Abstract

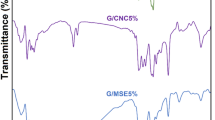

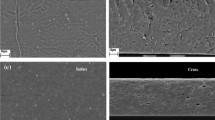

In this study, composite packaging films were produced from relatively inexpensive materials including Whey protein isolate (WPI) and Persian gum (PG), supplemented with betanin nanoliposomes (NLPs). Using response surface methodology (central composite design), we investigated the effects of two variables (PG [0%–2% w/v] and betanin NLPs’ [0%–10% w/v] content) on the physico-mechanical and antioxidant properties of the film treatments. Afterward, the optimal treatment was evaluated for structural and antimicrobial characteristics. The film samples' permeability to water vapor decreased with the addition of NLP (from 7.38 to 5.46 g/Pa.s.m) but increased with PG incorporation; decreased solubility was observed when either substance was added. Mechanical properties like Young’s modulus and tensile strength were weakened by PG addition, but the incorporation of NLPs led to pronounced tensile strength. XRD analysis revealed improved crystallinity through NLPs’ addition. The presence of NLPs in the nanocomposite film resulted in an elevated level of antibacterial activity against Staphylococcus aureus, while the addition of both PG and betanin NLPs led to improved antioxidative activity (63.45%). Considering the results, PG/WPI films loaded with betanin NLPs could be introduced in active packaging applications for the shelf life extension of perishable food products.

Similar content being viewed by others

Data Availability

Not applicable.

Code Availability

Not applicable.

References

Salarbashi D et al (2017) Eco-friendly soluble soybean polysaccharide/nanoclay Na+ bionanocomposite: Properties and characterization. Carbohyd Polym 169:524–532. https://doi.org/10.1016/j.carbpol.2017.04.011

Castro-Rosas J et al (2016) Biopolymer films and the effects of added lipids, nanoparticles and antimicrobials on their mechanical and barrier properties: a review. Int J Food Sci Technol 51(9):1967–1978. https://doi.org/10.1111/ijfs.13183

Farhan A, Hani NM (2020) Active edible films based on semi-refined κ-carrageenan: Antioxidant and color properties and application in chicken breast packaging. Food Packag Shelf Life 24:100476. https://doi.org/10.1016/j.fpsl.2020.100476

Galus S, Kadzińska J (2016) Whey protein edible films modified with almond and walnut oils. Food Hydrocolloids 52:78–86. https://doi.org/10.1016/j.foodhyd.2015.06.013

Khalesi H et al (2017) Effects of biopolymer ratio and heat treatment on the complex formation between whey protein isolate and soluble fraction of Persian gum. J Dispersion Sci Technol 38(9):1234–1241. https://doi.org/10.1080/01932691.2016.1230064

Emamverdian P et al (2020) Characterization and optimization of complex coacervation between soluble fraction of Persian gum and gelatin. Colloids Surf, A 607:125436. https://doi.org/10.1007/s10924-020-01906-5

Abbasi S (2017) Challenges towards characterization and applications of a novel hydrocolloid: Persian gum. Curr Opin Colloid Interface Sci 28:37–45. https://doi.org/10.1016/j.cocis.2017.03.001

Pak ES, Ghaghelestani SN, Najafi MA (2020) Preparation and characterization of a new edible film based on Persian gum with glycerol plasticizer. J Food Sci Technol Mysore. https://doi.org/10.1007/s13197-020-04361-1

Khezerlou A et al (2019) Development and characterization of a Persian gum–sodium caseinate biocomposite film accompanied by Zingiber officinale extract. J Appl Polym Sci 136(12):47215. https://doi.org/10.1002/app.47215

Khodaei D, Oltrogge K, Hamidi-Esfahani Z (2020) Preparation and characterization of blended edible films manufactured using gelatin, tragacanth gum and Persian gum. LWT 117:108617. https://doi.org/10.1016/j.lwt.2019.108617

Khorram F, Ramezanian A, Hosseini SMH (2017) Shellac, gelatin and Persian gum as alternative coating for orange fruit. Sci Hortic 225:22–28. https://doi.org/10.1016/j.scienta.2017.06.045

