Abstract

The global interest in sustainable production of chemicals and materials from lignocellulosic biomass is boosted by the need of replacing fossil derivatives. Cellulose nanocrystals may prove to be one of the most promising green materials of modern times due to its intrinsic properties, renewability and abundance. The preliminary steps to obtain pure cellulose fibers are crucial and must be performed carefully. Several chlorine-free treatments have been developed in order to decrease the environment impact of the pulping process. Among all, traditional pulping with sodium hydroxide and hydrogen peroxide is still the most viable method for industries. Based on that, this work is dedicated to propose and optimize chlorine-free purification routes for isolating cellulose nanocrystals from rice husk agroindustrial waste. The novelty addressed here is the application of mild industrially viable process conditions to perform the chlorine-free purification routes, previously unexplored for rice husk as a source of lignocellulosic raw material. Two routes were performed, reducing lignin from 20 to 2.91% and 4.65%. The formation of cellulose nanocrystals was confirmed by the significant increase in crystallinity, ranging from 40.87% of rice husk, to 77.45% for the first route and 66.21% for the second rout, both being cellulose II. Thus, it has been shown the viability to obtain cellulose nanocrystals using a totally chlorine-free technique to extract and bleach cellulose from rice husk under mild process conditions, in order to add value to this residue reducing its volume and impact on the environment.

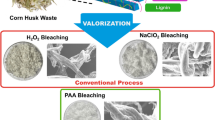

Graphic Abstract

Similar content being viewed by others

References

FAO - Food and Agriculture Organization of the United Nations: Rice Market Monitor, www.fao.org/economic/RMM

Lay, C.-H., Hsu, Y.-C., Lin, C.-Y., Chen, C.-C.: Anaerobic biohydrogen production using rice husk-based biologics. Waste Biomass Valorization. (2019). https://doi.org/10.1007/s12649-018-00544-2

Liou, T.-H.: Preparation and characterization of nano-structured silica from rice husk. Mater. Sci. Eng. A. 364, 313–323 (2004). https://doi.org/10.1016/j.msea.2003.08.045

Fernandes, I.J., Calheiro, D., Kieling, A.G., Moraes, C.A.M., Rocha, T.L.A.C., Brehm, F.A., Modolo, R.C.E.: Characterization of rice husk ash produced using different biomass combustion techniques for energy. Fuel 165, 351–359 (2016). https://doi.org/10.1016/j.fuel.2015.10.086

Moraes, C.A.M., Fernandes, I.J., Calheiro, D., Kieling, A.G., Brehm, F.A., Rigon, M.R., Filho, J.A.B., Schneider, I.A.H., Osorio, E.: Review of the rice production cycle: By-products and the main applications focusing on rice husk combustion and ash recycling. Waste Manag. Res. 32, 1034–1048 (2014). https://doi.org/10.1177/0734242X14557379

CONAB - Companhia Nacional de Abastecimento: Boletim de Acompanhamento da Safra Brasileira de Grãos V. 10. , Brasília, DF (2018)

Pedroso, G.B., Silva, L.O., Araujo, R.B., Saldanha, L.F., Denardi, L., Martins, A.F.: An innovative approach for the biotechnological production of succinoglycan from rice husks. Ind. Crops Prod. 137, 615–627 (2019). https://doi.org/10.1016/j.indcrop.2019.05.052

Castaldi, M., van Deventer, J., Lavoie, J.M., Legrand, J., Nzihou, A., Pontikes, Y., Py, X., Vandecasteele, C., Vasudevan, P.T., Verstraete, W.: Progress and prospects in the field of biomass and waste to energy and added-value materials. Waste Biomass Valorization 8, 1875–1884 (2017). https://doi.org/10.1007/s12649-017-0049-0

FitzPatrick, M., Champagne, P., Cunningham, M.F., Whitney, R.A.: A biorefinery processing perspective: treatment of lignocellulosic materials for the production of value-added products. Bioresour. Technol. 101, 8915–8922 (2010). https://doi.org/10.1016/j.biortech.2010.06.125

Hassan, S.S., Williams, G.A., Jaiswal, A.K.: Bioresource technology emerging technologies for the pretreatment of lignocellulosic biomass. Bioresour. Technol. 262, 310–318 (2018). https://doi.org/10.1016/j.biortech.2018.04.099

