Abstract

Apple fruit can be stored for long periods of time, especially with the use of controlled atmosphere storage, but like many fruits and vegetables are susceptible to water loss. Water loss can result in compromised appearance such as skin shriveling, as well as loss of firmness, and reduced saleable weight, which in turn affect the income of growers and other industry stakeholders. Preharvest factors that can influence water loss in apples during the postharvest period include climate, cultivar, fruit size, tree age, orchard practices, and harvest maturity. Postharvest factors such as the storage temperature, relative humidity, storage type, and duration can also affect water loss in apple fruit during storage. The mechanisms of cuticle biosynthesis in water permeance, the role of stomata and lenticels, microcracking, crosstalk with mechanical injuries, storage disorders, and decay incidence during the storage of apples are reviewed. Additionally, the review summarizes: preharvest and postharvest factors influencing water loss; recent management strategies including pre-cooling, cold storage, controlled atmospheres, packaging, and anti-senescence chemicals; the use of edible coatings, as well as other non-chemical approaches for modulating water loss and maintaining storage quality. The review also provides direction for the industry to manage this destructive problem in the postharvest supply chain of apple fruit.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Apple (Malus × domestica Borkh.) belongs to the Rosaceae family and is known as a pome fruit composed of two to five carpels covered with crunchy flesh. It is one of the leading fruit crops grown in more than 63 countries with diverse climatic zones including temperate and subtropical regions of the world; however, commercial production comes under 25° to 52° latitude limits (Musacchi & Serra, 2018). According to FAOSTAT (2020), it is grown on 6.5 million hectares of land with global production of 126 million tonnes. In total worldwide production, China is the leading producer of apples with 81.0 million tonnes of production followed by the United States of America (USA), Turkey, Poland, India, and Italy, Iran, and Russia.

It is one of the major fruit crops grown all over the world, and very popular among consumers due to their pleasant taste, attractive colour, unique aroma, crispness, and promising nutritional profile. Apples are consumed fresh due to a wide array of health-promoting compounds such as polyphenols, flavonoids, and enzymatic and non-enzymatic antioxidants that provides aid against chronic diseases in humans (Oyenihi et al., 2022; Watkins & Liu, 2011). In addition, apple fruit also contains a variety of macronutrients including sugars (glucose, fructose, sucrose, and sorbitol), protein, fat, and, vitamins such as B6, C, and E; organic acids (malic acid, fumaric acid, succinic acid, citric acid, and tartaric acid); minerals (nitrogen, potassium, calcium, magnesium), fibre, and trace elements (copper, iron, manganese, zinc) which help in boosting the immune system of the human body (Skinner et al., 2018). The bioactive compounds in fresh apple fruit reported significant pharmacological effects for curing different chronic diseases (Oyenihi et al., 2022). The apple fruit contained higher polyphenol antioxidants representing up to 25% of total polyphenols from fruit intake on a daily basis diet in the USA (Musacchi & Serra, 2018). Further, apple fruits have a wide range of individual phenolic acids such as quercetins, phloretin, epi-catechin, procyanidins, and chlorogenic acids, which vary with maturity stage, cultivar, agroclimatic conditions, and postharvest storage conditions and period (Pissard et al., 2013; Tokala et al., 2022).

Apples, depending on cultivar, can be stored for long time periods in air or under controlled atmosphere (CA) conditions, and shipped worldwide from temperate production zones. A large number of cultivars are grown, specific ones often associated with a given production region. Storage periods employed by the growing region are a function of cultivar and availability of storage technology. While apple fruits exhibit climacteric peaks of ethylene and respiration during their ripening period, they show great storage potential when compared to other climacteric fruits. Nevertheless, this temperate fruit experiences varied recurrent postharvest quality issues, including water loss and susceptibility to physiological disorders and pathogenic diseases, as well as mechanical and storage injuries that could be due to different pre- and postharvest factors, resulting in lower storage life and earlier senescence (Singh et al., 2022). Therefore, the apple industry is very keen to address postharvest handling issues, particularly towards reducing water loss and maintaining the quality of the fruit when stored for long-term periods.

Water loss, also known as weight loss, or moisture loss, has been regarded as a quality indicator during the postharvest period (Lufu et al., 2020). Apple fruit depending on the cultivar, is prone to water loss, considered one of the major constraints in long-term storage, which in turn reduces saleable weight, downgrades overall quality, limits their storability, and consequently lowers grower income (Singh et al., 2022). Substantial water loss in apple fruit results in higher skin shriveling, changes in wax composition, and enhanced fruit softening, as well as deteriorated cosmetic and eating quality during the postharvest period (Atkinson et al., 2012; Harker et al., 2019; Veraverbeke et al., 2001, 2003b) (Fig. 1). Studies have reported that fresh fruit and vegetables become unmarketable when they lose 5 to 10% of water content, which ends up in quality loss that includes wilting or skin shriveling during storage (Ben-Yehoshua & Rodov, 2002). Water loss in the postharvest phase depends on several factors related to production, harvest, postharvest handling, storage, and marketing (Lufu et al., 2020).

Though the adverse impact of water loss on apple fruit quality is apparent, research reports available in the last three decades have mainly focused on maintaining the overall quality of fresh apple fruit, where water loss has been identified as a quality attribute. However, a comprehensive review reporting varied preharvest, harvest, and postharvest factors affecting water loss and quality, as well as management strategies to minimise water loss in apple fruit during storage, has not yet been reported. This present review focuses on critical analysis of previously reported literature related to water loss and postharvest fruit quality of apples. The review also includes examination of permeance to water vapour (cuticular composition and role of cuticle) and role of lenticels and microcracking, as well as different preharvest and postharvest strategies tested for reducing water loss and maintaining fruit quality.

Morphology and Physiology of Apple Fruits that Affect Water Loss

Cuticle Biosynthesis and Water Permeance

The epidermis plays a vital role in biosynthesis of cuticles in fruits. ‘Cutin’, the major component of its composition, is composed of a polymeric scaffold that is insoluble in nature, with different waxes (amorphous intracuticular) that are embedded within it, which lead to the surface coating in fruits. These cuticular waxes are hydrophobic materials, originally containing long-chain (> C18) fatty acids, esters, ketones, aldehydes, alcohols, hydrocarbons, sterols, triterpenes, and flavonoids (Lara et al., 2015). The fruit surface is surrounded by a biopolymeric cuticle layer, which functions as the first barrier against biotic and abiotic conditions, and primarily limits water movement across surfaces in apples (Guan et al., 2015). The waxy cuticular layer also aids in protection against UV radiation, provides mechanical support in reducing postharvest injuries, and prevents fruit cracking (Lara et al., 2019). It has been well established that cuticle is one of the primary barriers for restricting water loss from fruits, leaves, and other parts of higher plants (Riederer & Schreiber, 2001). Leide et al. (2018) have reported that the cuticular waxes in apples cvs. ‘Prima’ and ‘Florina’ are mainly composed of pentacyclic triterpenoids such as ursolic acid with ≥ 70% despite of cuticle weight and thickness. However, the hydrophobic cuticle was found as a major impediment for restricting transpirational loss of water in apple cultivars from external plant surfaces while the chemical variations were not associated with permeance of water. In addition, changes of wax composition of apple fruit are likely to be involved in the formation of disorders such as superficial scald (Lurie & Watkins, 2012) and greasiness (Yang et al., 2017), as affected by modulation in esters and alcohols, where apple skin russeting occurs due to certain increasing changes in ursolic acid and oleanolic acid, respectively (Legay et al., 2017). Furthermore, it has been reported that the development of cuticle failure may result in excessive loss of water and aids the intrusion of fungal pathogen (Shi et al., 2013); however, the severe failure of cuticle results in the appearance of russeting disorder (Lara et al., 2014). Subsequently, after the formation of russeting, the suberin with large proportion develops the periderm layer which is largely regarded as waterproofing; however, the suberin is less effective for water retention as compared to cutin (Beisson et al., 2012; Khanal et al., 2013).

Stomata and Lenticels

Transpiration plays a key role in water loss from apple fruit, due to the movement of water in the form of liquid or vapour from intercellular spaces present in the cuticle. Water transport for transpiration and photosynthesis are generally controlled by surface pores with variable openings, known as stomata in plants, where young fruit are often stomatous. Usually these stomata remain open, but conditions like water vapour deficit, enhanced concentration of CO2, and darkness affect turgor loss in stomatal guard cells that result in their closure (Kerstiens, 1996). Stomata on a fruit surface are less than on leaves, mostly inactive, and closed and covered with a waxy layer, thereby reducing their role in water loss during storage. In this context, lenticels in apple fruit are regarded as non-controlled openings that are larger in size and without guard cells, which contribute more to water loss than stomata during storage (Veraverbeke et al., 2001). Lenticels usually appear in varying colours (white to brown), with size ranging from minute pore up to 2–3 mm of diameter, where they are distributed in different fruit regions. Apples have higher lenticel density in cheeks rather than the pedicel to calyx area, which is positively correlated to water permeance (Khanal et al., 2020). Occasionally, these lenticels are stuffed with suberised periderm material and develop an additional barrier for water transport through these openings (Veraverbeke et al., 2003a). Kritzinger and Lötze (2019) reported significant correlation between the number of open lenticels on fruit surface and peel permeability in cvs. ‘Songold’, ‘African Delight™’, and ‘Sapphire’ plums. Higher permeability due to large number of open lenticels ends up in increased moisture loss which markedly impact mass loss of fruit. In addition, surface openings such as lenticels and microcracks showed a significant role in excessive water loss partially established in pomegranate storage (Lufu et al., 2021). However, the extent of lenticels on fruit skin contribution to water loss may vary with lenticel size, cultivar, and harvest season (Kritzinger & Lötze, 2019; Lufu et al., 2021).

