Abstract

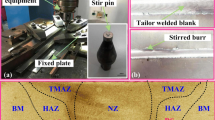

This study deals with an experimental investigation of the influence of friction stir welding parameters on the subsequent formability during incremental forming of aluminium alloy 6082-T6 blanks. Five welding conditions are considered, based on different combinations of rotational speed and feed rate. Truncated cones are chosen as benchmarks for single point incremental forming and tested up to their rupture limits. Formability is inferred measuring the cone height values, together with strain distributions, as recorded on the outer surface. The results clearly highlight the detrimental influence of a high feed rate of 100− 1at the friction stir welding stage, leading to a significantly reduced formability in incremental forming. Regarding other parameters, formability levels are similar to those of the unwelded blanks. Local mechanical properties are investigated by means of hardness measurements, to assess the evolution through the weld, and conventional tensile tests. Digital image correlation is used to properly capture the highly heterogeneous strain field and as a result, to estimate the local yield stress levels. The stress mismatch between the heat affected zone and the nugget zone presents the same trend as the formability. Finally, scanning electron microscopy observations of the fractured samples in tension highlight more differences between the base material and the welded specimen than between the different welded ones. This study therefore emphasises the importance and relevance of an integrated mechanical design approach, considering both welding and forming processes as a whole.

Similar content being viewed by others

References

Saunders FI, Wagoner RH (1996) Forming of tailor-welded blanks. Metall Mater Trans A 27A:2605–2616

Merklein M, Wieland M, Staud D (2009) Friction stir welds made out of precipitation hardenable aluminium alloys - experimental investigations of formability potential. Int J Mater Form 2:323–326

Tayebi P, Fazli A, Asadi P, Soltanpour M (2019) Formability analysis of dissimilar friction stir welded AA 6061 and AA 5083 blanks by SPIF process. CIRP J Manuf Sci Technol 25:50–68

Marré M, Ruhstorfer M, Tekkaya AE, Zaeh MF (2009) Manufacturing of lightweight frame structures by innovative joining by forming processes. Int J Mater Form 2:307–310

Padhy GK, Wu CS, Gao S (2018) Friction stir based welding and processing technologies - processes, parameters, microstructures and applications: A review. J Mater Sci Technol 34(1):1–38

Sharma N, Khan ZA, Siddiquee AN (2017) Friction stir welding of aluminum to copper—An overview. Trans Nonferrous Metals Soc China 27(10):2113–2136

Boşneag A, Constantin MA, Niţu E, Iordache M (2017) Friction Stir Welding of three dissimilar aluminium alloy used in aeronautics industry. IOP Conf Ser Mater Sci Eng 252:012041

Liu H, Zhang H, Pan Q, Yu L (2012) Effect of friction stir welding parameters on microstructural characteristics and mechanical properties of 2219-T,6 aluminum alloy joints. Int J Mat Form 5:235–241

Gratecap F, Racineux G, Marva S (2008) A simple methodology to define conical tool geometry and welding parameters in friction stir welding. Int J Mater Form 1:143–158

Leitao C, Leal RM, Rodrigues DM, Loureiro A, Vilaça P (2009) Mechanical behaviour of similar and dissimilar AA5182-H111 and AA6016-T4 thin friction stir welds. Mater Des 30(1):101–108

Behera AK, de Sousa RA, Ingarao G, Oleksik V (2017) Single point incremental forming: An assessment of the progress and technology trends from 2005 to 2015. J Manuf Process 27:37–62

Pereira Bastos RN, Alves de Sousa RJ, Fernandes Ferreira JA (2016) Enhancing time efficiency on single point incremental forming processes. Int J Mater Form 9(5):653–662

Sato YS, Sugiura Y, Shoji Y, Park SHC, Kokawa H, Ikeda K (2004) Post-weld formability of friction stir welded Al alloy 5052. Mater Sci Eng A 369(1-2):138–143

