Abstract

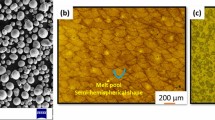

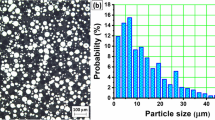

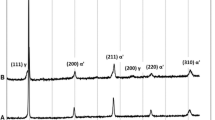

The shot peening (SP) post-processing was applied under different regimes to improve the surface characteristics of the nickel-based Inconel 718 alloy parts printed by a laser powder bed fusion (LPBF) additive manufacturing technique. The effects of SP treatment on surface topography, roughness, waviness, chemical composition, macrohardness, and defects on the surface of the LPBF-printed specimens were estimated in this work. The surface microstructure, phase state, subsurface porosity, microhardness distribution, and stress state in the near-surface layer of the LPBF-built and SP-processed specimens are also addressed to optimize the SP parameters for surface finishing and hardening of the LPBF-built superalloy parts. The experimentation on an industrial SP system and the surface roughness, hardness, and porosity analysis allowed the identification of appropriate peening pressure for surface treatment of the studied LPBF-built alloy. Particular attention is paid to the study of microstructural aspects induced by the severe surface plastic deformation. Results indicated that applied SP treatment leads to a decrease in the Ra roughness parameter providing a new wavy surface microrelief on the surface. The spherical/ellipsoidal balls and partially melted powder particles were successfully removed from the treated surface by the SP treatment, which also reduced a subsurface porosity. As compared to the LPBF-built sample (~370 HV0.025), the SP post-processing leads to work hardening, providing up to 75% increase in the surface microhardness due to the strain-induced grain refinement.

Similar content being viewed by others

References

T. Trosch, J. Strobner, R. Volkl and U. Glatzel, Microstructure and Mechanical Properties of Selective Laser Melted Inconel 718 Compared to Forging and Casting, Mater. Lett., 2016, 164, p 428–431.

R. Seede, A. Mostafa, V. Brailovski, M. Jahazi and M. Medraj, Microstructural and Microhardness Evolution from Homogenization and Hot isostatic Pressing on Selective Laser Melted Inconel 718: Structure, Texture, and Phases, Manuf. Mater. Process, 2018, 2, p 30–51.

J.D. Kim and I.S. Chao, Mechanical and Tribological Characteristics of Sintered Fe-Ni-Cr Alloy Subjected to High-frequency Ultrasonic Peening, Int. J. Surf. Sci. Eng., 2014, 8, p 239–254.

D.A. Lesyk, S. Martinez, V.V. Dzhemelinskyi, and A. Lamikiz, Additive Manufacturing of the Superalloy Turbine Blades by Selective Laser Melting: Surface Quality, Microstructure and Porosity, In: Karabegović I. (eds) New Technologies, Development and Application III. NT 2020. Lecture Notes in Networks and Systems, 2020, 128, p 267–275.

Y.L. Kuo, T. Nagahari and K. Kakehi, The Effect of Post-processes on the Microstructure and Creep Properties of Alloy718 Built up by Selective Laser Melting, Mater., 2018, 11, p 996–1009.

A.H. Maamoun, M.A. Elbestawi and S.C. Veldhuis, Influence of Shot Peening on AlSi10Mg Parts Fabricated by Additive Manufacturing, Manuf. Mater. Process, 2018, 2, p 40–56.

N.E. Uzan, S. Ramati, R. Shneck, N. Frage and O. Yeheskel, On the Effect of Shot-peening on Fatigue Resistance of AlSi10Mg Specimens Fabricated by Additive Manufacturing Using Selective Laser Melting (AM-SLM), Addit. Manuf., 2018, 21, p 458–464.

D.A. Lesyk, S. Martinez, B.N. Mordyuk, V.V. Dzhemelinskyi, and A. Lamikiz, Surface finishing of complexly shaped parts fabricated by selective laser melting, Grabchenko’s International Conference on Advanced Manufacturing Processes. InterPartner-2019. Lecture Notes in Mechanical Engineering, 2020, p 186–195.