Microcracking in Apple

In addition to stomata and lenticels, microcracks are another form of natural opening outburst in the cuticle layer of fruit surfaces, where they lead to higher water loss and result in varied skin disorders such as skin spotting (Grimm et al., 2012) and russeting (Khanal et al., 2019) in apple fruit. ‘Elstar’, ‘Golden Delicious’, and ‘Golden Spur’ apples have been shown to decay during storage due to microcracking in fruit surfaces (Grimm et al., 2012; Guan et al., 2015; Roy et al., 1999). Belding et al. (1998) have reported that microcracks usually develop in apple fruits after an average 130 days of full bloom during their development period. Faust and Shear (1972) have reported that ‘Golden Delicious’ apple cultivars exhibit abundant microcracks on fruit surfaces growing under hot and humid climatic conditions. However, apple fruits can show microcracks even when growing in normal climatic conditions, as reported in ‘Royal Gala’ apple cultivar (Curry, 2008). The development of apple fruit skin disorders and diseases in response to microcracking considerably affects market value at the commercial scale, though it has been shown to have no effect on nutritional quality in many cases. However, it does cause loss in textural quality, thereby lowering buying willingness among consumers (Khanal et al., 2021). Knoche and Lang (2017) have revealed that different fruit crops possess the capability of self-repair process for managing damaged cuticles, as reported in apple fruit in russeting. This occurs via the formation of periderm and depositing stacks of cork cells, which lead to the development of brownish skin colour and results in rejection at the farmgate as well as high-end markets (Khanal et al., 2019). Contrastingly, wax deposition effectively fills microcracks without disturbing morphological changes, as reported previously in apple fruits, which helps in reducing water permeance (Curry & Arey, 2010; Roy et al., 1999). Various pre- and postharvest treatments have been tested for management of microcracking in apple fruits, restricting water loss for deleterious effects on fruit quality during storage. Knoche et al. (2011) have reported preharvest application of gibberellin A4+7 (10 mg L−1), with four sprays after full bloom, to markedly reduced microcracking and russeting in ‘Golden Delicious’ apple fruit. Likewise, lipophilic formulation (emulsified products containing vegetable esters and plant extracts) sprays applied 3 weeks before harvest have been shown to significantly reduce lenticel breakdown disorder (70%), in turn reducing microcracking in ‘Gala’ apple fruit during 3 months of storage (Curry et al., 2008). During the postharvest period, edible coatings and heat treatments have been shown to significantly fill microcracks, through melting surface cuticular wax, which reduces water loss, delays postharvest ripening, and maintains the overall quality of apple fruits (Lurie et al., 1996; Synowiec et al., 2014).

Preharvest Factors Affecting Water Loss and Fruit Quality

Maturity Stage

The maturity stage at harvest influences post-storage quality and taste of apple fruit. Among several maturity indicators, days after full bloom (DAFB), fruit retention strength and abscission, Streif index (firmness, soluble solid contents, starch), prelim index (firmness, SSC, and TA), and Thiault index (total sugars) are currently used as indicators. However, the adoptability of maturity determination methods varies in accordance with cultivar, growing conditions, climate, and region (Musacchi & Serra, 2018). The maturity stage significantly affects the storability potential of commercial apple cultivars. Jan et al. (2012a) have reported that early harvested apple cultivars stored for 150 days at 5 ± 1 °C exhibited higher water loss (3.34%) as compared to fruits harvested at mid (2.26%) and late (1.93%) maturity stages, respectively (Table 1). The apple cv. ‘Red Delicious’ harvested at later maturity significantly retained higher fruit weight as compared to fruits harvested at an earlier stage, during storage for 100 days at 2 ± 1 °C (Ganai et al., 2018). Besides water loss, other quality attributes including physiological disorders and disease incidence have also been affected by the harvest maturity stage of apple fruit during storage. ‘Cripps Pink’ apples subjected to delayed harvest for 42 days following commercial harvest significantly enhanced export quality fruit, red blush on skin, and increased total anthocyanins, flavonoids, and phenolic compounds. However, delayed harvested fruits exhibited elevated internal ethylene production and reduced firmness of apple fruit cv. ‘Cripps Pink’ during cold storage for 135 days at 0 ± 1 °C (Shafiq et al., 2011a, b).

Cultivar

Cultivar is one of the primary preharvest factors influencing various quality attributes, including water loss during postharvest periods. The response of cultivars of a single species is dependent on several subfactors including fruit size, lenticels and microcracks, the natural waxy layer on the peel, water permeability of the cuticle, and metabolic rates (Lufu et al., 2020). Liang et al. (2015) have reported the apple fruit crop to have a diverse germplasm, where more than 10,000 cultivars have been documented. However, only a few cultivars dominate global apple production. The storage potential and fruit quality of apples are dependent on the genetic makeup of a cultivar while subjected to similar storage conditions. For example, water loss in 180-day cold-stored (0 °C) apple fruits has been shown to vary among cultivars such as ‘Gala’ (6.43%), ‘Golden Delicious’ (4.86%), ‘Starking Delicious’ (3.95%), and ‘Star Cremson’ (3.83%) (Ghafir, 2009) (Table 1). Likewise, Chai et al. (2020) have studied changes in physiological and wax composition of 10 apple cultivars stored at ambient conditions (25 °C with 90% RH) for 49 days. Among their 10 tested cultivars, the ‘Red Star’ apple fruit showed the highest water loss (8.37%), while the ‘Mutsu’ cultivar exhibited the lowest water loss (3.64%) after 49 days of shelf period. The ‘Red Star’ cultivar also exhibited lower total wax content at the end of the shelf period, linked with substantial changes in water loss (Table 2). Watkins and Mattheis (2019) have reported that apple cultivars considerably differ in metabolism, ripening rates, and potential of storage. For example, cv. ‘Anna’ exhibited a storage life of only weeks, while cvs. ‘Fuji’ and ‘Idared’ showed higher storability for months even under sub-optimum conditions with maintained quality acceptable among consumers. Kishor et al. (2018) have reported on 10 apple cultivars stored at ambient conditions, exhibited higher water loss, fruit decay, and lower firmness along with progression in shelf period until 49 days. Among all cultivars, ‘Red Delicious’ showed 24.5% of water loss with 74% fruit decay on the final day of assessment at ambient conditions, which make fruit unacceptable for consumers. However, ‘Red Delicious’ apples had 7.29% water loss with no decay until 14 days of shelf period and remained marketable. The similar apple cv. ‘Red Delicious’ kept in cold storage conditions (5 ± 1 °C with 60–70% RH) showed lower water loss (4.53%) after 150 days of storage (Jan et al., 2012a) (Table 2).

Fruit Size

Apple fruit size is the foremost ‘search characteristic’ of quality assessment among consumers prior to buying. Consumers usually define categories on base fruit dimensions depending on region, country, market type, age, education, and family income (Musacchi & Serra, 2018). Apple fruit size has been reported to be determined by cell numbers and their size expansion generally, developed within 28 to 42 days of fruit development. After attaining optimum fruit size, the continuous cell expansion results in lower storage potential and greater susceptibility to postharvest disorders (Nissen et al., 2016). Ben-Yehoshua and Rodov (2002) have revealed that fruits with larger size show lower water loss than small-sized fruits during storage, which could be due to surface area to volume ratio (higher in small size fruits and inverse in larger fruits). Prior to this, Maguire et al. (2010) have also shown that apples of smaller size show higher water loss than larger fruits during storage. Johnston et al., (2002a, b) have reported that small-sized ‘Royal Gala’ and ‘Cox’s Orange Pippen’ apples, following 150- and 300-day cold storage, showed significantly delayed fruit softening and textural loss, respectively. Moreover, fruit size also influences storage disorders in apple fruit. Lee et al. (2013) have indicated apple fruits of larger sizes to exhibit higher flesh breakdown and incidence of cracking after 6 months of cold storage at 0.5 °C.

