Abstract

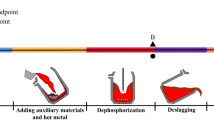

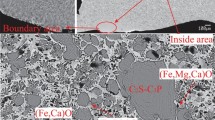

In the present work, the effect of dephosphorization slag basicity on the dephosphorization of hot metal has been studied in the lower temperature range of 1370 °C to 1420 °C and the lower basicity of 1.26 to 2.20 with new double slag converter steelmaking process (NDSP). Based on the ion-molecule coexistence theory (IMCT), the thermodynamic model IMCT-Ni of dephosphorization slag is established. With increasing basicity from 1.26 to 2.20, the phosphorus distribution ratio LP between hot metal and slag increases. The dephosphorization ratio and the decarbonization ratio both increase, while the demanganization ratio decreases. The morphologies of P-rich phase change from long strip shape (B = 1.26-1.37) to dendritic shape (B = 1.50) and to massive shape (B = 1.71-2.20). The area of P-rich phase increases from about 4 μm2 to about 8000 μm2. The content of P2O5 in the P-rich phase increases and the value of the coefficient n in nC2S-C3P of the P-rich phase decreases from 6-20 to 1-2. The phosphorus-enrichment contribution ratio of calcium silicate is in the order of \(R_{{{\text{C2S}}}}\)>\(R_{{{\text{CS}}}}\)>\(R_{{{\text{C3S}}}}\)>\(R_{{{\text{C3S2}}}}\). The phosphorus-enrichment degree in dephosphorization slag is enhanced mainly by C2S-C3P. With increasing basicity, the calculated results of IMCT-(pct C2S-CjP) and \(R_{{{\text{C2S}}}}\) are well consistent with the measurement results of AP-rich phase and (pct P2O5)P-rich phase of industrial experiment, indicating that the IMCT calculated results can correctly express the phosphorus-enrichment degree of dephosphorization slag.

Similar content being viewed by others

Abbreviations

- a i, b i :

-

Initial mole numbers of component i in 100 g dephosphorization slag, (mol)

- ∑n i :

-

Total equilibrium moles of all structural units in 100 g dephosphorization slag based on IMCT, (mol)

- N i :

-

Mass action concentration of structural unit i or ion couple i in dephosphorization slag based on IMCT, (−)

- \(\Delta _{{\text{r}}} G_{{{\text{m,}}ci}}^{\Theta }\) :

-

Change of standard molar Gibbs free energy of reaction for structural unit i or component i, (J/mol)

- \(K_{{ci}}^{\Theta }\) :

-

Standard equilibrium constants of chemical reactions for forming component i or structural unit i, (−)

- M i :

-

Relative atomic mass of element i or the relative molecular mass of component i, (−)

- \(N_{{Ci-Pj}}\) :

-

Defined-enrichment possibility of containing P2O5 solid solution based on the calculated mass action concentration Ni of complex molecule Ci and Pj, (−)

- \(R_{{Ci - Pj}}\) :

-

Enrichment degree of solid solution containing P2O5 based on IMCT, (−)

- \(R_{{Ci}}\) :

-

Phosphorus-enrichment contribution ratio of calcium silicate based on IMCT, (−)

- \(\eta _{{\text{i}}}\) :

-

Removal ratio of elements in hot metal, (pct)

- T :

-

Temperature, (°C)

- B:

-

Binary basicity, (−)

- r2 :

-

Fitting regression coefficient, (−)

- \(n{\text{(}}i{\text{)}}^{{{\text{ P - rich phase}}}}\) :

-

Mole number of i in P-rich phase, (mol)

- \( \Delta {\text{G}}_{{{\text{A{-}B}}}} \) :

-

Actual Gibbs free energy of A to B reaction, (J)

- IMCT-(pct C2S-CjP):

-

Mass fraction of C2S-CiP solid solution in P-rich phase by IMCT, (pct)

- AP-rich phase :

-

Average area fraction of P-rich phase at 1500 times under 3 fields of view, (pct)

References

Y. Ogawa, M. Yano, S. Y. Kitamura and H. Hirata: Tetsu-to-Hagané., 2001, vol. 87 (1), pp. 21-28.

Y. Ogawa, M. Yano, S. Y. Kitamura and H. Hirata: Steel Res. Int., 2003, vol. 74 (2), pp. 70-76.

N. Sasaki, Y. Ogawa, S. Mukawa and K. I. Miyamoto: Nippon Steel Tech. Rep., 2012, vol. 394, pp. 26-32.

Y. Wang, S. F. Yang, J. S. Li, J. Feng and F. Wang: High Temp. Mater. Proc., 2018, vol. 37(7), pp. 625-33.

W. K. Yang, J. Yang, Y. Q. Shi, Z. J. Yang, F. B. Gao, R. H. Zhang and G. F. Ye: Ironmaking Steelmaking., 2020. https://doi.org/10.1080/03019233.2020.1731256.

