Abstract

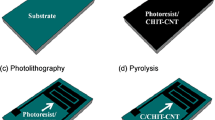

A novel microfabrication process based on optimized photolithography combined with pyrolysis-reduction is proposed to fabricate interdigital porous carbon/tin quantum dots (C/Sn QDs) microelectrodes. C/Sn QDs active microelectrodes are also employed as current collectors of a micro-supercapacitor (MSC). A uniform dispersion of Sn QDs (diameter of ∼3 nm) in the carbon matrix is achieved using our facile and controllable microfabrication process. The as-fabricated C/Sn QDs MSC obtained by carbonization at 900 °C exhibits a higher areal specific capacitance (5.79 mF·cm−2) than that of the pyrolyzed carbon-based MSC (1.67 mF·cm−2) and desirable cycling stability (93.3% capacitance retention after 5,000 cyclic voltammetry cycles). This novel microfabrication process is fully compatible with micromachining technologies, showing great potential for large-scale fine micropatterning of carbon-based composites for applications in micro/nano devices.

Similar content being viewed by others

References

Cai, Z. Y.; Xu, L.; Yan, M. Y.; Han, C. H.; He, L.; Hercule, K. M.; Niu, C. J.; Yuan, Z. F.; Xu, W. W.; Qu, L. B. et al. Manganese oxide/carbon yolk–shell nanorod anodes for high capacity lithium batteries. Nano Lett. 2015, 15, 738–744.

Béguin, F.; Presser, V.; Balducci, A.; Frackowiak, E. Carbons and electrolytes for advanced supercapacitors. Adv. Mater. 2014, 26, 2219–2251.

Hsia, B.; Kim, M. S.; Vincent, M.; Carraro, C.; Maboudian, R. Photoresist-derived porous carbon for on-chip microsupercapacitors. Carbon 2013, 57, 395–400.

Ren, S. Z.; Wang, M.; Xu, M. L.; Yang, Y.; Jia, C. Y.; Hao, C. Fabrication of high-performance supercapacitors based on hollow SnO2 microspheres. J. Solid State Electrochem. 2014, 18, 909–916.

Jang, J.; Bae, J.; Choi, M.; Yoon, S.-H. Fabrication and characterization of polyaniline coated carbon nanofiber for supercapacitor. Carbon 2005, 43, 2730–2736.

Huang, P.; Lethien, C.; Pinaud, S.; Brousse, K.; Laloo, R.; Turq, V.; Respaud, M.; Demortière, A.; Daffos, B.; Taberna, P. L. et al. On-chip and freestanding elastic carbon films for micro-supercapacitors. Science 2016, 351, 691–695.

Niu, Z. Q.; Zhou, W. Y.; Chen, X. D.; Chen, J.; Xie, S. S. Highly compressible and all-solid-state supercapacitors based on nanostructured composite sponge. Adv. Mater. 2015, 27, 6002–6008.

Liu, L. L.; Niu, Z. Q.; Chen, J. Design and integration of flexible planar micro-supercapacitors. Nano Res. 2017, 10, 1524–1544.

Liu, L. L.; Niu, Z. Q.; Chen, J. Unconventional supercapacitors from nanocarbon-based electrode materials to device configurations. Chem. Soc. Rev. 2016, 45, 4340–4363.

Yin, C.; He, L.; Wang, Y. F.; Liu, Z. H.; Zhang, G. B.; Zhao, K. N.; Tang, C. J.; Yan, M. Y.; Han, Y. L.; Mai, L. Q. Pyrolyzed carbon with embedded NiO/Ni nanospheres for applications in microelectrodes. RSC Adv. 2016, 6, 43436–43441.

Yang, Y. J.; He, L.; Tang, C. J.; Hu, P.; Hong, X. F.; Yan, M. Y.; Dong, Y. X.; Tian, X. C.; Wei, Q. L.; Mai, L. Q. Improved conductivity and capacitance of interdigital carbon microelectrodes through integration with carbon nanotubes for micro-supercapacitors. Nano Res. 2016, 9, 2510–2519.

