Abstract

Polyurethanes are one of most versatile and large class of polymer because of its wide range of applications. The products of polyurethane are innovative and life-enhancing that play a unique role in making the world more sustainable and can help to solve some of the world’s biggest challenges. Most of the polyurethane products and components are durable and long lasting due to its unique chemical structure. To a large extent, the characteristics of the polyurethane are determined by the chemical nature of the building blocks and modification by the addition of the components in the backbone chain of the polymer. This review summarises the synthesis of polyurethanes using different polyols and pre-polymers from renewable feedstock and modification by maleic anhydride via different synthetic routes for various industrial applications like paints, adhesives, foam, coatings, inks, leathers, toys, automotive, packaging, dispersions, hydrogels, composites, construction etc. The objective of this review is to provide a comprehensive, informative, valuable and critical summary about the current development in the field of maleic anhydride-based polyurethanes.

Graphical Abstract

Generally polyurethane synthesized from Renewable as well as petrochemical sources but Polyurethane from Renewable resources is most explored transformation in polymer chemistry. This review highlights the most recent developments in the role of maleic anhydride in polyurethane synthesis from renewable feedstock/ starting material.

Similar content being viewed by others

References

Malani RS, Malshe VC, Thorat BN (2022) Polyols and polyurethanes from renewable sources: past, present and future—part 1: vegetable oils and lignocellulosic biomass. J Coat Technol Res 19(1):201–222

Guo B, Glavas L, Albertsson A-C (2013) Biodegradable and electrically conducting polymers for biomedical applications. Prog Polym Sci 38(9):1263–1286

Sharma V, Kundu PP (2006) Addition polymers from natural oils—A review. Prog Polym Sci 31(11):983–1008

Siracusa V, Rocculi P, Romani S, Rosa MD (2008) Biodegradable polymers for food packaging: a review. Trends Food Sci Technol 19(12):634–643

Du Y, Shen SZ, Cai K, Casey PS (2012) Research progress on polymer–inorganic thermoelectric nanocomposite materials. Prog Polym Sci 37(6):820–841

Hussain F, Hojjati M, Okamoto M, Gorga RE (2006) Review article: Polymer-matrix Nanocomposites, Processing, Manufacturing, and Application: An Overview. J Compos Mater 40(17):1511–1575

Zhang C, Garrison TF, Madbouly SA, Kessler MR (2017) Recent advances in vegetable oil-based polymers and their composites. Prog Polym Sci 71:91–143

Sawpan MA (2018) Polyurethanes from vegetable oils and applications: a review. J Polym Res 25(8):184

Somarathna HMCC, Raman SN, Mohotti D, Mutalib AA, Badri KH (2018) The use of polyurethane for structural and infrastructural engineering applications: A state-of-the-art review. Constr Build Mater 190:995–1014

Sambhudevan S, S H, Reghunadhan A (2021) Polyurethane from Sustainable Routes. In: Polyurethane Chemistry: Renewable Polyols and Isocyanates, vol 1380. ACS Symposium Series, vol 1380. American Chemical Society, pp 75–106. ch004

Froidevaux V, Negrell C, Caillol S, Pascault J-P, Boutevin B (2016) Biobased Amines: From Synthesis to Polymers; Present and Future. Chem Rev 116(22):14181–14224

Liang C, Gracida-Alvarez UR, Gallant ET, Gillis PA, Marques YA, Abramo GP, Hawkins TR, Dunn JB (2021) Material Flows of Polyurethane in the United States. Environ Sci Technol 55(20):14215–14224

Banik J, Chakraborty D, Rizwan M, Shaik AH, Chandan MR (2023) Waste Manag Res 0734242X221146082:1–18

https://www.statista.com/statistics/720449/global-polyurethane-market-size-forecast/. Accessed 14 Mar 2023

Buchner GA, Wulfes N, Schomäcker R (2020) Techno-economic assessment of CO2-containing polyurethane rubbers. J CO2 Util 36:153–168