Y. R. Fang, B. C. Huang, Z. Y. Lai, B. Y. Chen and X. F. Zeng: Steelmaking., 2014, vol. 30(3), pp. 1-4.

F. Y. Liu, G. C. Wang, Y. Zhao, J. W. Tan, C. M. Zhao and Q. Wang: Ironmak. Steelmak.., 2019, vol. 46(4), pp. 392-403.

M. L. Wang and W. Y. Yang: Ironmak. Steelmak., 2019. https://doi.org/10.1080/03019233.2019.1673546.

G. F. Ye, J. Yang, R, H, Zhang, W. K. Yang and H. Sun: Int. J. Miner. Metall. Mater., 2021, vol. 28(1), pp. 66-75.

S. L. Xie and W. L. Wang: Steel Res. Int., 2016, vol. 87(3), pp. 376-85.

S. L. Xie, W. L. Wang, Z. C. Luo and D. Y. Huang: Metall. Mater. Trans. B., 2016, vol. 47B, pp. 1583-93.

S. Kakimoto, A. Kiyose and R. Murao: ISIJ Int., 2017, vol. 57(10), pp. 1710-17.

C. M. Du, N. N. Lv, C. Su, W. M. Liu, J. X. Yang and H. C. Wang: J. Iron Steel Res. Int., 2019, vol. 26, pp. 1162-70.

P. K. Son and Y. Kashiwaya: ISIJ Int., 2008, vol. 48(9), pp. 1165-74.

S. Fukagai, T. Hamano and F. Tsukihashi: ISIJ Int., 2010, vol. 47(1), pp. 187-89.

R. Inoue and H. Suito: ISIJ Int., 2006, vol. 46(2), pp. 174-79.

R. Inoue and H. Suito: ISIJ Int., 2006, vol. 46(2), pp. 180-87.

X. C. Ma, G. G. Cheng and J. Zhang: J. Univ. Sci. Technol. Beijing., 2011, vol. 33(11), pp. 1337-40.

G. G. Cheng and J. Zhang: Iron Steel Vanadium Titanium, 1994, vol. 15(3), pp. 1-2.

G. G. Cheng and J. Zhang: Iron Steel Vanadium Titanium, 1994, vol. 15(2), pp. 1-4.

G. G. Cheng and P. Zhao: J. Univ. Sci. Technol. Beijing., 1995, vol. 17, pp. 52-56.

X. M. Yang, J. P. Duan, C. B. Shi, M. Zhang, Y. L. Zhang and J. C. Wang: Metall. Mater. Trans. B., 2011, vol. 42B, pp. 738-70.

X. M. Yang, C. B. Shi, M. Zhang, J. P. Duan and J. Zhang: Metall. Mater. Trans. B., 2011, vol. 42B, pp. 951-76.

N. M. Chuiko: Ferrous Met., 1959, vol. 5, pp. 3-10.

J. Zhang: Computational Thermodynamics of Metallurgical Melt and Solutions, Metallurgical Industry Press, Beijing, China, 2007.

P. C. Li,X. M. Yang and J. Zhang: J. Univ. Sci. Technol. Beijing., 2014, vol. 36(12), pp. 1608-14.

S. L. Xie, W. L. Wang, D. Y. Huang, H. C. Li and Y. Du: Steel Res. Int., 2018, vol. 89, pp. 1700317.

J. Y. Li, M. Zhang, M. Guo and X. M. Yang: Metall. Mater. Trans. B., 2014, vol. 45B, pp. 1666-82.

J. Y. Li, M. Zhang, M. Guo and X. M. Yang: Int. J. Miner. Metall. Mater., 2016, vol. 23(5), pp. 520-33.

W. K. Yang, J. Yang, Y. Q. Shi, Z. J. Yang, F. B. Gao, R. H. Zhang and G. F. Ye: Steel Res. Int., 2021, vol. 92. https://doi.org/10.1002/srin.202000438.

W.K. Yang, J. Yang, Y.Q. Shi, Z.J. Yang, F.B. Gao, R.H. Zhang and H. Sun: Metals, 2021, vol. 11. https://doi.org/10.3390/met11030417.

X. Han, C.G. Zhou, J. Li, C.B. Shi, J.P. Ge and K.S. Cai: J. Iron Steel Res., 2016, vol. 28(9), pp. 40-49.

W.L. Dong, H.W. Pan, L. Luo, C.X. Ji, H.B. Li and Z.H. Tian: Iron and Steel, 2020, vol. 55(2), pp. 75-81, 94.

X. H. Huang: Principles of Iron and Steel Metallurgy, Metallurgical Industry Press, Beijing, China, 2002.

W. Xiong, J.Wang and F. Yang: Mining Metallurgy, 2013, vol. 22(4), pp. 47-50.

C. Li, H. J. Guo and G. G. Cheng: Special Steel, 2009, vol. 30(5), pp. 4-6.

Y. Liu, S. H. Peng, Y. J. Xia and X. B. Zhou: J. Univ. Sci. Technol. Anhui., 2019, vol. 36(1), pp. 7-12.

D. Z. Wang, Y. P. Bao and M. Wang: Chinese Journal of Engineering, 2018, vol. 40(1), pp. 65-72.

M. Timucin and A. Muan. J. Am. Cream. Soc., 1922, vol. 75, pp. 1399-1406.

I. Barin, O. Knacke and O. Kubaschewski. Thermochemical Properties of Inorganic Substances. Springer, Berlin. 1977.

S. Y. Kitamura, S. Saito, K. Utagawa, H. Shibata and D. G. C. Robertson: ISIJ Int., 2009, vol. 49(12), pp. 1838-44.

W. S. Zhang, J. T. Zhang, J. Y. Ye, J. S. Qian, W. G. Shen and Z. Y. Wang: J. Chin. Ceram. Soc. 2019, vol. 47(11), pp. 1664-69.

B. Dikens and W. E. Brown: Tsehermaks Min. Petr. Mitt., 1971, vol. 16, pp. 1-27.

Acknowledgments

The work was financially supported by the National Natural Science Foundation of China (U1960202).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted 9 April 2021; accepted 23 June 2021.

Rights and permissions

About this article

Cite this article

Sun, H., Yang, J., Zhang, RH. et al. Effect of Slag Basicity on Dephosphorization at Lower Basicity and Lower Temperature Based on Industrial Experiments and Ion-Molecular Coexistence Theory. Metall Mater Trans B 52, 3403–3422 (2021). https://doi.org/10.1007/s11663-021-02270-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02270-y