Brinchi, L., Cotana, F., Fortunati, E., Kenny, J.M.: Production of nanocrystalline cellulose from lignocellulosic biomass: technology and applications. Carbohydr. Polym. 94, 154–169 (2013). https://doi.org/10.1016/j.carbpol.2013.01.033

Coseri, S.: Cellulose: to depolymerize … or not to ? Biotechnol. Adv. 35, 251–266 (2017). https://doi.org/10.1016/j.biotechadv.2017.01.002

Visakh, P.M., Thomas, S.: Preparation of bionanomaterials and their polymer nanocomposites from waste and biomass. Waste Biomass Valorization 1, 121–134 (2010). https://doi.org/10.1007/s12649-010-9009-7

Tingaut, P., Zimmermann, T., Sèbe, G.: Cellulose nanocrystals and microfibrillated cellulose as building blocks for the design of hierarchical functional materials. J. Mater. Chem. 22, 20105–20111 (2012). https://doi.org/10.1039/C2JM32956E

Battisti, R., Fronza, N., Vargas Júnior, Á., Silveira, S.M., da Damas, M.S.P., Quadri, M.G.N.: Gelatin-coated paper with antimicrobial and antioxidant effect for beef packaging. Food Packag. Shelf Life. 11, 115–124 (2017). https://doi.org/10.1016/j.fpsl.2017.01.009

VandeVyver, S., Geboers, J., Jacobs, P.A., Sels, B.F.: Recent advances in the catalytic conversion of cellulose. ChemCatChem 3, 82–94 (2011). https://doi.org/10.1002/cctc.201000302

Battisti, R., Hafemann, E., Claumann, C.A., Machado, R.A.F., Marangoni, C.: Synthesis and characterization of cellulose acetate from Royal Palm tree agroindustrial waste. Polym. Eng. Sci. (2018). https://doi.org/10.1002/pen.25034

Balat, M., Balat, H., Öz, C.: Progress in bioethanol processing. Prog. Energy Combust. Sci. 34, 551–573 (2008). https://doi.org/10.1016/j.pecs.2007.11.001

Hafemann, E., Battisti, R., Marangoni, C., Machado, R.A.F.: Valorization of royal palm tree agroindustrial waste by isolating cellulose nanocrystals. Carbohydr. Polym. 218, 188–198 (2019). https://doi.org/10.1016/j.carbpol.2019.04.086

Mariano, M., El Kissi, N., Dufresne, A.: Cellulose nanocrystals and related nanocomposites: review of some properties and challenges. J. Polym. Sci. Part B 52, 791–806 (2014). https://doi.org/10.1002/polb.23490.

Salas, C., Nypelö, T., Rodriguez-abreu, C., Carrillo, C., Rojas, O.J.: Nanocellulose properties and applications in colloids and interfaces. Curr. Opin. Colloid Interface Sci. 19, 383–396 (2014). https://doi.org/10.1016/j.cocis.2014.10.003

Souza, V.C., Quadri, M.G.N.: Preparation and properties of cellulose nanocrystals derived from corn cobs: application as a reinforcing material for green nanocomposite-films. J. Biobased Mater. Bioenergy. 8, 495–505 (2014). https://doi.org/10.1166/jbmb.2014.1465

Pelegrini, B.L., Ré, F., de Oliveira, M.M., Fernandes, T., de Oliveira, J.H., Oliveira Junior, A.G., Girotto, E.M., Nakamura, C.V., Sampaio, A.R., Valim, A., de Souza Lima, M.M.: Cellulose nanocrystals as a sustainable raw material: cytotoxicity and applications on healthcare technology. Macromol. Mater. Eng. 304, 1900092 (2019). https://doi.org/10.1002/mame.201900092

Rajinipriya, M., Nagalakshmaiah, M., Robert, M., Elkoun, S.: Importance of agriculture and industrial waste in the field of nanocellulose and its recent industrial developments: a review. ACS Sustain. Chem. Eng. 6, 2807–2828 (2018). https://doi.org/10.1021/acssuschemeng.7b03437

Lamaming, J., Hashim, R., Leh, C.P., Sulaiman, O.: Properties of cellulose nanocrystals from oil palm trunk isolated by total chlorine free method. Carbohydr. Polym. 156, 409–416 (2017). https://doi.org/10.1016/j.carbpol.2016.09.053

