioenergy 14:205–218

Banerjee S, Sen R, Mudliar S, Pandey RA, Chakrabarti T, Satpute D (2011) Alkaline peroxide assisted wet air oxidation pretreatment approach to enhance enzymatic convertibility of rice husk. Biotechnol Prog 27:691–697

Berlin A, Balakshin M, Gilkes N, Kadla J, Maximenko V, Kubo S, Saddler JN (2006) Inhibition of cellulase, xylanase and β-glucosidase activities by softwood lignin preparations. J Biotechnol 125:198–209

Bondesson PM, Galbe M, Zacchi G (2013) Ethanol and biogas production after steam pretreatment of corn stover with or without the addition of sulphuric acid. Biotechnol Biofuels 6:11

Boonmanumsin P, Treeboobpha S, Jeamjumnunja K, Luengnaruemitchai A, Chaisuwan T, Wongkasemjit S (2012) Release of monomeric sugars from Miscanthus sinensis by microwave assisted ammonia and phosphoric acid treatments. Bioresour Technol 103:425–431

Carvalheiro F, Duarte LC, Gírio FM (2008) Hemicellulose biorefineries: a review on biomass pretreatments. J Sci Ind Res 67:849–864

Chandel AK, Chan EC, Rudravaram R, Narasu ML, Rao LV, Ravinda P (2007) Economics and environmental impact of bioethanol production technologies: an appraisal. Biotechnol Mol Biol Rev 2:14–32

Chandra RP, Bura R, Mabee WE, Berlin A, Pan X, Saddler JN (2007) Substrate pretreatment: the key to effective enzymatic hydrolysis of lignocellulosics. Adv Biochem Eng Biotechnol 108:67–93

Chang VS, Holtzapple MT (2000) Fundamental factors affecting biomass enzymatic reactivity. Appl Biochem Biotechnol 84:5–37

Chang VS, Nagwani M, Kim CH, Holtzapple MT (2001) Oxidative lime pretreatment of high-lignin biomass: poplar wood and newspaper. Appl Biochem Biotechnol 94:1–28

Chaturvedi V, Verma P (2013) An overview of key pretreatment processes employed for bioconversion of lignocellulosic biomass into biofuels and value added products. 3. Biotech 5:415–431

Chesson A, Forsberg CW (1988) Polysaccharide degradation by rumen microorganisms. In: Hobson (ed) The rumen microbial ecosystem, pp 251–284

da Costa SL, Chundawat SPS, Balan V, Dale BE (2009) `Cradle-to-grave’ assessment of existing lignocellulose pretreatment technologies. Curr Opin Biotechnol 20:339–347

Gámez S, González-Cabriales JJ, Ramírez JA, Garrote G, Vázquez M (2006) Study of the hydrolysis of sugar cane bagasse using phosphoric acid. J Food Eng 74:78–88

García-Cubero MT, González-Benito G, Indacoechea I, Coca M, Bolado S (2009) Effect of ozonolysis pretreatment on enzymatic digestibility of wheat and rye straw. Bioresour Technol 100:1608–1613

Geddes CC, Nieves IU, Ingram LO (2011) Advances in ethanol production. Curr Opin Biotechnol 22:312–319

Geng A, Xin F, Ip JY (2012) Ethanol production from horticultural waste treated by a modified organosolv method. Bioresour Technol 104:715–721

Hamelinck CN, van Hooijdonk G, Faaij APC (2005) Ethanol from lignocellulosic biomass: techno-economic performance in short-, middle- and long-term. Biomass Bioenergy 28:384–410

Hernández-Salas JM, Villa-Ramírez MS, Veloz-Rendón JS, Rivera-Hernández KN, González-César RA, Plascencia-Espinosa MA, Trejo-Estrada SR (2009) Comparative hydrolysis and fermentation of sugarcane and agave bagasse. Bioresour Technol 100:1238–1245

Hideno A, Kawashima A, Endo T, Honda K, Morita M (2013) Ethanol-based organosolv treatment with trace hydrochloric acid improves the enzymatic digestibility of Japanese cypress (Chamaecyparis obtusa) by exposing nanofibers on the surface. Bioresour Technol 18:64–70

Hon DNS, Shiraishi N (2001) Wood and cellulosic chemistry, 2nd edn. Dekker, New York

