Abstract

Building materials are constantly improved with various additives and admixtures in order to achieve goals ranging from obtaining increased durability or antimicrobial activity up to reducing the carbon footprint left by the cement production. Since nanomaterials were proposed for cement products, many studies explored the possibilities for their incorporation. One of the novel trends in studying these materials is evaluating their impact on living organisms, with the focus not only on toxicology but also on the application potential. Therefore, in this study, we investigated the effects of three types of calcium–silicate–hydrate (C–S–H) seeds on reference microorganisms in the scope of their basic physiology and primary metabolism. Shape, size and elemental composition of C–S–H seeds were also evaluated. The tests on the reference microorganisms have shown that the reaction to these nanomaterials can be specific and depends on the strain as well as the type of used nanomaterial. Furthermore, the presence of C–S–H seeds in the growth environment led to metabolic stimulation that resulted in faster growth, higher biochemical activity, and increased biofilm formation. Based on our findings, we conclude that even though C–S–H seeds have antimicrobial potential, they can be potentially used to promote the growth of selected microbial strains. This phenomenon could be further investigated towards the formation of beneficial biofilms on building materials.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The role of cement production in CO2 exhaustion has long been recognized and efforts were made to reduce the carbon footprint of this quickly expanding branch of industry (VDZ 2015). Since 1950 cement production increased from approximately 500 to almost 5000 Mt per year in 2017, China alone contributes 2250 Mt/year and the trend is rising (Miller et al. 2018). Since the most significant contribution originates from the burning of the raw materials, a reduction of the clinker share in cement and concretes is currently a widely spread technique to reduce the environmental impact of concrete. Nevertheless, reduced clinker content results in a reduced hydration activity, particularly at an early age, which restricts this approach to applications that do not require high early strengths (Land and Stephan 2015). In order to facilitate the clinker reduction for precast industry or ready-mix concrete, additives can be used to overcome the low hydration activity. Conventional hydration accelerators share some disadvantages. Calcium salts such as chlorides enhance the corrosiveness, whereas others, for example, sodium nitrate, compromise the long-term strength. Furthermore, most organic additives raise environmental concerns (Bost et al. 2016). Therefore, in recent years, various methods for accelerating the cement hydration process were sought with particular interest set on the incorporation of nanomaterials. Calcium silicate hydrate (C–S–H), silica (SiO2) and alumina (Al2O3) nanoparticles can be distinguished among the most popular cement hydration accelerators (Singh et al. 2011; John et al. 2019; Krivenko et al. 2019; Sikora et al. 2019; Skoczylas and Rucińska 2019; Szymanowski and Sadowski 2019; Zhan et al. 2019; Sanytsky et al. 2020).

The main clinker phase of ordinary Portland cement accountable for structure development is tricalcium silicate which main hydration product is calcium silicate hydrate (C–S–H, C—CaO, S—SiO2, H—H2O, according to construction chemistry nomenclature). Mature cement stone consists of approximately 80 wt% C–S–H phases which make them the most abundant synthetic material on earth. The acceleration of cement hydration with synthetic C–S–H seeds was mentioned in the 1960s, although during the past 10 years it has gained widespread attention because they overcome all the before mentioned drawbacks and show great potential in accelerating the early strength of blended cement (Schunack 1969; John et al. 2019). The artificially added C–S–H crystals are supposed to accelerate the silicate reaction by providing an almost ideal template for hydration products to grow in the pore spaces which directs the structure development away from the surface of the clinker and results in the formation of a denser microstructure. The impact of C–S–H seeds onto the hydration and strength development of concrete, cement, and C3S has been previously reviewed (Nicoleau 2011; John et al. 2018).

Even though the incorporation of nanosized materials such as C–S–H, silica nanoparticles, carbon nanotubes, titanium dioxide, and others has been widely studied in the literature of the last two decades (Spinazzè et al. 2016; Bossa et al. 2017; Diamond et al. 2017; Miller et al. 2017), still, there are strong concerns regarding the handling and safety of using nanosized admixtures during cement-based composites production, as well as during the demolition works (Lee et al. 2010; Van Broekhuizen et al. 2011; Jones et al. 2016; Strokova et al. 2018; Torres-Carrasco et al. 2019). There are many factors affecting the potentially hazardous effects of nanomaterials arising from their size, shape, chemical composition, the tendency to agglomerate, solubility, surface area and charge (Nawrotek and Augustyniak 2015; Miller et al. 2017; Augustyniak et al. 2019). While the toxicity of nanoparticles has been proven by many studies in laboratory conditions (Aruguete et al. 2013; Mosselhy et al. 2017; Díez-Pascual 2018), their toxicity under the mass production of cementitious composites may vary due to the fact that most of the nanosized admixtures are not stabilized in a working aqueous suspension. In addition, the full dispersion of nanoparticles in aqueous solution is also hindered due to the limited amount of water that is used for the composite production (Sikora et al. 2018).

