Abstract

With environmental and resource issues become increasingly prominent, as well as the requirements of the bioeconomy, the synthesis of polyurethane tends to follow the green chemistry and uses sustainable biological resources as raw materials. As a kind of biomass material, sorbitol has great potential for the bio-based polyurethane industry because of the high performance that sorbitol brings to polyurethane. What,s more, the various extraction technologies for sorbitol have matured. This paper reviews the extraction methods of sorbitol and analyzes the effects of sorbitol as polyols, crosslinkers and chain extenders used in polyurethane. Sorbitol based non-isocyanate polyurethane was also introduced.

Similar content being viewed by others

References

Akindoyo JO, Beg MDH, Ghazali S, Islam MR, Jeyaratnama N, Yuvaraj AR (2016) Polyurethane types, synthesis and applications-a review. RSC Adv 6:114

Ugarte L, Gomez-Fernandez S, Pena-Rodriuez C, Prociak A (2015) Maria Angeles Corcuera and Arantxa Eceiza, tailoring mechanical properties of rigid polyurethane foams by sorbitol and corn derived biopolyol mixtures. ACS Sustainable Chem Eng 3:3382–3387

Hojabri L, Kong X, Narine SS (2009) Produced from vegetable oil: synthesis, polymerization and characterization. Biomacromol 10:415

Allauddin S, Narayan R, Raju KVSN (2019) Synthesis and properties of alkoxy silane castor oil and their polyurethane/urea-silica hybrid coating films. ACS Sustainable Chemistry & Engineering 1(8):910–918

Wang C, Zheng Y, Xie Y, Qiao K, Sun Yi, Yue L (2015) Synthesis of bio-castor oil polyurethane flexible foams and the influence of biotic component on their performance. J Polym Res 22:145

Ozgur Seydibeyoglu M, Misra M, Mohanty A, Blaker JJ, Lee KY, Bismarck A, Kazemizadeh M (2013) Green polyurethane nanocomposites from soy polyol and bacterial cellulose. J Mater Sci 48:2167–2175

Aunga Min Min, Yaakobb Zahira, Kamarudinb Siti, Abdullah Luqman Chuah (2014) Synthesis and characterization of Jatropha (Jatropha curcas L) oil-based polyurethane wood adhesive. Indus Crops Prod 60:177–185

Patil CK, Rajput SD, Marathe RJ, Kulkarni RD, Phadnis H, Sohn D, Mahulikar PP, Gite VV (2017) Synthesis of bio-based polyurethane coatings from vegetable oil and dicarboxylic acids. Prog Org Coat 106:87

Prociak A, Malewska E, Kuranska M, Bqk S, Budny P (2018) Flexible polyurethane foams synthesized with palm oil-based bio-polyols obtained with the use of different oxirane ring opener. Ind Crops Prod 115:69–77

Marcovich NE, Kuranska M, Prociak A, Malewska E, Kulpa K (2017) Open cell semi-rigid polyurethane foams synthesized using palm oil-based bio-polyol. Ind Crops Prod 102:88–96

Meshram PD, Puri RG, Patil AL, Gite VV (2012) High performance moisture cured poly(ether–urethane) amide coatings based on renewable resource (cottonseed oil). J Coat Technol Res 10(3):331–338

Headey D (2011) Rethinking the global food crisis: The role of trade shocks[J]. Food Policy 36(2):136–146

Zhang P, Lu Y, Fan M et al (2019) Modified cellulose nanocrystals enhancement to mechanical properties and water resistance of vegetable oil- based waterborne polyurethane[J]. J Appl Polym Sci 136(47):48228

Chang WL, US Patent, US 6,420,446B1, 2002.