Hu ZH, Wen ZY (2008) Enhancing enzymatic digestibility of switchgrass by microwave-assisted alkali pretreatment. Biochem Eng J 38:369–378

Ishizawa CI, Davis MF, Schell DF, Johnson DK (2007) Porosity and its effect on the digestibility of dilute sulfuric acid pretreated corn stover. J Agric Food Chem 55:2575–2581

Jeoh T, Johnson DK, Adney WS, Himmel ME (2005) Measuring cellulase accessibility of dilute-acid pretreated corn stover. Prepr Symp Am Chem Soc Div Fuel Chem 50(2):673–674

Joglekar HG, Rahman I, Kulkarni BD (2007) The path ahead for ionic liquids. Chem Eng Technol 30:819–828

Karimi K, Shafiei M, Kumar R (2013) Progress in physical and chemical pretreatment of lignocellulosic biomass. In: Gupta VK, Tuohy MG (eds) Biofuel technologies. Springer, Berlin Heidelberg, pp 53–96

Karunanithy C, Muthukumarappan K, Julson JL (2008) Influence of high shear bioreactor parameters on carbohydrate release from different biomasses. American Society of Agricultural and Biological Engineers Annual International Meeting 2008. St. Joseph, Mich

Kim S, Holtzapple MT (2006) Delignification kinetics of corn stover in lime pretreatment. Bioresour Technol 97:778–785

Kim KH, Hong J (2001) Supercritical CO2 pretreatment of lignocellulose enhances enzymatic cellulose hydrolysis. Bioresour Technol 77:139–144

Kim TH, Taylor F, Hicks KB (2008) Bioethanol production from barley hull using SAA (soaking in aqueous ammonia) pretreatment. Bioresour Technol 99:5694–5702

Kim JW, Kim KS, Lee JS, Park SM, Cho HY, Park JC, Kim JS (2011) Two-stage pretreatment of rice straw using aqueous ammonia and dilute acid. Bioresour Technol 102:8992–8999

Kumar R, Wyman CE (2009a) Effects of cellulase and xylanase enzymes on the deconstruction of solids from pretreatment of poplar by leading technologies. Biotechnol Prog 25:302–314

Kumar R, Wyman CE (2009b) Does change in accessibility with conversion depend on both the substrate and pretreatment technology. Bioresour Technol 100:4193–4202

Kumar L, Saddler JN, Arantes V, Chandra R (2012) The lignin present in steam pretreated softwood binds enzymes and limites cellulose accessibility. Bioresour Technol 103:201–208

Laser M, Schulman D, Allen SG, Lichwa J, Antal MJ, Lynd LR (2002) A comparison of liquid hot water and steam pretreatments of sugar cane bagasse for conversion to ethanol. Bioresour Technol 81:33–44

Laureano-Pérez L, Teymouri F, Alizadeh H, Dale BE (2005) Understanding factors that limit enzymatic hydrolysis of biomass. Appl Biochem Biotechnol 121:1081–1099

Lee J, Jeffries TW (2011) Efficiencies of acid catalysts in the hydrolysis of lignocellulosic biomass over a range of combined severity factors. Bioresour Technol 102:5884–5890

Lee SH, Doherty TV, Linhardt RJ, Dordick JS (2009) Ionic liquid-mediated selective extraction of lignin from wood leading to enhanced enzymatic cellulose hydrolysis. Biotechnol Bioeng 102:1368–1376

Lee J, Houtman CJ, Kim H, Choi I, Jeffries TW (2011) Scale-up study of oxalic acid pretreatment of agricultural lignocellulosic biomass for the production of bioethanol. Bioresour Technol 102:7451–7456

Liu C, Wyman CE (2003) The effect of flow rate of compressed hot water on xylan, lignin, and total mass removal from corn stover. Ind Eng Chem Res 42:5409–5416

Lu X, Xi B, Zhang Y, Angelidaki I (2011) Microwave pretreatment of rape straw for bio-ethanol production: focus on energy efficiency. Bioresour Technol 102:7937–7940

Martins S, Teixeira JA, Mussatto SI (2013) Solid-State fermentation as a strategy to improve the bioactive compounds recovery from Larrea tridentata leaves. Appl Biochem Biotechnol 171:1227–1239