Tree Age

Tree age is also considered a key contributing factor in determining overall fruit quality, significantly influencing storability during the postharvest period (Khalid et al., 2017). Tahir et al. (2007) have reported that ‘Aroma’ apples harvested from young trees (less than 6 years) showed high water loss, elevated ethylene production, less firmer fruits, poor flavour quality, and high susceptibility to skin bruising and Pezicula malicorticis decay after 4 months of storage at 2–3 °C (Table 1). Recently, the impact of tree age was studied on postharvest dry matter prediction in 58 apple accessions, in which fruits harvested from established mature trees showed higher accuracy for dry matter content estimation during near-infrared (NIR) calibration and assessments (Teh et al., 2020). Tree age has been shown to not influence the internal browning ‘Rosy Glow’ apples during 5 months of CA storage following 42 days of cold storage (Doe, 2020).

Orchard Practices

Different cultural practices including irrigation, application of fertilizers, and preharvest nutrient/biostimulant sprays can also influence yield and fruit quality in harvest and postharvest phases. Uncertain changes in water status of apple trees have been shown to induce fruit cracking, resulting in fast water loss during the postharvest period (Maguire et al., 2010). Kilili et al. (1996) have reported that withholding irrigation in ‘Braeburn’ apples resulted in lower water loss, as compared to fully watered control during 9 weeks of cold storage at 1 °C. Similarly, apple fruit cv. ‘Pacific Rose™’, harvested from trees receiving restricted partial irrigation, exhibited lower water loss during 14 weeks of cold storage at 0 °C (Zegbe et al., 2008). The apple trees cv. ‘Cripps Pink’ subjected to regulated deficit irrigation (75%) followed by fruit storage significantly conserved higher firmness and SSC as compared to fruits harvested from trees receiving commercial irrigation, during cold and CA storage for 135 and 155 days, respectively (Wan Zaliha & Singh, 2009a).

Soil application of nutrients to apple trees also influences water loss during the postharvest period. Various physiological disorders are associated with toxicity or deficiency of mineral nutrients (Musacchi & Serra, 2018). Accordingly, Alhaj-Alali et al. (2020) have reported increased application of ammonium-based nitrogen through irrigation to significantly reduced water loss in ‘Golab’, ‘Gala’, and ‘Granny Smith’ apples during cold storage.

Postharvest Factors Affecting Water Loss and Fruit Quality

Temperature

Temperature in postharvest storage plays a critical role in downregulating metabolic activities and lowering water loss in fresh horticultural produce. Harvested fruits release field heat and energy via evaporation of water into the surrounding air to achieve sustainable equilibrium with the environment, resulting in higher water loss and earlier senescence. High temperature has a deleterious effect on fruit peel that enhances membrane permeability, which results in skin shriveling and loss of cosmetic quality (Lufu et al., 2020). Apple fruits are usually stored at 0–3 °C depending upon cultivar to maintain the fruit quality. However, optimization of storage temperature may result in lowering fruit firmness and nutritional quality, and increasing water loss and softening during the postharvest period (Johnston et al., 2002a). For instance, ‘Cripps Pink’ and ‘Granny Smith’ apples subjected to cold storage for 120 days at 0 °C showed significant differences in water loss (2.39 and 1.54%), respectively, irrespective of the postharvest treatments (Tokala et al., 2021a). In contrast, ‘Cripps Pink’ apples stored at an elevated temperature (5 °C) significantly lowered storage life up to 56 days and exhibited a difference of 1.11% at the end of the storage period (Thakur et al., 2019). Further, the higher temperature at ambient conditions enhances water loss during shelf period. This claim has been supported with findings by Sharma et al. (2013), who reported that apple cv. ‘Royal Delicious’ stored at ambient conditions (22–28 °C and 52–68% RH) demonstrated higher water loss during a period of 42 days, with the highest water loss (18.2%) observed on the last day of assessment. Therefore, harvested apple fruit needs to be pre-cooled immediately to minimize temperature of field heat carried by the fruit itself (Singh et al., 2022). Accordingly, storage temperature is believed to be the most important factor determining the storage potential of apple fruits.

As far as the influence of storage temperature on fruit quality is concerned, apple fruits subjected to different temperature regimes during storage can show remarkable variation in physio-chemical quality. Apple fruit cv. Fuji showed higher fruit firmness, SSC, and acidity when stored at 0 °C than at 2 °C for 6 months in CA storage (Kweon et al., 2013). In another study, apple fruit cv. ‘Maxi Gala’ subjected to 2 and 3 °C resulted in higher percentage of healthy fruit and firmness and conserved better keeping quality as compared to fruits stored at 0 °C coupled with dynamic CA for 9 months following 7 and 14 days of shelf-life (Wendt et al., 2022). Nonetheless, certain apple cultivars stored at low temperature are susceptible to the development of storage disorders which downgrade their quality and market value. Watkins et al. (2004) have reported that ‘Honeycrisp’ apples displayed a higher incidence of soggy breakdown and soft scald disorders when stored for 12 weeks at 0 or 0.5 °C as compared to fruit stored at 2.2, 2.8, and 3 °C for the same period.

Relative Humidity

It is another contributing factor along with temperature for preserving storage quality and extending the market window of apple fruits. However, the small variations in RH percentage at stable temperature markedly affect the water loss and overall quality. Lufu et al. (2020) have stated that water vapour pressure deficit (WVPD) in fruit increases with decrease in RH, thereby enhancing water diffusion from fruit into the environment. Lidster (1990) has reported that apple cv. ‘McIntosh’ stored at five different levels of RH (from 96 to 100%) under CA and low oxygen showed lower water loss during CA storage, but showed higher incidence of senescence breakdown disorder and sensile brown core. Tu et al. (2000) have reported that apple fruit cvs. ‘Braeburn’ and ‘Jonagold’ subjected to different RH conditions significantly influenced water loss during 18 days of retail storage after 1 month of ultra-low oxygen (ULO) storage. Apple cvs. ‘Braeburn’ and ‘Jonagold’ stored at 30% RH showed higher water loss (5.3 and 6.0%) as compared to fruit stored at 65% RH (3.8 and 4.0%) and 95% RH (1.0 and 1.0%) at constant simulated retail temperature (20 °C) respectively. Accordingly, the optimum RH alone or in combination with other technology is imperative for reducing water loss and retaining better quality in apple fruit during different storage. The optimum RH for apple storage ranges between 90 and 95% for long-term storage depending on the cultivar. Fruit stored at an RH above 95% results in significant reduction of water and firmness loss, but is also susceptible to a variety of storage disorders (Lidster, 1990). Apple fruit is generally kept in storage chambers having an RH system producing steam or atomized water droplets for maintaining closed humid environments (Tu et al., 2000). The effect of different RH conditions used to maintain respective RH such as low > 75% RH (CaCl2 salt in the chamber) followed by > 90% RH (ambient) and high 95% (putting distilled water in the chamber) has been shown in studies. High RH storage reduced water loss by 1.03% compared to fruit stored under low RH (4.82%), attained by placing brine solution (CaCl2 salt) inside the chamber, after 8 months of CA storage (Prange et al., 2001). Although steam or water droplet–producing RH systems are beneficial for maintaining quality inside the storage chamber, they may cause condensation of water vapour on packages and stored commodities, which may result in microbial spoilage and loss of quality (Lufu et al., 2020). Mist spraying accompanied by ultrasonic humidification and nano-mist spray humidification system producing droplet < 100 nm of particle size may be helpful in reducing water loss in apple fruit during postharvest periods under different settings of cold, controlled atmosphere (CA), dynamic controlled atmosphere (DCA), and ultra-low oxygen (ULO) storage types.

Storage Type

Growers usually decide the harvesting time of apple fruits based on the intended market, either domestic or international, which varies with fluctuating price return. Apple fruit generally exhibits short shelf-life at ambient room conditions, but can be stored for longer time (few weeks to 9–10 months) by employing different storage technologies. The lowering of temperature to 0 ± 1 °C and RH 90–95% for apple fruits cv. ‘Red Delicious’, which has a storage potential of 6 months, followed by CA storage, helps in extending storability up to 10 months. While long-term storage employing cold and CA storage results in maintained quality, fruit exhibits signs of storage disorders, which may be reduced with use of ultra-low oxygen for apple cv. ‘Red Delicious’ (Mitcham et al., 1999). The commercial application of CA, DCA, and ULO might have certain limitations, but countries with developed economies can use this to conserve apple fruit for year-round availability in the market. The utilization of storage systems significantly impacts water loss, fruit quality, and storage duration of apple fruit for local as well as high-end international markets.

Crosstalk with Water Loss and Fruit Quality

Mechanical Injuries

Mechanical injury in the form of vibrations, shocks, and compression in harvested fruit may occur due to inappropriate harvest handling, faulty operations in the packhouse, storage, and transport, thereby deteriorating the quality and significantly reducing the final product value. Bruising is the most familiar kind of mechanical injury in apple fruit, eventually causing tissue damage that results in 10–25% of postharvest losses within the supply chain. Even minor injuries, such as bruises, result in cell wall rupture due to absorption of water, intercellular wall breakdown, and cell dysfunction due to the loss of cell fluid, leading to inferior cosmetic and internal quality of fruit (Van Zeebroeck et al., 2007). In one study, flesh browning and darkening was observed in apple cv. ‘Gala’ subjected to compression damage at 70-N force. However, bruised fruit showed a non-significant effect on water loss during 20 days of shelf period at 15 °C (Ergun, 2017). Apple fruit cv. ‘Fuji’ damaged by artificial vibration significantly escalated ethylene production and respiration rate, decreased SSC, TA, firmness, and increased ion leakage and malondialdehyde (MDA) content during 28 days of shelf period (Shu et al., 2020).