Rand L, Thir B, Reegen SL et al (1965) Kinetics of alcohol-isocyanate reactions with metal catalysts[J]. J Appl Polym Sci 9(5):1787–1795

Ajithkumar S, Kansara SS, Patel NK (1998) Kinetics of castor oil based polyol-toluene diisocyanate reactions[J]. Eur Polymer J 34(9):1273–1276

Dyer E, Taylor HA, Mason SJ et al (1949) The rates of reaction of isocyanates with alcohols I Phenyl isocyanate with 1-and 2-butanol[J]. J Am Chem Soc 71(12):4106–4109

Lee S, Shin S-R, Lee D-S (2018) Sorbitol as a chain extender of polyurethane prepolymers to prepare self-healable and robust polyhydroxyurethane elastomers. Molecules 23(10):2515

Balandin AA, Vasyunina NA, Barysheva GS et al (1957) Hydrogenation catalysts for polysaccharides[J]. Bull Acad Sci USSR Div Chem Sci 6:403

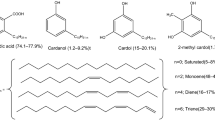

Marques C, Tarek R, Sara M, Brar SK (2016) Sorbitol Production From Biomass and Its Global Market. Platform Chem Bioref 17:217–227

Jacobs PA, Hinnekens H (1989) Single-step catalytic process for the direct conversion of polysaccharides to polyhydric alcohols by simultaneous hydrolysis and hydrogenation[J]. Eur Patent Appl 18:329

Kobayashi H, Ohta H, Fukuoka A (2012) Conversion of lignocellulose into renewable chemicals by heterogeneous catalysis. Catal Sci Technol 2:869–883

Xu L, Wei W, Li H et al (2014) Combination of enzyme and Ru-B amorphous alloy encapsulated in yolk-shell silica for one-pot dextrin conversion to sorbitol [J]. ACS Catalysis 4(1):251–258

Zhang J, Li J, Wu S et al (2013) Efficient conversion of maltose into sorbitol over magnetic catalyst in extremely low acid[J]. BioResources 8(3):4676–4686

Schmitt Helene, Creton Nicolas, Prashantha Kalappa, Soulestin Jeremie, Lacrampe Marie-France, Krawczak Patricia (2019) Preparation and characterization of plasticized starch/halloysite porous nanocomposites possibly suitable for biomedical applications. J Appl Polym Sci 9:41341

Barrett Devin G, Merkel Timothy J, Christopher Luft J, Yousaf Muhammad N (2010) One-step syntheses of photocurable polyesters based on a renewable resource. Macromolecules 43:9660–9667

Teng Lijing, Nie Wangyan, Zhou Yifeng, Song Linyong, Chen Pengpeng (2015) Synthesis and characterization of star-shaped PLLA with sorbitol as core and its microspheres application in controlled drug release. J Appl Polym Sci 27:132

Maniganda S, Sankar V, Nair JB, Raghu KG, Maiti KK (2014) A lysosome- targeted drug delivery system based on sorbitol backbone towards efficient cancer therapy. Org Biomol Chem 12(34):6564–6569

Almeida MRH, Barbano EP, de Carvalho MF, Tulio PC, Carlos IA (2015) Copper-zinc electrodeposition in alkaline-sorbitol medium: Electrochemical studies and structural, morphological and chemical composition characterization. Appl Surf Sci 333:13

Abdel Hamid Z, Abdel Aal A (2009) New environmentally friendly noncyanide alkaline electrolyte for copper electroplating. Surf Coat Technol 203:1360–1365

Zhang Q, Wang T, Li B, Jiang T, Ma L, Zhang X, Liu Q (2012) Aqueous phase reforming of sorbitol to bio-gasoline over Ni/HZSM-5 catalyst. Appl Energy 97:509–513

Bozell Joseph J, Petersen Gene R (2015) Technology development for the production of biobased products from biorefnery carbohydrates the US department of energy’s ‘Top 10’’ revisited.’ Green Chemistry 12(4):539

Fukuoka A, Dhepe PL (2006) Catalytic conversion of cellulose into sugar alcohols. Angew Chem 118:5285–5287

Kobayashi H, Ito Y, Komanoya T, Hosaka Y, Dhepe PL, Kasai K, Fukuoka A (2011) Synthesis of sugar alcohols by hydrolytic hydrogenation of cellulose over supported metal catalysts. Green Chem 13(2):326–333

Hilgert J, Meine N, Rinaldi R, Schüth F (2013) Mechanocatalytic depolymerization of cellulose combined with hydrogenolysis as a highly efficient pathway to sugar alcohols. Energy Environ Sci 6(1):92–96

Ding L-N, Wang A-Q, Zheng M-Y, Zhang T (2010) Selective transformation of cellulose into sorbitol by using a bifunctional nickel phosphide catalyst. Chemsuschem 3:818–821