Leitao C, Emílio B, Chaparro BM, Rodrigues DM (2009) Formability of similar and dissimilar friction stir welded AA 5182-H111 and AA 6016-T4 tailored blanks. Mater Des 30(8):3235–3242

Silva MB, Skjoedt M, Vilaça P, Bay N, Martins PAF (2009) Single point incremental forming of tailored blanks produced by friction stir welding. J Mater Process Technol 209(2):811–820

Duflou JR, Habraken AM, Cao J, Malhotra R, Bambach M, Adams D, Vanhove H, Mohammadi A, Jeswiet J (2018) Single point incremental forming: state-of-the-art and prospects. Int J Mater Form 11(6):743–773

Afonso D, Alves de Sousa R, Torcato R (2018) Integration of design rules and process modelling within SPIF technology-a review on the industrial dissemination of single point incremental forming. Int J Adv Manuf Technol 94(9-12):4387–4399

Fratini L, Ambrogio G, Di Lorenzo R, Filice L, Micari F (2004) Influence of mechanical properties of the sheet material on formability in single point incremental forming. CIRP Annals 53(1):207–210

Ambrogio G, Fratini L, Micari F (2006) Incremental forming of friction stir welded taylored sheets. In: Proceedings of 8th Biennial ASME conference on engineering systems design and analysis, ESDA2006 pp 757–762

Rattanachan K, Sirivedin K, Chungchoo C (2014) Formability of tailored welded blanks in single point incremental forming process. In: Applied physics and material science, volume 979 of advanced materials research, pp 339–342. Trans Tech Publications Ltd

Ebrahimzadeh P, Baseri H, Mirnia MJ (2018) Formability of aluminum 5083 friction stir welded blank in two-point incremental forming process. Proc Inst Mech Eng Part E J Process Mech Eng 232(3):267–280

Leitao C, Galvao I, Leal RM, Rodrigues DM (2012) Determination of local constitutive properties of aluminium friction stir welds using digital image correlation. Mater Des 33:69–74

Carlone P, Palazzo GS (2013) Influence of process parameters on microstructure and mechanical properties in aa2024-t3 friction stir welding. Metallography Microstruct Anal 2(4):213–222

Raja AR, Yusufzai MZK, Vashista M (2016) Characterization of advancing and retreating weld of friction stir welding of aluminium. In: International conference on advances in materials and manufacturing (Bangalore, India)

Andrade-Campos A, Thuillier S, Martins J, Carlone P, Tucci F, Valente R, Paulo RMF, Alves de Sousa RJ (2020) Integrated design in welding and incremental forming: Material model calibration for friction stir welded blanks. Procedia Manuf 47:429–434. 23rd International Conference on Material Forming

Alves De Sousa RJ, Ferreira JAF, Sa De Farias JB, Torrão JND, Afonso DG, Martins MABE (2014) SPIF-A On the development of a new concept of incremental forming machine. Struct Eng Mech 49 (5):645–660

Hussain G, Gao L (2007) A novel method to test the thinning limits of sheet metals in negative incremental forming. Int J Mach Tools Manuf 47:419–435

Liu Z, Li Y, Meehan PA (2013) Experimental investigation of mechanical properties, formability and force measurement for AA7075-O aluminum alloy sheets formed by incremental forming. Int J Precis Eng Manuf 14(11):1891–1899

Kumar A, Gulati V, Kumar P, Singh H (2019) Forming force in incremental sheet forming: a comparative analysis of the state of the art. J Brazilian Soc Mech Sci Eng 41(6):251

Bansal A, Lingam R, Yadav SK, Venkata Reddy N (2017) Prediction of forming forces in single point incremental forming. J Manuf Process 28:486–493

Aerens R, Eyckens P, Van Bael A, Duflou JR (2010) Force prediction for single point incremental forming deduced from experimental and fem observations. Int J Adv Manuf Technol 46(9):969–982

Filice L, Ambrogio G, Micari F (2006) On-line control of single point incremental forming operations through punch force monitoring. CIRP Ann 55(1):245–248