Storage Disorders

Skin appearance is a pivotal criterion of apple fruit quality, where any sort of surface defect generally downgrades the overall quality and market value (Singh et al., 2022). Apple fruit usually subjected to variable storage conditions such as temperature, high carbon dioxide, low oxygen, RH, and storage duration, irrespective of storage technology, exhibits different physiological disorders that vary with cultivars (Watkins & Mattheis, 2019). Wilkinson and Fidler (1973) have reported excessive water loss during storage to increase brown core disorder in apple fruit, developing discolouration in the form of brown and pink spots in the core area that extend to the cortex region in flesh. Apple cv. ‘Honeycrisp™’ stored for 4 months of cold storage at 3.5 °C following 4 days at shelf temperature 30 °C was shown to significantly increase greasiness by 62% and water loss (1.45%) (Delong et al., 2009). Watercore in apple fruit is another prominent physiological disorder characterized as internal flesh browning observed preharvest and during cold storage. Liu et al. (2021) have reported that watercored apple cv. ‘Fuji’ subjected to cold storage at 0 ± 1 ℃ for 180 days increased water loss up to 9.2% with extension of duration.

Microbial Decay

Like other fruit crops that show high postharvest losses in supply chains, apple fruit also exhibits various losses during the postharvest period from field, storage, to the retailer. Buzby et al. (2011) have reported that fresh apples undergo wastage by 28.6% at retail point and consumer level in the United States. In addition to other factors as described previously contributing to losses, microbial decay seems to be most obvious cause of apple fruit wastage, in which several pathogenic species have potential to cause decay, while only a few leads to decay oriented losses under commercial settings. Escalated water loss was found to be proportionally associated with fruit decay during storage, leading to unmarketable apple fruits. Jo et al. (2014) have reported that apple fruit cv. ‘Fuji’ showed higher water loss of 7.7% and microbial decay in terms of aerobic bacteria, yeast, and moulds in untreated control fruit during 5 months of cold storage at 1 ± 1 °C. Postharvest losses caused by fungal pathogens range from 0.25 to 70% depending on orchard condition, harvest maturity, growing region, postharvest treatment with fungicides, and duration of storage (Argenta et al., 2021; Kim & Xiao, 2008; Neuwald & Kittemann, 2015). Among all pathogens causing postharvest rots, Penicillium expansum causes decay and loss up to 50% during storage. Wang et al. (2018) have revealed that apple fruit cv. ‘Fuji’ depicted higher fungal decay due to Penicillium expansum, increased water loss, lower firmness, and SSC during cold storage following reconditioning at shelf conditions. In addition, the higher RH also contributes to enhanced fungal decay and water loss in apple fruits during the postharvest period. Ali et al. (2020) reported that apple fruit cv. ‘Rich Red’ showed higher water loss and fungal decay in fruits subjected to lower RH (65%) during the shelf period at 22 ± 2 °C for 45 days. Moreover, apple fruit cv. ‘Anna’ also exhibited lower bioactive compounds such as flavonoids, anthocyanins, total antioxidants, and phenolic concentrations along with higher fungal decay and water loss in untreated control fruit during 35 days of cold storage (Khalifa et al., 2017).

Postharvest Water Loss and Quality Management

Pre-Cooling

Field heat downgrades quality of freshly harvested apple fruit by increasing water loss and lowering saleable weight, which directly affects growers’ income (Singh et al., 2022). Wu and Defraeye (2018) have reported that fresh produce without pre-cooling substantially increased water loss by 28% during cool chain system. Cool chain logistics have been extensively utilized to preserve horticultural produce for longer periods of time by focusing on temperature management in the supply chain. Pre-cooling has been regarded as the first stage of a cool chain system employed to remove field heat instantly from harvested produce, which helps in lowering the metabolic activities and extending storage during the postharvest period. Various pre-cooling methods including room cooling, forced air cooling, hydro cooling, ice cooling, vacuum cooling, and liquid nitrogen-based cooling have been tested and used at commercial scale (Duan et al., 2020). Brackmann et al. (1996) have reported that apples subjected to hydro-cooling at 10 °C (until attainment of core pulp temperature) showed lower water loss and skin shriveling in cold storage for 5 and 6 months, and 8 months of CA storage of ‘Golden Delicious’ and ‘Fuji’ fruits, respectively. However, hydro-cooling at 4.5 °C exhibited higher rot incidence and cracking as compared to fruit treated with hydro-cooling at 10 °C and control during the entire period of storage. In another study, apple cv. ‘Red Delicious’ subjected to hydrocooling following wax coating retained better colour values and sensory quality and maintained higher anthocyanins than fruits kept under shade or room cooling during 100 days of cold storage (Ganai et al., 2015). Hydrocooling for apples seems to be effective in reducing water loss, and is inexpensive, but its use is limited to fruit in bins as compared to cartons. Forced air cooling has been reported as a substitute for apples in cartoons instead of bins (Watkins, 2003). Forced air cooling has also been extensively used for pre-cooling at commercial scale in the fresh produce industry (Gong et al., 2021). Wijewardane and Guleria (2013) reported that apple fruit cv. ‘Royal Delicious’ exposed to low-pressure container pre-cooling at 10–15 °C and 70–75% RH followed by postharvest edible coating (1.5–2%) and low-density polyethylene (LDPE) liner decreased disease incidence and water loss, maintained higher firmness and anthocyanins, and reduced activities of softening enzyme during 45 days of shelf period. Contrastingly, the apple fruit cv. ‘Red Delicious’ exposed to cold N2 vapour pre-cooled rapidly at 1 °C in CA storage rooms exhibited lower water loss and soluble solid contents, and maintained higher flesh firmness and ascorbic acid, while titratable acidity was not affected by pre-cooling and storage treatments (Mahajan & Goswami, 2002).

Cold Storage

Metabolic activities, respiration rate in particular, significantly affect the quality maintenance of apple fruit during postharvest period. Low-temperature storage ranging between − 0.5 and 4 °C is regarded as the optimum temperature for several cultivars considering the aspect of chilling sensitivity of apple cultivar and associated injuries (Watkins, 2003). Selection of temperature in apple fruit storage plays a critical role in water loss management and preservation of eating quality and determines the storage potential of specific cultivars. Table 2 summarises the effect of storage temperature on water loss per day and water loss at the end of storage period in apple fruits. Apple fruits kept at ambient room conditions showed higher water loss as compared to fruits stored in cooler environments. Apple cv. ‘Golden Delicious’ subjected to shelf-life assessment at 22 ± 2 °C exhibited 8.3% water loss after 28 days while the similar cultivar showed 2.9% loss of water after 150 days of cold storage at 5 ± 1 °C (Jan et al., 2012a; Radenkovs & Juhnevica-Radenkova, 2018) (Table 2).

Intermittent Warming

Apple fruits stored at relatively low-temperature conditions alone or in combination with controlled atmosphere for longer durations subsequently exhibit several physiological disorders that lower consumer attraction and prompt reduced prices in the market (Singh et al., 2022). Intermittent warming by fruits exposed to high temperature is a unique non-chemical postharvest technique in which short periodic interruptions in ongoing storage have been widely tested to relieve chilling injury and other specific storage disorders, and to maintain quality of apple fruits. Han et al. (2021) have reported water loss increases with increasing warming frequency and duration, while significantly decreasing chilling injury and energy consumption. Further, apple fruit cvs. ‘Cortland’, ‘Delicious’, and ‘Law Rome’ treated with periodic warming for 1 day at 20 °C after 1 week in cold storage significantly reduced superficial scald when assessed after 154 days of storage (Alwan & Watkins, 1999).

Controlled Atmospheres

CA technology is considered an advancement in postharvest science for storage life extension of fresh horticultural produce and generally functions on the principle of reducing O2 and increasing CO2 which significantly delays the respiration and mitigates ethylene biosynthesis and its action during the postharvest period. The era of CA technology development has been divided into three sections: the development of protocols by optimizing gas composition for apple fruit, resolving quality issues including physiological appearance disorders by lowering oxygen levels regarded as ULO storage, which also results in certain low oxygen injuries in sensitive cultivars which warrants the future research for the development of DCA (dynamic controlled atmosphere) technology (Singh et al., 2022).

