Abstract

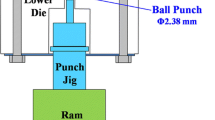

Finite element (FE) analysis of plastic deformation associated with impression creep deformation of 316LN stainless steel was carried out. An axisymmetric FE model of 10 × 10 × 10 mm specimen with 1-mm-diameter rigid cylindrical flat punch was developed. FE simulation of impression creep deformation was performed by assuming elastic-plastic-power-law creep deformation behavior. Evolution of the stress with time under the punch during elastic, plastic, and creep processes was analyzed. The onset of plastic deformation was found to occur at a nominal stress about 1.12 times the yield stress of the material. The size of the developed plastic zone was predicted to be about three times the radius of the punch. The material flow behavior and the pile-up on specimen surface have been modeled.

Similar content being viewed by others

References

M.D. Mathew, Naveena, and D. Vijayanand, Impression Creep Behavior of 316LN Stainless Steel, J. Mater. Eng. Perform., 2013, 22, p 492–497

Naveena, V.D. Vijayanand, V. Ganesan, K. Laha, and M.D. Mathew, Evaluation of the Effect of Nitrogen on Creep Properties of 316LN Stainless Steel from Impression Creep Tests, Mater. Sci. Eng. A., 2012, 552, p 112–118

J.C.M. Li and S.N.G. Chu, Impression Creep: A New Creep Test, J. Mater. Sci., 1977, 12, p 2200–2208

T.H. Hyde, W. Sun, and C.J. Hyde, Small Specimen Creep Testing, Applied Creep Mechanics, McGraw-Hill Education, New York, 2013, p 327–334.

I. Sneddon, The Relation Between Load and Penetration in the Axisymmetric Boussinesq Problem for a Punch of Arbitrary Profile, Int. J. Eng. Sci., 1965, 3, p 47–57

K.L. Johnson, Contact Mechanics, Cambridge University Press, Cambridge, 1987

D.A. Hills, D. Nowell, and A. Sackfield, Mechanics of Elastic Contacts, Butterworth, Oxford, 1993

G. Feng, S. Qu, Y. Huang, and W.D. Nix, An Analytical Expression for the Stress Field Around an Elastoplastic Indentation/Contact, Acta. Mater., 2007, 55, p 2929–2938

F. Yang, J.C.M. Li, and C.W. Shih, Computer Simulation of Impression Creep using the Hyperbolic Sine Stress Law, Mater. Sci. Eng. A., 1995, 201, p 50–57

E.C. Yu and J.C.M. Li, Impression Creep of LiF Single Crystals, Philos. Mag., 1977, 36(4), p 811–825

T.H. Hyde, K.A. Yehia, and A.A. Becker, Interpretation of Impression Creep Data using a Reference Approach, Int. J. Mech. Sci., 1993, 35, p 451–462

Y.C. Lu, S.N.V.R.K. Kurapati, and F. Yang, Finite Element Analysis of Cylindrical Indentation for Determining Plastic Properties of Materials in Small Volumes, J. Phys. D Appl. Phys., 2008, 11, p 115415–115500

ABAQUS Inc., ABAQUS Theory Manual, Hibbitt, Karlson, and Sorensen, Inc., Pawtucket, 2010

RCC-MR, 2007, Design and Construction Rules for Mechanical Components of Nuclear Installations, Section 2, Subsection Z.A3.3S.22, AFCEN, Paris, 2007

V. Ganesan, M.D. Mathew, and K. Bhanu Sankara Rao, Influence of Nitrogen on Tensile Properties of 316LN SS, Mater. Sci. Technol., 2009, 25, p 614–618

J. Ganesh Kumar, M. Chowdar, V. Ganesan, R.K. Paretkar, K. Bhanu Sankara Rao, and M.D. Mathew, High Temperature Design Curves for High Nitrogen Grades of 316LN Stainless Steel, Nucl. Eng. Des., 2010, 240, p 1363–1370

A.C. Fischer-Cripps, Introduction to Contact Mechanics, Springer, New York, 2000

R.T. Shield, On the Plastic Flow of Metals Under Conditions of Axial Symmetry, Proc. R. Soc., 1956, 233, p 267–287

G. Eason, R.T. Shield, and F. Angew, The Plastic Indentation of a Semi-infinite Solid by a Perfectly Rough Circular Punch, Math. M. Phy., 1960, 11, p 33–42

J.W. Harding and L.N. Sneddon, The Elastic Stresses Produced by the Indentation of the Plane Surface of a Semi-infinite Elastic Solid by a Rigid Punch, Proc. Cambridge Phil. Soc., 1945, 41, p 16–26

H.Y. Yu, M.A. Imam, and B.B. Rath, Study of the Deformation Behaviour of Homogeneous Materials by Impression Tests, J. Mater. Sci., 1985, 20, p 636–642

D. Tabor, A Simple Theory of Static and Dynamic Hardness, Proc. R. Soc. Lond. A., 1948, 192, p 247–274

S. Timoshenko, Theory of Elasticity, McGraw Hill, New York, 1934, p 344

D.R. Hayhurst and J.T. Henderson, Creep Stress Redistribution in Notched Bars, Int. J. Mech. Sci., 1977, 19, p 133–146

G. Eggeler and C. Wiesner, A Numerical Study of Parameters Controlling Stress Redistribution in Circular Notched Specimens During Creep, J. Strain. Anal., 1993, 28, p 13–22

S. Goyal, K. Laha, C.R. Das, P. Panneerselvi, and M.D. Mathew, Finite Element Analysis of Effect of Tri-axial State of Stress on Creep Cavitation and Rupture Behavior of 2.25Cr-1Mo steel, Int. J. Mech. Sci., 2013, 75, p 233–243

H.Y. Yu and J.C.M. Li, Computer Simulation of Impression Creep by the Finite Element Method, J. Mater. Sci., 1977, 12, p 2214–2222

D. Pan and I. Dutta, A Mechanics-Induced Complication of Impression Creep and Its Solution: Application to Sn-3.5Ag Solder, Mater. Sci. Eng. A., 2004, 379, p 154–163

G. Das, S. Ghosh, S. Ghosh, and R.N. Ghosh, Materials Characterization and Classification on the Basis of Materials Pile-up Surrounding the Indentation, Mater. Sci. Eng. A., 2005, 408, p 158–164

Acknowledgments

The authors thank Dr. Vani Shankar, Fatigue Studies Section, for EBSD analysis. The authors gratefully acknowledge the support and encouragement received from Dr. K. Laha, Head, Creep Studies Section; Dr. A. K. Bhaduri, Associate Director, Materials Development and Technology group; and Dr. T. Jayakumar, Director, Metallurgy and Materials Group, Indira Gandhi Centre for Atomic Research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Naveena, Ganesh Kumar, J. & Mathew, M.D. Finite Element Analysis of Plastic Deformation During Impression Creep. J. of Materi Eng and Perform 24, 1741–1753 (2015). https://doi.org/10.1007/s11665-014-1225-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1225-z