Maurya DP, Singh D, Pratap D, Maurya JP (2012) Optimization of solid state fermentation conditions for the production of cellulase by Trichoderma reesei NCIM 992. J Environ Biol 33:3–8

Maurya DP, Vats S, Rai S, Negi S (2013) Optimization of enzymatic saccharification of microwave pretreated sugarcane tops through response surface methodology for biofuel. Indian J Exp Biol 51:992–996

Miura T, Lee SH, Inoue S, Endo T (2012) Combined pretreatment using ozonolysis and wet-disk milling to improve enzymatic saccharification of Japanese cedar. Bioresour Technol 126:182–186

Mosier N, Wyman C, Dale B, Elander R, Lee YY, Holtzapple M, Ladisch M (2005) Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour Technol 96:673–686

Nomanbhay SM, Hussain R, Palanisamy K (2013) Microwave assisted enzymatic saccharification of oil palm empty fruit bunch fiber for enhanced fermentable sugar yield. J Sustain Bioenergy Syst 3:7–17

Oliva JM, Sáez F, Ballesteros I, Gónzalez A, Negro MJ, Manzanares P, Ballesteros M (2003) Effect of lignocellulosic degradation compounds from steam explosion pretreatment on ethanol fermentation by thermotolerant yeast Kluyveromyces marxianus. Appl Microbiol Biotechnol 105:141–154

Palonen H (2004) Role of lignin in the enzymatic hydrolysis of lignocellulose. VTT Pub 520:1–80

Pan X, Xie D, Gilkes N, Gregg DJ, Saddler JN (2005) Strategies to enhance the enzymatic hydrolysis of pretreated softwood with high residual lignin content. Appl Biochem0 Biotechnol- Part A Enz Eng. Biotechnol 124:1069–1079

Pérez JA, Ballesteros I, Ballesteros M, Sáez F, Negro MJ, Manzanares P (2008) Optimizing liquid hot water pretreatment conditions to enhance sugar recovery from wheat straw for fuel-ethanol production. Fuel 87:3640–3647

Pinto PA, Dias AA, Fraga I, Marques G, Rodrigues MA, Colaco J, Sampaio A, Bezerra RM (2012) Influence of ligninolytic enzymes on straw saccharification during fungal pretreatment. Bioresour Technol 111:261–267

Potumarthi R, Baadhe RR, Nayak P, Jetty A (2013) Simultaneous pretreatment and sacchariffication of rice husk by Phanerochete chrysosporium for improved production of reducing sugars. Bioresour Technol 128:113–117

Quievy N, Jacquet N, Sclavons M, Deroanne C, Paquot M, Devaux J (2009) Influence of homogenization and drying on the thermal stability of microfibril-lated cellulose. Poly Degrad Stabil 95:306–314

Rodriguez-Chong A, Ramirez JA, Garrote G, Vazquez M (2004) Hydrolysis of sugarcane bagasse using nitric acid: a kinetic assessment. J Food Eng 61:143–152

Saha BC, Cotta MA (2007) Enzymatic saccharification and fermentation of alkaline peroxide pretreated rice hulls to ethanol. Enzyme Microb Tech 41:528–532

Saini JK, Saini R, Tewari L (2014) Lignocellulosic agriculture wastes as biomass feedstocks for second-generation bioethanol production: concepts and recent developments. 3 Biotech. doi 10.1007/s13205-014-0246-5 (in press)

Sánchez ÓJ, Cardona CA (2008) Trends in biotechnological production of fuel ethanol from different feedstocks. Bioresour Technol 99:5270–5295

Saritha M, Arora A, Lata (2012) Biological pretreatment of lignocellulosic substrates for enhanced delignification and enzymatic digestibility. Indian J Microbiol 52:122–130

Sarkanen KV (1980) Acid-catalyzed delignification of lignocellulosics in organic solvents. Prog Biomass Convers 2:127–144

Sathitsuksanoh N, Zhu Z, Zhang YHP (2012) Cellulose solvent-based pretreatment for corn stover and avicel: concentrated phosphoric acid versus ionic liquid [BMIM]Cl. Cellulose 19:1161–1172

Schacht C, Zetzl C, Brunner G (2008) From plant materials to ethanol by means of supercritical fluid technology. J Supercrit Fluids 46:299–321