Meier MA, Metzger JO, Schubert US (2007) Plant oil renewable resources as green alternatives in polymer science. J Chem Soc Rev 36(11):1788–1802

Raquez JM, Deléglise M, Lacrampe MF, Krawczak P (2010) Thermosetting (bio)materials derived from renewable resources: A critical review. Prog Polym Sci 35(4):487–509

Miao S, Wang P, Su Z, Zhang S (2014) Acta Biomater

Ginju M, David SB (2019) Characteristic studies on novel biodegradable polyurethane thin films from soyabean oil. Orient J Chem 35(2):877

Das S, Pandey P, Mohanty S, Nayak SK (2017) Insight on castor oil based polyurethane and nanocomposites: recent trends and development. Polym-Plast Technol Eng 56(14):1556–1585

Gaddam SK, Kutcherlapati SNR, Palanisamy A (2017) Self-cross-linkable anionic waterborne polyurethane-silanol dispersions from cottonseed-oil-based phosphorylated polyol as ionic soft segment. ACS Sustain Chem Eng 5(8):6447–6455

Hayes DG, Dumont M-J (2016) In: McKeon TA, Hayes DG, Hildebrand DF, Weselake RJ (eds) Industrial Oil Crops, chap-3, AOCS Press

Man L, Feng Y, Hu Y, Yuan T, Yang Z (2019) A renewable and multifunctional eco-friendly coating from novel tung oil-based cationic waterborne polyurethane dispersions. J Clean Prod 241:118341

Salleh WNFW, Tahir SM, Mohamed NS (2018) Synthesis of waste cooking oil-based polyurethane for solid polymer electrolyte. Polym Bull 75(1):109–120

Si H, Liu H, Shang S, Song J, Liao S, Wang D, Song Z (2016) Preparation and properties of maleopimaric acid-based polyester polyol dispersion for two-component waterborne polyurethane coating. Prog Org Coat 90:309–316

Xu X, Shang S, Song Z, Cui S, Wang H, Wang D (2011) Preparation and characterization of rosin-based waterborne polyurethane from maleopimaric acid polyester polyol. Bioresources 6(3):2460–2470

Hsieh C-C, Chen Y-C (2020) Synthesis of bio-based polyurethane foam modified with rosin using an environmentally-friendly process. J Clean Prod 276:124203

Spaans CJ, Belgraver VW, Rienstra O, de Groot JH, Veth RPH, Pennings AJ (2000) Solvent-free fabrication of micro-porous polyurethane amide and polyurethane-urea scaffolds for repair and replacement of the knee-joint meniscus. Biomaterials 21(23):2453–2460

Zhang T, Yang J, Zhang N, Huang T, Wang Y (2017) Achieving large dielectric property improvement in poly(ethylene vinyl acetate)/thermoplastic polyurethane/multiwall carbon nanotube nanocomposites by tailoring phase morphology. Ind Eng Chem Res 56(13):3607–3617

Ugarte L, Gómez-Fernández S, Peña-Rodrı́uez C, Prociak A, Corcuera MA, Eceiza A (2015) Tailoring mechanical properties of rigid polyurethane foams by sorbitol and corn derived biopolyol mixtures. ACS Sustain Chem Eng 3(12):3382–3387. https://doi.org/10.1021/acssuschemeng.5b01094

Członka S, Strąkowska A, Pospiech P, Strzelec K (2020) Effects of chemically treated eucalyptus fibers on mechanical, thermal and insulating properties of polyurethane composite foams. Materials 13(7):1781

Wang Z, Li W, Yang X, Cao J, Tu Y, Wu R, Wang W (2018) Highly stretchable and compressible shape memory hydrogels based on polyurethane network and supramolecular interaction. Mater Today Commun 17:246–251

Lin Z, Sun Z, Xu C, Zhang A, Xiang J, Fan HJRa (2021) A self-matting waterborne polyurethane coating with admirable abrasion-resistance. RSC Adv 11(44):27620–27626