Ambrogio G, Filice L, Micari F (2006) A force measuring based strategy for failure prevention in incremental forming. J Mater Process Technol 177(1):413–416

Duflou J, Tunçkol Y, Szekeres A, Vanherck P (2007) Experimental study on force measurements for single point incremental forming. J Mater Process Technol 189(1):65–72

Wan L, Huang Y, Lv Z, Lv S, Feng J (2014) Effect of self-support friction stir welding on microstructure and microhardness of 6082-T6 aluminum alloy joint. Mater Des 55:197–203

Naumov A, Morozova I, Rylkov E, Obrosov A, Isupov F, Michailov V, Rudskoy A (2019) Metallurgical and mechanical characterization of high-speed friction stir welded AA6082-T6 aluminum alloy. Materials 12(24):4211. https://doi.org/10.3390/ma12244211

Zettler R, Vugrin T, Schmucker M (2010) 9 - effects and defects of friction stir welds. In: Lohwasser D, Chen Z (eds) Friction stir welding, woodhead publishing series in welding and other joining technologies, pp 245–276. Woodhead Publishing

Al-Ghamdi KA, Hussain G (2015) Forming forces in incremental forming of a geometry with corner feature: investigation into the effect of forming parameters using response surface. Int J Adv Manuf Technol 76 (9):2185–2197

Hussain G, Gao L, Hayat N (2011) Forming parameters and forming defects in incremental forming of an aluminum sheet: Correlation, empirical modeling, and optimization: Part A. Mater Manuf Process 26 (12):1546–1553

Hussain G, Al-Ghamdi KA, Khalatbari H, Iqbal A, Hashemipour M (2014) Forming parameters and forming defects in incremental forming process: Part B. Mater Manuf Process 29(4):454– 460

Abdelkefi A, Guines D, Léotoing L, Thuillier S (2113) Influence of the mechanical model of titanium t40 on the predicted forces during incremental forming process. In: AIP Conference Proceedings ESAFORM 2019, pp 170010, p 2019

Emmens WC, van den Boogaard AH (2009) An overview of stabilizing deformation mechanisms in incremental sheet forming. J Mater Process Technol 209(8):3688–3695

Hussain G, Gao L, Hayat N, Ziran X (2009) A new formability indicator in single point incremental forming. J Mater Process Technol 209(9):4237–4242

Jakobsen JV (2016) Microstructure and mechanical properties of welded aa6082 aluminium alloys. PhD thesis, Norwegian Universiy of Science and Technology

Liu G, Murr LE, Niou C-S, McClure JC, Vega FR (1997) Microstructural aspects of the friction-stir welding of 6061-t6 aluminum. Scr Mater 37(3):355–361

El-Rayes MM, El-Danaf EA (2012) The influence of multi-pass friction stir processing on the microstructural and mechanical properties of aluminum alloy 6082. J Mater Process Technol 212(5):1157–1168

Niu P, Li W, Zhang Z, Yang X (2017) Global and local constitutive behaviors of friction stir welded AA2024 joints. J Mater Sci Technol 33(9):987–990

Le Louëdec G, Pierron F, Sutton MA, Reynolds AP (2013) Identification of the local elasto-plastic, behavior of FSW welds using the virtual fields method. Exp Mech 53(5):849–859

Acknowledgements

R. J. Alves de Sousa acknowledges grants UID/EMS/00481/2019-FCT and CENTRO-01-0145-FEDER-022083 - Centro2020, European Regional Development Fund (ERDF).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

One of the authors (R.J. Alves de Sousa) acknowledges the financial support from FCT (grant number UID/EMS/00481/2019-FCT) and FEDER (grant number CENTRO-01-0145-FEDER-022083).

Conflict of Interests

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Carlone, P., Thuillier, S., Andrade-Campos, A. et al. Incremental forming of friction-stir welded aluminium blanks: an integrated approach. Int J Mater Form 14, 1121–1137 (2021). https://doi.org/10.1007/s12289-021-01628-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-021-01628-6