While nanosized C–S–H nanoparticles are already available on the market, it is imperative to evaluate their potential effects on human health in order to evaluate the risk assessment and provide proper handling techniques to satisfy the safety of workers as well as environment during occasional release and emergency situations. Therefore, all materials should be studied in order to fully explore their versatility in various applications, such as fluorimetric determination of ions, catalytic activity in dyes degradation, or biocidal activity against cancer cells (Bandi et al. 2020; Alle et al. 2020a, b). In vivo study on the effects of C–S–H inhalation by rats that were led for 5 days followed by the 21-day recovery period showed the low toxicity of a commercial C–S–H product with no test-related change in bronchoalveolar lavage (Bräu et al. 2012). Besides, a minimal to a mild increase in alveolar macrophages in the lungs of rats was reported. However, this value dropped to the control level after 21 days of recovery. Based on a search in Scopus database, there is a lack of literature on the activity of C–S–H seeds on reference microorganisms. These small life forms are interacting with cementitious composite often leading to their deterioration (Kong et al. 2017). However, in some cases, microbial activity may be used for crack healing or the biocementation process in order to produce new composites (Abo-El-Enein et al. 2019). In that scope, there is a necessity to investigate whether various admixtures such as C–S–H seeds have an inhibitory or rather stimulative effect on microorganisms. In further perspective, it could lead to the development of novel materials used to affect the biological growth on the surfaces in the desired way (Nielsen 2017). Therefore, there is the strong research need to understand the role of nanoparticles and their safety-related issues in the construction industry as concrete is the most man-made produced material around the world, and thus the exposure to this material is inevitable. Microorganisms are the first organisms to make contact with these structures; therefore, it is advised to study all nanomaterials on microbiological models (Holden et al. 2014). In this study, we aimed at characterizing the effects of three types of nanosized C–S–H phases on the selected physiological characteristics of reference microorganisms.

Materials and methods

Materials

In this study, three types of C–S–H phases were used: one synthesized in the laboratory designated as CSH-S and two commercial products marked as CSH-C1 and CSH-C2. Both these materials were prepared by coprecipitation of water-soluble Ca and Si compounds in the presence of water-soluble comb-polymer (superplasticizer). Both commercial products had pH around 12 and were stabilised by polycarboxylate (PCE). One of them (in this study designated as CSH-C2) was nitrate-free.

Five reference strains were used for microbiological studies including four bacteria: Escherichia coli ATCC® 8739™, Staphylococcus aureus ATCC® 25923™ (for growth kinetics), Staphylococcus aureus ATCC® 6538™ (for biofilm formation), Pseudomonas aeruginosa ATCC® 27583™ and a yeast: Candida albicans ATCC® 10231™. These microorganisms were selected because they are commonly used in microbiological analyses of various materials.

Synthesis and characterisation of C–S–H

For the pozzolanic synthesis of C–S–H seeds the starting materials were mixed in the desired molar calcium to silicon (Ca/Si = 1) and water to solid ratio (w/s = 10). The suspension was transferred into plastic bottles and kept under constant mixing in a shaker for 7 days. Before the application, the dry mass of the C–S–H was determined, and the water content adjusted. The product was not dried, in order to avoid aggregation.

The morphology of the C–S–H samples was analysed with a transmission electron microscope (TEM, Tecnai G2 F20 S-TWIN, FEI) with the accelerating voltage of 200 kV. TEM was also equipped with the X-ray energy dispersive spectroscopy (EDS) for elemental analysis. The samples for TEM and EDS were suspended in acetone and evaporated at 50 ℃ on the TEM grid with a lacey carbon film. Gatan Digital Micrograph software was used for the analysis of TEM images that included the measurements of size and thickness of studied nanoparticles.

Preparation of C–S–H seeds for microbiological studies

The stock suspensions of C–S–H seeds (10% w/v) were diluted to make the 2% working solution. Afterwards, the solution was vortexed for 10 s and dispersed in a water bath sonicator (Digital Pro PS-20A, 40 Hz) for 30 min. Subsequently, samples were further diluted with deionized water or tryptone soy broth (depending on the test) in order to reach final concentrations of 1%, 0.5%, 0.25%, and 0.125%. Samples containing 1% of C–S–H seeds were treated as the main test concentration because this is the typical concentration that can be used for the preparation of cement-based composites. Remaining concentrations were used in acute and chronic toxicity tests that are described below. Every single experiment was conducted from the same nanomaterial suspension, whereas a new suspension was prepared for each of the three repetitions of the experiments.

Growth kinetics curves

Overnight cultures of studied strains were inoculated in ratio 1:200 to fresh tryptone soya broth (TSB) liquid medium containing C–S–H seeds (1% w/v) or ultrapure water in the control sample. Cultures were led at 30 ℃ for P. aeruginosa and 37 ℃ for remaining microorganisms in Biotek H1 (BioTek Instruments, Winooski, VT, USA) spectrophotometer set for the kinetic mode. Optical density (λ = 600 nm) of liquid culture was measured every 30 min for 8–11 h (depending on the microorganism). Because of the high pH of C–S–H seed suspensions, the effect of pH was incorporated into the study as an additional control.