Ghasemlou M, Daver F, Ivanova EP, Adhikari B (2019) Polyurethanes from seed oil-based polyols: A review of synthesis, mechanical and thermal properties. Ind Crops Prod 142:111841

Tian H, Wang Y, Zhang L, Quan C, Zhang X (2010) Improved flexibility and water resistance of soy protein thermoplastics containing waterborne polyurethane. Ind Crops Prod 32(1):13–20

Septevani AA, Evans DAC, Martin DJ, Annamalai PK (2018) Hybrid polyether-palm oil polyester polyol based rigid polyurethane foam reinforced with cellulose nanocrystal. Ind Crops Prod 112:378–388

Singh I, Samal SK, Mohanty S, Nayak SK (2020) Recent advancement in plant oil derived polyol-based polyurethane foam for future perspective: a review. Eur J Lipid Sci Technol 122(3):1900225

Kanyanta V, Ivankovic A (2010) Mechanical characterisation of polyurethane elastomer for biomedical applications. J Mech Behav Biomed Mater 3(1):51–62

Hirai T, Sadatoh H, Ueda T, Kasazaki T, Kurita Y, Hirai M, Hayashi S (1996) Polyurethane‐elastomer‐actuator. Makromol Chem Appl Macromol Chem Phys 240 (1):221–229

Paroli RM, Cole KC, Delgado AH (1995) Evaluating the Weatherability of Polyurethane Sealants. In: Multidimensional Spectroscopy of Polymers, vol 598. ACS Symposium Series, vol 598. American Chemical Society, pp 117–136. ch007

Chew MYL (2004) Retention of movement capability of polyurethane sealants in the tropics. Constr Build Mater 18(6):455–459

Chew MY (2004) Retention of movement capability of polyurethane sealants in the tropics. Construction and Building Materials 18 (6):455-459

Segura DM, Nurse AD, McCourt A, Phelps R, Segura A (2005) Chapter 3 Chemistry of polyurethane adhesives and sealants. In: Cognard P (ed) Handbook of Adhesives and Sealants, vol 1. Elsevier Science Ltd, pp 101–162

Kowalczyk K, Łuczka K, Grzmil B, Spychaj T (2012) Anticorrosive polyurethane paints with nano- and microsized phosphates. Prog Org Coat 74(1):151–157

Figovsky OL, Shapovalov LD Features of reaction amino‐cyclocarbonate for production of new type nonisocyanate polyurethane coatings. In: Macromolecular Symposia, 2002. vol 1. Wiley Online Library, pp 325–332

Choi M, Kim Y, Park S, Ka D, Kim T, Lee S, Sohn EH, Jin Y, Hong J (2021) Functionalized polyurethane-coated fabric with high breathability, durability, reusability, and protection ability. Adv Func Mater 31(24):2101511

Zhang Y, Maxted J, Barber A, Lowe C, Smith R (2013) The durability of clear polyurethane coil coatings studied by FTIR peak fitting. Polym Degrad Stab 98(2):527–534

Chaudhari A, Kulkarni R, Mahulikar P, Sohn D, Gite V (2015) Development of PU coatings from neem oil based alkyds prepared by the monoglyceride route. J Am Oil Chem Soc 92(5):733–741

Khatoon H, Iqbal S, Irfan M, Darda A, Rawat NK (2021) A review on the production, properties and applications of non-isocyanate polyurethane: A greener perspective. Prog Org Coat 154:106124

Gama NV, Ferreira A, Barros-Timmons A (2018) Polyurethane foams: Past, present, and future. Materials 11 (10):1841

Liu Y, Deng K, Wang S, Xiao M, Han D, Meng Y (2015) A novel biodegradable polymeric surfactant synthesized from carbon dioxide, maleic anhydride and propylene epoxide. Polym Chem 6(11):2076–2083