CA Storage

Gorny and Kader (1996) have highlighted that controlled atmosphere storage has been commercially applied since the 1930s in the apple industry by modulating gas composition in storage rooms. CA storage of apples significantly prolonged storability than conventional cold storage. Erkan et al. (2004) have reported that apple cv. ‘Granny Smith’ subjected to CA storage 2% O2 + 3% CO2 at 0 °C with 90–92% RH significantly reduced water loss by 1.2% as compared to control (air storage conditions) after 270 days of storage (Table 3). The apple fruits respond well when subjected to traditional CA storage in combination with application of ethylene antagonists. Tokala et al. (2022) have reported that apple fruit cv. ‘Cripps Pink’ treated with 1H-cyclopropa[b]naphthalene (NC), 1H-cyclopropabenzene (BC), and 1-MCP stored under CA conditions 3.45 ± 0.45% O2 and 2.40 ± 0.36% CO2 showed significant results for physiochemical parameters during 150 days of storage. CA combined with 1-MCP followed by BC and NC fumigation treatments markedly reduced water loss, ethylene production, and respiration rate, and preserved higher antioxidant compounds during the entire period of storage (Table 3). Conversely, fruits stored under normal CA conditions exhibited inferior results for retaining quality attributes during storage. While CA offers beneficial effects on storage quality of apple fruit, it does have certain quality issues, including appearance of physiological disorders which limit marketability. Accordingly, CA storage has the potential to reduce water loss and maintain overall quality alone or in combination with other chemical or non-chemical technologies being employed at commercial scale. The extension of CA technology into ULO systems in which O2 is reduced to approximately 1% has been reported to significantly reduce physiological disorders and pathogenic diseases in apple fruit. Onursal and Koyuncu (2021) revealed that apple fruit cv. ‘Scarlet Spur’ stored under ULO conditions expressively reduced water loss for 300 days following 7 days at shelf-life conditions, as compared to fruit stored under normal CA and DCA conditions. ULO treatment also displayed inhibition of ethylene production, retained higher flesh firmness, delayed SSC, and maintained TA during the period of storage. Kittemann et al. (2015) reported that ULO combined with 1-MCP treatment significantly reduced water loss and disease incidence in apple fruit cvs. ‘Golden Delicious’, ‘Jonagold’, and ‘Pinova’ stored for 210 days following 7 days of shelf period.

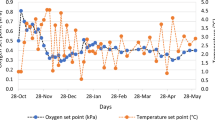

DCA Storage

Physiological disorder development in apple fruit during long-term storage has been regarded as the prime issue in the apple industry, and for which DPA and 1-MCP chemical treatments are commercially employed before storage. However, DPA have been prohibited by several countries due to the hazard they pose for animals and aquatic environments (Mditshwa et al., 2018). The detrimental aspects of CA and ULO storage have been adequately documented; however, there are several negative effects associated with apples in ULO storage conditions including low O2 damage, development of postharvest disease incidence, and accumulation of off-flavour necessitated further research for DCA development (Weber et al., 2015; Wright et al., 2015). DCA technology is basically the progression of ULO in which O2 levels are reduced until the lower oxygen limit (LOL), before the initiation of aerobic respiration, and instantly convert back to previous storage conditions. The LOL was assessed by CF and RQ (respiration quotient) and ET (ethanol) sensor technologies (Mditshwa et al., 2018). Onursal and Koyuncu (2021) have revealed that apple fruit cv. ‘Scarlet Spur’ stored under DCA conditions for 300 days showed comparable results for water loss with fruits stored under ULO conditions, while much lower than fruits kept at normal CA storage conditions. In another study, apple fruit cv. ‘Maxi Gala’ were tested under DCA storage conditions combined with 1-MCP, CF, and RQ sensors and evaluated for their impact on wax composition and fruit quality during 240 days of storage following 7 days at retail shelf conditions. DCA-CF technology outclassed other treatments for reducing water loss by 1.84% without subjecting it to pre-storage 1-MCP treatment. ‘Maxi Gala’ apples stored under DCA-RQ conditions showed a higher water loss of 4.22% even when treated with 1-MCP treatment. In addition, DCA-CF significantly reduced ethylene biosynthesis and maintained higher fatty acid and cuticular wax composition during the period of storage (Klein et al., 2021) (Table 3). Further, storage disorders including superficial scald, watercore, internal browning, and core flush were markedly reduced in different apple cultivars during long-term storage under DCA conditions (Bessemans et al., 2016; DeLong et al., 2006; Köpcke, 2015; Mditshwa et al., 2017; Weber et al., 2015, 2017).

Packaging

Packaging is another postharvest technique being employed in the apple industry supply chain, starting from the farmgate to the consumer end, which is important in protecting harvested fruits from the external environment, and to conserve quality and ensure traceability and extension of storage life. Several packaging materials have been used including conventional packaging such as wooden crates and corrugated boxes with the function of transportation to the market, a measure widely practiced in developing countries, while non-conventional packaging such as modified atmosphere packaging, polyethylene packaging (low-density polyethylene (LDPE)), and films impregnated with coating/anti-ripening martials are also used. The conventional packaging used for apples makes them more prone to mechanical injuries, has a low capacity to absorb shocks during transportation, and badly affects the storage life of apple fruits (Bhat et al., 2022). However, MA packaging has been tested for storage life extension of apple fruits in both cold storage and CA rooms. Rocha et al. (2004) have reported that apple fruit cv. ‘Bravo de Esmolfe’ packed in MAP bags results in lower water loss and retained colour and fruit firmness during cold storage at 2 °C for 195 days. Likewise, apple fruit cvs. ‘Golden Delicious’ and ‘Red Delicious’ packed in MAP bags kept at ambient conditions exhibited significantly reduced water loss during the shelf period (Khan et al., 2006). Polyethylene (PE) packaging also exhibited lower water loss and skin shriveling and conserved higher consumer acceptability in apple fruit cv. ‘Banky’ during 60 days of shelf period (Hayat et al., 2005). In addition, the shrink film packaging along with exogenous application of neem oil significantly reduced water loss, retained overall postharvest quality in terms of higher firmness, biochemical attributes, and anthocyanin content, and reduced softening enzymes in ‘Red Delicious’ apple fruit after 45 days at ambient conditions (Wijewardane & Guleria, 2013). Further to this, the active packaging impregnated with different film forming anti-microbial compounds significantly helped in reducing microbial spoilage, maintained quality, and extended storability of harvested fruit. Liu et al. (2021) investigated the effect of active packaging developed from combining a nano-titanium dioxide, litchi peel extract in chitosan matrix, markedly restricted the rate of respiration, reduced water loss, flesh softening, MDA content, ion leakage, and polyphenol oxidase activity, thereby maintaining the quality of watercored ‘Fuji’ apple fruit during 180 days of cold storage at 0 ± 1℃. In line with concerns around plastic waste, researchers may consider biodegradable materials for manufacturing thin film to wrap/pack fruit with adequate potential in inducing internal modified atmosphere.

Edible Coatings

Among various novel technologies, the application of edible coating has been reported as the most convenient and food-safe approach for preservation of fresh fruit and vegetables, working on the principle of modified atmosphere inside coated commodities which restricts gaseous exchange, thereby delaying senescence during storage (Hasan et al., 2021). There are several edible coating materials tested for their potential in extending storability of apple fruits. Commercial wax coating is the practice in the USA for developing glossiness in apple fruit, which also helps in reducing water loss, delaying ethylene production, and extending storage life (Bai & Plotto, 2012). Bai et al. (2003) have reported that candelilla wax coating significantly reduced water loss and developed internal modified atmosphere as compared to other formulations, i.e. carnauba wax, shellac, and carnauba-shellac, in commercial apple cvs. ‘Delicious’, ‘Fuji’, ‘Braeburn’, and ‘Granny Smith’ during 150 days of CA storage (Table 4). Similarly, apple fruit cv. ‘Fuji’ coated with carnauba-shellac wax alone or impregnated with lemongrass oil showed lower water loss and population of aerobic bacteria, and no growth of yeast and mould observed as compared to uncoated control fruit during 150 days of cold storage (Jo et al., 2014) (Table 4). In another study, banana peel extract combined with chitosan coating exhibited significant results for inhibiting respiration, lowering SSC, water loss, and maintaining higher ascorbic acid content in apple fruit cv. ‘Huangyuanshuai’ during 30 days of shelf period (Zhang et al., 2020a) (Table 4). Chitosan films combined with litchi peel extract displayed the lessening of watercore disorder in coated Fuji apples, in addition to reduced oxidative stress, water loss, and softening during 180 days of cold storage (Liu et al., 2021). Furthermore, apple fruit cv. ‘Golab Kohanz’ coated with nano-chitosan coating substantially reduced water loss, delayed climacteric peak of ethylene, and retained higher firmness during cold storage (Gardesh et al., 2016) (Table 4). Nano-silicon oxides combined with soy protein isolate showed better film-forming ability which aids in preventing quality loss in terms of reduced water loss and delayed climacteric peaks in ‘Red Fuji’ apples during cold storage (Liu et al., 2017). Fungal-based coating ‘Pullulans’ known as an excellent film-forming polysaccharide combined with Satureja hortensis extract showed strong antimicrobial and antifungal properties, and expressively reduced water loss and shriveling signs in apple fruit cv. ‘Jonagored’ during storage at two different temperature conditions (Kraśniewska et al., 2014). Starch-based edible coatings with major extraction from rice grains showed better quality by retaining fruit colour, reducing water loss, and maintaining bioactive compounds of ‘Cripps Pink’ apple fruit during storage (Thakur et al., 2019) (Table 4). Moreover, the apple fruit cv. ‘Golden Delicious’ coated with polyvinyl alcohol coating incorporated with starch and carvacol showed non-significant effects in reducing water loss, retaining firmness, and markedly reduced disease spread and fruit decay during the entire storage period (Sapper et al., 2020).