Acute and chronic toxicity

Acute toxicity was recorded according to Ivask et al. (2014). In order to perform the experiment, the overnight culture (16 h) was inoculated to fresh TSB medium and incubated at 30 ℃ until log phase was reached. Afterwards, cultures were centrifuged (10 min at 3500 rpm) and resuspended in ultrapure water. C–S–H suspensions or ultrapure water was added to the samples and they were incubated at room temperature for 4 h without the light access. In the next step, samples were diluted with serial dilutions method and spread (100 µL each) on tryptone soya agar (TSA) plates. Following the overnight incubation at 37 ℃, colonies were counted. In every case, inoculation was executed in three repetitions. Experiments were replicated in order to confirm gained tendencies of results. Additional control was conducted with medium with increased pH corresponding to the pH of C–S–H suspensions.

Chronic toxicity was evaluated in 96-well transparent flat-bottomed polystyrene plates. Overnight cultures were inoculated in the ratio of 1:200 to TSB medium containing C–S–H seeds (1%, 0.5%, 0.25%, and 0.125% w/v). Absorbance (λ = 600 nm) was measured in t = 0 and after 24 h of incubation. Each case was prepared in eight repetitions. Biochemical activity of cells was measured in alamarBlue® assay according to the user’s manual by recording fluorescence of cultures (λex = 520 nm; λem = 590 nm) after 0.5–4 h depending on the microorganism. Both absorbance and fluorescence were measured on BioTek Synergy H1 (BioTek Instruments,Winooski, VT, USA) The controls in this experiment included medium with increased pH, medium with given C–S–H seeds and medium with ultrapure water.

Biofilm formation studies

Biofilm formation was studied in 96-well transparent round-bottomed polystyrene plates. Each sample was prepared in the volume of 150 µL that included 120 µL of fresh TSB medium along with 15 µL of C–S–H seeds’ suspension (or ultrapure water) and 15 µL of the overnight culture of reference microorganisms. Working suspensions were prepared in order to reach C–S–H concentrations of 1%, 0.5%, 0.25% and 0.125% (w/v). Samples were incubated for 24 h at 30 ℃ (P. aeruginosa) or 37 ℃ (remaining microorganisms). Afterwards, plates were rinsed thrice with phosphate-buffered saline (PBS), and wells were filled with fresh TSB medium containing 10% of alamarBlue® reagent. In the next step, plates were incubated at 30 ℃ up to 4 h (depending on the microorganism). Fluorescence (representing the biochemical activity of microorganisms) was measured on BioTek Synergy H1 (BioTek Instruments, Winooski, VT, USA) (λex = 520 nm; λem = 590 nm). In the next stage, plates were rinsed three times with deionized water, and biomass was fixed with methanol for 15 min at ambient temperature. After that time, plates were emptied, air dried, filled with 1% (w/v) solution of filtered crystal violet and stained for 15 min at room temperature. Subsequently, plates were washed with tap water and air-dried. Then, biomass was decolourized with 200 µL of ethanol:acetone (8:2 v/v) solution. In the last stage, 100 µL was mixed by pipetting and transferred to a 96-well flat-bottom plate. The results were recorded by measuring absorbance (λ = 570 nm) on BioTek Synergy H1 (BioTek Instruments, Winooski, VT, USA) microplate reader.

Statistical snalysis

One-way ANOVA was used in the statistical analysis of the results along with Tukey’s post-hoc test, results for which p < 0.05 was considered significant. The assumptions for the ANOVA were checked for each dataset.

Results and discussion

C–S–H chemical and microscopical analysis

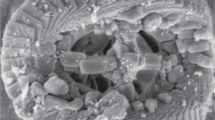

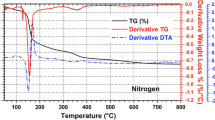

Electron microscopy has been proven to be a useful tool for determining the size of nanoparticles (Bandi et al. 2020; Alle et al. 2020a). Transmission electron microscopy allowed the structure visualisation of the small and thin nanoparticles (Alle et al. 2020b). All C–S–H samples have a flake-like structure as shown in Fig. 1. The CSH-S material consisted of agglomerated flakes, with the mean diameter equal to 5 nm. The CSH-C1 material created complex 2-dimensional agglomerates made from nano-sized flakes with a thickness of 6 nm (Fig. 1e–h). It has been observed that this layered structure had cavity-like defects (depicted in Fig. 2). The last sample (CSH-C2) consisted of small agglomerated nano-sized flakes that were 4 nm thick (Fig. 1i–l). Additional TEM images are presented in the Supplementary Material. Unlike CSH-C1, CSH-C2 was free from the observed defects, although the sample contained also some rods and shapeless particles (Fig. 1j). Depending on the synthesis, C–S–H seeds can form in other shapes. Wang et al. (2019a) have shown that C–S–H material produced with the mechanochemical method can be formed as spheres. On the other hand, the size of obtained particles may differ depending on the stabiliser such as polycarboxylate (PCE) or polysulfonate (PSE) polymers (Wang et al. 2019b). In our study, the CSH-S was not stabilised, while commercial materials were stabilised with PCE.