He, L.; Toda, M.; Kawai, Y.; Miyashita, H.; Omori, M.; Hashida, T.; Berger, R.; Ono, T. Fabrication of CNT-carbon composite microstructures using Si micromolding and pyrolysis. Microsyst. Technol. 2014, 20, 201–208.

De Volder, M. F. L.; Vansweevelt, R.; Wagner, P.; Reynaerts, D.; van Hoof, C.; Hart, A. J. Hierarchical carbon nanowire microarchitectures made by plasma-assisted pyrolysis of photoresist. ACS Nano 2011, 5, 6593–6600.

Wei, L.; Nitta, N.; Yushin, G. Lithographically patterned thin activated carbon films as a new technology platform for on-chip devices. ACS Nano 2013, 7, 6498–6506.

Jariwala, D.; Sangwan, V. K.; Lauhon, L. J.; Marks, T. J.; Hersam, M. C. Carbon nanomaterials for electronics, optoelectronics, photovoltaics, and sensing. Chem. Soc. Rev. 2013, 42, 2824–2860.

Sevilla, M.; Mokaya, R. Energy storage applications of activated carbons: Supercapacitors and hydrogen storage. Energy Environ. Sci. 2014, 7, 1250–1280.

Niu, Z. Q.; Zhang, L.; Liu, L. L.; Zhu, B. W.; Dong, H. B.; Chen, X. D. All-solid-state flexible ultrathin microsupercapacitors based on graphene. Adv. Mater. 2013, 25, 4035–4042.

Beidaghi, M.; Wang, C. L. Micro-supercapacitors based on three dimensional interdigital polypyrrole/C-MEMS electrodes. Electrochim. Acta 2011, 56, 9508–9514.

Wei, L.; Sevilla, M.; Fuertes, A. B.; Mokaya, R.; Yushin, G. Polypyrrole-derived activated carbons for high-performance electrical double-layer capacitors with ionic liquid electrolyte. Adv. Funct. Mater. 2012, 22, 827–834.

Malladi, K.; Wang, C. L.; Madou, M. Fabrication of suspended carbon microstructures by e-beam writer and pyrolysis. Carbon 2006, 44, 2602–2607.

Galobardes, F.; Wang, C.; Madou, M. Investigation on the solid electrolyte interface formed on pyrolyzed photoresist carbon anodes for C-MEMS lithium-ion batteries. Diam. Relat. Mater. 2006, 15, 1930–1934.

Lu, X. X.; Yang, F.; Geng, X.; Xiao, P. Enhanced cyclability of amorphous carbon-coated SnO2-graphene composite as anode for Li-ion batteries. Electrochim. Acta 2014, 147, 596–602.

Lee, J. A.; Lee, S. W.; Lee, K.-C.; Park, S. I.; Lee, S. S. Fabrication and characterization of freestanding 3D carbon microstructures using multi-exposures and resist pyrolysis. J. Micromech. Microeng. 2008, 18, 035012.

Beidaghi, M.; Chen, W.; Wang, C. L. Electrochemically activated carbon micro-electrode arrays for electrochemical micro-capacitors. J. Power Sources 2011, 196, 2403–2409.

Min, H.-S.; Park, B. Y.; Taherabadi, L.; Wang, C. L.; Yeh, Y.; Zaouk, R.; Madou, M. J.; Dunn, B. Fabrication and properties of a carbon/polypyrrole three-dimensional microbattery. J. Power Sources 2008, 178, 795–800.

Wei, L.; Yushin, G. Nanostructured activated carbons from natural precursors for electrical double layer capacitors. Nano Energy 2012, 1, 552–565.

Chen, W.; Beidaghi, M.; Penmatsa, V.; Bechtold, K.; Kumari, L.; Li, W. Z.; Wang, C. L. Integration of carbon nanotubes to C-MEMS for on-chip supercapacitors. IEEE Trans. Nanotechnol. 2010, 9, 734–740.