Johar, N., Ahmad, I., Dufresne, A.: Extraction, preparation and characterization of cellulose fibres and nanocrystals from rice husk. Ind. Crop. Prod. 37, 93–99 (2012). https://doi.org/10.1016/j.indcrop.2011.12.016

de Oliveira, J.P., Bruni, G.P., el Halal, S.L.M., Bertoldi, F.C., Dias, A.R.G., da Rosa Zavareze, E.: Cellulose nanocrystals from rice and oat husks and their application in aerogels for food packaging. Int. J. Biol. Macromol. 124, 175–184 (2019). https://doi.org/10.1016/j.ijbiomac.2018.11.205

Das, A.M., Ali, A.A., Hazarika, M.P.: Synthesis and characterization of cellulose acetate from rice husk: Eco-friendly condition. Carbohydr. Polym. 112, 342–349 (2014). https://doi.org/10.1016/j.carbpol.2014.06.006

Ooi, S.Y., Ahmad, I., Cairul, M., Mohd, I.: Cellulose nanocrystals extracted from rice husks as a reinforcing material in gelatin hydrogels for use in controlled drug delivery systems Gelatin/CNC hydrogel Gelatin hydrogel. Ind. Crop. Prod. 93, 227–234 (2016). https://doi.org/10.1016/j.indcrop.2015.11.082

Rosa, S.M.L., Rehman, N., de Miranda, M.I.G., Nachtigall, S.M.B., Bica, C.I.D.: Chlorine-free extraction of cellulose from rice husk and whisker isolation. Carbohydr. Polym. 87, 1131–1138 (2012). https://doi.org/10.1016/j.carbpol.2011.08.084

Al-Dulaimi, A.A., Wanrosli, W.D.: Isolation and characterization of nanocrystalline cellulose from totally chlorine free oil palm empty fruit bunch pulp. J. Polym. Environ. 25, 192–202 (2017). https://doi.org/10.1007/s10924-016-0798-z

Robles, E., Fernández-Rodríguez, J., Barbosa, A.M., Gordobil, O., Carreño, N.L.V., Labidi, J.: Production of cellulose nanoparticles from blue agave waste treated with environmentally friendly processes. Carbohydr. Polym. 183, 294–302 (2018). https://doi.org/10.1016/j.carbpol.2018.01.015

Teh, K.C., Tan, R.R., Aviso, K.B., Promentilla, M.A.B., Tan, J.: An integrated analytic hierarchy process and life cycle assessment model for nanocrystalline cellulose production. Food Bioprod. Process. 118, 13–31 (2019). https://doi.org/10.1016/j.fbp.2019.08.003

Candido, R.G., Gonçalves, A.R.: Synthesis of cellulose acetate and carboxymethylcellulose from sugarcane straw. Carbohydr. Polym. 152, 679–686 (2016). https://doi.org/10.1016/j.carbpol.2016.07.071

Beck-Candanedo, S., Roman, M., Gray, D.G.: Effect of reaction conditions on the properties and behavior of wood cellulose nanocrystal suspensions. Biomacromol 6, 1048–1054 (2005). https://doi.org/10.1021/bm049300p

Mariano, M., Cercená, R., Soldi, V.: Thermal characterization of cellulose nanocrystals isolated from sisal fibers using acid hydrolysis. Ind. Crops Prod. 94, 454–462 (2016). https://doi.org/10.1016/j.indcrop.2016.09.011

Yokoyama, T., Kadla, J.F., Chang, H.: Microanalytical method for the characterization of fiber components and morphology of woody plants. J. Agric. Food Chem. 50, 1040–1044 (2002). https://doi.org/10.1021/jf011173q

Segal, L., Creely Jr., J.J., Martin, A.E., Conrad, C.M.: An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text. Res. J. 29, 786–794 (1959)

Tserki, V., Zafeiropoulos, N.E., Simon, F., Panayiotou, C.: A study of the effect of acetylation and propionylation surface treatments on natural fibres. Composites A 36, 1110–1118 (2005). https://doi.org/10.1016/j.compositesa.2005.01.004

