Abstract

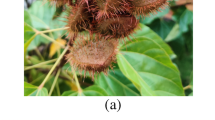

A small, continuous power operated machine with a capacity of 132 kg/h was designed, fabricated and evaluated its performance for separation of annatto (Bixa orellana L.) seeds from freshly harvested pods. Physical and engineering parameters of annatto pods and seeds were evaluated to design a machine. The densities of pod, seed, and husk are 134.7 to 186.0 kg/m3, 1206 to 1253.9 kg/m3, 317 to 381.4 kg/m3 respectively. The moisture content of seeds were in the range 18.83 – 20.1 % (db) and pod 8 to 10 % (db). Bixin content of seed was in the range 1.34 to 1.765 %. The friction angle for pod, seed, and husk lies between angle 30.15° to 35.76°. Breaking force was 98 N at a span of 14.5 mm. The machine consisted of concentric cylinders and beaters with different pitch of 40, 45 and 50 mm and a length of shaft is 800 mm. The actual machine output was observed to be 132.5 kg/h. Maximum bixin content was found to be retained at 300 rpm.

Similar content being viewed by others

Abbreviations

- N sh :

-

Rotational speed of rotor cylinder shaft in rpm

- T:

-

Torque applied, N m

- P:

-

Power, watt

- E1 :

-

Kinetic energy, joule

- Vlin :

-

Linear velocity m s−1

- m1 :

-

Mass of beater in N

- m2 :

-

Mass of annatto pod in N

- δV:

-

Change in velocity after collision, m s−1

- E0 :

-

Energy required to break one pod, joule

- Fmax :

-

Maximum cutting (shear) force, N

- Dpod :

-

Diameter of annatto pod, m

- D in :

-

Inner cylinder, m

- D eff :

-

Effective diameter, m

- g:

-

Gravitational force, 9.81 ms−1

- D sh :

-

Diameter rotor cylinder shaft, m

- K t :

-

Co-efficient of fatigue and shock factor in torsion, 1.5

- k b :

-

Co-efficient of fatigue and shock factor in bending, 2

- M :

-

Bending moment, N m

- τ :

-

Shear stress, N m−2

- Wbtt :

-

Weight of each beater, kg

- L:

-

Length of beater, m

- R2 :

-

Radial distance between centre of rotor shaft to the circumference of inner cylinder, m

- Ym :

-

Deflection at midpoint, m

- W:

-

Total weight, kg

- Wsh :

-

Weight of shaft, kg

- E:

-

Young’s modulus of mild steel, 210 GPa

- L sh :

-

Length of rotor shaft, m

- N c :

-

Critical speed of shaft, rpm

- K:

-

Radius of gyration

- R n :

-

Number of rows

- M:

-

Equivalent mass, kg

- De :

-

Dehulling Efficiency

- μ:

-

Co-efficient of friction

- S e :

-

Specific energy consumption, kj/kg

- W seed :

-

Weight of seed, kg

- W husk :

-

Weight of husk, kg

- W dust :

-

Weight of dust, kg

- W e :

-

Total power consumed by the machine during dehulling, watts

- W o :

-

Power consumed at no load condition, watts

- t :

-

Time in hrs

- t p :

-

Passed time for breaking of one pod, sec

- F :

-

Feed in kg

- S e :

-

Specific energy consumption of machine, kj/kg

- W pod :

-

Total weight of annatto pod processed in machine (Wpod)

- AFBMA:

-

Anti-Friction Bearing Manufacturers Association

- ASME:

-

American Society of Mechanical Engineers

References

Aydin C (2003) Physical properties of almond nuts and kernel. J Food Eng 60:315–320

Encyclopaedia of Spices (2011) The Epicentre.com. Archived from the original on 16 July 2011

Gupta RK, Das SK (1999) Performance of centrifugal dehulling system for sunflower seed. J Food Eng 42:191–198

Güzela E, Akçalib İD, Mutluc H, Incea A (2005) Research on the fatigue behaviour for peanut shelling. J Food Eng 67:373–378

ISI (1966) Indian standard methods for analysis of oil seed, IS: 3579. Indian Standard institute, New Delhi

Khurmi R, Gupta J (2005) A Textbook of Machine Design. Eurasia Publishing House (pvt) Ltd, New Delhi

Mohesenin NN (1970) Physical properties of plant and animal materials. Gorden and Breach Science Publishers, New York

Ojolo SJ, Ogunsina BS (2007) Development of a cashew nut cracking device. Agric Eng Int: CIGR E J IX. Manuscript PM 06 030

Omid G, Khoshtaghaza MH, Ahmad DB (2008) Design and development of special cutting system for sweet sorghum harvester. J Cent Eur Agric 9:469–474

Prabhakara Rao PG, Satyanarayana A, Rao DG (2002) Effect of storage on the stability of water soluble annatto dye formulation in a simulated orange RTS beverage model system. LWT Food Sci Technol 35:617–621

Prabhakara Rao PG, Jyothirmayi T, Balaswamy K, Satyanarayana A, Rao DG (2005) Effect of processing conditions on the stability of annatto (Bixa orellana L.) dye incorporated into some foods. LWT Food Sci Technol 38(7):779–784

Pradhan RC, Naik SN, Bhatnagar N, Vijay VK (2010) Design, development and testing of hand operated decorticator for jatropha fruit. Appl Energy 87(3):762–768

Prabhakara Rao PG, Satyanarayana A, Balaswamy K, Jyothirmayi T, Nagender A, Rao DG (2007) Application of annatto dye formulation in bakery and extruded food products. J Foodserv 18:53–58

Reith JF, Gielen JW (1971) Properties of bixin and norbixin and the composition of annatto extracts. J Foodserv 36:861–864

Riel RR, Gibson CA (1958) Use of annatto for colouring butter. J Dairy Sci 41(5):624–629

Scotter MJ, Wilson AL, Appleton GP, Castle L (1998) Analysis of annatto (Bixa orellana) food colouring formulations. I. Determination of colouring compounds and coloured thermal degradation products by high performance liquid chromatography with photodiode array detection system. J Agric Food Chem 46:1031–1038

Satyanarayana A, Prabhakara Rao PG, Rao DG (2003) Chemistry, processing and toxicology of annatto (Bixa orellana L.). J Food Sci Technol 40(2):131–141

Satyanarayana A, Prabhakara Rao PG, Balaswamy K, Velu V, Rao DG (2006) Application of annatto dye formulations in different fruit and vegetable products. J Foodserv 17:1–5

Satyanarayana A, Prabhakara Rao PG, Rao DG (2010) Influence of source and quality on the colour characteristics of annatto dyes and formulations. LWT Food Sci Technol 43:1456–1460

The Wealth of India (1988) Raw Materials. PID, CSIR, New Delhi, pp 157–160

Acknowledgments

The authors thank the Ministry of Food Processing Industries, New Delhi for the award of a research grant (No. 52/ MFPI/ R&D/2006) to carry out this study. The authors wish to thank Director, CFTRI, and Head, CFTRI Resource centre, Hyderabad for their cooperation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Math, R.G., Ramesh, G., Nagender, A. et al. Design and development of annatto (Bixa orellana L.) seed separator machine. J Food Sci Technol 53, 703–711 (2016). https://doi.org/10.1007/s13197-015-2019-5

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-015-2019-5