Abstract

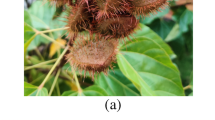

This work aimed to determine the engineering properties of hairless canary seeds (Phalaris canariensis L.) of the variety “CDC Maria” and the optimum combination of operating conditions of the dehulling process with a pilot-scale centrifugal dehuller. The engineering properties analyzed in this study were the principal dimensions, length (4.8 mm), width (1.95 mm) and thickness (1.41 mm); geometric mean diameter (2.36 mm); the sphericity (49.2%); apparent and true densities (752 and 1191.47 kg/m3, respectively); the porosity (0.37); 1000 grains weight (7.28 g); angle of repose (15.89°) and the static coefficient of friction (galvanized steel, 0.325; plywood, 0.372; aluminium, 0.316). For the process optimization, a two-variable Doehlert design was used, analyzing the effect of impact dehuller rotor speed (peripheral speed 30.4 to 47.1 m/s) and seed moisture content (10 to 14% d.b.) by maximizing the dehulling ability (DA) and maintaining the production of fines by 3%. Under the experimental conditions of 36.7 m/s (peripheral speed) and 10% d.b. (seed moisture), with a double pass through the dehuller, the optimum value of DA (94%) was obtained, with a fine production of 3%. The optimized dehulling process allows removing a large percentage (98%) of the canary seed hull.

Similar content being viewed by others

Availability of data and materials

All data generated and analyzed in this study are included in this article.

Code availability

Not applicable.

Abbreviations

- NFE:

-

Nitrogen-free extract

- A.S.T.M:

-

American society for testing and materials

- DA:

-

Dehulling ability

- d.b.:

-

Dry basis

- F:

-

Fines

- MC:

-

Moisture content

- PS:

-

Peripheral speed

- RSM:

-

Response surface methodology

- D:

-

Desirability function

References

Abdel-Aal ESM (2021) Nutritional and functional attributes of hairless canary seed groats and components and their potential as functional ingredients. Trends Food Sci Technol 111:680–687. https://doi.org/10.1016/j.tifs.2021.03.029

Abdel-Aal EM, Hucl PJ, Sosulski FW (1997) Structural and compositional characteristics of canaryseed (Phalaris canariensis L.). J Agric Food Chem 45:3049–3055. https://doi.org/10.1021/jf970100x

Abdel-Aal ESM, Hucl P, Patterson CA, Gray D (2010) Fractionation of hairless canaryseed (Phalaris canariensis L.) into starch, protein and oil. J Agric Food Chem 58:7046–7050. https://doi.org/10.1021/jf100736m

Abdel-Aal E-SM, Hucl P, Patterson CA, Gray D (2011) Phytochemicals and heavy metals content of hairless canary seed: a variety developed for food use. LWT Food Sci Technol 44:904–910. https://doi.org/10.1016/j.lwt.2010.10.019

AOCS (1998) Official methods and recommended practices of the American oil chemists’ society. AOCS Press, Champaign, USA

Bertero J, Durruty MX, de Figueiredo AK, Nolasco SM, Riccobene IC (2016) Evaluación del rendimiento del descascarado de granos de alpiste en una descascaradora centrífuga. Anal Del VI Congreso Int De Ciencia y Tecnol De Alimentos (CICYTAC) 114:118

Chandrasekara A, Shahidi F (2011) Bioactivities and antiradical properties of millet grains and hulls. J Agric Food Chem 59:9563–9571. https://doi.org/10.1021/jf201849d

Chen Z, Yu L, Wang X, Gu Z, Beta T (2016) Changes of phenolic profiles and antioxidant activity in canary seed (Phalaris canariensis L.) during germination. Food Chem 194:608–618. https://doi.org/10.1016/j.foodchem.2015.08.060

Cogliatti M (2014) El cultivo de Alpiste (Phalaris canariensis L.). 1ª ed. Capítulo IV Manejo del Cultivo: 38–54. Universidad Nacional del Centro de la Provincia de Buenos Aires, Tandil, Argentina

de Figueiredo AK, Baümler E, Riccobene IC, Nolasco SM (2011) Moisture dependent engineering properties of sunflower seeds with different structural characteristics. J Food Eng 102(1):58–65. https://doi.org/10.1016/j.jfoodeng.2010.08.003

de Figueiredo AK, Rodríguez LM, Lindström LI, Riccobene IC, Nolasco SM (2013) Performance analysis of a dehulling system for safflower grains. Ind Crops Prod 43:311–317. https://doi.org/10.1016/j.indcrop.2012.07.026

de Figueiredo AK, Rodriguez LM, Fernández MB, Riccobene IC, Nolasco SM (2015) Loss of lipid material during the dehulling of oilseeds with different structural characteristics. J Food Sci Technol 52(12):7934–7943. https://doi.org/10.1007/s13197-015-1910-4