J. Gale and A. Achuhan, Application of Ultrasonic Peening During DMLS Production of 316L Stainless Steel and Its Effect on Material Behavior, Rapid Prototyp., 2017, 23, p 1185–1194.

X. Xing, X. Duan, T. Jiang, J. Wang and F. Jiang, Ultrasonic Peening Treatment Used to Improve Stress corrosion Resistance of AlSi10Mg Components Fabricated Using Selective Laser Melting, Metals, 2019, 9, p 103–111.

A. Amanov, Advancement of Tribological Properties of Ti–6Al–4V Alloy Fabricated by Selective Laser Melting, Tribol. Int., 2021, 155, 106806.

D.A. Lesyk, S. Martinez, B.N. Mordyuk, V.V. Dzhemelinskyi, A. Lamikiz, and G.I. Prokopenko, Post-processing of the Inconel 718 Alloy Parts Fabricated by Selective Laser Melting: Effects of Mechanical Surface Treatments on Surface Topography, Porosity, Hardness and Residual Stress, Surf. Coat. Technol., 2020, 381, 125136.

L. Hackel, J.R. Rankin, A. Rubenchik, W.E. King and M. Matthews, Laser Peening: A Tool for Additive Manufacturing Post-processing, Addit. Manuf., 2018, 24, p 67–75.

N. Kalentics, E. Boillat, P. Peyre, C. Gorny, C. Kenel, C. Leinenbach, J. Jhabvala and R.E. Loge, 3D Laser Shock Peening: A New Method for the 3D Control of Residual Stresses in Selective Laser Melting, Mater. Des., 2017, 130, p 350–356.

H. Sasaki, F. Takeo, and H.Soyama, Cavitation Erosion Resistance of the Titanium Alloy Ti–6Al–4V Manufactured Through Additive Manufacturing with Various Peening Methods, Wear, 2020, 462–463, 203518.

H. Soyama and Y. Okura, The Use of Various Peening Methods to Improve the Fatigue Strength of Titanium Alloy Ti6Al4V Manufactured by Electron Beam Melting, Mater. Sci., 2018, 5, p 1000–1015.

M. Khorasani, I. Gibson, A.H. Ghasemi, M. Brandt and M. Leary, On the Role of Wet Abrasive Centrifugal Barrel Finishing on Surface Enhancement and Material Removal rate of LPBF Stainless Steel 316L, J. Manuf. Process, 2020, 59, p 523–534.

A. Boschetto, L. Bottini, L. Macera and F. Veniali, Post-processing of Complex SLM Parts by Barrel Finishing, Appl. Sci., 2020, 10, p 1382.

Y. Kaynak and E. Tascioglu, Post Processing Effects on the Surface Characteristics of Inconel 718 Alloy Fabricated by Selective Laser Melting Additive Manufacturing, Prog. Addit. Manuf., 2020, 5, p 221–234.

Z. Baicheng, L. Xiaohua, B. Jiaming, G. Junfeng, W. Pan, S. Chen-nan, N. Muiling, Q. Guojun and W. Jun, Study of Selective Laser Melting (SLM) Inconel 718 Part Surface Improvement by Electrochemical Polishing, Mater. Des., 2017, 116, p 531–537.

D.A. Lesyk, S. Martinez, O.O. Pedash, V.V. Dzhemelinskyi, and B.N. Mordyuk, Combined thermo-mechanical techniques for post-processing of the SLM-printed Ni-Cr-Fe alloy parts, In: Ivanov V. et al. (eds) Advances in Design, Simulation and Manufacturing III. DSMIE 2020. Lecture Notes in Mechanical Engineering, 2020, p 295–304.

O.V. Mythreyi, A. Raja, B.K. Nagesha and R. Jayaganthan, Corrosion Study of Selective Laser Melted IN718 Alloy Upon Post Heat Treatment and Shot Peening, Metals, 2020, 10, p 1562.