Chemical Treatments

1-Methylcyclopropene (1-MCP)

1-MCP has great potential in inhibiting ethylene biosynthesis and its action at the cellular level via blocking receptor cites irreversibly and down-expressing their respective genes (Sisler, 2006). 1-MCP is one of the most common synthetic chemicals extensively used in the apple industry around the globe in combination with different storage conditions for extending storability and ensuring year-round availability of fruit in local and high-end markets. 1-MCP significantly delays ripening and senescence by reducing respiration rate and ethylene production in apples during storage. Nevertheless, the application and response of 1-MCP significantly depend upon the cultivar to be treated, concentration, treatment duration, coupling storage type, and temperature conditions (Watkins, 2006). Table 5 illustrates the positive effect of 1-MCP application on water loss and postharvest quality of apple fruit during different storage conditions. Weis and Bramlage (2002) reported that apple cv. ‘Redchief Delicious’ subjected to 1-MCP treatment significantly reduced the water loss and internal ethylene concentration, and maintained higher firmness after 90 days of cold storage following recondition for 7 days at shelf conditions. Contrastingly, apple fruit cv. ‘Cripps Pink’ treated with 1-MCP followed by storage under CA conditions equipped with a photocatalytic oxidation (PO) setup markedly reduced water loss, retarded ethylene production, and retained higher firmness and ascorbic acid and total phenolic concentrations during the period of storage (Tokala et al., 2022). In addition to postharvest application, preharvest sprays of Harvista™ (liquid formulation of sprayable 1-MCP) to apple trees cv. ‘Golden Delicious’ exhibited significantly reduced water loss and ethylene production and downregulated their respective gene expressions, maintained firmness, SSC, and TA, and also modulated the wax composition during 150 days of cold storage at 0–1 °C and 90–95% RH (Li et al., 2022). However, 1-MCP application has been reported deleterious in some susceptible cultivars, for example downgraded eating properties in ‘Anna’ and ‘McIntosh’ apples (Pre-Aymard et al., 2005) and pronounced storage disorders and increased disease incidence during storage (Saba & Watkins, 2020; Watkins, 2008).

1H-Cyclopropabenzene and 1H-cyclopropa[b]naphthalene

There are few constraints faced by fresh produce industry stakeholders in relation to 1-MCP, including rapid vaporisation due its compound instability in liquid formulation at ambient room temperature (Sisler, 2006). Likewise, 1-MCP application via fumigation faced similar issues such as less diffusion capacity into fruits and less effectiveness due to its rapid off-gassing (Choi et al., 2008). Singh’s group has discovered two new ethylene antagonist compounds, namely 1H-cyclopropabenzene (NC) and 1H-cyclopropa[b]naphthalene (BC). These have a different chemical structure from 1-MCP, but are similar in function, and were tested as dip and fumigation for delaying ripening and maintaining postharvest quality of fresh horticultural produce during storage (Singh et al., 2018). Postharvest application of fumigation and dip treatment of NC and BC compounds significantly downregulated ethylene production and respiration rate, reduced water loss, and maintained higher firmness and total phenolic concentrations in apple fruit cvs. ‘Cripps Pink’ and ‘Granny Smith’ under different storage conditions such as traditional cold storage, ozonated cold storage, CA storage, and CA storage coupled with PO up to 120 to 150 days in separate experiments (Tokala et al., 2020, 2021a, b, 2022) (Table 5). NC and BC compounds performed well in apple storage when applied as fumigation treatment instead of liquid formulation with more stability at room conditions (Tokala et al., 2020).

Nitric Oxide (NO)

NO is another substitute for ethylene antagonists and it has been reported to delay postharvest senescence by reducing ethylene biosynthesis and respiration rate, and suppressing oxidative stress during apple storage. The exogenous application of NO, via either fumigation or dip treatment, also helps in reducing storage disorders and pathogenic rot, and maintaining quality in apple fruit during the postharvest period (Manjunatha et al., 2012; Steffens et al., 2022). Brackmann et al. (2017) have reported that apple fruit cv. ‘Galaxy’ subjected to NO treatment showed lower water loss as compared to ethanol and untreated control fruits after 240 days of CA storage following 7 days in shelf-life conditions (Table 5). In addition, apple fruit cv. ‘Cripps Pink’ subjected to NO fumigation significantly lessened superficial scald and rate of respiration, and increased TPC and total antioxidants during 180 days of CA storage following 7 days reconditioning in shelf conditions. Sucrose metabolism in ‘Fuji’ apples was modulated by sodium nitroprusside (NO donor) dip treatment by increasing sucrose phosphate synthase (SPS) and sucrose synthase synthesis (SSS) activities and delayed fruit softening during shelf period (Chen et al., 2019). Moreover, the NO application also contributed to attenuating flesh browning in fresh cut apples during storage (Huque et al., 2013; Pristijono et al., 2008).

Salicylic Acid (SA)

SA is a well-known endogenous plant growth regulator and key signalling molecule derived from willow bark, and works as a chemical messenger and functions in mediating plant defence responses against various abiotic stresses (Wang et al., 2022). Pre-storage application of SA treatment in fresh horticultural produce showed great potential in alleviating high postharvest losses by extending durability during storage (Asghari & Aghdam, 2010). Kazemi et al. (2011) have reported that apple cv. ‘Jonagold’ treated with SA showed lower water loss, browning index, and ion leakage, while maintaining higher firmness, ascorbic acid content, and activities of SOD and POD, and prevented fruit softening during cold storage for 60 days at 5 °C. Similarly, the dip application of SA reduced water loss, downregulated ethylene production, and maintained higher firmness in apple fruit cv. ‘Granny Smith’ during 140 days of cold storage (Shirzadeh & Kazemi, 2012) (Table 5). Furthermore, Li et al. (2006) revealed that SA application also maintained higher total ester regeneration in the peel of apple cv. ‘Golden Delicious’ during 240 days of cold storage. This feature also displayed great potential for suppressing microbial growth and inhibiting deleterious pathogens, thereby reducing disease incidence during the postharvest period (da Rocha Neto et al., 2016; Zhao & Wang, 2015).

Calcium Chloride (CaCl2)

Calcium is one of the many important nutrients which play an imperative role in maintaining pre- and postharvest quality of apple fruits (Fallahi et al., 1997). The deficiency of Ca nutrients in apple plants may result in higher incidence of field and storage disorders including bitter pit, lenticel blotch, internal breakdown, superficial scald, watercore, and low-temperature breakdown. In addition, Ca-deficient apples showed higher susceptibility to fungal pathogens, postharvest decay, and lower potential of storage (Wójcik & Borowik, 2013). Ca nutrients are generally sprayed on apple trees using CaCl2 and Ca-nitrate [Ca(NO3)2] materials for uplifting the internal Ca content in trees and also the fruits in order to overcome quality issues. CaCl2 is the most popular product sprayed and postharvest dip treatment in apple crops. Elham et al. (2011) have reported CaCl2 dip treatment to significantly reduce water loss and internal ethylene, maintain higher firmness and antioxidant enzyme activities, and lower sugar acid ratio, pH, and peroxidase activity in ‘Jonagold’ apple fruit during 150 days of cold storage (Table 5). Similarly, the results of reduced water loss were obtained in apple fruit cvs. ‘Red Delicious’, ‘Royal Gala’, ‘Mondial Gala’, and ‘Golden Delicious’ treated with CaCl2 dip treatment following cold storage (Hussain et al., 2012; Jan et al., 2013) (Table 5). Advancements in technology and preharvest sprays of CaCl2 and nano CaCl2 products have been evaluated for their impact on postharvest quality of apple fruits. Results have revealed that apple trees cv. ‘Red Delicious’ sprayed with nano-CaCl2 outclassed other traditional CaCl2 treatments and exhibited lower water loss, activities of cell wall–degrading enzymes, i.e. pectin methylesterase (PME), polygalacturonase (PG), and β-galactosidase (β-Gal), delayed internal browning, and retained higher firmness, total antioxidants, TPC, and fibre content during the period of cold storage for 120 days (Ranjbar et al., 2018).