Moghaddas Kia E, Ghasempour Z, Alizadeh M (2018) Fabrication of an eco-friendly antioxidant biocomposite: Zedo gum/sodium caseinate film by incorporating microalgae (Spirulina platensis). J Appl Polymer Sci 135(13):46024. https://doi.org/10.1007/s10924-020-01906-5

Golkar A, Nasirpour A, Keramat J (2015) β-lactoglobulin-Angum gum (Amygdalus Scoparia Spach) complexes: Preparation and emulsion stabilization. J Dispersion Sci Technol 36(5):685–694. https://doi.org/10.1080/01932691.2014.919587

Azarikia F, Abbasi S (2016) Mechanism of soluble complex formation of milk proteins with native gums (tragacanth and Persian gum). Food Hydrocolloids 59:35–44. https://doi.org/10.1016/j.foodhyd.2015.10.018

Khan MI (2016) Plant betalains: Safety, antioxidant activity, clinical efficacy, and bioavailability. Compr Rev Food Sci Food Saf 15(2):316–330. https://doi.org/10.1111/1541-4337.12185

Moghaddas Kia EM, Langroodi AM, Ghasempour Z, Ehsani A (2020) Red beet extract usage in gelatin/gellan based gummy candy formulation introducing Salix aegyptiaca distillate as a flavouring agent. J Food Sci Technol 57(9):3355–3362. https://doi.org/10.1007/s13197-020-04368-8

Teixeira Vieira, da Silva D et al (2019) Betanin, a natural food additive: Stability, bioavailability, antioxidant and preservative ability assessments. Molecules 24(3):458. https://doi.org/10.3390/molecules24030458

Ghasempour Z, Javanmard N, Langroodi AM, Alizadeh-Sani M, Ehsani A, Kia EM (2020) Development of probiotic yogurt containing red beet extract and basil seed gum; techno-functional, microbial and sensorial characterization. Biocatal Agric Biotechnol 29:101785. https://doi.org/10.1016/j.bcab.2020.101785

Amjadi S et al (2018) Improvement in the stability of betanin by liposomal nanocarriers: Its application in gummy candy as a food model. Food Chem 256:156–162. https://doi.org/10.1016/j.foodchem.2018.02.114

Amjadi S et al (2020) Multifunctional betanin nanoliposomes-incorporated gelatin/chitosan nanofiber/ZnO nanoparticles nanocomposite film for fresh beef preservation. Meat Sci. https://doi.org/10.1016/j.meatsci.2020.108161

Peng Y, Wu Y, Li Y (2013) Development of tea extracts and chitosan composite films for active packaging materials. Int J Biol Macromol 59:282–289. https://doi.org/10.1016/j.ijbiomac.2013.04.019

Jahed E et al (2017) Physicochemical properties of Carum copticum essential oil loaded chitosan films containing organic nanoreinforcements. Carbohyd Polym 164:325–338. https://doi.org/10.1016/j.carbpol.2017.02.022

Alizadeh-Sani M et al (2020) Preparation of active nanocomposite film consisting of sodium caseinate, ZnO nanoparticles and rosemary essential oil for food packaging applications. J Polym Environ. https://doi.org/10.1007/s10924-020-01906-5

Aziz SG-G, Almasi H (2018) Physical characteristics, release properties, and antioxidant and antimicrobial activities of whey protein isolate films incorporated with thyme (Thymus vulgaris L.) extract-loaded nanoliposomes. Food Bioproc Technol 11(8):1552–1565. https://doi.org/10.1016/j.foodhyd.2019.105338

Li X et al (2020) Gelatin films incorporated with thymol nanoemulsions: Physical properties and antimicrobial activities. Int J Biol Macromol 150:161–168. https://doi.org/10.1016/j.ijbiomac.2020.02.066

Calva-Estrada SJ, Jiménez-Fernández M, Lugo-Cervantes E (2019) Protein-based films: Advances in the development of biomaterials applicable to food packaging. Food Eng Rev 11(2):78–92. https://doi.org/10.1007/s12393-019-09189-w

Zhang X et al (2020) High performance PVA/lignin nanocomposite films with excellent water vapor barrier and UV-shielding properties. Int J Biol Macromol 142:551–558. https://doi.org/10.1016/j.ijbiomac.2019.09.129