The chemical composition of the C–S–H phases was analysed with the Energy-dispersive X-ray spectroscopy (EDS) (Fig. 3). Carbon and copper signals that were detected in all samples originated from the used TEM grids. The EDS spectrum of CSH-S contained peaks attributable to carbon, oxygen, silica, copper and calcium (see Fig. 3a). Except of these elements, weak signals at the noise level could be attributed to sulphur, phosphor, chlorine and potassium. However, the signal intensity from oxygen, silica and calcium showed that CSH-S was free from contaminants. The EDS spectrum of CSH-C1 (Fig. 3b) shows the higher intensity of the signal from sulphur, phosphor, chlorine and potassium, and the additional signal from fluoride and sodium. The signals from oxygen, silica and calcium were the most intense which suggest that the sample was mostly composed of the C–S–H phase. Similarly, CSH-C2 was also mainly composed of the C–S–H phase. Except for the elements originating from C–S–H phase additional signals from sodium and sulphur (that possibly originated from the additional particles visible in Fig. 1j) were detected.

Effect of C–S–H on growth kinetic curves

Testing the growth kinetics with selected reference microorganisms showed several effects that are presented in Fig. 4. In general, studied nanomaterials delayed the kinetic growth in the case of all bacteria, although it was not stopped. In the case of C. albicans (Fig. 4d), both commercial materials inhibited the population growth, while CSH-S has allowed the population of this yeast to grow. The fact that this microorganism grew in the presence of the self-made material proves that apart from the high pH in the culture, the type of C–S–H materials can change the microbial response. However, the specific response of selected microorganisms to a stressor can depend also on whether a given bacterium is Gram-positive or Gram-negative. The first group has a thick cell wall with characteristic teichoic acids while the other expresses a thin cell envelope with an additional outer membrane composed of lipopolysaccharide (LPS) (Wang et al. 2019c). In this case, bacteria were generally less susceptible to the nanomaterials than the yeast regardless whether they were Gram-positive or Gram-negative. Similar results were reported in our work on metal oxide nanoparticles, where Al2O nanoparticles inhibited C. albicans more than studied bacteria (Sikora et al. 2018). An interesting effect was observed in the sample containing E. coli and CSH-C1 (Fig. 4a). This nanomaterial was promoting the growth of the bacterium and led to significantly higher biomass yield. In the case of CSH-C2, the obtained OD was not higher than in the control sample, although the shape of the obtained curve suggested that the bacterium entered the later stage growth instead of the plateau (Martínez et al. 2014). Another effect that was recorded during this stage of experiments was the stimulation of agglomeration behaviour in P. aeruginosa in the sample containing the CSH-S material (Fig. 4b). Such behaviour could be associated with the stress response of this bacterium (Gotoh et al. 2010).

Toxicity of C–S–H in acute and chronic test

All microorganisms were negatively affected in the acute toxicity test (Fig. 5). In these experiments, microorganisms were suspended in deionized water without any addition of bacteriological medium. The lowest resistance was recorded in S. aureus that was inhibited by all tested materials and grew only in the control sample. On the other hand, the highest resistance was shown by C. albicans which (taken together with the outcome of the growth kinetic analysis) suggests that tested materials worked as a fungistatic agent rather than fungicidal (Vazquez-Muñoz et al. 2014). The pH of C–S–H materials was on a high level (around ten for each suspended material); therefore, the effect of pH was examined separately. The obtained results showed that the pH was inhibiting studied microorganisms, although the effect was in each case strengthened when C–S–H was included in the sample. Positive results in growth kinetics experiments with these nanomaterials can be explained by the fact that in the suspension of C–S–H materials with the liquid medium, pH was lower (approximately nine). However, suspending nanomaterials in the bacteriological medium could have an impact on the nanomaterial (Boverhof and David 2010).

Figures 6 and 7 present the effect of C–S–H seeds on the population growth (Fig. 6) and its viability (Fig. 7) in the chronic toxicity test. In the highest concentrations, all materials had an inhibitory effect on the populations with certain exceptions described above. Similarly to the kinetic curve, E. coli reached higher OD value in the sample containing CSH-C1 in comparison to the reference. The difference in the case of this experiment was that this phenomenon occurred in the sample with the smallest working concentration of the nanomaterial. However, the viability of the cells was considerably lower, which means that cells could multiply to reach a high OD (as in growth kinetics), but they were inactivated afterwards. In the case of S. aureus, the population reached lower OD than in the control sample (Fig. 6), while in samples containing 0.125% of CSH-C2 and 0.25% of CSH-C1 the viability was significantly higher than recorded for the reference (Fig. 7). The highest resistance to C–S–H seeds was observed in P. aeruginosa where in two lowest concentrations there was a significant increase in OD and viability in comparison to the control sample (Figs. 6, 7). Such stimulation was previously observed in experiments on the effects of metal oxide nanoparticles to these microorganisms (Sikora et al. 2018). Interestingly, C. albicans produced considerably lower OD (Fig. 6) which is an additional proof that a fungistatic process has occurred. However, the biochemical testing revealed that even though the OD was lower, it was not followed by the metabolic activity (Fig. 7). The population was indeed growing slower, although it seems that cells had their metabolic activity up-regulated in the case of all studied C–S–H seeds.