Melatonin (MT)

MT is an indolic compound having low molecular weight, discovered firstly in animals, which performs several functions in plants by modulating growth productivity, abiotic stresses where it acts as a scavenger of free radicals, and helps in inducing pathogenic resistance. Postharvest application of MT has received much attention lately and it has been well documented for delaying ripening and senescence, developing CI tolerance, reducing microbial decay, and maintaining overall quality of fresh fruits and vegetables (Shah et al., 2023; Wang et al., 2020). Postharvest MT dip treatment to ‘Fuji’ apples significantly reduced water loss and ethylene production with downregulated expression of respective genes, and maintained better skin structure as well as activities of antioxidant enzymes during cold storage (Onik et al., 2021) (Table 5). Additionally, apple fruit cv. ‘Golden Delicious’ subjected to MT dip treatment significantly reduced respiratory peaks, maintained higher textural quality, ascorbic acid content, SSC, and acidity, modulated sucrose metabolism by increasing sucrose synthase synthesis (SS-S) and sucrose phosphate synthase (SPS) activities, and suppressed sorbitol oxidase, sorbitol dehydrogenase, and sucrose synthase cleavage in fruit during ambient storage (Fan et al., 2022). MT treatment was also reported as reducing postharvest grey mould and CI in apple fruit during the postharvest period (Dong et al., 2022; Sun et al., 2021).

Non-chemical Treatments

Heat Treatments

Several fruits and vegetables have been subjected to heat treatment at commercial scale due to its important role in disinfestation of quarantine insects, disease incidence, and improving quality during postharvest period (Malik et al., 2021). Apple fruits subjected to heat treatment result in inhibition of disease spread but negatively affects the quality during storage. Shao et al. (2012) have reported that apple cv. ‘Gala’ subjected to hot air treatment with subsequent application of chitosan showed lower water loss as compared to fruit treated with heat during the entire period of storage. Similarly, the hot water dip treatment in apple fruit cv. ‘Golden Delicious’ significantly reduced microfungal growth; however, it also resulted in water loss, increased peel damage with pronounced internal breakdown, surface browning, and also promoted ripening during storage (Moscetti et al., 2013). Hot air storage treatment showed higher ethylene biosynthesis and lower respiration, and maintained firmness in apple fruit cvs. ‘Ana’ and ‘Granny Smith’ during posttreatment cold storage (Lurie et al., 1996). Besides the beneficial aspect of heat treatment, it has been shown to have deleterious effects on water loss and quality during storage (Moscetti et al., 2013; Shao et al., 2012).

Irradiation

Postharvest irradiation technology is being employed in several developing as well as developed countries for disinfestation of insects and microorganisms with the intention of extending storability of fresh horticultural produce in their supply chains (Arvanitoyannis et al., 2009). Gamma irradiation (GI) was applied to apple cvs. ‘Golden Delicious’ and ‘Starking’ followed by cold storage in two subsequent years which showed non-significant results for reducing water loss; however, reduced skin scald and the growth of Aspergillus niger were observed (Al-Bachir, 1999). In another study, the apple fruit cv. ‘Red Delicious’ treated with GI combined with pre-storage CaCl2 dip treatment showed lower water loss during storage. These contradictory results might be due to differences in cultivar and combination of coating to irradiation treatment (Hussain et al., 2012).

Ozone

Ozone is an oxidizing agent used in either gaseous or aqueous form for cleaning and is considered as a substitute for traditional chlorine application (Maryam et al., 2021). This has been tested as a sanitizer for surface disinfestation of microflora in apple fruits. However, ozone treatment showed no effect on physiological water loss and other physical quality attributes during storage. Sheng et al. (2018) have reported that the application of ozone in ‘Fuji’ apples commercial cold and CA storage rooms facilities significantly inhibited the growth of Listeria innocua without affecting cosmetic quality of fruit during the entire period of storage. Ozonized cold storage of apple fruit cv. ‘Granny Smith’ showed non-significant results on water loss, with slightly increased ethylene biosynthesis, but helped in maintaining overall quality (Tokala et al., 2021a). Accordingly, the ozone application has apparently no direct impact on water loss in apple storage.

Molecular Aspects

As evident in previous literature reviews, it has now been established that several factors are associated directly or inversely with water loss in apple fruit during the postharvest period. Initially, the composition of apple cuticular wax has been found responsible for water diffusion from fruit peel during storage. The wax biosynthesis pathway in apple is partly similar to that reported in Arabidopsis. Several candidate genes including CER1, CER4, CER10, FDH, KCS7/2, LACS2, LCR, LTPG1, PAS2, WBC11, and WIN1 have been identified through expression sequence tag (EST) and genomic sequence analysis (GSA) for their possible involvement in wax biosynthesis in apple fruits (Albert et al., 2013; Velasco et al., 2010). The wax deposition as a thicker layer on apple plant leaves has been upregulated at transcriptional and translational levels of genes (MdCER1 and MdCER2) encoding in response to drought, which may prevent earlier desiccation and pathogenic infection (Qi et al., 2019; Zhang et al., 2020b; Zhong et al., 2020). Cuticular wax biosynthesis was promoted by MYB96 associated with abscisic acid (ABA) mediated stress by binding to the KCS/KCR promoters (Seo et al., 2011). As far as genetic expression of genes involved in cuticle biosynthesis in apple fruit skin is concerned, it has been visualized from a study in which russeting skin disorder in apple is induced by the surface moisture by depletion of wax composition in which expression of ABCG11, GPAT6, KCS10, SHN3, WSD1, and CER6 genes was downregulated consequently higher incidence of microcracking thereby increasing water loss (Straube et al., 2021). KCS genes were identified by the genome-wide analysis (GWA) technique which can further be utilized for regulation of wax biosynthesis in apple fruits (Lian et al., 2020). Atkinson et al. (2012) reported that downregulation of POLYGALACTURONASE1 (PG1) linked with cell wall disassembly reveals its role in transpirational water loss in apple fruit ripening. In another study, upregulation of beta-galactosidase associated gene Mdb-GAL2 showed more softening in untreated control ‘Jonagold’ and ‘Granny Smith’ apple fruits as compared to 1-MCP treated fruit during 180 days of CA storage (Gwanpua et al., 2016). Considering changing climate and harsh environmental conditions causing degradation of apple fruit quality, Zhang et al. (2020c) have reported the identification of long-chain acyl-CoA synthetase MdLACS2 gene in apple while their transgenic Arabidopsis expressed lower water loss and epidermal permeability. Additionally, it has also exhibited the association of the variations in gene expression of biosynthesis of cuticular wax, transport, and their regulation at transcriptional level, and wax composition. The information about these candidate genes from this study has far-reaching implications in future apple breeding plan for developing varieties resistant to high stress and improved fruit quality.

Conclusion and Prospects

Based on a review of the literature, water loss has been established as a complex quality marker associated with different metabolic responses and is greatly influenced by multiple preharvest and postharvest factors during the value chain, from farmgate to consumption. As discussed in detail, a waxy layer of polymeric cutin plays an important role in retaining water content, providing protection against environmental stresses, injuries, and cracking during storage in apple fruit. However, susceptibility to water loss varies with cultivar. Apple fruit containing many lenticels with variable size, colour, and positioning on fruit skin expressively contributed to water loss and quality during storage. Similarly, microcracking on apple fruit surface also contributed to earlier or delayed desiccation along progression during the postharvest period. Preharvest factors including climate change, cultivar, maturity stage, fruit size, tree age, nutritional schedule, and irrigation aid in reducing water loss in apple fruit. The postharvest variables that include temperature, RH, humidification system, and storage type depicted significant changes in postharvest water loss and fruit quality. Postharvest implications of packaging and cold storage coupled with CA, ULO, DCA, pre-storage 1-MCP application, and edible coatings could be the possible solution in reducing water loss, though the response to technology might be not suitable for different cultivars at commercial scale. This review article provides the information with a multiscale approach for reducing water loss along the postharvest value chain. Future apple breeding programmes should focus on modulation of wax composition in fruit peel, as evidence suggests that this might help in lessening water loss during the postharvest period. The preharvest application of plant growth regulators and other factors may also be beneficial in reducing water loss during storage, but is yet to be investigated in detail, while the traditional humidification systems used usually produce water droplets in storage rooms which may substantially increase skin moisture and microcracking provides a favourable condition for higher water loss and intrusion of fungal pathogens consequently results in accelerated decay. This humidification system in storage may be modified to overcome these constraints. DCA-CF technology could be a better alternative for CA storage for reducing water loss and maintaining higher internal quality attributes by alleviating physiological changes during storage.

Data Availability

The data/information used in this review article were extracted from already available published scientific works.

