Abstract

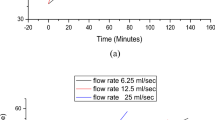

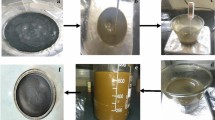

In this work to increase the thermal capacity and performance of pristine paraffin wax (phase change material), it is mixed with COOH group functionalized graphene. The various concentrations of graphene mixed with paraffin wax are 0.25 volume percent to 1 volume percent at an increment of 0.25 volume% at three different volumetric flow rates of 6.25 mL s−1, 12.5 mL s−1, and 25 mL s−1. The charging performance is analyzed, and Fourier transform infrared spectroscopy (FTIR), X ray diffraction (XRD), differential scanning calorimetric (DSC) analysis, Thermo gravimetric analysis (TGA), field effective scanning electron microscopy, with energy dispersive spectroscopy are done for characterizing chemical structure, crystal structure, enthalpy, thermal stability, and microstructure, along with elemental composition, respectively. The results indicated that with increasing percentages of COOH group functionalized graphene the charging time decreases by 6.25–25% for the HTF flow rate 6.25 mL s−1, 6.67–26.67% for HTF flow rate 12.5 mL s−1, and 15.38–38% for HTF flow rate 25 mL s−1 over pure paraffin wax owing to increasing percentage and thermal conductivity of COOH group functionalized graphene in paraffin wax. This advanced material with the help of XRD and FTIR also showed that the functionalized COOH graphene was chemically inert and did not lead to any new product being formed. Through TGA the advanced functional materials manifested that they were thermally very stable and by DSC it showed that it was having very high enthalpy of melting.

Similar content being viewed by others

References

Bhatti MM, Abdelsalam SI. Thermodynamic entropy of a magnetized Ree‐Eyring particle‐fluid motion with irreversibility process: a mathematical paradigm. Wiley Online Library; 2021. p. e202000186.

Zhang Z, Feng L, Liu H, Wang L, Wang S, Tang Z. Mo 6+P 5+ co-doped Li 2 ZnTi 3 O 8 anode for Li-storage in a wide temperature range and applications in LiNi 0.5 Mn 1.5 O 4/Li 2 ZnTi 3 O 8 full cells. Inorg Chem Front. 2022;9(1):35–43.

Mozaffari M, D’Orazio A, Karimipour A, Abdollahi A, Safaei MR. Lattice Boltzmann method to simulate convection heat transfer in a microchannel under heat flux: gravity and inclination angle on slip-velocity. Int J Numer Methods Heat Fluid Flow. 2019;30:3371.

<EcoTESTS 2.0 Product Manual - Final.pdf>.

Gasia J, Miró L, de Gracia A, Barreneche C, Cabeza L. Experimental evaluation of a paraffin as phase change material for thermal energy storage in laboratory equipment and in a shell-and-tube heat exchanger. Appl Sci. 2016;6(4):112. https://doi.org/10.3390/app6040112.

Nair AM, Naidu PVK. Comparison of charging and discharging period analysis of phase change materials-paraffin wax and myristic acid. Int J Curr Eng Technol. 2018. https://doi.org/10.14741/ijcet.v8i01.10886.

Kanimozhi B, Harish K, Tarun BS, Sainath Reddy PS, Sujeeth PS. Charging and discharging processes of thermal energy storage system using phase change materials. IOP Conf Ser Mater Sci Eng. 2017;197:012040. https://doi.org/10.1088/1757-899x/197/1/012040.

Wang M, Jiang C, Zhang S, Song X, Tang Y, Cheng H-M. Reversible calcium alloying enables a practical room-temperature rechargeable calcium-ion battery with a high discharge voltage. Nat Chem. 2018;10(6):667–72.

Zhao Q, He F, Zhang Q, Fan J, He R, Zhang K, et al. Microencapsulated phase change materials based on graphene Pickering emulsion for light-to-thermal energy conversion and management. Solar Energy Mater Solar Cells. 2019;203:110204. https://doi.org/10.1016/j.solmat.2019.110204.

Alkanhal TA. Comprehensive investigation of reduced graphene oxide (rGO) in the base fluid: thermal analysis and ANN modeling. J Ther Anal Calorim. 2021;144(6):2605–14.

Liu X, Rao Z. Experimental study on the thermal performance of graphene and exfoliated graphite sheet for thermal energy storage phase change material. Thermochim Acta. 2017;647:15–21. https://doi.org/10.1016/j.tca.2016.11.010.

Kumar P, Kumar Singh P, Nagar S, Sharma K, Saraswat M. Effect of different concentration of functionalized graphene on charging time reduction in thermal energy storage system. Mater Today Proc. 2021;44:146–52. https://doi.org/10.1016/j.matpr.2020.08.548.