D.T. Ardi, L. Guowei, N. Maharjan, B. Mutiargo, S.H. Leng, and R. Srinivasan, Effects of Post-processing Route on Fatigue Performance of Laser Powder Bed Fusion Inconel 718, Addit. Manuf., 2020, 36, 101442.

X. Yan, S. Yin, C. Chen, R. Jenkins, R. Lupoi, R. Bolot, W. Ma, M. Kuang, H. Liao, J. Lu and M. Liu, Fatigue Strength Improvement of Selective Laser Melted Ti6Al4V Using Ultrasonic Surface Mechanical Attrition, Mater. Res. Lett., 2019, 7, p 327–333.

C.S. Bagherifard, N. Beretta, S. Monti, M. Riccio, M. Bandini and M. Guagliano, On the Fatigue Strength Enhancement of Additive Manufactured AlSi10Mg Parts by Mechanical and Thermal Post-processing, Mater. Des., 2018, 145, p 28–41.

M. Zhang, C. Liu, X. Shi, X. Chen, C. Chen, J. Zuo, J. Lu and S. Ma, Residual Stress, Defects and Grain Morphology of Ti-6Al-4V Alloy Produced by Ultrasonic Impact Treatment Assisted Selective Laser Melting, Appl. Sci., 2016, 6, p 304–311.

Z. Wang, Z. Xiao, C. Huang, L. Wen and W. Zhang, Influence of Ultrasonic Surface Rolling on Microstructure and Wear Behavior of Selective Laser Melted Ti-6Al-4V Alloy, Mater., 2017, 10, p 1203.

H. Soyama and F. Takeo, Effect of Various Peening Methods on the Fatigue Properties of Titanium Alloy Ti6Al4V Manufactured by Direct Metal Laser Sintering and Electron Beam Melting, Mater., 2020, 13, p 2216.

B. AlMangour and J.M. Yang, Improving the Surface Quality and Mechanical Properties by Shot-Peening of 17–4 Stainless Steel Fabricated by Additive Manufacturing, Mater. Des., 2016, 110, p 914–924.

M. Sugavaneswaran, A.V. Jebaraj, M.D.B. Kumar, K. Lokesh and A.J. Rajan, Enhancement of Surface Characteristics of Direct Metal Laser Sintered Stainless Steel 316L by Shot Peening, Surf. Interf., 2018, 12, p 31–40.

J. Damon, S. Dietrich, F. Vollert, J. Gibmeier and V. Schulze, Process Dependent Porosity and the Influence of Shot Peening on Porosity Morphology Regarding Selective Laser Melted AlSi10Mg Parts, Addit. Manuf., 2018, 20, p 77–89.

S. Martinez, N. Ortega, D. Celentano, A.J.S. Egea, E. Ukar and A. Lamikiz, Analysis of the Part Distortions for Inconel 718 SLM: A Case Study on the NIST Test Artifact, Mater., 2020, 13, p 5087.

D.J. Child, G.D. West and R.C. Thomson, Assessment of Surface Hardening Effects from Shot Peening on a Ni-based Alloy Using Electron Backscatter Diffraction Techniques, Acta Mater., 2011, 59, p 4825–4834.

D.A. Lesyk, B.N. Mordyuk, S. Martinez, M.O. Iefimov, V.V. Dzhemelinskyi, and A. Lamikiz, Influence of Combined Laser Heat Treatment and Ultrasonic Impact Treatment on Microstructure and Corrosion Behavior of AISI 1045 Steel, Surf. Coat. Technol., 2020, 401, 126275.

D.A. Lesyk, S. Martinez, V.V. Dzhemelinskyi, O. Stamann, B.N. Mordyuk, and A. Lamikiz, Surface Polishing of Laser Powder Bed Fused Superalloy Components by Magnetic Post-treatment, 2020 IEEE 10th International Conference Nanomaterials: Applications & Properties (NAP), 2020, 20327559, p 02SAMA17-1–02SAMA17-4.