Musa OM (2016) Handbook of maleic anhydride based materials. Springer 10:978–973

Lorences MJ, Patience GS, Díez FV, Coca J (2003) Butane Oxidation to Maleic Anhydride: Kinetic Modeling and Byproducts. Ind Eng Chem Res 42(26):6730–6742

Du Z, Ma J, Wang F, Liu J, Xu J (2011) Oxidation of 5-hydroxymethylfurfural to maleic anhydride with molecular oxygen. Green Chem 13(3):554–557

Cheng M-J, Goddard WA III (2013) The Critical Role of Phosphate in Vanadium Phosphate Oxide for the Catalytic Activation and Functionalization of n-Butane to Maleic Anhydride. J Am Chem Soc 135(12):4600–4603

Lan J, Lin J, Chen Z, Yin G (2015) Transformation of 5-Hydroxymethylfurfural (HMF) to Maleic Anhydride by Aerobic Oxidation with Heteropolyacid Catalysts. ACS Catal 5(4):2035–2041

Alonso-Fagúndez N, Granados ML, Mariscal R, Ojeda M (2012) Selective conversion of furfural to maleic anhydride and furan with VOx/Al2O3 catalysts. Chemsuschem 5(10):1984–1990

Bapat AP, Ray JG, Savin DA, Sumerlin BS (2013) Redox-Responsive Dynamic-Covalent Assemblies: Stars and Miktoarm Stars. Macromolecules 46(6):2188–2198

Wei W, Wang T, Yi C, Liu J, Liu X (2015) Self-assembled micelles based on branched poly (styrene-alt-maleic anhydride) as particulate emulsifiers. RSC Adv 5(2):1564–1570

Yao Z, Zhang JS, Chen ML, Li BJ, Lu YY, Cao K (2011) Preparation of well-defined block copolymer having one polystyrene segment and another poly (styrene-alt-maleic anhydride) segment with RAFT polymerization. J Appl Polym Sci 121(3):1740–1746

Mohebby B, Kevily H, Kazemi-Najafi S (2014) Oleothermal modification of fir wood with a combination of soybean oil and maleic anhydride and its effects on physico-mechanical properties of treated wood. Wood Sci Technol 48(4):797–809

Echeverri DA, Perez WA, Rios LA (2013) Maleinization of Soybean Oil Glycerides Obtained from Biodiesel-Derived Crude Glycerol. J Am Oil Chem Soc 90(12):1877–1882

Hong J (2014) Lightweight Materials Prepared from Vegetable Oils and Their Derivatives. In: Lightweight Materials from Biopolymers and Biofibers, vol 1175. ACS Symposium Series, vol 1175. American Chemical Society, pp 53–67. ch004

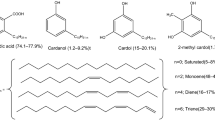

Wu F, Musa OM (2016) Vegetable Oil–Maleic Anhydride and Maleimide Derivatives: Syntheses and Properties. Handbook of Maleic Anhydride Based Materials: Syntheses, roperties Applications:151–208

Maia DL, Fernandes FA (2018) Production of castor oil maleate using di-tert-butyl peroxide as free radical catalyst. Braz J Chem Eng 35:699–708

Xia Y, Quirino RL, Larock RC (2013) Bio-based thermosetting polymers from vegetable oils. J Renew Mater 1(1):3–27

Miao S, Wang P, Su Z, Zhang S (2014) Vegetable-oil-based polymers as future polymeric biomaterials. Acta Biomater 10(4):1692–1704

Soto M, Sebastián RM, Marquet J (2014) Photochemical Activation of Extremely Weak Nucleophiles: Highly Fluorinated Urethanes and Polyurethanes from Polyfluoro Alcohols. J Org Chem 79(11):5019–5027

Charlon M, Heinrich B, Matter Y, Couzigné E, Donnio B, Avérous L (2014) Synthesis, structure and properties of fully biobased thermoplastic polyurethanes, obtained from a diisocyanate based on modified dimer fatty acids, and different renewable diols. Eur Polymer J 61:197–205