Effect of C–S–H on biofilm formation

The selected reference strains showed the variable reaction to the contact with C–S–H seeds, depending on the used material. In the case of P. aeruginosa there was a tendency to increase the biomass with the increasing concentration of C–S–H seeds with the strongest effect observed for the CSH-S sample. A similar effect was observed on the kinetic growth curve, which suggests that the synthesized material had a higher impact on the formation of microcolonies and the biofilm than commercial C–S–H seeds. The increase in biofilming ability in pseudomonads can be a response to environmental stressors (Gotoh et al. 2010; Rasamiravaka et al. 2015). The increase in biomass was in this case followed by the increase of biochemical activity. On the other hand, the biofilm biomass produced by S. aureus was higher in the sample containing 1% of nanomaterials in comparison to the control sample. However, the metabolic activity of these biofilms was significantly reduced. The weakest inhibition was recorded for CSH-C1 material. The differences in biofilm formation between the two used bacteria can be associated with the characteristics of their biofilm formation. P. aeruginosa forms the most of biomass at the top of polystyrene well, whereas the biofilm formed by S. aureus is located rather at the well bottom (O’Toole 2011; Latimer et al. 2012; Rasamiravaka et al. 2015). Since the C–S–H materials can descend in aqueous suspensions and form higher concentration at the well bottom, it can be assumed that S. aureus cells were more exposed to C–S–H seeds than P. aeruginosa (Fig. 8).

Gained results in scope of applied microbiology and construction chemistry

All studied materials showed antimicrobial activity leading to changes in the studied physiological parameters, although a series of potential stimulation effects were also revealed. Interestingly, in some cases, the response was specific, e.g. in the higher OD obtained in E. coli culture exposed to CSH-C1. As opposed to CSH-S and CSH-C2, this product contained nitrates that boost the growth of E. coli. A similar phenomenon was observed during in mammal gut environment (Tiso and Schechter 2015). The results confirmed that the effect of a given admixture may depend on its structure (that differed under TEM) and/or chemical composition. The chemical variability could be associated with the presence of organic stabiliser (CSH-C1 and CSH-C2), or the absence of nitrates (CSH-C2). Apparently, the lack of stabiliser in the CSH-S possibly affected the formation of microcolonies in tested microorganisms (Fig. 4). This phenomenon can be stimulated by environmental conditions, including stress or chemical signals (such as surfactants) (Gotoh et al. 2010; Yong et al. 2015). Taking these results into account, novel composites could be designed with knowledge on how certain admixtures may influence the microorganisms. Our results have shown that depending on the admixture, it was possible to pose more antimicrobial effect or rather stimulative. Recently, there is more and more data showing that stressors (such as nanomaterials) can stimulate certain microorganisms and up-regulate their metabolism (Maurer-Jones et al. 2013; Augustyniak et al. 2016; Lemire et al. 2017). Thus, changing admixtures could modify the selective pressure on microorganisms that may be beneficial for the composite (Sarjit et al. 2015). One of the challenges in propagating beneficial biofilms is their viability on the surface. Microorganisms are susceptible to changing environment; therefore, the efficient stimulants should be sought in order to achieve a successful (and beneficial) colonisation (Soleimani et al. 2013; Huang et al. 2019). This research was executed with reference strains that are frequently applied as models in microbiological studies (Sikora et al. 2018). We have chosen reference microorganisms because this manuscript may be the first (in the Scopus database) to associate microbiological studies with C–S–H products. Furthermore, based on the differences in the physiology of various microorganisms, we decided that our group should contain both Gram-positive and Gram-negative bacteria as well as yeast. In order to further investigate described effects on environmental strains, there is a need to follow this research with experiments on bacteria and yeasts that naturally occur on building materials, e.g. urease-positive Bacillus or Sporosarcina strains that are capable of biocementation process (Kashyap and Radhakrishna 2013; Abo-El-Enein et al. 2019).