Roncero, M.B., Torres, A.L., Colom, J.F., Vidal, T.: The effect of xylanase on lignocellulosic components during the bleaching of wood pulps. Bioresour. Technol. 96, 21–30 (2005). https://doi.org/10.1016/j.biortech.2004.03.003

Kljun, A., Benians, T.A.S., Goubet, F., Meulewaeter, F., Knox, J.P., Blackburn, R.S.: Comparative analysis of crystallinity changes in cellulose I polymers using ATR-FTIR, X-ray diffraction, and carbohydrate-binding module probes. Biomacromol 12, 4121–4126 (2011). https://doi.org/10.1021/bm201176m

Jiang, F., Hsieh, Y.-L.: Cellulose nanocrystal isolation from tomato peels and assembled nanofibers. Carbohydr. Polym. 122, 60–68 (2015). https://doi.org/10.1016/j.carbpol.2014.12.064

Trache, D., Hussin, M.H., Haafiz, M.K.M., Thakur, V.K.: Recent progress in cellulose nanocrystals: sources and production. Nanoscale. 9, 1763–1786 (2017). https://doi.org/10.1039/C6NR09494E

Mandal, A., Chakrabarty, D.: Isolation of nanocellulose from waste sugarcane bagasse (SCB) and its characterization. Carbohydr. Polym. 86, 1291–1299 (2011). https://doi.org/10.1016/j.carbpol.2011.06.030

Sun, J.X., Sun, X.F., Sun, R.C., Su, Y.Q.: Fractional extraction and structural characterization of sugarcane bagasse hemicelluloses. Carbohydr. Polym. 56, 195–204 (2004). https://doi.org/10.1016/j.carbpol.2004.02.002

Yussuf, A.A., Massoumi, I., Hassan, A.: Comparison of polylactic acid/kenaf and polylactic acid/rise husk composites: the influence of the natural fibers on the mechanical, thermal and biodegradability properties. J. Polym. Environ. 18, 422–429 (2010). https://doi.org/10.1007/s10924-010-0185-0

Chandrasekhar, S., Satyanarayana, K.G., Pramada, P.N., Raghavan, P., Gupta, T.N.: Review processing, properties and applications of reactive silica from rice husk—an overview. J. Mater. Sci. 38, 3159–3168 (2003). https://doi.org/10.1023/A:1025157114800

Kumar, A., Negi, Y.S., Choudhary, V., Bhardwaj, N.K.: Characterization of cellulose nanocrystals produced by acid-hydrolysis from sugarcane bagasse as agro-waste. J. Mater. Phys. Chem. 2, 1–8 (2014). https://doi.org/10.12691/jmpc-2-1-1

Kargarzadeh, H., Ahmad, I., Abdullah, I., Sheltami, A.D., Zainudin, S.Y., Sheltami, R.M.: Effects of hydrolysis conditions on the morphology, crystallinity, and thermal stability of cellulose nanocrystals extracted from kenaf bast fibers. Cellulose 19, 855–866 (2012). https://doi.org/10.1007/s10570-012-9684-6

Aguayo, M.G., Fernández Pérez, A., Reyes, G., Oviedo, C., Gacitúa, W., Gonzalez, R., Uyarte, O.: Isolation and characterization of cellulose nanocrystals from rejected fibers originated in the kraft pulping process. Polymers (Basel) (2018). https://doi.org/10.3390/polym10101145

Jonoobi, M., Niska, K.O., Harun, J., Misra, M.: Chemical composition, crystallinity, and thermal degradation of bleached and unbleached kenaf bast. BioResources 4, 626–639 (2009)

Li, Y., Liu, Y., Chen, W., Wang, Q., Liu, Y., Li, J., Yu, H.: Facile extraction of cellulose nanocrystals from wood using ethanol and peroxide solvothermal pretreatment followed by ultrasonic nanofibrillation. Green Chem. 18, 1010–1018 (2016). https://doi.org/10.1039/c5gc02576a

Pereira, A.L.S., do Nascimento, D.M., de sá Souza Filho, M., Morais, J.P.S., Vasconcelos, N.F., Feitosa, J.P.A., Brígida, A.I.S., de Rosa, M.: Improvement of polyvinyl alcohol properties by adding nanocrystalline cellulose isolated from banana pseudostems. Carbohydr. Polym. 112, 165–172 (2014). https://doi.org/10.1016/j.carbpol.2014.05.090