Wang, C. L.; Jia, G. Y.; Taherabadi, L. H.; Madou, M. J. A novel method for the fabrication of high-aspect ratio C-MEMS structures. J. Microelectromech. Syst. 2005, 14, 348–358.

Schueller, O. J. A.; Brittain, S. T.; Whitesides, G. M. Fabrication of glassy carbon microstructures by soft lithography. Sensor Actuat. A-Phys. 1999, 72, 125–139.

Jiang, H.; Lee, P. S.; Li, C. Z. 3D carbon based nanostructures for advanced supercapacitors. Energy Environ. Sci. 2013, 6, 41–53.

McCreery, R. L. Advanced carbon electrode materials for molecular electrochemistry. Chem. Rev. 2008, 108, 2646–2687.

Li, J.; Le, D. B.; Ferguson, P. P.; Dahn, J. R. Lithium polyacrylate as a binder for tin–cobalt–carbon negative electrodes in lithium-ion batteries. Electrochim. Acta 2010, 55, 2991–2995.

Tang, J.; Liu, J.; Torad, N. L.; Kimura, T.; Yamauchi, Y. Tailored design of functional nanoporous carbon materials toward fuel cell applications. Nano Today 2014, 9, 305–323.

Lee, J. A.; Lee, K. C.; Park, S. I.; Lee, S. S. The fabrication of carbon nanostructures using electron beam resist pyrolysis and nanomachining processes for biosensing applications. Nanotechnology 2008, 19, 215302.

Sheeja, D.; Tay, B. K.; Lau, S. P.; Yu, L. J.; Miao, J. M.; Chua, H. C.; Milne, W. I. Fabrication of smooth amorphous carbon micro-cantilevers by lift-off. Sensor Actuat. B-Chem. 2004, 98, 275–281.

Yan, S.; Wu, Q. S. Micropored Sn-SnO2/carbon heterostructure nanofibers and their highly sensitive and selective C2H5OH gas sensing performance. Sensor Actuat. B-Chem. 2014, 205, 329–337.

Luo, B.; Wang, B.; Liang, M. H.; Ning, J.; Li, X. L.; Zhi, L. J. Reduced graphene oxide-mediated growth of uniform tin-core/carbon-sheath coaxial nanocables with enhanced lithium ion storage properties. Adv. Mater. 2012, 24, 1405–1409.

Sun, L. M.; Wang, X. H.; Susantyoko, R. A.; Zhang, Q. High performance binder-free Sn coated carbon nanotube array anode. Carbon 2015, 82, 282–287.

Noh, M.; Kwon, Y.; Lee, H.; Cho, J.; Kim, Y.; Kim, M. G. Amorphous carbon-coated tin anode material for lithium secondary battery. Chem. Mater. 2005, 17, 1926–1929.

Chen, S. Q.; Chen, P.; Wu, M. H.; Pan, D. Y.; Wang, Y. Graphene supported Sn–Sb@carbon core-shell particles as a superior anode for lithium ion batteries. Electrochem. Commun. 2010, 12, 1302–1306.

Liu, C.-J.; Huang, H.; Cao, G.-Z.; Xue, F.-H.; Paredes Camacho, R. A.; Dong, X.-L. Enhanced electrochemical stability of Sn-carbon nanotube nanocapsules as lithium-ion battery anode. Electrochim. Acta 2014, 144, 376–382.

Guo, B. K.; Shu, J.; Tang, K.; Bai, Y.; Wang, Z. X.; Chen, L. Q. Nano-Sn/hard carbon composite anode material with high-initial coulombic efficiency. J. Power Sources 2008, 177, 205–210.

Lee, K. T.; Jung, Y. S.; Oh, S. M. Synthesis of tinencapsulated spherical hollow carbon for anode material in lithium secondary batteries. J. Am. Chem. Soc. 2003, 125, 5652–5653.

Simon, P.; Gogotsi, Y. Materials for electrochemical capacitors. Nat. Mater. 2008, 7, 845–854.

