Abstract

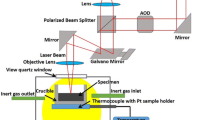

The agglomeration behavior of non-metallic inclusions in the steelmaking process is important for controlling the cleanliness of the steel. In this work, the observation of agglomeration behaviors of inclusions at steel/Ar and steel/slag interfaces using a high-temperature confocal laser scanning microscope (HT-CLSM) is summarized. This HT-CLSM technique has been applied to observe phase transformation during solidification and heat treatment and the engulfment and pushing behavior of inclusions in front of the solidified interface. In the current work, the inclusion agglomeration behavior at steel/Ar and steel/slag interfaces is summarized and discussed. Subsequently, the development of the theoretical work investigating inclusion agglomeration at steel/Ar and steel/slag interfaces including the initial capillary force model and Kralchevsky–Paunov model is described. Finally, the Kralchevsky–Paunov model is applied to investigating nitride inclusion agglomeration at high-manganese steel/Ar interfaces. This work aims to give a critical review of the application of HT-CLSM in secondary refining as well as a better control of inclusion elimination for clean steel production.

Similar content being viewed by others

References

L. Zhang and B.G. Thomas, ISIJ Int. 43, 271 (2003).

T.A. Engh, Principles of Metals Refining (New York: Oxford University Press, 1992), pp. 1–3.

L. Zhang and B.G. Thomas, Metall. Mater. Trans. B 37B, 733 (2006).

O. Wijk: Inclusion engineering, in Proc. 7th Int. Conf. Refining Process (SCANINJECT 733. VII), Luleå, Sweden (1995), p. 35.

H. Chikama, H. Shibata, T. Emi, and M. Suzuki, Mater. Trans. JIM 37, 620 (1996).

H. Shibata, H.B. Yin, S. Yoshinaga, T. Emi, and M. Suzuki, ISIJ Int. 38, 149 (1998).

W. Mu, H. Shibata, P. Hedström, P.G. Jönsson, and K. Nakajima, Steel Res. Int. 87, 10 (2016).

W. Mu, P.G. Jönsson, and K. Nakajima, J. Mater. Sci. 51, 2168 (2016).

H.B. Yin, H. Shibata, T. Emi, and M. Suzuki, ISIJ Int. 37, 936 (1997).

H.B. Yin, H. Shibata, T. Emi, and M. Suzuki, ISIJ Int. 37, 946 (1997).

K. Nakajima and S. Mizoguchi, Metall. Mater. Trans. B 32, 629 (2001).

S. Kimura, K. Nakajima, and S. Mizoguchi, Metall. Mater. Trans. B 32, 79 (2001).

W. Mu, N. Dogan, and K.S. Coley, Metall. Mater. Trans. B 48, 2379 (2017).

W. Mu, N. Dogan, and K.S. Coley, Metall. Mater. Trans. B 48, 2092 (2017).

W. Mu, N. Dogan, and K.S. Coley, J. Mater. Sci. (2018). https://doi.org/10.1007/s10853-018-2268-6.

B. Coletti, B. Blanpain, S. Vantilt, and S. Sridhar, Metall. Mater. Trans. B 34, 533 (2003).

S. Vantilt, B. Coletti, B. Blanpain, J. Fransaer, P. Wollants, and S. Sridhar, ISIJ Int. 44, 1 (2004).

G. Liang, C. Wang, and Y. Fang, Acta Metall. Sin. Chin. Ed. 42, 708 (2006).

J. Appelberg, K. Nakajima, H. Shibata, A. Tilliander, and P. Jönsson, Mater. Sci. Eng. A 495, 330 (2008).

Y. Kang, B. Sahebkar, P.R. Scheller, K. Morita, and D. Sichen, Metall. Mater. Trans. B 42, 522 (2011).

G. Du, J. Li, Z.B. Wang, and C.B. Shi, Steel Res. Int. 88, 1600185 (2016). https://doi.org/10.1002/srin.201600185.

S.K. Michelic, U.D. Salgado, C. Bernhard, and I.O.P. Conf, Series. Mater. Sci. Eng. 143, 012010 (2016).

