Abstract

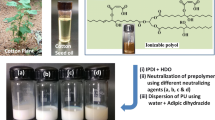

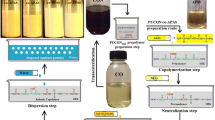

A novel class of bio-based, DMPA free, catalyst free, anionic waterborne polyurethane dispersions (PUD) have been successfully synthesized. Hydroxylated cottonseed oil has been maleated using maleic anhydride to introduce hydroxyl groups and ionisable carboxyl groups. This maleated polyol (MAHCSO) has been employed to develop water-based polyurethane dispersions through a prepolymer method and chain extension with dihydrazides at the dispersion stage. The –OH groups of the MAHCSO formed urethane bonds, and the carboxylate groups acted as an internal ionizer to stabilize the polymer dispersion in water. The significant effect of the ionic content in the polyol (MAHCSO) and chain length of dihydrazide on particle size, physico-chemical, thermal and mechanical properties of the resulting PUD films were investigated.

Similar content being viewed by others

References

Bozell JJ (2010) Connecting biomass and petroleum processing with a chemical bridge. Science 329(5991):522–523. doi:10.1126/science.1191662

Meier MAR, Metzger JO, Schubert US (2007) Plant oil renewable resources as green alternatives in polymer science. Chem Soc Rev 36(11):1788–1802. doi:10.1039/B703294C

Williams CK, Hillmyer MA (2008) Polymers from renewable resources: a perspective for a special issue of polymer reviews. Polym Rev 48(1):1–10. doi:10.1080/15583720701834133

Yu L, Chen L (2008) Polymer materials from renewable resources. In: Yu L (ed) Biodegradable polymer blends and composites from renewable resources. Wiley, Hoboken, pp 1–15

Noble K-L (1997) Waterborne polyurethanes. Prog Org Coat 32(1):131–136. doi:10.1016/S0300-9440(97)00071-4

Lu Y, Larock RC (2008) Soybean-oil-based waterborne polyurethane dispersions: effects of polyol functionality and hard segment content on properties. Biomacromolecules 9(11):3332–3340. doi:10.1021/bm801030g

Fu C, Zheng Z, Yang Z, Chen Y, Shen L (2014) A fully bio-based waterborne polyurethane dispersion from vegetable oils: from synthesis of precursors by thiol-ene reaction to study of final material. Prog Org Coat 77(1):53–60. doi:10.1016/j.porgcoat.2013.08.002

Meier MA (2009) Metathesis with oleochemicals: new approaches for the utilization of plant oils as renewable resources in polymer science. Macromolec Chem Phys 210(13–14):1073–1079. doi:10.1002/macp.200900168

Petrović ZS (2008) Polyurethanes from vegetable oils. Polym Rev 48(1):109–155. doi:10.1080/15583720701834224

Mosiewicki MA, Aranguren MI (2013) A short review on novel biocomposites based on plant oil precursors. Eur Polym J 49(6):1243–1256. doi:10.1016/j.eurpolymj.2013.02.034

Guo A, Demydov D, Zhang W, Petrovic ZS (2002) Polyols and polyurethanes from hydroformylation of soybean oil. J Polym Environ 10(1–2):49–52. doi:10.1023/A:1021022123733

Guo A, Cho Y, Petrović ZS (2000) Structure and properties of halogenated and nonhalogenated soy‐based polyols. J Polym Sci A Polym Chem 38(21):3900–3910. doi:10.1002/1099-0518(20001101)38

Nikje, M. A., Abedinifar, F., & Idris, A. (2011) Epoxidized soybean oil ring opening reaction under MW irradiation. Arch Appl Sci Res, 3, 383–388. http://scholarsresearchlibrary.com/archive.html

Petrovic ZS, Zhang W, Javni I (2005) Structure and properties of polyurethanes prepared from triglyceride polyols by ozonolysis. Biomacromolecules 6(2):713–719. doi:10.1021/bm049451s

Hou CT (1995) Microbial oxidation of unsaturated fatty acids. Adv Appl Microbiol 41:1–23. doi:10.1016/S0065-2164(08)70306-X

Garrison TF, Zhang Z, Kim HJ, Mitra D, Xia Y, Pfister DP, Kessler MR (2014) Thermo‐mechanical and antibacterial properties of soybean Oil‐based cationic polyurethane coatings: effects of amine ratio and degree of crosslinking. Macromol Mater Eng 299(9):1042–1051. doi:10.1002/mame.201300423

Saalah S, Abdullah LC, Aung MM, Salleh MZ, Biak DRA, Basri M, Jusoh ER (2015) Waterborne polyurethane dispersions synthesized from Jatropha oil. Ind Crop Prod 64:194–200. doi:10.1016/j.indcrop.2014.10.046