References

Akbudak, B., Ozer, M., Erturk, U., & Cavusoglu, S. (2009). Response of 1-methylcyclopropene treated “Granny Smith” apple fruit to air and controlled atmosphere storage conditions. Journal of Food Quality, 32(1), 18–33. https://doi.org/10.1111/j.1745-4557.2008.00233.x

Al-Bachir, M. (1999). Effect of gamma irradiation on storability of apples (Malus domestica L.). Plant Foods for Human Nutrition, 54(1), 1–11. https://doi.org/10.1023/A:1008007502187

Albert, Z., Ivanics, B., Molnár, A., Miskó, A., Tóth, M., & Papp, I. (2013). Candidate genes of cuticle formation show characteristic expression in the fruit skin of apple. Plant Growth Regulation, 70(1), 71–78. https://doi.org/10.1007/s10725-012-9779-y

Alhaj-Alali, F., Askari Sarcheshmeh, M. A., & Babalar, M. (2020). The influence of various levels of ammonium to total nitrogen on post-harvest performance of three apple cultivars (Golab Kohans, Gala, and Granny Smith). DYSONA-Applied Science, 1(1), 11–19. https://doi.org/10.30493/DAS.2020.103716

Ali, U., Basu, S., & Mazumder, K. (2020). Improved postharvest quality of apple (Rich Red) by composite coating based on arabinoxylan and β-glucan stearic acid ester. International Journal of Biological Macromolecules, 151, 618–627. https://doi.org/10.1016/j.ijbiomac.2020.02.081

Alwan, T. F., & Watkins, C. B. (1999). Intermittent warming effects on superficial scald development of ‘Cortland’, ‘Delicious’ and ‘Law Rome’ apple fruit. Postharvest Biology and Technology, 16(3), 203–212. https://doi.org/10.1016/S0925-5214(99)00017-4Getrightsandcontent

Argenta, L. C., de Freitas, S. T., Mattheis, J. P., Vieira, M. J., & Ogoshi, C. (2021). Characterization and quantification of postharvest losses of apple fruit stored under commercial conditions. HortScience, 56(5), 608–616. https://doi.org/10.21273/HORTSCI15771-21

Arvanitoyannis, I. S., Stratakos, A. C., & Tsarouhas, P. (2009). Irradiation applications in vegetables and fruits: A review. Critical Reviews in Food Science and Nutrition, 49(5), 427–462. https://doi.org/10.1080/10408390802067936

Asghari, M., & Aghdam, M. S. (2010). Impact of salicylic acid on post-harvest physiology of horticultural crops. Trends in Food Science & Technology, 21(10), 502–509. https://doi.org/10.1016/j.tifs.2010.07.009

Atkinson, R. G., Sutherland, P. W., Johnston, S. L., Gunaseelan, K., Hallett, I. C., Mitra, D., Brummell, D. A., Schröder, R., Johnston, J. W., & Schaffer, R. J. (2012). Down-regulation of POLYGALACTURONASE1 alters firmness, tensile strength and water loss in apple (Malus x domestica) fruit. BMC Plant Biology, 12(1), 1–13. https://doi.org/10.1186/1471-2229-12-129

Bai, J., & Plotto, A. (2012). Coatings for fresh fruits and vegetables. In Edible coatings and films to improved food quality (Second ed., pp. 185–242). Taylor & Francis Group.

Bai, J., Hagenmaier, R. D., & Baldwin, E. A. (2003). Coating selection for ‘Delicious’ and other apples. Postharvest Biology and Technology, 28(3), 381–390. https://doi.org/10.1016/S0925-5214(02)00201-6

Beisson, F., Li-Beisson, Y., & Pollard, M. (2012). Solving the puzzles of cutin and suberin polymer biosynthesis. Current Opinion in Plant Biology, 15(3), 329–337. https://doi.org/10.1016/j.pbi.2012.03.003

Belding, R. D., Blankenship, S. M., Young, E., & Leidy, R. B. (1998). Composition and variability of epicuticular waxes in apple cultivars. Journal of the American Society for Horticultural Science, 123(3), 348–356. https://doi.org/10.21273/JASHS.123.3.348

Ben-Yehoshua, S., & Rodov, V. (2002). Transpiration and water stress. In Postharvest physiology and pathology of vegetables (pp. 143–197). CRC Press.

Bessemans, N., Verboven, P., Verlinden, B., & Nicolaï, B. (2016). A novel type of dynamic controlled atmosphere storage based on the respiratory quotient (RQ-DCA). Postharvest Biology and Technology, 115, 91–102. https://doi.org/10.1016/j.postharvbio.2015.12.019

Bhat, S. A., Rizwan, D., Mir, S. A., Wani, S. M., & Masoodi, F. (2022). Advances in apple packaging: A review. Journal of Food Science and Technology, 1–13. https://doi.org/10.1007/s13197-022-05447-8

Błaszczyk, J., & Gasparski, K. (2019). Influence of 1-methylcyclopropene (1-MCP) on the quality and storability of 'Red Jonaprince' apples stored in different conditions. Acta Scientiarum Polonorum Hortorum Cultus, 18(6), 7–15. https://doi.org/10.24326/asphc.2019.6.1

Brackmann, A., Ludwig, V., Thewes, F. R., Anese, R. O., Schultz, E. E., & Bergetti, M. R. P. (2017). Ethanol and nitric oxide in quality maintenance of ‘Galaxy’ apples stored under controlled atmosphere. Revista Brasileira de Fruticultura, 39. https://doi.org/10.1590/0100-29452017322

Brackmann, A., Mazaro, S. M., & Cecchini, R. (1996). Precooling and postharvest chemical treatment of “Golden Delicious” and “Fuji” apples. Ciência Rural, 26, 185–189. https://doi.org/10.1590/S0103-84781996000200003

Buzby, J. C., Hyman, J., Stewart, H., & Wells, H. F. (2011). The value of retail-and consumer-level fruit and vegetable losses in the United States. Journal of Consumer Affairs, 45(3), 492–515. https://doi.org/10.1111/j.1745-6606.2011.01214.x

Chai, Y., Li, A., Wai, S. C., Song, C., Zhao, Y., Duan, Y., Zhang, B., & Lin, Q. (2020). Cuticular wax composition changes of 10 apple cultivars during postharvest storage. Food Chemistry, 324, 126903.

Chen, H. Y., Jiang, L. F., Zeng, J. H., Huo, Y. R., & Li, Y. X. (2020). Combination of carnauba wax-based coating and 1-methylcyclopropene (1-MCP) maintains better “Fuji” apple qualities during storage at low temperature. Journal of Food Processing and Preservation, 44(12), e14925. https://doi.org/10.1111/jfpp.14925

Chen, Y., Ge, Y., Zhao, J., Wei, M., Li, C., Hou, J., Cheng, Y., & Chen, J. (2019). Postharvest sodium nitroprusside treatment maintains storage quality of apple fruit by regulating sucrose metabolism. Postharvest Biology and Technology, 154, 115–120. https://doi.org/10.1016/j.postharvbio.2019.04.024

Choi, S. T., Tsouvaltzis, P., Lim, C. I., & Huber, D. J. (2008). Suppression of ripening and induction of asynchronous ripening in tomato and avocado fruits subjected to complete or partial exposure to aqueous solutions of 1-methylcyclopropene. Postharvest Biology and Technology, 48(2), 206–214. https://doi.org/10.1016/j.postharvbio.2007.10.008

Curry, E. (2008). Effects of 1‐MCP applied postharvest on epicuticular wax of apples (Malus domestica Borkh.) during storage. Journal of the Science of Food and Agriculture, 88(6), 996–1006.

Curry, E., & Arey, B. (2010). Apple cuticle: The perfect interface. Scanning Microscopy 2010,

Curry, E. A., Torres, C., & Neubauer, L. (2008). Preharvest lipophilic coatings reduce lenticel breakdown disorder in ‘Gala’ apples. HortTechnology, 18(4), 690–696.

da Rocha Neto, A. C., Beaudry, R., Maraschin, M., Di Piero, R. M., & Almenar, E. (2019). Double-bottom antimicrobial packaging for apple shelf-life extension. Food Chemistry, 279, 379–388. https://doi.org/10.1016/j.foodchem.2018.12.021

da Rocha Neto, A. C., Luiz, C., Maraschin, M., & Di Piero, R. M. (2016). Efficacy of salicylic acid to reduce Penicillium expansum inoculum and preserve apple fruits. International Journal of Food Microbiology, 221, 54–60. https://doi.org/10.1016/j.ijfoodmicro.2016.01.007

De León-Zapata, A., & M., Ventura-Sobrevilla, J. M., Salinas-Jasso, T. A., Flores-Gallegos, A. C., Rodríguez-Herrera, R., Pastrana-Castro, L., Rua-Rodríguez, M. L., & Aguilar, C. N. (2018). Changes of the shelf life of candelilla wax/tarbush bioactive based-nanocoated apples at industrial level conditions. Scientia Horticulturae, 231, 43–48. https://doi.org/10.1016/j.scienta.2017.12.005

De León-Zapata, M. A., Sáenz-Galindo, A., Rojas-Molina, R., Rodríguez-Herrera, R., Jasso-Cantú, D., & Aguilar, C. N. (2015). Edible candelilla wax coating with fermented extract of tarbush improves the shelf life and quality of apples. Food Packaging and Shelf Life, 3, 70–75. https://doi.org/10.1016/j.fpsl.2015.01.001

Delong, J. M., Harrison, P., & Prange, R. (2006). Chlorophyll fluorescence-based low-O2 ca storage of organic 'Cortland' and 'Delicious' apples. Acta Horticulturae, 31–37. https://doi.org/10.17660/ActaHortic.2007.737.3