J. Wikström, K. Nakajima, H. Shibata, A. Tilliander, and P. Jönsson, Ironmak Steelmak 35, 589 (2008).

P. Misra, V. Chevrier, S. Sridhar, and A. Cramb, Metall. Mater. Trans. B 31, 1135 (2000).

P. Misra, S. Sridhar, and A. Cramb, Metall. Mater. Trans. B 32, 963 (2001).

J. Wikström, K. Nakajima, H. Shibata, A. Tilliander, and P. Jönsson, Mater. Sci. Eng. A 495, 316 (2008).

P.A. Kralchevsky, V.N. Paunov, N.D. Denkov, I.B.V. Ivanoc, and K. Nagayama, J. Colloid. Interface Sci. 155, 420 (1993).

V.N. Paunov, P.A. Kralchevsky, N.D. Denkov, and K. Nagayama, J. Colloid. Interface Sci. 157, 100 (1993).

S.C. Lee, C. Tse, K.W. Yi, P. Misra, V. Chevrier, C. Orrling, S. Sridhar, and A. Cramb, J. Non-Cryst. Solids 282, 41 (2001).

K. Miao, A. Haas, M. Sharma, W. Mu, and N. Dogan, Metall. Mater. Trans. B (2017, Unpublished work).

B.J. Monaghan and L. Chen, J. Non-Cryst. Solids 347, 254 (2004).

B.J. Monaghan and L. Chen, Ironmak Steelmak 33, 323 (2006).

B.J. Monaghan, L. Chen, and J. Sorbe, Ironmak Steelmak 32, 258 (2005).

S. Feichtinger, S.K. Michelic, Y.B. Kang, and C. Bernhard, J. Am. Ceram. Soc. 97, 316 (2014).

E. Jahnke, F. Emde, and F. Lösch, Tables of Higher Functions (New York: McGraw-Hill, 1960).

M. Abramovitz and I.A. Stegun, Handbook of Mathematical Functions (New York: Dover, 1965).

C.F. Chan Man Fong, D. De Kee, and P.N. Kaloni, Advanced Mathematics for Engineering and Science (Singapore: World Scientific Publishing Co. Pte. Ltd., 2003), p. 5.

Y.N. Wang, J. Yang, X.L. Xin, R.Z. Wang, and L.Y. Xu, Metall. Mater. Trans. B 47, 1378 (2016). https://doi.org/10.1007/s11663-015-0568-7.

J. Yang, Y.N. Wang, X.M. Ruan, R.Z. Wang, K. Zhu, Z.J. Fan, Y.C. Wang, C.B. Li, and X.F. Jiang, Metall. Mater. Trans. B 46, 1365 (2015).

J.H. Park, D.-J. Kim, and D.J. Min, Metall. Mater. Trans. A 43, 2316 (2012).

N. Kikuchi, S. Nabeshima, Y. Kishimoto, T. Matsushita, and S. Sridhar, ISIJ Int. 47, 1255 (2007).

J.F. Lynch, C.G. Ruderer, and W.H. Duckworth, Engineering Properties of Selected Ceramic Materials (Columbus, OH: American Ceramic Society, Inc., 1966).

B.J. Keene, Contact angle and work of adhesion between ferrous melts and non-metallic solid, Slag Atlas (2nd edn), ed. by Verein Deutsscher Eisenhüttenleute (VDEh) (Verlag Stahleisen GmbH, 1995), pp. 513–539.

B.J. Keene and K.C. Mills, Densities of molten slag, Slag Atlas (2nd edn), ed. by Verein Deutsscher Eisenhüttenleute (VDEh) (Verlag Stahleisen GmbH, 1995), pp. 313–347.

G.S. Ershov and A.M. Kovalenko, Russ. Metall. 1, 47 (1968).

C.V. Ciobanu, D.T. Tambe, and V.B. Shenoy, Surf. Sci. 582, 145 (2005).

S.K. Rhee, J. Am. Ceram. Soc. 53, 639 (1970).

Acknowledgements

The authors thank the Natural Sciences and Engineering Research Council of Canada (NSERC), the Canada Foundation for Innovation John Evans Leaders Fund (CFI JELF, Project No. 32826), and the McMaster Steel Research Centre (SRC) members for funding the research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mu, W., Dogan, N. & Coley, K.S. In Situ Observations of Agglomeration of Non-metallic Inclusions at Steel/Ar and Steel/Slag Interfaces by High-Temperature Confocal Laser Scanning Microscope: A Review. JOM 70, 1199–1209 (2018). https://doi.org/10.1007/s11837-018-2893-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-018-2893-1