Zhu Yinghuai, Kong Zhen Ning, Stubbs Ludger Paul, Lin Huang, Shen Shoucang, Anslyn Eric V, Maguire John A (2010) Conversion of cellulose to hexitols catalyzed by ionic liquid—stabilized ruthenium nanoparticles and a reversible binding agent. Chem Sus Chem 3:67–70

Kobayashi H, Matsuhashi H, Komanoya T, Hara K, Fukuoka A (2011) Transfer hydrogenation of cellulose to sugar alcohols over supported ruthenium catalysts. Chem Commun 47(8):2366–2368

Ogasawara Y, Itagaki S, Yamaguchi K, Mizuno N (2011) Saccharification of natural lignocellulose biomass and polysaccharides by highly negatively charged heteropolyacids in concentrated aqueous solution. Chemsuschem 4(4):519–525

Zhang J, Li J-B, Shu-Bin Wu, Liu Y (2013) Advances in the catalytic production and utilization of sorbitolInd. Eng Chem Res 52:11799–11815

Joung Woo Han (2012) Hyunjoo Lee, Direct conversion of cellulose into sorbitol using dualfunctionalized catalysts in neutral aqueous solution. Catal Commun 19:115–118

Shrotri Abhijit, Tanksale Akshat, Beltramini Jorge Norberto, Gurav Hanmant, Chilukuri Satyanarayana V (2012) Conversion of cellulose to polyols over promoted nickel catalysts. Catal Sci Technol 2:1852–1858

Wang D, Niu W, Tan M, Mingbo Wu, Zheng X, Li Y, Tsubaki N (2014) Pt Nanocatalysts supported on reduced graphene oxide for selective conversion of cellulose or cellobiose to sorbitol. Chemsuschem 7:1398–1406

Abhijeet Anand RD, Kulkarni V.V. Gite (2012) Preparation and properties of eco-friendly two pack PU coatings based on renewable source (sorbitol) and its property improvement by nano ZnO. Progress in Organic Coatings 74:764–767

Maria J (2011) Climent, Avelino Corma, Sara Iborra, Converting carbohydrates to bulk chemicals and fine chemicals over heterogeneous catalysts. Green Chem 13:520–540

Raquez J-M, Deleglise M, Lacrampe M-F, Krawczak P (2010) Thermosetting (bio)materials derived from renewable resources: a critical review. Prog Polym Sci 35:487–509

Maisonneuve L, Lamarzelle O, Rix E (2015) Etienne grauhenri cramail, isocyanate- free routes to polyurethanes and poly(hydroxy urethane)s. Chem Rev 115(22):12407–12439

Anand Abhijeet, Kulkarni Ravindra D, Patil Chandrashekhar K, Gite Vikas V (2013) Utilization of renewable bio-based resources viz sorbitol diol and diacid in the preparation of two pack PU anticorrosive coatings. J Name 00:1–3

Mahmood N, Yuan Z, Schmidt J (2016) Chunbao (Charles) Xu, Depolymerization of lignins and their applications for the preparation of polyols and rigid polyurethane foams: a review. Renew Sustain Energy Rev 60:317–329

Ugarte L, Gomez-Fernandez S, Pena-Rodriuez C, Prociak A (2015) Maria Angeles Corcuera, Arantxa Eceiza, sorbitol as a chain extender of polyurethane prepolymers to prepare self-healable and robust polyhydroxyurethane elastomers. ACS Sustainable Chem Eng 3(12):3382–3387

Brocas Anne-Laure, Mantzaridis Christos, Tunc Deniz, Carlotti Stephane (2015) Polyether synthesis: from activated or metal-free anionic ring-opening polymerization of epoxides to Functionalization. Prog Polym Sci 38(6):845–873

Bailosky Linda C, Bender Lynn M, Bode Daniel, Choudhery Riaz A, Craun Gary P, Gardner Kenneth J, Michalski Candice R, Rademacher Jude T, Stella Guy J, Telford David J (2016) Synthesis of polyether polyols with epoxidized soy bean oil. Prog Org Coat 76(12):1712–1719

Dutta AS (2018). Polyurethane Foam Chemistry. Recycling of Polyurethane Foams. 17–27

Basterretxea Andere, Lopez Xabier, de Pariza Elena, Gabirondo Sara Marina, Martin Jaime, Etxeberria Agustin, Mecerreyes David, Sardon Haritz (2013) Synthesis and characterization of fully biobased copolyether polyols. Indus Eng Chem Res 20:214

D.Kyriacos, Polyols for PU. All producers and plant capacities. June 2017. ISBN 9789078546313, (n.d.).