Campanella A, Bonnaillie L, Wool R (2009) Polyurethane foams from soyoil-based polyols. J Appl Polym Sci 112(4):2567–2578

Ji Y, Chen S, Cheng Y (2019) Synthesis and acoustic study of a new tung oil-based polyurethane composite foam with the addition of miscanthus lutarioriparius. J Polym 11(7):1144

Feng Y, Man L, Hu Y, Chen L, Xie B, Zhang C, Yuan T, Yang Z (2019) One-pot synthesis of polyurethane-imides with tailored performance from castor and tung oil. Prog Org Coat 132:62–69

Huang Y, Pang L, Wang H, Zhong R, Zeng Z, Yang J (2013) Synthesis and properties of UV-curable tung oil based resins via modification of Diels-Alder reaction, nonisocyanate polyurethane and acrylates. Prog Org Coat 76(4):654–661

Yuan C, Zhao X, Shao L, Tang K (2014) Preparation and properties of Tung oil-based polyurethane. Transactions of Tianjin University 20(4):273–281. https://doi.org/10.1007/s12209-014-2208-8

Shirke AG, Dholakiya BZ, Kuperkar K (2018) Modification of tung oil–based polyurethane foam by anhydrides and inorganic content through esterification process. J Appl Polym Sci 135(5):45786

Guan J, Song Y, Lin Y, Yin X, Zuo M, Zhao Y, Tao X, Zheng Q (2011) Progress in Study of Non-Isocyanate Polyurethane. Ind Eng Chem Res 50(11):6517–6527

Lubguban AA, Ruda RJG, Aquiatan RH, Paclijan S, Magadan KO, Balangao JKB, Escalera ST, Bayron RR, Debalucos B, Lubguban AA (2017) Soy-based polyols and polyurethanes. J. Kimika 28(1):1–19

Hussain N, Bonnia N, Ismail SS, Ramli R, Surip S Physical properties of a soy-based polyol as polyurethane coatings. In: AIP Conference Proceedings, 2018. vol 1. AIP Publishing LLC, p 020058

Tu Y-C (2008) Polyurethane foams from novel soy-based polyols. University of Missouri--Columbia

https://oil-mill-plant.com/cooking-oil-processing-line/soybean-oil-production-line.html. Accessed 14 Mar 2023

Li Y, Yang L, Zhang H Synthesis and characterization of a novel bio-based resin from maleated soybean oil polyols. In: IOP Conference Series: Materials Science and Engineering, 2017. vol 1. IOP Publishing, p 012001

Sharma V, Kundu PP (2008) Condensation polymers from natural oils. Prog Polym Sci 33(12):1199–1215

Osorio-González CS, Gómez-Falcon N, Sandoval-Salas F, Saini R, Brar SK, Ramírez AA (2020) Production of biodiesel from castor oil: A review. Energies 13(10):2467

Ogunniyi DS (2006) Castor oil: A vital industrial raw material. Biores Technol 97(9):1086–1091

Panda SS, Panda BP, Nayak SK, Mohanty S (2018) A Review on Waterborne Thermosetting Polyurethane Coatings Based on Castor Oil: Synthesis, Characterization, and Application. Polym-Plast Technol Eng 57(6):500–522. https://doi.org/10.1080/03602559.2016.1275681

Dai Z, Jiang P, Zhang P, Wai PT, Bao Y, Gao X, Xia J, Haryono A (2021) Multiwalled carbon nanotubes/castor-oil–based waterborne polyurethane nanocomposite prepared using a solvent-free method. Polym Adv Technol 32(3):1038–1048

Bhosale N, Shaik A, Mandal SK (2015) Synthesis and characterization of castor oil based hybrid polymers and their polyurethane–urea/silica coatings. RSC Adv 5(125):103625–103635