Cejudo-Bastante MJ et al (2020) Optical, structural, mechanical and thermal characterization of antioxidant ethylene vinyl alcohol copolymer films containing betalain-rich beetroot. Food Packag Shelf Life 24:100502. https://doi.org/10.1016/j.fpsl.2020.100502

Marín-Peñalver D et al (2019) Carboxymethyl cellulose films containing nanoliposomes loaded with an angiotensin-converting enzyme inhibitory collagen hydrolysate. Food Hydrocolloids 94:553–560. https://doi.org/10.1016/j.foodhyd.2019.04.009

Burrington KJ (2012) Whey protein heat stability. Estados Unidos 27(2):411–420

Rahmati NF, Koocheki A, Varidi M, Kadkhodaee R (2018) Thermodynamic compatibility and interactions between Speckled Sugar bean protein and xanthan gum for production of multilayer O/W emulsion. J Food Sci Technol 55:1143–1153. https://doi.org/10.1007/s13197-017-3030-9

Doost AS et al (2019) Pickering stabilization of thymol through green emulsification using soluble fraction of almond gum–Whey protein isolate nano-complexes. Food Hydrocolloids 88:218–227. https://doi.org/10.1016/j.foodhyd.2018.10.009

Alizadeh-Sani M, Khezerlou A, Ehsani A (2018) Fabrication and characterization of the bionanocomposite film based on whey protein biopolymer loaded with TiO2 nanoparticles, cellulose nanofibers and rosemary essential oil. Ind Crops Prod 124:300–315. https://doi.org/10.1016/j.indcrop.2018.08.001

Petera B et al (2015) Characterization of arabinogalactan-rich mucilage from Cereus triangularis cladodes. Carbohyd Polym 127:372–380. https://doi.org/10.1016/j.carbpol.2015.04.001

Tang X, Alavi S, Herald TJ (2008) Barrier and mechanical properties of starch-clay nanocomposite films. Cereal Chem 85:433–439. https://doi.org/10.1094/CCHEM-85-3-0433

Wihodo M, Moraru CI (2013) Physical and chemical methods used to enhance the structure and mechanical properties of protein films: A review. J Food Eng 114:292–302. https://doi.org/10.1016/j.jfoodeng.2012.08.021

George A, Sanjay MR, Srisuk R, Parameswaranpillai J, Siengchin SA (2020) Comprehensive review on chemical properties and applications of biopolymers and their composites. Int J Biol Macromol 154:329–338. https://doi.org/10.1016/j.ijbiomac.2020.03.120

Acquah C et al (2020) Formation and characterization of protein-based films from yellow pea (Pisum sativum) protein isolate and concentrate for edible applications. Current Res Food Sci 2:61–69. https://doi.org/10.1016/j.crfs.2019.11.008

Jiang S et al (2020) The influence of the addition of transglutaminase at different phase on the film and film forming characteristics of whey protein concentrate-carboxymethyl chitosan composite films. Food Packag Shelf Life 25:100546

Shankar S et al (2015) Preparation, characterization, and antimicrobial activity of gelatin/ZnO nanocomposite films. Food Hydrocolloids 45:264–271. https://doi.org/10.1016/j.foodhyd.2014.12.001

Wu J et al (2015) The preparation, characterization, antimicrobial stability and in vitro release evaluation of fish gelatin films incorporated with cinnamon essential oil nanoliposomes. Food Hydrocolloids 43:427–435. https://doi.org/10.1016/j.foodhyd.2014.06.017

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

ZG: Conceptualization; Project administration; Writing—original draft. SK: Investigation; Methodology; Validation; Writing—original draft. HA: Investigation; Methodology; Writing—original draft. HH: Resources; Supervision; Writing—review & editing. SA: Investigation; Methodology. EMK: Conceptualization; Formal analysis; Writing—original draft. AE: Funding acquisition; Resources; Writing—review & editing.

Corresponding authors

Ethics declarations

Conflict of interest

None.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ghasempour, Z., Khodaeivandi, S., Ahangari, H. et al. Characterization and Optimization of Persian Gum/Whey Protein Bionanocomposite Films Containing Betanin Nanoliposomes for Food Packaging Utilization. J Polym Environ 30, 2800–2811 (2022). https://doi.org/10.1007/s10924-021-02367-0

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-021-02367-0