Mishra V, Mohanty I, Patel MR, Patel KI (2015) Development of green waterborne UV curable castor Oil based urethane acrylate coatings: preparation and property analysis. Int J Polym Anal Charact. doi:10.1080/1023666x.2015.1050852

Xia Y, Larock RC (2011) Preparation and properties of aqueous castor oil‐based polyurethane–silica nanocomposite dispersions through a sol–gel process. Macromol Rapid Commun 32(17):1331–1337. doi:10.1002/marc.201100203

Xia Y, Zhang Z, Kessler MR, Brehm‐Stecher B, Larock RC (2012) Antibacterial soybean‐Oil‐based cationic polyurethane coatings prepared from different amino polyols. ChemSusChem 5(11):2221–2227. doi:10.1002/cssc.201200352

Chang CW, Lu KT (2012) Natural castor oil based 2-package waterborne polyurethane wood coatings. Prog Org Coat 75(4):435–443. doi:10.1016/j.porgcoat.2012.06.013

Chen R, Zhang C, Kessler MR (2014) Anionic waterborne polyurethane dispersion from a bio-based ionic segment. RSC Adv 4(67):35476–35483. doi:10.1039/c4ra07519f

Athawale VD, Kulkarni MA (2010) Polyester polyols for waterborne polyurethanes and hybrid dispersions. Prog Org Coat 67(1):44–54. doi:10.1016/j.porgcoat.2009.09.015

Vogel AI, Tatchell AR, Furnis BS, Hannaford AJ, Smith PWG (1996) Vogel’s text book of practical organic chemistry, 5th edn. ELBS, London, p 703

Utraki LA (1989) Polymer alloys and blends. Hans Publishers, New York

Athawale VD, Kulkarni MA (2010) Effect of dicarboxylic acids on the performance properties of polyurethane dispersions. J Appl Polym Sci 117(1):572–580. doi:10.1002/app.31267

Li QA, Sun DC (2007) Synthesis and characterization of high solid content aqueous polyurethane dispersion. J Appl Polym Sci 105(5):2516–2524. doi:10.1002/app.24627

Banu P, Sundar S, Dhathathreyan A, Radhakrishnan G (2004) Synthesis and surface properties of aqueous dispersions of poly (ester-imide) prepared from anhydride terminated polyester prepolymer and diisocyanate. J Colloid Interface Sci 277(2):304–308. doi:10.1016/j.jcis.2004.04.044

Liaw DJ (1997) The relative physical and thermal properties of polyurethane elastomers: effect of chain extenders of bisphenols, diisocyanate, and polyol structures. J Appl Polym Sci 66(7):1251–1265. doi:10.1002/(SICI)1097-4628(19971114)66

Bao LH, Lan YJ, Zhang SF (2006) Synthesis and properties of waterborne polyurethane dispersions with ions in the soft segments. J Polym Res 13(6):507–514. doi:10.1007/s10965-006-9073-7

Lei L, Zhong L, Lin X, Li Y, Xia Z (2014) Synthesis and characterization of waterborne polyurethane dispersions with different chain extenders for potential application in waterborne ink. Chem Eng J 253:518–525. doi:10.1016/j.cej.2014.05.044

Kim B, Yang J, Yoo S, Lee J (2003) Waterborne polyurethanes containing ionic groups in soft segments. Colloid Polym Sci 281(5):461–468. doi:10.1007/s00396-002-0799-4

Lei L, Xia Z, Lin X, Yang T, Zhong L (2015) Synthesis and adhesion properties of waterborne polyurethane dispersions with long‐branched aliphatic chains. J Appl Polym Sci 132(12):41688. doi:10.1002/app.41688

Subramani S, Lee JM, Cheong IW, Kim JH (2005) Synthesis and characterization of water‐borne crosslinked silylated polyurethane dispersions. J Appl Polym Sci 98(2):620–631. doi:10.1002/app.22071

Xin W, Yu X (1997) Synthesis and properties of sulfonated polyurethane ionomers with anions in the polyether soft segments. J Polym Sci B Polym Phys 35:225–232. doi:10.1002/(SICI)1099-0488(19970130)

Acknowledgments

The authors wish to thank CSIR XII 5-year plan project “INTELCOAT” (CSC 0114) for the financial support. One of the authors Sashivinay Kumar Gaddam wishes to thank CSIR for the Senior Research Fellowship (SRF).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOCX 758 kb)

Rights and permissions

About this article

Cite this article

Gaddam, S.K., Palanisamy, A. Anionic waterborne polyurethane dispersions from maleated cotton seed oil polyol carrying ionisable groups. Colloid Polym Sci 294, 347–355 (2016). https://doi.org/10.1007/s00396-015-3787-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-015-3787-1