Conclusions

C–S–H seeds can have an inhibitory effect on reference microorganisms. However, the reaction depends on the strain and the concentration of the nanomaterial as well as its type. In some cases, these nanomaterials can lead to the stimulation in growth or metabolic activity in microorganisms. The observed differences between C–S–H products could have been induced by differences in the chemical composition (one of them does not contain nitrates, and the commercial ones were PCE stabilised). Observed differences could be potentially used for the design of functional composites that can pose a selective pressure on selected microorganisms. In further perspective, such interactions could be also used to propagate a functional biofilm that would protect the composite or give it other beneficial properties. In order to achieve this goal, further studies are needed that would focus on microorganisms that have an impact on building materials.

References

Abo-El-Enein SA, Ali AH, Talkhan FN, Abdel-Gawwad HA (2019) Application of microbial biocementation to improve the physico-mechanical properties of cement mortar. HBRC J 9:36–40. https://doi.org/10.1016/j.hbrcj.2012.10.004

Alle M, Reddy GB, Kim TH et al (2020a) Doxorubicin-carboxymethyl xanthan gum capped gold nanoparticles: microwave synthesis, characterization, and anti-cancer activity. Carbohydr Polym 229:115511. https://doi.org/10.1016/j.carbpol.2019.115511

Alle M, Lee SH, Kim JC (2020b) Ultrafast synthesis of gold nanoparticles on cellulose nanocrystals via microwave irradiation and their dyes-degradation catalytic activity. J Mater Sci Technol 41:168–177. https://doi.org/10.1016/j.jmst.2019.11.003

Aruguete DM, Kim B, Hochella MF et al (2013) Antimicrobial nanotechnology: its potential for the effective management of microbial drug resistance and implications for research needs in microbial nanotoxicology. Environ Sci Process Impacts 15:93–102. https://doi.org/10.1039/c2em30692a

Augustyniak A, Cendrowski K, Nawrotek P et al (2016) Investigating the interaction between Streptomyces sp. and titania/silica nanospheres. Water Air Soil Pollut 227:230. https://doi.org/10.1007/s11270-016-2922-z

Augustyniak A, Sikora P, Cendrowski K et al (2019) Challenges in studying the incorporation of nanomaterials to building materials on microbiological models. In: Fesenko O, Yatsenko L (eds) Nanophotonics, nanooptics, nanobiotechnology, and their applications. Springer Nature, Basel, pp 285–303

Bandi R, Dadigala R, Gangapuram BR et al (2020) N-Doped carbon dots with pH-sensitive emission, and their application to simultaneous fluorometric determination of iron(III) and copper(II). Microchim Acta 187:1–10. https://doi.org/10.1007/s00604-019-4017-1

Bossa N, Chaurand P, Levard C et al (2017) Environmental exposure to TiO2 nanomaterials incorporated in building material. Environ Pollut 220:1160–1170. https://doi.org/10.1016/j.envpol.2016.11.019

Bost P, Regnier M, Horgnies M (2016) Comparison of the accelerating effect of various additions on the early hydration of Portland cement. Constr Build Mater 113:290–296. https://doi.org/10.1016/j.conbuildmat.2016.03.052

Boverhof DR, David RM (2010) Nanomaterial characterization: considerations and needs for hazard assessment and safety evaluation. Anal Bioanal Chem 396:953–961. https://doi.org/10.1007/s00216-009-3103-3

Bräu M, Ma-Hock L, Hesse C et al (2012) Nanostructured calcium silicate hydrate seeds accelerate concrete hardening: a combined assessment of benefits and risks. Arch Toxicol 86:1077–1087. https://doi.org/10.1007/s00204-012-0839-x

Van Broekhuizen P, Van Broekhuizen F, Cornelissen R, Reijnders L (2011) Use of nanomaterials in the European construction industry and some occupational health aspects thereof. J Nanoparticle Res 13:447–462. https://doi.org/10.1007/s11051-010-0195-9

Diamond SA, Kennedy AJ, Melby NL et al (2017) Assessment of the potential hazard of nano-scale TiO2 in photocatalytic cement: application of a tiered assessment framework. NanoImpact 8:11–19. https://doi.org/10.1016/j.impact.2017.06.006

Díez-Pascual AM (2018) Antibacterial activity of nanomaterials. Nanomaterials 8:6–11. https://doi.org/10.3390/nano8060359

Gotoh H, Kasaraneni N, Devineni N et al (2010) SOS involvement in stress-inducible biofilm formation. Biofouling 26:603–611. https://doi.org/10.1080/08927014.2010.501895

Holden PA, Schimel JP, Godwin HA (2014) Five reasons to use bacteria when assessing manufactured nanomaterial environmental hazards and fates. Curr Opin Biotechnol 27:73–78. https://doi.org/10.1016/j.copbio.2013.11.008

Huang J, Liu S, Zhang C et al (2019) Programmable and printable Bacillussubtilis biofilms as engineered living materials. Nat Chem Biol 15:34–41. https://doi.org/10.1038/s41589-018-0169-2

Ivask A, Kurvet I, Kasemets K et al (2014) Size-dependent toxicity of silver nanoparticles to bacteria, yeast, algae, crustaceans and mammalian cells in vitro. PLoS ONE 9:1–14. https://doi.org/10.1371/journal.pone.0102108

