Abstract

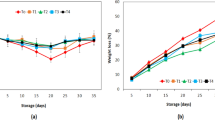

Immature green cucumber cv. ‘Padmini’ fruits were individually shrink wrapped with Cryovac D955 (60 guage) film and stored at 12 ± 1 °C, 90–95% RH as well as ambient conditions (29–33 °C, 65–70% RH). At 12 ± 1 °C and 90–95% RH, individual shrink wrapped cucumber recorded minimum Physiological loss in weight (0.66%) as compared with unwrapped fruits (11.11%) at the end of refrigerated storage (15 days). The softening (loss of firmness) was maximum (1304.6–876.6 g force) in unwrapped cucumbers whereas in shrink wrapping, minimum loss in firmness (1304.6–1065.3 g force) was observed after 12 days storage at 12 ± 1 °C and 90–95% RH but greater loss of weight and firmness makes the control cucumbers unmarketable after 9 days of storage. There were no rotting at all both in shrink wrapped and unwrapped cucumbers upto 15 days of storage at 12 ± 1 °C and 90–95% RH. After 15 days storage of shrink wrapped cucumbers at 12 ± 1 °C and 90–95% RH, there was loss of green colour and development of yellowness and decay. The sensory attributes score was highest in shrink wrapped cucumbers as compared to unwrapped cucumbers at end of both storage conditions. Thus it can be concluded that individual shrink wrapped cucumber can be stored well upto 15 days at 12 ± 1 °C and 90–95% RH and for 5 days at ambient conditions (29–33 °C, 65–70% RH) with maximum retention of green colour, no spoilage, minimum weight and firmness loss and very good sensory quality attributes whereas, unwrapped fruits can be stored well upto 9 days at 12 ± 1 °C and 90–95% RH and for 2 days at ambient conditions with maximum retention of physico-chemical quality attributes.

Similar content being viewed by others

References

Adamicki F (1985) Effect of storage temperature and wrapping on the keeping quality of cucumber fruits. Acta Hortic 156:269–272

Amerine MA, Pangborn RM, Roessler EB (1965) Principles of sensory evaluation of food. Academic, New York

Ben-Yehoshua S (1985) Individual seal packaging of fruits and vegetables in plastic film- a new postharvest technique. Hortic Sci 20:32–37

Elkashif ME, Huber DJ, Sherman M (1983) Delaying deterioration of broccoli and cucumber using polymeric films. In: Proc Florida State Horticultural Society 96:332–335

Heaton EK, Dobson JW, Lane RP, Beuchat LR (1990) Evaluation of shrink-wrap packaging for maintaining quality of apples. J Food Prot 53(7):598–599

Homin K, Woo PK (1999) Effects of packing methods and handling temperatures on postharvest quality during storage of cucumber. Korean Soc Hort Sci 40(10):9–12

Hunter S (1975) The measurement of appearance. Wiley, New York, pp 304–305

Nanda S, Sudhakar Rao DV, Krishnamurthy S (2001) Effect of shrink film wrapping and storage temperature on the shelf life and quality of pomegranate fruits cv. Ganesh. Postharvest Biol Technol 22:61–69

Risse LA (1989) Individual film wrapping of Florida fresh fruits and vegetables. Acta Hortic 258:263–270

Risse LA, Miller WR, Chun D (1985) Effect of film wrapping, waxing and imazalil on weight loss and decay of Florida cucumbers. In: Proc Florida State Horticultural Society 98:189–191

Seagall RH, Dow A, Davis PL (1974) Effect of waxing on decay, weight loss and volatile patterns of cucumber. In: Proc Florida State Horticultural Society 87:249–251

Singh SP, Sudhakar Rao DV (2005) Quality assurance of papaya by shrink film wrapping during storage and ripening. J Food Sci Technol 42(6):523–525

Sonkar RK, Ladaniya MS (1999) Individual film wrapping of Nagpur mandarin (Citrus reticulata Blanco) with heat-shrinkable and stretch-cling films for refrigerated storage. J Food Sci Technol 36(3):273–276

Sudhakar Rao DV, Gopalakrishna Rao KP (2002) Individual shrink-wrapping of fruits and vegetables. Packag India 34:27–32

Sudhakar Rao DV, Gopalakrishna Rao KP, Krishnamurthy S (2000) Extension of shelf life of cucumber by modified atmosphere packaging (MAP) and shrink wrapping. Indian Food Pack 54:65–71

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dhall, R.K., Sharma, S.R. & Mahajan, B.V.C. Effect of shrink wrap packaging for maintaining quality of cucumber during storage. J Food Sci Technol 49, 495–499 (2012). https://doi.org/10.1007/s13197-011-0284-5

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-011-0284-5