Doehlert DH (1970) Uniform shell designs. J R Stat Soc 19(3):231–239. https://doi.org/10.2307/2346327

Doehlert DC, Wiesenborn DP, McMullen MS, Ohm JB, Riveland NR (2009) Effects of impact dehuller rotor speed on dehulling characteristics of diverse oat genotypes grown in different environments. Cereal Chem 86(6):653–660. https://doi.org/10.1094/CCHEM-86-6-0653

FAO (Food and agriculture organization of the United Nations) 2021. Statistic database online. https://www.fao.org/faostat/es/#data/QCL Accessed on 12th Jul 2023

Grajeda Iglesias C, Carvajal Millán E, Santana Rodríguez VM, Licón Trillo A, Márquez Méndez R (2012) Evaluación del efecto de un tratamiento alcalino sobre las propiedades fisicoquímicas y funcionales de la harina de alpiste (Phalaris canariensis L.). In: Proceedings book (ECITE) 64–75. ISBN: 978–607–95042–9–8

Guiotto EN, Ixtaina VY, Tomás MC, Nolasco SM (2013) Moisture-dependent engineering properties of chia (Salvia Hispanica L.) seeds. Food Indus. https://doi.org/10.5772/53173

Gupta RK, Gas SK (1999) Performance of centrifugal dehulling system for sunflower seeds. J Food Eng 42:191–198. https://doi.org/10.1016/S0260-8774(99)00119-3

IUPAC (1992). Standard methods for the analysis of oils, fats and derivates. In: Paquot C, Hautffenne eds. A international union of pure and applied chemistry. Blackwell Scientific Publications Inc., Oxford

Ixtaina VY, Nolasco SM, Tomás MC (2008) Physical properties of chia (Salvia hispanica L.) seeds. Ind Crops Prod 28(3):286–293. https://doi.org/10.1016/j.indcrop.2008.03.009

Kalkan F, Kara M (2011) Handling, frictional and technological properties of wheat as affected by moisture content and cultivar. Powder Technol 213:116–122. https://doi.org/10.1016/j.powtec.2011.07.015

Kwiatkowski JR, Cheryan M (2002) Extraction of oil from ground corn using ethanol. J Am Oil Chem Soc 79:825–830. https://doi.org/10.1007/s11746-002-0565-8

Li W, Beta T (2012) An evaluation of carotenoid levels and composition of glabrous canaryseed. Food Chem 133:782–786. https://doi.org/10.1016/j.foodchem.2012.01.092

Markowski M, Majewska K, Kwiatkowski D, Małkowski M, Burdyło G (2010) Selected geometric and mechanical properties of barley (Hordeum vulgare L.) grain. Int J Food Prop 13:890–903. https://doi.org/10.1080/10942910902908888

Markowski M, Zuk-Golaszewska K, Kwiatkowski D (2013) Influence of variety on selected physical and mechanical properties of wheat. Ind Crops Prod 47:113–117. https://doi.org/10.1016/j.indcrop.2013.02.024

Mohsenin NN (1986) Physical properties of plant and animal materials. Gordon and Breach Science Publishers, New Work

Rikal LI, de Figueiredo AK, Riccobene IC (2023) Physicochemical and functional properties of canaryseed (Phalaris canariensis L) with and without spicules flour. Cereal Chem. https://doi.org/10.1002/cche.10669

SAGyP (1994) Secretaria de agricultura, ganadería, pesca y alimentos. Normas nacionales, Resolución SAGyP N°1075/94. Norma I- Alpiste: http://www.senasa.gob.ar/normativas/resolucion-1075-1994-sagpya-secretaria-de-agricultura-ganaderia-pesca-y-alimentos Accesed on 21th Dec, 2021

Sarkar AK, Chakraverty A, Mujumdar AS, Raghavan GSV, Ramaswamy HS (2003) Grain-milling operations. Handbook of postharvest technology cereals, fruits, vegetables, tea, and spices. Marcel Dekker Inc., New York, pp 253–427

ASAE standards (1999) Standard engineering practices data (46th ed.) American society of agricultural engineers

Acknowledgements

The authors acknowledge the Universidad Nacional del Centro de la Provincia de Buenos Aires and Molino Olavarría S.A. for providing the sample material.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

AKF and MMR proposed the objectives and supervised the work, MXD and AKF carried out the experiments and analyzed the data, SMN and ICR wrote the manuscript. All authors participated in the manuscript edition.

Corresponding author

Ethics declarations

Conflict of interest

Not applicable.

Consent to participate

All authors are agree to be part of the auditing of the manuscript and are aware to the submission to JFST journal.

Consent to publication

Not applicable.

Ethical approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Durruty, M.X., de Figueiredo, K., Rodríguez, M. et al. Engineering properties and optimization of the dehulling process for hairless canary seed. J Food Sci Technol (2023). https://doi.org/10.1007/s13197-023-05898-7

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13197-023-05898-7