John E, Matschei T, Stephan D (2018) Nucleation seeding with calcium silicate hydrate—a review. Cem Concr Res 113:74–85

John E, Epping JD, Stephan D (2019) The influence of the chemical and physical properties of C–S–H seeds on their potential to accelerate cement hydration. Constr Build Mater 228:116723. https://doi.org/10.1016/j.conbuildmat.2019.116723

Jones W, Gibb A, Goodier C et al (2016) Nanomaterials in construction—what is being used, and where? Proc Inst Civ Eng Mater. https://doi.org/10.1680/jcoma.16.00011

Kashyap VN, Radhakrishna (2013) A study on effect of bacteria on cement composites. In: International Journal of Research in Engineering and Technology, pp 356–360

Kong L, Zhang B, Fang J (2017) Study on the applicability of bactericides to prevent concrete microbial corrosion. Constr Build Mater 149:1–8. https://doi.org/10.1016/j.conbuildmat.2017.05.108

Krivenko P, Sanytsky M, Kropyvnytska T (2019) The effect of nanosilica on the early strength of alkali-activated portland composite cements. In: Solid State Phenomena. Trans Tech Publications Ltd, pp 21–26

Land G, Stephan DA (2015) The synthesis of C–S–H seeds Methods, variables and their impact on the ability to accelerate cement hydration. In: Conference: 14th International Conference on the chemistry of cement (14th ICCC), Bejing

Latimer J, Forbes S, McBain AJ (2012) Attenuated virulence and biofilm formation in staphylococcus aureus following sublethal exposure to triclosan. Antimicrob Agents Ch 56:3092–3100. https://doi.org/10.1128/AAC.05904-11

Lee J, Mahendra S, Alvarez PJJ (2010) Nanomaterials in the construction industry: a review of their applications and environmental health and safety considerations. ACS Nano 4:3580–3590. https://doi.org/10.1021/nn100866w

Lemire J, Alhasawi A, Appanna VP et al (2017) Metabolic defence against oxidative stress: the road less travelled so far. J Appl Microbiol 123:798–809. https://doi.org/10.1111/jam.13509

Martínez H, Sánchez J, Cruz JM et al (2014) Modeling of scale-dependent bacterial growth by chemical kinetics approach. Sci World J 2014:1–8. https://doi.org/10.1155/2014/820959

Maurer-Jones MA, Gunsolus IL, Meyer BM et al (2013) Impact of TiO2 nanoparticles on growth, biofilm formation, and flavin secretion in Shewanellaoneidensis. Anal Chem 85:5810–5818. https://doi.org/10.1021/ac400486u

Miller HD, Mesgari S, Akbarnezhad A, Foster S (2017) Safety risks associated with carbon nanotube-reinforced mortar. ACI Mater J 114:897–909. https://doi.org/10.14359/51700892

Miller SA, John VM, Pacca SA, Horvath A (2018) Carbon dioxide reduction potential in the global cement industry by 2050. Cem Concr Res 114:115–124. https://doi.org/10.1016/j.cemconres.2017.08.026

Mosselhy D, Granbohm H, Hynönen U et al (2017) Nanosilver-silica composite: prolonged antibacterial effects and bacterial interaction mechanisms for wound dressings. Nanomaterials 7:1–19. https://doi.org/10.3390/nano7090261

Nawrotek P, Augustyniak A (2015) Nanotechnology in microbiology-selected aspects|Nanotechnologia w mikrobiologii-wybrane aspekty. Postep Mikrobiol 54:275–282

Nicoleau L (2011) Accelerated growth of calcium silicate hydrates: experiments and simulations. Cem Concr Res 41:1339–1348. https://doi.org/10.1016/j.cemconres.2011.04.012

Nielsen J (2017) Systems biology of metabolism. Annu Rev Biochem 86:245–275. https://doi.org/10.1146/annurev-biochem-061516-044757

O’Toole GA (2011) Microtiter dish biofilm formation assay. JoVE 47:1–2. https://doi.org/10.3791/2437

Rasamiravaka T, Labtani Q, Duez P, El Jaziri M (2015) The formation of biofilms by Pseudomonasaeruginosa: a review of the natural and synthetic compounds interfering with control mechanisms. Biomed Res Int. https://doi.org/10.1155/2015/759348

Sanytsky M, Marushchak U, Olevych Y, Novytskyi Y (2020) Nano-modified ultra-rapid hardening portland cement compositions for high strength concretes. In: Lecture Notes in Civil Engineering. Springer, pp 392–399

Sarjit A, Mei Tan S, Dykes GA (2015) Surface modification of materials to encourage beneficial biofilm formation. AIMS Bioeng 2:404–422. https://doi.org/10.3934/bioeng.2015.4.404

Schunack H (1969) Versuche mit Kristallisation keimen bei der Betonherstellung zur Erreichung hoher Anfangsfestigkeiten. Silikattechnik 7:326–330