Shaheen, T.I., Emam, H.E.: Sono-chemical synthesis of cellulose nanocrystals from wood sawdust using acid hydrolysis. Int. J. Biol. Macromol. 107, 1599–1606 (2018). https://doi.org/10.1016/j.ijbiomac.2017.10.028

Karimi, K., Taherzadeh, M.J.: A critical review of analytical methods in pretreatment of lignocelluloses: composition, imaging, and crystallinity. Bioresour. Technol. 200, 1008–1018 (2016). https://doi.org/10.1016/j.biortech.2015.11.022

Zhang, Y.-H.P., Lynd, L.R.: Toward an aggregated understanding of enzymatic hydrolysis of cellulose: noncomplexed cellulase systems. Biotechnol. Bioeng. 88, 797–824 (2004). https://doi.org/10.1002/bit.20282

Xing, L., Gu, J., Zhang, W., Tu, D., Hu, C.: Cellulose I and II nanocrystals produced by sulfuric acid hydrolysis of Tetra pak cellulose I. Carbohydr. Polym. 192, 184–192 (2018). https://doi.org/10.1016/j.carbpol.2018.03.042

Cao, X., Ding, B., Yu, J., Al-deyab, S.S.: Cellulose nanowhiskers extracted from TEMPO-oxidized jute fibers. Carbohydr. Polym. 90, 1075–1080 (2012). https://doi.org/10.1016/j.carbpol.2012.06.046

Asempour, F., Emadzadeh, D., Matsuura, T., Kruczek, B.: Synthesis and characterization of novel cellulose nanocrystals-based thin film nanocomposite membranes for reverse osmosis applications. Desalination 439, 179–187 (2018). https://doi.org/10.1016/j.desal.2018.04.009

French, A.D.: Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21, 885–896 (2014). https://doi.org/10.1007/s10570-013-0030-4

Chen, Y.W., Tan, T.H., Lee, H.V., Bee, S., Hamid, A.: Easy fabrication of highly thermal-stable cellulose nanocrystals using Cr (NO3)3 catalytic hydrolysis system: a feasibility study from macro- to nano-dimensions. Materials (Basel) 10, 42 (2017). https://doi.org/10.3390/ma10010042

Lu, P., Hsieh, Y.-L.: Preparation and characterization of cellulose nanocrystals from rice straw. Carbohydr. Polym. 87, 564–573 (2012). https://doi.org/10.1016/j.carbpol.2011.08.022

Chang, C., Wang, I., Hung, K.: Preparation and characterization of nanocrystalline cellulose by acid hydrolysis of cotton linter. Taiwan J. For. Sci. 25, 251–264 (2010)

Lani, N.S., Ngadi, N., Johari, A., Jusoh, M.: Isolation, characterization, and application of nanocellulose from oil Palm empty fruit bunch fiber as nanocomposites. J. Nanomater. 2014, 9 (2014). https://doi.org/10.1155/2014/702538

Xiang, Q., Lee, Y.Y., Pettersson, P.O., Torget, R.W.: Heterogeneous aspects of acid hydrolysis of α-cellulose. In: Davison, B.H., Lee, J.W., Finkelstein, M., McMillan, J.D. (eds.) Biotechnology for Fuels and Chemicals: The Twenty-Fourth Symposium, pp. 505–514. Humana Press, Totowa, NJ (2003)

Flórez Pardo, L.M., Salcedo Mendoza, J.G., López Galán, J.E.: Influence of pretreatments on crystallinity and enzymatic hydrolysis in sugar cane residues. Braz. J. Chem. Eng. 36, 131–141 (2019). https://doi.org/10.1590/0104-6632.20190361s20180093

Pech-Cohuo S-C, Canche-Escamilla G, Valadez-González A, Fernández-Escamilla VV, Uribe-Calderon J.: Production and modification of cellulose nanocrystals from Agave tequilana weber waste and its effect on the melt rheology of PLA. Int. J. Polym. Sci. (2018). https://doi.org/10.1155/2018/3567901

Leszczyńska, A., Radzik, P., Haraźna, K., Pielichowski, K.: Thermal stability of cellulose nanocrystals prepared by succinic anhydride assisted hydrolysis. Thermochim. Acta 663, 145–156 (2018). https://doi.org/10.1016/j.tca.2018.03.015