Abd Elmaboud Y, Abdelsalam SI. DC/AC magnetohydrodynamic-micropump of a generalized Burger’s fluid in an annulus. Phys Scr. 2019;94(11):115209.

Singh PK, Nagar S, Singh M. Experimental analysis of thermal efficiency of functionalized graphene (COOH) reinforced PCM for thermal energy storage system. IOP Conf Ser Mater Sci Eng. 2021;1116(1):012008. https://doi.org/10.1088/1757-899x/1116/1/012008.

Yang J, Jia Y, Bing N, Wang L, Xie H, Yu W. Reduced graphene oxide and zirconium carbide co-modified melamine sponge/paraffin wax composites as new form-stable phase change materials for photothermal energy conversion and storage. Appl Therm Eng. 2019;163:114412. https://doi.org/10.1016/j.applthermaleng.2019.114412.

Hussain A, Abidi IH, Tso CY, Chan KC, Luo Z, Chao CYH. Thermal management of lithium ion batteries using graphene coated nickel foam saturated with phase change materials. Int J Therm Sci. 2018;124:23–35. https://doi.org/10.1016/j.ijthermalsci.2017.09.019.

Bhatti M, Abdelsalam SI. Bio-inspired peristaltic propulsion of hybrid nanofluid flow with Tantalum (Ta) and Gold (Au) nanoparticles under magnetic effects. Waves Random Complex Media. 2021. https://doi.org/10.1080/17455030.2021.1998728.

Salimpour MR, Darvanjooghi MHK, Abdollahi A, Karimipour A, Goodarzi M. Providing a model for Csf according to pool boiling convection heat transfer of water/ferrous oxide nanofluid using sensitivity analysis. Int J Numer Methods Heat Fluid Flow. 2019;30:2867.

Raza R, Mabood F, Naz R, Abdelsalam SI. Thermal transport of radiative Williamson fluid over stretchable curved surface. Therm Sci Eng Progress. 2021;23: 100887.

Eldesoky I, Abdelsalam SI, El-Askary WA, Ahmed M. The integrated thermal effect in conjunction with slip conditions on peristaltically induced particle-fluid transport in a catheterized pipe. J Porous Media. 2020;23(7):695–713.

Abumandour RM, Eldesoky IM, Kamel MH, Ahmed MM, Abdelsalam SI. Peristaltic thrusting of a thermal-viscosity nanofluid through a resilient vertical pipe. Z Naturforschung A. 2020;75(8):727–38.

Elkoumy S, Barakat E, Abdelsalam S. Hall and transverse magnetic field effects on peristaltic flow of a Maxwell fluid through a porous medium. Glob J Pure Appl Math. 2013;9(2):187–203.

Peng Y, Ghahnaviyeh MB, Ahmad MN, Abdollahi A, Bagherzadeh SA, Azimy H, et al. Analysis of the effect of roughness and concentration of Fe3O4/water nanofluid on the boiling heat transfer using the artificial neural network: an experimental and numerical study. Int J Therm Sci. 2021;163:106863.

Longo R, Catauro M, Sorrentino A, Guadagno L. Thermal and mechanical characterization of complex electrospun systems based on polycaprolactone and gelatin. J Therm Anal Calorim. 2022;147:5391–9.

Li L, Shan Y, Wang F, Chen X, Zhao Y, Zhou D, et al. Improving fast and safe transfer of lithium ions in solid-state lithium batteries by porosity and channel structure of polymer electrolyte. ACS Appl Mater Interfaces. 2021;13(41):48525–35.

Zhang X, Tang Y, Zhang F, Lee CS. A novel aluminum–graphite dual-ion battery. Adv Energy Mater. 2016;6(11):1502588.

Bakhtiari R, Kamkari B, Afrand M, Abdollahi A. Preparation of stable TiO2-graphene/water hybrid nanofluids and development of a new correlation for thermal conductivity. Powder Technol. 2021;385:466–77.

Acknowledgements

The authors of this paper are indebted to Lovely professional University and IIT Kanpur for providing research facilities for conduction of various characterization tests and thermal conductivity test, respectively. The authors are also thankful to Ecosense sustainable solutions private limited, New Delhi, India, for the equipment thermal energy storage system for finding energy storage, accumulated energy and energy losses including charging efficiencies.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nagar, S., Sharma, K., Singh, M. et al. Charging analysis and characterizations of COOH group functionalized graphene combined with paraffin wax as phase change material for thermal energy storage applications. J Therm Anal Calorim 147, 11021–11038 (2022). https://doi.org/10.1007/s10973-022-11365-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11365-w