Sikora P, Augustyniak A, Cendrowski K et al (2018) Antimicrobial activity of Al2O3, CuO, Fe3O4, and ZnO nanoparticles in scope of their further application in cement-based building materials. Nanomaterials 8:212. https://doi.org/10.3390/nano8040212

Sikora P, Cendrowski K, Abd Elrahman M et al (2019) The effects of seawater on the hydration, microstructure and strength development of Portland cement pastes incorporating colloidal silica. Appl Nanosci. https://doi.org/10.1007/s13204-019-00993-8

Singh LP, Bhattacharyya SK, Mishra G, Ahalawat S (2011) Functional role of cationic surfactant to control the nano size of silica powder. Appl Nanosci 1:117–122. https://doi.org/10.1007/s13204-011-0016-1

Skoczylas K, Rucińska T (2019) The effects of low curing temperature on the properties of cement mortars containing nanosilica. Nanotechnol Constr 11:536–544. https://doi.org/10.15828/2075-8545-2019-11-5-536-544

Soleimani S, Ormeci B, Isgor OB (2013) Evaluation of E. coli biofilm as a protective barrier against microbiologically influenced deterioration of concrete (MICD) under mesophilic temperatures. Water Sci Technol 68:303–310. https://doi.org/10.2166/wst.2013.252

Spinazzè A, Cattaneo A, Limonta M et al (2016) Titanium dioxide nanoparticles: occupational exposure assessment in the photocatalytic paving production. J Nanoparticle Res. https://doi.org/10.1007/s11051-016-3462-6

Strokova V, Nelubova VV, Sivalneva M, Kobzev V (2018) Phytotoxicity analysis of different compositions of nanostructured binder. Key Eng Mater 761:189–192. https://doi.org/10.4028/www.scientific.net/KEM.761.189

Szymanowski J, Sadowski L (2019) The development of nanoalumina-based cement mortars for overlay applications in concrete floors. Materials. https://doi.org/10.3390/ma12213465

Tiso M, Schechter AN (2015) Nitrate reduction to nitrite, nitric oxide and ammonia by gut bacteria under physiological conditions. PLoS ONE. https://doi.org/10.1371/journal.pone.0119712

Torres-Carrasco M, Reinosa JJ, de la Rubia MA et al (2019) Critical aspects in the handling of reactive silica in cementitious materials: effectiveness of rice husk ash vs nano-silica in mortar dosage. Constr Build Mater 223:360–367. https://doi.org/10.1016/j.conbuildmat.2019.07.023

Vazquez-Muñoz R, Avalos-Borja M, Castro-Longoria E (2014) Ultrastructural analysis of candida albicans when exposed to silver nanoparticles. PLoS ONE. https://doi.org/10.1371/journal.pone.0108876

VDZ (2015) Umweltdaten der deutschen Zementindustrie Environmental Data of the German Cement Industry

Wang B, Yao W, Stephan D (2019a) Preparation of calcium silicate hydrate seeds by means of mechanochemical method and its effect on the early hydration of cement. Adv Mech Eng 11:168781401984058. https://doi.org/10.1177/1687814019840586

Wang F, Kong X, Wang D, Wang Q (2019b) The effects of nano-C–S–H with different polymer stabilizers on early cement hydration. J Am Ceram Soc 102:5103–5116. https://doi.org/10.1111/jace.16425

Wang Q, Jones AAD, Gralnick JA et al (2019c) Microfluidic dielectrophoresis illuminates the relationship between microbial cell envelope polarizability and electrochemical activity. Hist da Historiogr 11:1–12. https://doi.org/10.1126/sciadv.aat5664

Yong Y-C, Wu X-Y, Sun J-Z et al (2015) Engineering quorum sensing signaling of Pseudomonas for enhanced wastewater treatment and electricity harvest: a review. Chemosphere 140:18–25. https://doi.org/10.1016/j.chemosphere.2014.10.020

Zhan BJ, Xuan DX, Poon CS (2019) The effect of nanoalumina on early hydration and mechanical properties of cement pastes. Constr Build Mater 202:169–176. https://doi.org/10.1016/j.conbuildmat.2019.01.022

Acknowledgements

Open Access funding provided by Projekt DEAL. This research was funded by the National Science Centre (Poland) within Projects No. 2016/21/N/ST8/00095 (PRELUDIUM 11) and No. 2018/31/N/NZ1/03064 (PRELUDIUM 16). P.S. is supported by the Foundation for Polish Science (FNP). This study was funded by the German Research Foundation (DFG) as part of the Research Training Group on Urban Water Interfaces (GRK 2032) and Project No. STE 1086/15-1.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Augustyniak, A., Sikora, P., Jablonska, J. et al. The effects of calcium–silicate–hydrate (C–S–H) seeds on reference microorganisms. Appl Nanosci 10, 4855–4867 (2020). https://doi.org/10.1007/s13204-020-01347-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-020-01347-5