Schmidt A, Thomsen A (1998) Optimization of wet oxidation pretreatment of wheat straw. Bioresour Technol 64:139–151

Sendich E, Laser M, Kim S, Alizadeh H, Laureano-Perez L, Dale B, Lynd L (2008) Recent process improvements for the ammonia fiber expansion (AFEX) process and resulting reductions in minimum ethanol selling price. Bioresour Technol 99:8429–8435

Shafizadeh F, Bradbury AGW (1979) Thermal degradation of cellulose in air and nitrogen at low temperatures. J Appl Poly Sci 23:1431–1442

Shao Q, Chundawat SP, Krishnan C, Bals B, da Sousa LC, Thelen KD, Dale BE, Balan V (2010) Enzymatic digestibility and ethanol fermentability of AFEX-treated starch-rich lignocellulosics such as corn silage and whole corn plant. Biotechnol Biofuels 9:3–12

Shi J, Chinn MS, Sharma-Shivappa RR (2008) Microbial pretreatment of cotton stalks by solid state cultivation of Phanerochaete chrysosporium. Bioresour Technol 99:6556–6564

Shi J, Gladden JM, Sathitsuksanoh N, Kambam P, Sandoval L, Mitra D, Zhang S, George A, Singer SW, Simmons BA, Singh S (2013) One-pot ionic liquid pretreatment and saccharification of switchgrass. Green Chem 15:2579–2589

Sindhu R, Kuttiraja M, Binod P, Janu KU, Sukumaran RK, Pandey A (2011) Dilute acid pretreatment and enzymatic saccharification of sugarcane tops for bioethanol production. Bioresour Technol 102:10915–10921

Singh J, Suhag M, Dhaka A (2015) Augmented digestion of lignocellulose by steam explosion, acid and alkaline pretreatment methods: a review. Carbohyd Poly 117:624–631

Singla A, Inubushi K (2014) Effect of biochar on CH4 and N2O emission from soils vegetated with paddy. Paddy Water Environ 12:239–243

Singla A, Paroda S, Dhamija SS (2011) Isolation and evaluation of xylose-utilizing yeasts for ethanol production. Environ Ecol 29:1071–7075

Singla A, Paroda S, Dhamija SS, Goyal S, Shekhawat K, Amachi S, Inubushi K (2012) Bioethanol production from xylose: problems and possibilities. J Biofuels 3:39–49

Singla A, Dubey SK, Iwasa H, Inubushi K (2013) Nitrous oxide flux from komatsuna (Brassica rapa) vegetated soil: a comparison between biogas digested liquid and chemical fertilizer. Biol Fertil Soils 49:971–976

Singla A, Iwasa H, Inubushi K (2014a) Effect of biogas digested slurry based-biochar and digested liquid on N2O, CO2 flux and crop yield for three continuous cropping cycles of komatsuna (Brassica rapa var. perviridis). Biol Fertil Soils 50:1201–1209

Singla A, Dubey SK, Singh A, Inubushi K (2014b) Effect of biogas digested slurry-based biochar on methane flux and methanogenic archaeal diversity in paddy soil. Agric Ecosyst Environ 197:278–287

Sun F, Chen H (2008) Organosolv pretreatment by crude glycerol from oleochemicals industry for enzymatic hydrolysis of wheat straw. Bioresour Technol 99:5474–5479

Sun Y, Cheng J (2002) Hydrolysis of lignocellulosic materials for ethanol production: a review. Bioresour Technol 83:1–11

Sun RC, Lawther JM, Banks WB (1995) Influence of alkaline pretreatments on the cell-wall components of wheat-straw. Indus Crops Products 4:127–145

Szijarto N, Kadar Z, Varga E, Thomsen AB, Costa-Ferreira M, Reczey K (2009) Pretreatment of reed by wet oxidation and subsequent utilization of the pretreated fibers for ethanol production. Appl Biochem Biotechnol 155:386–396

Taherzadeh MJ, Karimi K (2008) Pretreatment of lignocellulosic wastes to improve ethanol and biogas production: a review. Int J Mol Sci 9:1621–1651

Taherzsadeh MJ, Karimi K (2007) Enzymatic-based hydrolysis processes for ethanol from lignocellulosic materials: a review. Bioresources 2:707–738

