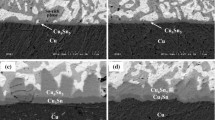

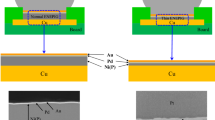

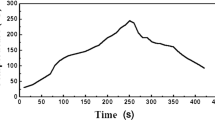

This study provides a comparison of the influence of Pd(P) thickness on reactions during soldering with the Sn-3Ag-0.5Cu alloy. Soldering was carried out in an infrared-enhanced conventional reflow oven, and a multiple reflow test method (up to ten cycles) was performed. With increasing Pd(P) thickness, the (Cu,Ni)6Sn5 grew more slowly at the solder/Ni(P) interface, while the Ni2SnP/Ni3P bilayer became predominant after the first reflow. These three intermetallics, i.e., (Cu,Ni)6Sn5, Ni2SnP, and Ni3P, gradually coarsened as the number of reflow cycles increased. Furthermore, an additional (Ni,Cu)3Sn4 layer appeared between (Cu,Ni)6Sn5 and Ni2SnP, especially for the case of a thicker Pd(P) layer (0.2 μm). The attachment of the (Ni,Cu)3Sn4 to the Ni2SnP, however, was fairly poor, and a series of microcracks formed along the (Ni,Cu)3Sn4/Ni2SnP interface. To quantify the mechanical response of the interfacial microstructures, shear testing was conducted at two different shear speeds (0.0007 m/s and 2 m/s). The results indicated that the interfacial strength and the Pd(P) thickness were strongly correlated.

Similar content being viewed by others

References

J. Glazer, Int. Mater. Rev. 40, 65 (1995).

K.N. Tu and K. Zeng, Mater. Sci. Eng. R34, 1 (2001).

T. Laurila, V. Vuorinen, and J.K. Kivilahti, Mater. Sci. Eng. R49, 1 (2005).

A.J.G. Strandjord, S. Popelar, and C. Jauernig, Microelectron. Reliab. 42, 265 (2002).

J.W. Jang, P.G. Kim, K.N. Tu, D.R. Frear, and P. Thompson, J. Appl. Phys. 85, 8456 (1999).

P. Snugovsky, P. Arrowsmith, and M. Romansky, J. Electron. Mater. 30, 1262 (2001).

R.J. Coyle, D.E.H. Popps, A. Mawer, D.P. Cullen, G.M. Wenger, and P.P. Solan, IEEE Trans. Comp. Packag. Technol. 26, 724 (2003).

K. Zeng, R. Stierman, D. Abbott, and M. Murtuza, JOM 58, 75 (2006).

K. Suganuma and K.S. Kim, JOM 60, 61 (2008).

B.K. Kim, S.J. Lee, J.Y. Kim, K.Y. Ji, Y.J. Yoon, M.Y. Kim, S.H. Park, and J.S. Yoo, J. Electron. Mater. 37, 527 (2008).

P. Ratchev, S. Stoukatch, and B. Swinnen, Microelectron. Reliab. 46, 1315 (2006).

W. Sun, W.H. Zhu, E.S.W. Poh, H.B. Tan, and R.T. Gan, Proceeding of International Conference on Electronic Packaging Technology & High Density Packaging, ICEPT-HDP (2008), p. 1.

Y. Oda, M. Kiso, S. Kurosaka, A. Okada, K. Kitajima, and S. Hashimoto, Proceeding of International Microelectronics & Packaging Society, IMAPS (2008).

P.G. Kim, K.N. Tu, and D.C. Abbott, J. Appl. Phys. 84, 770 (1998).

G. Ghosh, J. Electron. Mater. 28, 1238 (1999).

S.P. Peng, W.H. Wu, C.E. Ho, and Y.M. Huang, J. Alloys Compd. 493, 431 (2010).

W.H. Wu, H.L. Chung, C.N. Chen, and C.E. Ho, J. Electron. Mater. 38, 2563 (2009).

BGA Ball Shear, JESD22-B117, JEDEC Solid State Technology Association (2006).

C.E. Ho, R.Y. Tsai, Y.L. Lin, and C.R. Kao, J. Electron. Mater. 31, 584 (2002).

K. Zeng and K.N. Tu, Mater. Sci. Eng. R38, 55 (2002).

C.E. Ho, S.C. Yang, and C.R. Kao, J. Mater. Sci.: Mater. Electron. 18, 155 (2007).

Y.C. Lin and J.G. Duh, Scripta Mater. 54, 1161 (2006).

Y.C. Lin, T.Y. Shih, S.K. Tien, and J.G. Duh, Scripta Mater. 56, 49 (2007).

Y.C. Lin, K.J. Wang, and J.G. Duh, J. Electron. Mater. 39, 283 (2010).

Z.P. Xia, Y. Lin, and Z.Q. Li, Mater. Charact. 59, 1324 (2008).

J.W. Yoon and S.B. Jung, J. Alloys Compd. 396, 122 (2005).

S. Furuseth and H. Fjellvåg, ACTA Chem. Scand. Ser. A 39, 537 (1985).

H. Matsuki, H. Ibuka, and H. Saka, Sci. Technol. Adv. Mater. 3, 261 (2002).

S.W. Kim, J.W. Yoon, and S.B. Jung, J. Electron. Mater. 33, 1182 (2004).

Y.C. Sohn, J. Yu, S.K. Kang, D.Y. Shih, and T.Y. Lee, J. Mater. Res. 19, 2428 (2004).

S.J. Wang and C.Y. Liu, Scripta Mater. 49, 813 (2003).

C.E. Ho, Y.M. Chen, and C.R. Kao, J. Electron. Mater. 28, 1231 (1999).

G. Ghosh, Acta Mater. 48, 3719 (2000).

K.N. Tu, Solder Joint Technology—Materials, Properties, and Reliability (New York: Springer, 2007).

Y. Wang and K.N. Tu, Appl. Phys. Lett. 67, 1069 (1995).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, W.H., Lin, C.S., Huang, S.H. et al. Influence of Palladium Thickness on the Soldering Reactions Between Sn-3Ag-0.5Cu and Au/Pd(P)/Ni(P) Surface Finish. J. Electron. Mater. 39, 2387–2396 (2010). https://doi.org/10.1007/s11664-010-1351-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-010-1351-9