M. Lutter-Günther, M. Bröker, T. Mayer, S. Lizak, C. Seidel and G. Reinhart, Spatter Formation During Laser Beam Melting of AlSi10Mg and Effects on Powder Quality, Procedia CIRP, 2018, 74, p 33–38.

J. Wang, S. Liu, Y. Fang and Z. He, A Short Review on Selective Laser Melting of H13 Steel, Int. J. Adv. Manuf. Syst., 2020, 108, p 2453–2466.

D. Cai, P. Nie, J. Shan, W. Liu, Y. Gao and M. Yao, Precipitation and Residual Stress Relaxation Kinetics in Shot-Peened Inconel 718, J. Mater. Eng. Perform., 2006, 15, p 614–617.

X.P. Wei, W.J. Zheng, Z.G. Song, T. Lei, Q.l. Yong, and Q.C. Xie, Strain-Induced Precipitation Behavior of δ Phase in Inconel 718 Alloy, J. Iron Steel Res. Int., 2014, 3, p 375–381.

R.J. Vikram, A. Singh and S. Suwas, Effect of Heat Treatment on the Modification of Microstructure of Selective Laser Melted (SLM) IN718 and Its Consequences on Mechanical Behavior, J. Mater. Res., 2020, 35, p 1949–1962.

L.S.B. Ling, Z. Yin, Z. Hu, J.H. Liang, Z.-Y. Wang, J. Wang and B.D. Sun, Effects of the γ”-Ni3Nb Phase on Mechanical Properties of Inconel 718 Superalloys with Different Heat Treatments, Mater., 2020, 13, p 151.

Y. Tian, D. McAllister, H. Colijn, M. Mills, D. Farson, M. Nordin and S. Babu, Rationalization of Microstructure Heterogeneity in INCONEL 718 Builds Made by the Direct Laser Additive Manufacturing Process, Met. Mat. Trans. A, 2014, 45, p 4470–4483.

M. Renderos, A. Torregaray, M. Esther Gutierrez-Orrantia, A. Lamikiz, N. Saintier, and F. Girot, Microstructure Characterization of Recycled IN718 Powder and Resulting Laser Clad Material, Mater. Charact., 2017, 134, p 103–113.

C. Kumara, A. Segerstark, F. Hanning, N. Dixit, S. Joshi, J. Moverare and P. Nylen, Microstructure Modelling of Laser Metal Powder Directed Energy Deposition of Alloy 718, Addit. Manuf., 2019, 25, p 357–364.

S. Yan, Y. Wang, Q. Wang, C. Zhang, D. Chen and G. Cui, Enhancing Mechanical Properties of the Spark Plasma Sintered Inconel 718 Alloy by Controlling the Nano-scale Precipitations, Mater., 2019, 12, p 3336.

F. Lyu, F. Liu, X. Hu, X. Yang, C. Huang and D. Shi, The δ Phase Precipitation of an Inconel 718 Superalloy Fabricated by Electromagnetic Stirring Assisted Laser Solid Forming, Mater., 2019, 12, p 2604.

Acknowledgments

This work was partially supported by the German Academic Exchange Service (DAAD) in frame of the Research Grants for Doctoral Candidates and Young Academics and Scientists program. The authors would like to thank O. Stamann and S. Faust (Otto von Guericke University Magdeburg, Germany) for the support provided with the surface topography measurements.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special topical focus in the Journal of Materials Engineering and Performance on Additive Manufacturing. The issue was organized by Dr. William Frazier, Pilgrim Consulting, LLC; Mr. Rick Russell, NASA; Dr. Yan Lu, NIST; Dr. Brandon D. Ribic, America Makes; and Caroline Vail, NSWC Carderock.

Rights and permissions

About this article

Cite this article

Lesyk, D.A., Dzhemelinskyi, V.V., Martinez, S. et al. Surface Shot Peening Post-processing of Inconel 718 Alloy Parts Printed by Laser Powder Bed Fusion Additive Manufacturing. J. of Materi Eng and Perform 30, 6982–6995 (2021). https://doi.org/10.1007/s11665-021-06103-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06103-6