Tang J, Chen K, Huang F, Xu J, Li J (2013) Characterization of the pretreatment liquor of biomass from the perennial grass, Eulaliopsis binata, for the production of dissolving pulp. Bioresour Technol 129:548–552

Teymouri F, Laureano-Pérez L, Alizadeh H, Dale BE (2005) Optimization of the ammonia fiber explosion (AFEX) treatment parameters for enzymatic hydrolysis of corn stover. Bioresour Technol 96:2014–2018

Uppugundla N, da Costa SL, Chundawat S, Yu X, Simmons B, Singh S, Gao X, Kumar R, Wyman C, Dale B, Balan V (2014) A comparative study of ethanol production using dilute acid, ionic liquid and AFEXTM pretreated corn stover. Biotechnol Biofuels 7:72

Varga E, Klinke HB, Reczey K, Thomsen AB (2004) High solid simultaneous saccharification and fermentation of wet oxidized corn stover to ethanol. Biotechnol Bioeng 88:567–574

Vats S, Maurya DP, Shaimoon M, Agarwal A, Negi S (2013) Development of a microbial consortium for the production of blend enzymes for the hydrolysis of agricultural waste into sugars. J Sci Ind Res 72:585–590

Vidal PF, Molinier J (1988) Ozonolysis of lignin-Improvement of in vitro digestibility of poplar sawdust. Biomass 16:1–17

Wan C, Li Y (2012) Fungal pretreatment of lignocellulosic biomass. Biotechnol Adv 30:1447–1457

Wang M, Saricks C, Santini D (1999) Effects of fuel ethanol use on fuel-cycle energy and greenhouse gas emissions. Illinois

Wyman CE, Hinman ND (1990) Ethanol fundamentals of production from renewable feedstocks and use as a transportation fuel. Appl Biochem Biotechnol 24(25):735–753

Wyman CE, Dale BE, Elander RT, Holtzapple M, Ladisch MR, Lee YY (2005) Coordinated development of leading biomass pretreatment technologies. Bioresour Technol 96:1959–1966

Xu J, Chen H, Ka´da´r Z, Thomsen AB, Schmidt JE, Peng H (2011) Optimization of microwave pretreatment on wheat straw for ethanol production. Biomass Bioenergy 35:385–386

Yang B, Wyman CE (2004) Effect of xylan and lignin removal by batch and flowthrough pretreatment on the enzymatic digestibility of corn stover cellulose. Biotechnol Bioeng 86:88–95

Yang B, Wyman CE (2008) Pretreatment: the key to unlocking low cost cellulosic ethanol. Biofuels Bioprod Bioref 2:26–40

Zhao H, Jones CL, Baker GA, Xia S, Olubajo O, Person VN (2009a) Regenerating cellulose from ionic liquids for an accelerated enzymatic hydrolysis. J Biotechnol 139:47–54

Zhao X, Cheng K, Liu D (2009b) Organosolv pretreatment of lignocellulosic biomass for enzymatic hydrolysis. Appl Microbiol Biotechnol 82:815–827

Zheng Y, Lin HM, Tsao GT (1998) Pretreatment for cellulose hydrolysis by carbon dioxide explosion. Biotechnol Prog 14:890–896

Zheng J, Choo K, Bradt C, Lehoux R, Rehmann L (2014) Enzymatic hydrolysis of steam exploded corncob residues after pretreatment in a twin-screw extruder. Biotechnol Rep 3:99–107

Zhu JY, Pan XJ (2010) Woody biomass pretreatment for cellulosic ethanol production: technology and energy consumption evaluation. Bioresour Technol 101:4992–5002

Zhu S, Wu Y, Yu Z, Wang C, Yu F, Jin S, Ding Y, Chi R, Liao J, Zhang Y (2006) Comparison of three microwave/chemical pretreatment processes for enzymatic hydrolysis of rice straw. Biosyst Eng 93:279–283

Acknowledgments

The first author is thankful to Department of Biotechnology, MNNIT, Allahabad.

Conflict of Interest

All the authors declare that they have no conflict of interest in the publication.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Maurya, D.P., Singla, A. & Negi, S. An overview of key pretreatment processes for biological conversion of lignocellulosic biomass to bioethanol. 3 Biotech 5, 597–609 (2015). https://doi.org/10.1007/s13205-015-0279-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13205-015-0279-4