Abo-Elenien OM, Elsaeed AM, El-Sockary MA (2014) Synthesis of new polyurethane coating based on rosin for corrosion protection of petroleum industries equipment. J Eng Res Appl 4(1):148–155

Liu G, Wu G, Chen J, Kong Z (2016) Synthesis, modification and properties of rosin-based non-isocyanate polyurethanes coatings. Prog Org Coat 101:461–467

Soliman AA, Elsawy MM, Alian NA, Shaker NO (2021) Characterization, coating and biological evaluation of polyol esters rosin derivatives as coating films. J Coat Technol Res 18(2):373–381

https://www.pinterest.com/pin/602778731364227097/. Accessed 14 Mar 2023

Wu G, Chen J, Yang Z, Jin C, Liu G, Huo S, Kong Z (2022) Preparation and Properties of Autocatalytic Biobased Waterborne Polyol from Rosin Based Epoxy Resin. J Polym Environ 30(8):3340–3350

Boga K, Gaddam SK, Chepuri RR, Palanisamy A (2019) Development of biobased polyurethane-imides from maleinized cottonseed oil and castor oil. Polym Adv Technol 30(11):2742–2749

Narute P, Rao GR, Misra S, Palanisamy A (2015) Modification of cottonseed oil for amine cured epoxy resin: Studies on thermo-mechanical, physico-chemical, morphological and antimicrobial properties. Prog Org Coat 88:316–324

Gaikwad MS, Gite VV, Mahulikar PP, Hundiwale DG, Yemul OS (2015) Eco-friendly polyurethane coatings from cottonseed and karanja oil. Prog Org Coat 86:164–172

Agarwal D, Singh P, Chakrabarty M, Shaikh A, Gayal SJtt, (2003) Cottonseed Oil Quality, Utilization and Processing. CICR Technical. Bulletin 25:5

Gaddam SK, Palanisamy A (2016) Anionic waterborne polyurethane dispersions from maleated cotton seed oil polyol carrying ionisable groups. Colloid Polym Sci 294(2):347–355

http://www.oilmillmachinery.net/cottonseed-oil-processing.html. Accessed 14 Mar 2023

Dang Y, Luo X, Wang F, Li Y (2016) Value-added conversion of waste cooking oil and post-consumer PET bottles into biodiesel and polyurethane foams. Waste Manage 52:360–366

Polaczek K, Kurańska M, Prociak A (2022) Open-cell bio-polyurethane foams based on bio-polyols from used cooking oil. J Clean Prod 359:132107

Kirpluks M, Cabulis U, Ivdre A, Kuranska M, Zieleniewska M, Auguscik M (2016) Mechanical and thermal properties of high-density rigid polyurethane foams from renewable resources. J Renew Mater 4(1):86–100

Kurańska M, Polaczek K, Auguścik-Królikowska M, Prociak A, Ryszkowska J (2020) Open-cell rigid polyurethane bio-foams based on modified used cooking oil. Polymer 190:122164

Koh E, Lee S, Shin J, Kim Y-W (2013) Renewable Polyurethane Microcapsules with Isosorbide Derivatives for Self-Healing Anticorrosion Coatings. Ind Eng Chem Res 52(44):15541–15548

Xia X-X, Zhong J-J, Qian Z-G (2014) Direct biosynthesis of adipic acid from a synthetic pathway in recombinant Escherichia coli. Biotechnol Bioeng 111(12):2580–2586

Wu M, Di J, Gong L, He Y-C, Ma C, Deng Y (2023) Enhanced adipic acid production from sugarcane bagasse by a rapid room temperature pretreatment. Chem Eng J 452:139320

Skoog E, Shin JH, Saez-Jimenez V, Mapelli V, Olsson L (2018) Biobased adipic acid – The challenge of developing the production host. Biotechnol Adv 36(8):2248–2263

Alonso S, Rendueles M, Díaz M (2015) Microbial production of specialty organic acids from renewable and waste materials. Crit Rev Biotechnol 35(4):497–513. https://doi.org/10.3109/07388551.2014.904269