Tersac G (2007) Chemistry and technology of polyols for polyurethanes Shrewbury, UK. Polym Int 56(6):820–820

Furtwengler P, Averous L (2018) From D-sorbitol to five-membered bis(cyclo-carbonate) as a platform molecule for the synthesis of different original biobased chemicals and polymers. Sci Rep 8(1):215

Mazurek-Budzyńska MM, Rokicki G, Drzewicz M, Guńka PA, Zachara J (2016) Bis(cyclic carbonate) based on d-mannitol, d-sorbitol and di(trimethylolpropane) in the synthesis of non-isocyanate poly(carbonate-urethane)s. Eur Polym J 84:799–811

Gomez-Jimenez-Aberasturi O, Ochoa-Gomez JR (2017) New approaches to producing polyols from biomass. J Chem Technol Biotechnol 92(4):705–711

Michalowski S, Hebda E, Pielichowski K (2017) Thermal stability and flammability of polyurethane foams chemically reinforced with POSS. J Therm Anal Calorim 130(1):155–163

Kirpluks M, Kalnbunde D, Benes H, Cabulis U (2018) Natural oil based highly functional polyols as feedstock for rigid polyurethane foam thermal insulation. Ind Crops Prod 122:627–636

Ionescu M (2005) Polyether polyols for rigid polyurethane foams. In: Chemistry and technology of polyols for polyurethanes. Rapra Technology Limited. 343–4

Chatti S, Bortolussi M, Loupy A, Blais JC, Bogdal D, Majdoub M (2002) Efficient synthesis of polyethers from isosorbide by microwave-assisted phase transfer catalysis. Eur Polymer J 38:1851–1861

Hammami N, Majdoub M, Habas J-P (2017) Structure-properties relationships in isosorbide-based polyacetals: Influence of linear or cyclic architecture on polymer physicochemical properties. Eur Polymer J 93:795–804

Lukaszczyk J, Janicki B, Kozuch J, Wojdyla H (2013) Synthesis and characterization of low viscosity dimethacrylic resin based on isosorbide. J Appl Polym Sci 130(4):2514–2522

Fleche G, Huchette M (1986) Isosorbide preparation properties and chemistry. Starch Starke 38(1):26–30

Kamaruzaman MR, Jiang XX, Hu XD, Chin SY (2020) High yield of isosorbide production from sorbitol dehydration catalysed by amberlyst 36 under mild condition. Chem Eng J 388:124186

Saxon DJ, Nasiri M, Mandal M, Maduskar S, Dauenhauer PJ, Cramer CJ, LaPointe AM, Reineke TM (2019) Architectural control of isosorbide-based polyethers via ring-opening polymerization. J Am Chem Soc 141:5107–5111

Jiang Ting, Wang Wenjuan, Dinghua Yu, Huang Di, Wei Na, Yi Hu, Huang He (2018) Synthesis and characterization of polyurethane rigid foam architectural controls from polyether polyols with isosorbide as the bio-based starting agent. J Polym Res 25:140

Domanska Agata, Boczkowska Anna (2014) Biodegradable polyurethanes from crystalline prepolymers. Polym Degrad Stability 108:175181

Carothers WH (1971) Polymers and polyfunctionality. Trans Faraday Soc 67:P001–P002

Carothers WH, Dorough GL, Natta FJ (1932) Studies of polymerization and ring formation X. The reversible polymerization of six-membered cyclic esters[J]. J Am Chem Soc 54(2):761–772

Carothers WH (1929) Studies on polymerization and ring formation. I An introduction to the general theory of condensation polymers[J]. J Am Chem Soc 51(8):2548–2559

Bednarek M (2016) Branched aliphatic polyesters by ring-opening (co)polymerization. Prog Polym Sci 58:27–58

Benning Calvin J, Wilson Christopher L (2016) Method of making polyester composition.US patent 2863855.

