Abstract

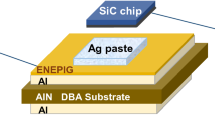

Ag sinter-joining technology has become one of the leading candidates to replace conventional high-Pb soldering technology for wide bandgap (WBG) power modules. In many cases of die-attach applications, Ni/Au plating is an inevitable choice for both die-back faces and substrates. In this study, a preheating treatment of the Ni/Au plating was utilized to increase the bond strength of the Ag sinter-joined structure of Cu-to-Cu to the electroless Ni/Au plating. Our research determined that the microstructure of the Ni/Au plating can be modified by performing an optimized preheating treatment. The thickness of the Ni underlayer was fixed at 5 μm, and the Au was plated with two different thicknesses of 0.1 μm and 0.3 μm. Ni/Au plated Cu substrates and Cu chips were preheated at various temperatures from 150°C to 350°C and then bonded with hybrid Ag particles at a low temperature of 250°C with a pressureless sintering process. Without the preheating treatment, average shear strength was 14.2 MPa (as plated Au), however, after a 1 h preheating treatment at 250°C, the interface microstructure change resulted in a 26.3 MPa shear strength, an increase of about 85%. The same improvement effect was also confirmed for the Au plating layer with a thickness of 0.3 μm. Energy dispersive x-ray spectrometry (EDS) and x-ray diffraction (XRD) analysis indicated that the preheating treatment influences the grain structure of the Au plating layer and removes defects, resulting in an increase of bond strength for the Au plated joint structure.

Similar content being viewed by others

References

R. Khazaka, L. Mendizabal, D. Henry, and R. Hanna, IEEE. Trans. Power Electron. 30, 2456 (2015).

C. Buttay, D. Planson, B. Allard, D. Bergogne, P. Bevilacqua, C. Joubert, M. Lazar, C. Martin, H. Morel, D. Tournier, and C. Raynaud, Mater. Sci. Eng. 176, 283 (2011).

C. Chen, S. Nagao, H. Zhang, J. Jiu, T. Sugahara, K. Suganuma, T. Iwashige, K. Sugiura, and K. Tsuruta, J. Electron. Mater. 46, 1576 (2017).

C. Pei, C. Chen, G. Fu, and K. Suganuma, J. Electron. Mater. 47, 811 (2018).

K. Suganuma, S.J. Kim, and K.S. Kim, J. Minerals. Metals. Mater. Soc. 61, 64 (2009).

K. Suganuma, S. Sakamoto, N. Kagami, D. Wakuda, K.-S. Kim, and M. Nogi, Microelectron. Reliab. 52, 375 (2012).

C. Chen, S. Nagao, K. Suganuma, J. Jiu, T. Sugahara, H. Zhang, T. Iwashige, K. Sugiura, and K. Tsuruta, Acta Mater. 129, 41 (2017).

C. Chen, S. Nagao, K. Suganuma, J. Jiu, H. Zhang, T. Sugahara, T. Iwashige, K. Sugiura, and K. Tsuruta, Appl. Phys. Lett. 109, 093503 (2016).

K. Siow, J. Electron. Mater. 43, 947 (2014).

P. Peng, A. Hu, A.P. Gerlich, G. Zou, L. Liu, and Y.N. Zhou, ACS Appl. Mater. Interfaces 7, 12597 (2015).

H. Zhang, W. Li, Y. Gao, H. Zhang, J. Jiu, and K. Suganuma, J. Electron. Mater. 46, 5201 (2017).

H. Zhang, C. Chen, J. Jiu, S. Nagao, and K. Suganuma, J. Mater. Sci. Mater. Electron. 29, 8854 (2018).

C. Chen, K. Suganuma, T. Iwashige, K. Sugiura, and K. Tsuruta, J. Mater. Sci.: Mater. Electron. 29, 1785 (2018).

T. Fan, H. Zhang, P. Shang, C. Li, C. Chen, J. Wang, Z. Liu, H. Zhang, and K. Suganuma, J. Alloys Compd. 731, 1280 (2018).

N. Okuya, H. Minami, H. Kurashige, S. Murahara, S. Suzuki, and T. Tanaka, Dent. Mater. J. 29, 177 (2010).

Q. Xu, Y. Mei, X. Li, and G.Q. Lu, J. Alloys Compd. 675, 317 (2016).

C. Chen, Z. Zhang, S. Nagao, K. Suganuma, T. Iwashige, K. Sugiura, and K. Tsuruta, IEEE ICEP-IAAC (2018)

S.A. Paknejad, G. Dumas, G. West, G. Lewis, and S.H. Mannan, J. Alloys Compd. 617, 994 (2014).

S.T. Chua and K.S. Siow, J. Alloys Compd. 687, 486 (2016).

S. Kobayashi, R. Fukasawa, and T. Watanabe, Mater. Sci. Forum 706–709, 2880 (2012).

X. Zhang, X. Song, and D. Zhang, Chin. Phys. B 19, 086802 (2010).

B.C. Charboneau, F. Wang, J.D. van Wyk, D. Boroyevich, Z. Liang, E.P. Scott, and C.W. Tipton, IEEE Trans. Ind. Appl. 44, 1645 (2008).

Y. Zhong, J. Meng, P. Ning, and X. Wen, IEEE. ITEC Asia-Pacific, 1 (2014).

H. Zhang and S.S. Ang, J. Microelectron. Electron. Packag. 13, 23 (2016).

M. Maruyama, R. Matsubayashi, H. Iwakuro, S. Isoda, and T. Komatsu, Appl. Phys. A Mater. Sci. Process. 93, 467 (2008).

M.H. Roh, H. Nishikawa, S. Tsutsumi, N. Nishiwaki, K. Ito, K. Ishikawa, A. Katsuya, N. Kamada, and M. Saito, J. Mater. Sci. Mater. Electron. 28, 7292 (2017).

M.H. Roh, H. Nishikawa, S. Tsutsumi, N. Nishiwaki, K. Ito, K. Ishikawa, A. Katsuya, N. Kamaka, and M. Saito, Mater. Trans. 57, 1209 (2016).

M. El-Kemary, N. Nagy, and I. El-Mehasseb, Mat. Sci. Semiconduct. Proc. 16, 1747 (2013).

U. Kwon, B.G. Kim, D.C. Nguyen, J.-H. Park, N.Y. Ha, S.-J. Kim, S.H. Ko, S. Lee, D. Lee, and H.J. Park, Sci. Rep. 6, 30759 (2016).

A.G. Blachman, Metall. Trans. 236, 699 (1971).

Acknowledgments

This work was supported by the JST Advanced Low Carbon Technology Research and Development Program (ALCA) project “Development of a high frequency GaN power module package technology” (Grant No. JPMJAL1610). The author is thankful to the Network Joint Research Centre for Materials and Devices, Dynamic Alliance for Open Innovation Bridging Human, Environment and Materials, also thanks to the Daicel Corporation, DENSO Corporation, and C. Uyemura & Co., Ltd for help in the experiments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, C., Zhang, Z., Choe, C. et al. Improvement of the Bond Strength of Ag Sinter-Joining on Electroless Ni/Au Plated Substrate by a One-Step Preheating Treatment. J. Electron. Mater. 48, 1106–1115 (2019). https://doi.org/10.1007/s11664-018-06842-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-018-06842-8