Yang, H., Yan, R., Chen, H., Lee, D.H., Zheng, C.: Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86, 1781–1788 (2007). https://doi.org/10.1016/j.fuel.2006.12.013

Roman, M., Winter, W.T.: Effect of sulfate groups from sulfuric acid hydrolysis on the thermal degradation behavior of bacterial cellulose. Biomacromol 5, 1671–1677 (2004). https://doi.org/10.1021/bm034519+

Sheltami, R.M., Abdullah, I., Ahmad, I., Dufresne, A., Kargarzadeh, H.: Extraction of cellulose nanocrystals from mengkuang leaves (Pandanus tectorius). Carbohydr. Polym. 88, 772–779 (2012). https://doi.org/10.1016/j.carbpol.2012.01.062

Bano, S., Negi, Y.S.: Studies on cellulose nanocrystals isolated from groundnut shells. Carbohydr. Polym. 157, 1041–1049 (2017). https://doi.org/10.1016/j.carbpol.2016.10.069

Rosa, M.F., Medeiros, E.S., Malmonge, J.A., Gregorski, K.S., Wood, D.F., Mattoso, L.H.C., Glenn, G., Orts, W.J., Imam, S.H.: Cellulose nanowhiskers from coconut husk fibers: effect of preparation conditions on their thermal and morphological behavior. Carbohydr. Polym. 81, 83–92 (2010). https://doi.org/10.1016/j.carbpol.2010.01.059

Kasiri, N., Fathi, M.: Production of cellulose nanocrystals from pistachio shells and their application for stabilizing Pickering emulsions. Int. J. Biol. Macromol. 106, 1023–1031 (2018). https://doi.org/10.1016/j.ijbiomac.2017.08.112

Souza, A.G.D., Rocha, D.B., Kano, F.S., Rosa, S.: Valorization of industrial paper waste by isolating cellulose nanostructures with di fferent pretreatment methods. Resour. Conserv. Recycl. 143, 133–142 (2019). https://doi.org/10.1016/j.resconrec.2018.12.031

Mascheroni, E., Rampazzo, R., Ortenzi, M.A., Piva, G., Bonetti, S., Piergiovanni, L.: Comparison of cellulose nanocrystals obtained by sulfuric acid hydrolysis and ammonium persulfate, to be used as coating on flexible food-packaging materials. Cellulose 23, 779–793 (2016). https://doi.org/10.1007/s10570-015-0853-2

Brito, B.S.L., Pereira, F.V., Putaux, J.-L., Jean, B.: Preparation, morphology and structure of cellulose nanocrystals from bamboo fibers. Cellulose 19, 1527–1536 (2012)

Boluk, Y., Danumah, C.: Analysis of cellulose nanocrystal rod lengths by dynamic light scattering and electron microscopy. J. Nanoparticle Res. 16, 2174 (2013). https://doi.org/10.1007/s11051-013-2174-4

Marett, J., Aning, A., Foster, E.J.: The isolation of cellulose nanocrystals from pistachio shells via acid hydrolysis. Ind. Crop. Prod. 109, 869–874 (2017). https://doi.org/10.1016/j.indcrop.2017.09.039

Morais, J.P.S., de Freitas Rosa, M., de sá Moreira de Souza Filho, M., Nascimento, L.D., do Nascimento, D.M., Cassales, A.R.: Extraction and characterization of nanocellulose structures from raw cotton linter. Carbohydr. Polym. 91, 229–235 (2013). https://doi.org/10.1016/j.carbpol.2012.08.010

Acknowledgements

The authors are grateful to Coordination for the Improvement of Higher Level Personnel (CAPES), National Council for Scientific and Technological Development (CNPq), Federal University of Santa Catarina (UFSC), and Federal Institute of Education, Science and Technology of Santa Catarina (IFSC), for providing financial and technological support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hafemann, E., Battisti, R., Bresolin, D. et al. Enhancing Chlorine-Free Purification Routes of Rice Husk Biomass Waste to Obtain Cellulose Nanocrystals. Waste Biomass Valor 11, 6595–6611 (2020). https://doi.org/10.1007/s12649-020-00937-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-020-00937-2