Yang, Y.; Ren, S. Z.; Ma, S. B.; Hao, C.; Ji, M. The synthesis of ordered Sn-C composite microspheres and their mechanical properties. Colloid. Surf. A 2015, 471, 81–85.

Zhang, G. H.; Zhu, J.; Zeng, W.; Hou, S. C.; Gong, F. L.; Li, F.; Li, C. C.; Duan, H. G. Tin quantum dots embedded in nitrogen-doped carbon nanofibers as excellent anode for lithium-ion batteries. Nano Energy 2014, 9, 61–70.

Ramana, B. V.; Das, A.; Dhara, S.; Amirthapandian, S.; Tyagi, A. K. Synthesis and surface functionalization of SnO2 nanoparticles and their superhydrophobic coatings. Sci. Adv. Mater. 2013, 5, 865–872.

Egashira, M.; Takatsuji, H.; Okada, S.; Yamaki, J.-I. Properties of containing Sn nanoparticles activated carbon fiber for a negative electrode in lithium batteries. J. Power sources 2002, 107, 56–60.

Zhao, K. N.; Zhang, L.; Xia, R.; Dong, Y. F.; Xu, W. W.; Niu, C. J.; He, L.; Yan, M. Y.; Qu, L. B.; Mai, L. Q. SnO2 quantum dots@graphene oxide as a high-rate and long-life anode material for lithium-ion batteries. Small 2016, 12, 588–594.

Zhang, L.; Zhao, K. N.; Xu, W. W.; Dong, Y. F.; Xia, R.; Liu, F. N.; He, L.; Wei, Q. L.; Yan, M. Y.; Mai, L. Q. Integrated SnO2 nanorod array with polypyrrole coverage for high-rate and long-life lithium batteries. Phys. Chem. Chem. Phys. 2015, 17, 7619–7623.

Xu, W. W.; Zhao, K. N.; Niu, C. J.; Zhang, L.; Cai, Z. Y.; Han, C. H.; He, L.; Shen, T.; Yan, M. Y.; Qu, L. B. et al. Heterogeneous branched core–shell SnO2-PANI nanorod arrays with mechanical integrity and three dimentional electron transport for lithium batteries. Nano Energy 2014, 8, 196–204.

Zhou, P.; Yang, X.; He, L.; Hao, Z. M.; Luo, W.; Xiong, B.; Xu, X.; Niu, C. J.; Yan, M. Y.; Mai, L. Q. The young’s modulus of high-aspect-ratio carbon/carbon nanotube composite microcantilevers by experimental and modeling validation. Appl. Phys. Lett. 2015, 106, 111908.

Chen, M. M.; Xia, X. X.; Wang, Z. L.; Li, Y. L.; Li, J. J.; Gu, C. Z. Rectifying behavior of individual SnO2 nanowire by different metal electrode contacts. Microelectron. Eng. 2008, 85, 1379–1381.

Acknowledgements

This work was supported by the National Key Research and Development Program of China (Nos. 2016YFA0202603 and 2016YFA0202604), the National Basic Research Program of China (No. 2013CB934103), the Programme of Introducing Talents of Discipline to Universities (No. B17034), the National Natural Science Foundation of China (Nos. 51502227, 51579198 and 51521001), the National Natural Science Fund for Distinguished Young Scholars (No. 51425204), the China Postdoctoral Science Foundation (No. 2015T80845), the Hubei Province Natural Science Fund (No. 2016CFB582), the Fundamental Research Funds for the Central Universities (WUT: 2016III001 and 2016III005). Prof. Liang He and Prof. Liqiang Mai gratefully acknowledged financial support from China Scholarship Council (Nos. 201606955094 and 201606955096).

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Hong, X., He, L., Ma, X. et al. Microstructuring of carbon/tin quantum dots via a novel photolithography and pyrolysis-reduction process. Nano Res. 10, 3743–3753 (2017). https://doi.org/10.1007/s12274-017-1587-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12274-017-1587-2