Mishra VK, Patel KI (2015) Nonionic Diol Modified UV-Curable Polyurethane Dispersions: Preparation and Characterization. J Dispersion Sci Technol 36(3):351–362. https://doi.org/10.1080/01932691.2014.903805

Yusuff AS, Adeniyi OD, Olutoye MA, Akpan UG (2018) Development and characterization of a composite anthill chicken eggshell catalyst for biodiesel production from waste frying oil. Int J Technol 1:1–11

Lopes D, Ferreira MJ, Russo R, Dias JM (2015) Natural and synthetic rubber/waste – Ethylene-Vinyl Acetate composites for sustainable application in the footwear industry. J Clean Prod 92:230–236

Ma J, Shao L, Xue C, Deng F, Duan Z (2014) Compatibilization and properties of ethylene vinyl acetate copolymer (EVA) and thermoplastic polyurethane (TPU) blend based foam. Polym Bull 71(9):2219–2234

https://fkur.com/en/bioplastics/im-green-eva/. Accessed 14 Mar 2023

Fukuoka A, Dhepe PL (2006) Catalytic conversion of cellulose into sugar alcohols. Angew Chem Int Ed 45(31):5161–5163

Anand A, Kulkarni RD, Gite VV (2012) Preparation and properties of eco-friendly two pack PU coatings based on renewable source (sorbitol) and its property improvement by nano ZnO. Prog Org Coat 74(4):764–767

Han JW, Lee H (2012) Direct conversion of cellulose into sorbitol using dual-functionalized catalysts in neutral aqueous solution. Catal Commun 19:115–118

Marques C, Tarek R, Sara M, Brar SK (2016) Chapter 12 - Sorbitol Production From Biomass and Its Global Market. In: Kaur Brar S, Jyoti Sarma S, Pakshirajan K (eds) Platform Chemical Biorefinery. Elsevier, Amsterdam, pp 217–227

Błażek K, Datta J (2019) Renewable natural resources as green alternative substrates to obtain bio-based non-isocyanate polyurethanes-review. Crit Rev Environ Sci Technol 49(3):173–211

Rand L, Thir B, Reegen S, Frisch K (1965) Kinetics of alcohol–isocyanate reactions with metal catalysts. J Appl Polym Sci 9(5):1787–1795

Dyer E, Taylor HA, Mason SJ, Samson J (1949) The rates of reaction of isocyanates with alcohols. I. Phenyl isocyanate with 1-and 2-butanol. J Am Chem Soc 71(12):4106–4109

Xiang J, Yang S, Zhang J, Wu J, Shao Y, Wang Z, Yang M (2022) The preparation of sorbitol and its application in polyurethane: a review. Polym Bull 79(4):2667–2684

Clark JH, Farmer TJ, Ingram ID, Lie Y (2018) North M (2018) Renewable Self-Blowing Non-Isocyanate Polyurethane Foams from Lysine and Sorbitol. Eur J Org Chem 31:4265–4271

Wu Z, Dai J, Tang L, Qu J (2019) Sorbitol-based aqueous cyclic carbonate dispersion for waterborne nonisocyanate polyurethane coatings via an environment-friendly route. J Coat Technol Res 16(3):721–732

Acknowledgements

N. S. thanks SVNIT Surat for the laboratory facility and UGC for fellowship. B. D. and T. N. thanks to the Director, SVNIT, Surat for providing research facility. T. N. thanks to the Director, SVNIT, Surat for providing SEED GRANT for the research. T. N. gratefully acknowledges the financial support from the CSIR-HRDG, India, Project File No. 02(0449)/21/EMR-II.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

There are no conflicts to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Savani, N.G., Naveen, T. & Dholakiya, B.Z. A review on the synthesis of maleic anhydride based polyurethanes from renewable feedstock for different industrial applications. J Polym Res 30, 175 (2023). https://doi.org/10.1007/s10965-023-03543-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-023-03543-7