Gustini Liliana, Noordover Bart A.J., Gehrels Coen, Dietz Carin, Koning Cor E (2019) Enzymatic synthesis and preliminary evaluation as coating of sorbitol-based hydroxy-functional polyesters with controlled molecular weights. Eur Polym J 67:459–475

Furtwengler P, Averous L (2018) Renewable polyols for advanced polyurethane foams from diverse biomass resources. Polym Chem 9:4258–4287

Furtwengler P, Perrin R, Redl A et al (2017) Synthesis and characterization of polyurethane foams derived of fully renewable polyester polyols from sorbitol[J]. Eur Polymer J 97:319–327

Khanderay JC, Gite VV (2019) Fully biobased polyester polyols derived from renewable resources toward preparation of polyurethane and their application for coatings. J Appl Polym Sci 47:558

Kirchmeyer Stephan, Muller Hanns-Peter, Ullrich Martin, Liesenfelder Ulrich (2017) Homogeneously mixing polyisocyanate zerewitinoff active hydrogen compound and chain extender for condensation polymerization continuous degassing and extrusion. US patent 64:17312

Yamasaki S, Nishiguchi D, Kojio K et al (2007) Effects of polymerization method on structure and properties of thermoplastic polyurethanes. J Polym Sci, Part B: Polym Phys 45:800–814

Oprea S, Timpu D, Oprea V (2019) Design-properties relationships of polyurethanes elastomers depending on different chain extenders structures. J Polym Res 26:117

Chun Byoung Chul, Cha Sang Hyuk, Park Chul, Chung Yong-Chan, Park Myung Ju, Cho Jae Whan (2003) Dynamic Mechanical Properties of Sandwich-Structured Epoxy Beam Composites Containing Poly(ethyleneterephthalate)/Poly (ethyleneglycol)copolymer with shape memory effect. J Appl Polym Sci 90:3141–3149

Chung Yong-Chan, Choi Jung Hoon, Chun Byoung Chul (2008) Shape-memory effects of polyurethane copolymer cross-linked by dextrin. J Mater Sci 43:6366–6373

Chung Yong-Chan, Choi Jae Won, Kim Ha Youn, Chun Byoung Chul (2012) Low temperature shape recovery effect of polyurethane copolymer grafted with pendant n-butyl group. Fibers Polym 13:8–15

Guo A, Javni I, Petrovic Z (2000) Rigid polyurethane foams based on soybean oil. J Appl Polym Sci 77:467–473

Blazek K, Datta J (2019) Renewable natural resources as green alternative substrates to obtain bio-based non-isocyanate polyurethanes-review. Critical Rev Environ Sci Technol 2:1–39

Dyer E, Scott H (1957) The preparation of polymeric and cyclic urethans and ureas from ethylene carbonate and amines. J Am Chem Soc 79(3):672–675

Ghasemlou M, Daver F, Ivanova EP, Adhikari B (2019) Bio-based routes to synthesize cyclic carbonates and polyamines precursors of non-isocyanate polyurethanes: a review. Eur Polymer J 118:668–684

Zhijun Wu, Tang Liuyan, Dai Jingtao, Jinqing Qu (2016) Synthesis and properties of fluorinated nonisocyanate polyurethanes coatings with good hydrophobic and oleophobic properties. J Coat Technol Res 12:125

Mazurek-Budzynfska Magdalena M, Rokicki Gabriel, Drzewicz Mateusz, Piotr A, Janusz Z (2016) Bis(cyclic carbonate) based on D-mannitol, D-sorbitol and di(trimethylolpropane) in the synthesis of non-isocyanate poly(carbonate-urethane)s. Eur Polym J 84:799–811

Acknowledgements

This research was financially supported by the Science and Technology Research Projects of Lishui sci-tech bureau (No.2020GYX02 and No. 2019GYX01), the Project of New Seedling Talents Program of Zhejiang Province (No. 2018R434004), the General Research Projects of Zhejiang Provincial Department of Education (No. Y201840153).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xiang, J., Yang, S., Zhang, J. et al. The preparation of sorbitol and its application in polyurethane: a review. Polym. Bull. 79, 2667–2684 (2022). https://doi.org/10.1007/s00289-021-03639-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-021-03639-4