Abstract

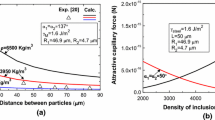

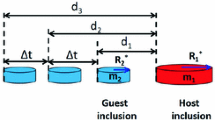

Better understanding of agglomeration behavior of nonmetallic inclusions in the steelmaking process is important to control the cleanliness of the steel. In this work, a revision on the Paunov simplified model has been made according to the original Kralchevsky–Paunov model. Thus, this model has been applied to quantitatively calculate the attractive capillary force on inclusions agglomerating at the liquid steel/gas interface. Moreover, the agglomeration behavior of Al2O3 inclusions at a low carbon steel/Ar interface has been observed in situ by high-temperature confocal laser scanning microscopy (CLSM). The velocity and acceleration of inclusions and attractive forces between Al2O3 inclusions of various sizes were calculated based on the CLSM video. The results calculated using the revised model offered a reasonable fit with the present experimental data for different inclusion sizes. Moreover, a quantitative comparison was made between calculations using the equivalent radius of a circle and those using the effective radius. It was found that the calculated capillary force using equivalent radius offered a better fit with the present experimental data because of the inclusion characteristics. Comparing these results with other studies in the literature allowed the authors to conclude that when applied in capillary force calculations, the equivalent radius is more suitable for inclusions with large size and irregular shape, and the effective radius is more appropriate for inclusions with small size or a large shape factor. Using this model, the effect of inclusion size on attractive capillary force has been investigated, demonstrating that larger inclusions are more strongly attracted.

Similar content being viewed by others

Notes

JEOL is a trademark of Japan Electron Optics Ltd., Tokyo.

References

T.A. Engh: Principles of Metals Refining, Oxford University Press, New York, NY, 1992, pp. 1–3.

L. Zhang and B.G. Thomas: ISIJ Int., 2003, vol. 43, pp. 271–91.

O. Wijk: Proc. 7th Int. Conf. Refining Process (SCANINJECT VII), Luleå, Sweden, 1995, pp. 35–67.

Y. Sahai and T. Emi: Tundish Technology for Clean Steel Production, World Scientific Publishing Co. Pte. Ltd., pp. 292–94.

S. Taniguchi and A. Kikuchi: Testu-to-Hagané, 1992, vol. 78, pp. 527–35.

Y. Miki, H. Kitaoka, T. Sakuraya, and T. Fuji: Testu-to-Hagané, 1992, vol. 78, pp. 431–38.

K. Nakanishi and J. Szekely: Trans. ISIJ, 1975, vol. 15, pp. 522–30.

H.B. Yin, H. Shibata, T. Emi, and M. Suzuki: ISIJ Int., 1997, vol. 37, pp. 936–45.

H.B. Yin, H. Shibata, T. Emi, and M. Suzuki: ISIJ Int., 1997, vol. 37, pp. 946–55.

S. Kimura, K. Nakajima, and S. Mizoguchi: Metall. Mater. Trans. B, 2001, vol. 32B, pp. 79–85.

K. Nakajima and S. Mizoguchi: Metall. Mater. Trans. B, 2001, vol. 32B, pp. 629–41.

J. Appelberg, K. Nakajima, H. Shibata, A. Tilliander, and P. Jönsson: Mater. Sci. Eng. A, 2008, vol. 495, pp. 330–34.

J. Wikström, K. Nakajima, H. Shibata, A. Tilliander, and P. Jönsson: Ironmaking & Steelmaking, 2008, vol. 35, pp. 589–99.

Y. Kang, B. Sahebkar, P.R. Scheller, K. Morita, and D. Sichen: Metall. Mater. Trans. B, 2011, vol. 42B, pp. 522–34.

G. Du, J. Li, Z.B. Wang, and C.B. Shi: Steel Res. Int., 2017, vol. 88, art. no. 1600185.

P.A. Kralchevsky, V.N. Paunov, N.D. Denkov, I.B.V. Ivanoc, and K. Nagayama: J. Coll. Interface Sci., 1993, vol. 155, pp. 420–37.

V.N. Paunov, P.A. Kralchevsky, N.D. Denkov, and K. Nagayama: J. Coll. Interface Sci., 1993, vol. 157, pp. 100–12.

H. Chikama, H. Shibata, T. Emi, and M. Suzuki: Mater. Trans., JIM, 1996, vol. 37, pp. 620–26.

J. Monaghan and L. Chen: J. Non-Crystalline Solids, 2004, vol. 347, pp. 254–61.

W. Mu, H. Shibata, P. Hedström, P.G. Jönsson, and K. Nakajima: Metall. Mater. Trans. B, 2016, vol. 47B, pp. 2133–47.

W. Mu, P.G. Jönsson, and K. Nakajima: J. Mater. Sci., 2016, vol. 51, pp. 2168–80.

C. Xuan, H. Shibata, S. Sukenaga, P.G. Jönsson, and K. Nakajima: ISIJ Int., 2015, vol. 55, pp. 1882–90.

K. Ogino, K. Nogi, and Y. Koshida: Tetsu-to-Hagané, 1973, vol. 59, pp. 1380–87.

E. Jahnke, F. Emde, and F. Lösch: Tables of Higher Functions, McGraw-Hill, New York, NY, 1960.

M. Abramovitz and I.A. Stegun: Handbook of Mathematical Functions, Dover, New York, NY, 1965.

C.F. Chan Man Fong, D. De Kee, and P.N. Kaloni: Advanced Mathematics for Engineering and Science, World Scientific Publishing Co. Pte. Ltd., 2003, p. 5.

W. Mu, N. Dogan, and K.S. Coley: 5th Int. Conf. on Process Development in Iron and Steelmaking (SCANMET V), Luleå, June 12–15, 2016, CD-Rom.

W. Mu, N. Dogan, and K.S. Coley: Metall. Mater. Trans. B, 2017, vol. 48, pp. 2092–103.

K. Sasai and Y. Mizukami: ISIJ Int., 2001, vol. 41, pp. 1331–39.

C. Xuan, W. Mu, Z.I. Olano, P.G. Jönsson, and K. Nakajima: Steel Res. Int., 2016, vol. 87, pp. 911–20.

Acknowledgments

The authors thank the Natural Sciences and Engineering Research Council of Canada (NSERC), the Canada Foundation for Innovation John Evans Leaders Fund (CFI JELF, Project No. 32826), and the McMaster Steel Research Centre (SRC) members for funding the research. Professor Keiji Nakajima (KTH Royal Institute of Technology) is also acknowledged by one of the authors (WM) for introducing the agglomeration experiment. Dr. Hongbin Yin (ArcelorMittal, Global R&D) is acknowledged by the authors for discussing the details of in situ observation experiments using CLSM. The Canadian Centre for Electron Microscopy (CCEM), McMaster University, is also acknowledged for the support of characterization.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 23, 2017.

Rights and permissions

About this article

Cite this article

Mu, W., Dogan, N. & Coley, K.S. Agglomeration of Non-metallic Inclusions at Steel/Ar Interface: In-Situ Observation Experiments and Model Validation. Metall Mater Trans B 48, 2379–2388 (2017). https://doi.org/10.1007/s11663-017-1027-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-017-1027-4